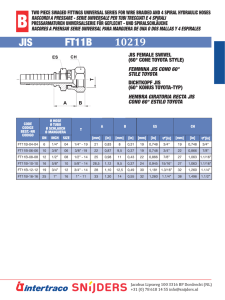

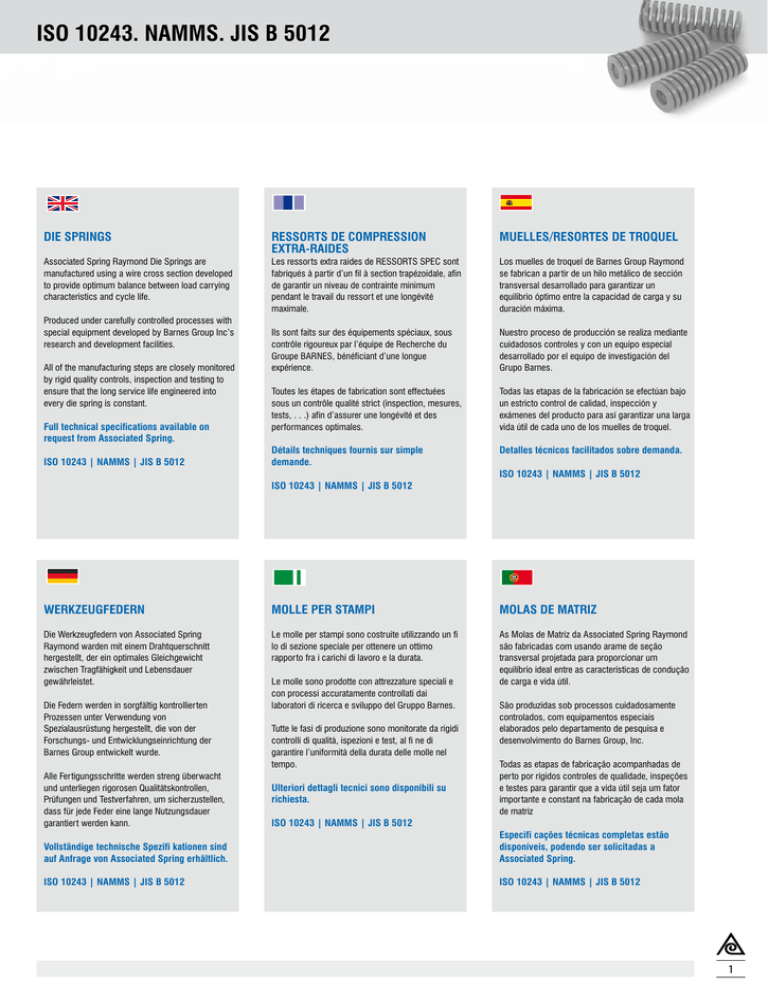

ISO 10243. NAMMS. JIS B 5012

Anuncio