Breve resumen de los terminales de válvulas

Anuncio

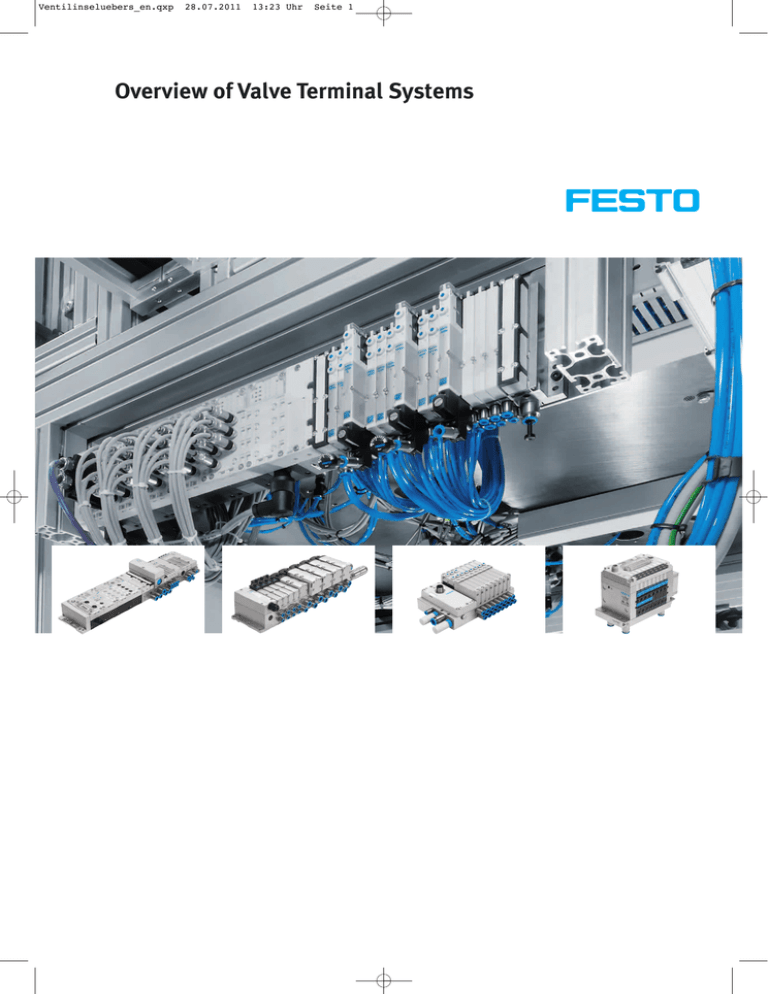

Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 1 Overview of Valve Terminal Systems Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 2 Putting you in a leading position, no matter whether the solution you need is simple or complex Can you imagine defending a unique position for more than 20 years? No? But this is precisely what we have done. Ever since Festo invented the valve terminal, we have been the leader, both in terms of the scope of our product portfolio and the development of new and better functions. And we mean to hold on to that position – to help you, our customers, create a lead for yourselves over your competitors. You will find suggestions on how to do this on the following pages. Simple and inexpensive: 5 valve terminal ranges with bus node CTEU Whenever you need solutions which are simple but nonetheless compatible with fieldbus systems: Festo offers 5 inexpensive valve terminal ranges equipped with a bus node CTEU. This strikingly simple fieldbus technology replaces existing installations with multi-pin 2 connectors or individual wiring – and doesn’t cost any etxra! The basis for this communication interface for all CTEU-compatible valve terminals is the Festo specific “I-Port” as a universal M12 connector. This offers the flexibility of accepting the new fieldbus/Ethernet bus modules type CTEU or being configured for IO Link. Ventilinseluebers_en.qxp 28.07.2011 Keeping complex tasks firmly under control with valve terminals MPA or VTSA combined with the modular electrical terminal CPX 13:23 Uhr Seite 3 These valve terminals are created for automation in the 21st century and are unique in the world thanks to function integration and a holistic approach: In combination with CPX, these valve terminals are able to display their strengths to the full as an automation platform for electrical I/O, standard, proportional and servopneumatics, sensors and compact vision systems and with motion control. With CPX and valve terminals, it is possible for the first time to combine functions such as: • Front-end control • Motion control • Measurement and control • Diagnostics and condition monitoring and implement universal communication via a fieldbus system and Ethernet from the field level up to the master control level. What is more, CPX opens up these valve terminals for use with all normal fieldbus systems and all electrical installation standards. A complete pneumatic control chain can be controlled via just one fieldbus connection, while the integrated motion control functions allow electrical and servopneumatic positioning. And the heavy-duty front-end controllers make it possible to carry out comprehensive process optimization using their signal pre-processing functions. A full range of integrated automation options from Festo. 3 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 4 Overview: The world of Festo valve terminals The valve terminal selection table … Flow rate (litres/min. per valve, max.) Valve terminals Electrical periphery Electrical inputs (max. per valve terminal) Decentralised … will guide you quickly to the right solution. It shows a wealth of valve terminal variants, together with their key technical features and recommendations for industry-specific requirements or particular applications. 8 VSVA/VTIA – ISO 15407-1 Modular, individual connectors M8/M12, C type For a rapid initial selection: universal terminals and terminals for specific requirements at a glance. Universal terminals Individual valves and valve terminals in one range VTUG Modular valve terminals on sub-bases MPA, VTSA Compact valve terminals CPV CPX/VTSA/VTSA-F – ISO 15407-2 and 5599-2 Modular, high pneumatic functionality, with electrical I/O - Zone 1 (cat. 2) 92 144 512 16 550/700 1100/1400 1800/1800 3000/3000 4500/- CPX/MPA-S/MPA-F/MPA-L Universal, modular, flexible, serial valve control, with electrical I/O 360 700 900 CPV Universal, compact, high performance 400 VTUG Universal, compact sub-base, high flow rate 200 VUVB/VTUB Universal, highly economical 800 1600 300 800 200 VTOC Compact, flexible 2x 3/2-way pilot valves 10 CDVI Clean Design IP65/67 650 12 VB12 400 500 VB20 VB20 VB20 VTSA VSVA/VTIA VTUB VTOC CDVI CPX terminal: multifunctional, modular, flexible periphery. Independent platform, comprehensive diagnositics and function integration. Options: remote I/O, remote control and motion control. CPV, MPA, CPX CPV-EXi CTEU/CAPC Flexible fieldbus and installation concept for up to 2 I/O modules or valve terminals. CPI system decentralised installation system. Up to 16 I/O modules and valve terminals. 3 platforms, for I/O modules, valve terminals and master modules. For fast help with planning, why not use the valve terminal configurator in the electronic catalogue of Festo? Available via www.festo.com, this assists you with the configuration of almost 20 valve terminal ranges to meet your requirements. 4 8 1000 1000 ISO standard - Multi-pin/fieldbus (sizes 02, 01, 1, 2, 3) - Individual connections Weight-optimised (polymer) Pilot valves (semicon, PA) Easy to clean ATEX - Zone 2 (cat. 3) 72 500 800 Specific requirements 16 3) 24 Decentralised 16 24 32 1) 3) 40 48 56 64 128 512 2) Integrated controller 1) 1) 1) 1) 1) Communication protocol Web-based, web monitor Preventve maintenance/CMS Module/channel-oriented Protection class Status bit Explosion-proof IP67 IP65 Valve properties IP40 Several pressure zones Vacuum Piloted Electrical connection Directly actuated Profinet/IO RT CC Link CANopen Interbus Profibus DeviceNet Modbus/TCP 4) Ethernet/IP 2) EtherCat 2) AS Interface 13:23 Uhr IO Link, I-Port Function integration Multi-pin Vertical stacking Electrical voltage zones 28.07.2011 Soft start/exhaust valves Safety technology valves Multi-axis interface for electric axes Servopneumatic positioning system End-position controller Soft Stop Proportional pressure regulator No. of valve coils (max. per valve terminal) Pressure sensor Ventilinseluebers_en.qxp Seite 5 Diagnostics 12 3) Via CPI system 2) For example: manual pressure regulators, pressure gauges, flow control plates, flow control/shut-off plates (hot-swap), pressure supply, integrated non-return functions/back-pressure valves Via CTEU/CAPC system, up to 32 inputs or 96 valves 4) MPA-L only 5 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 6 Festo’s world of valve terminals in detail A brief overview of selected valve terminals and peripheral products, together with services and support facilities. Valve terminal VTUG/ individual valves VUVG The universal valve terminal at an attractive price. Small, with high flow rates and all major functions. Valve terminal VTUB Flexible and simple, with an excellent price/performance ratio. Sizes VB12 or VB20. Valve terminal CPV Maximum performance density in a minimum of space. Direct integration of all common bus interfaces. Compact, with a fixed grid dimension. Valve terminal CDVI Clean and modular, in IP65/IP67. Easy to clean and corrosion-resistant, suitable for all zones up to the splash zone. Pilot valve terminal VTOC Compact and flexible, ideal for piloting process valves in the semicon, photovoltaics and process industries. More information can be found on our Internet Support Portal: www.festo.com Here you will find detailed descriptions of almost 20 valve terminal ranges – just enter the type (e.g. VTSA). 6 Valve terminal VSVA (ISO 15407-1, 5599-1, individual connections) Pre-assembled, for medium to high flow rates. 4 valve sizes can be combined without the need for adapters. Integrated safety functions possible. Valve terminals VTSA/VTSA-F (ISO 15407-2, 5599-2, plug-in) Modular, convertible and expandable sub-base concept, based on ISO standard, for everything up to complete installation solutions. Offers maximum pneumatic function integration and many safety functions. Modular valve terminals MPA1/MPA2/MPA-F Fieldbus or multi-pin terminals or individual valves with IP65 metal valve bodies and subbases. Serial stacking for fulldiagnostic and condition monitoring functionality and integrated proportional pneumatics. MPA-F: 30% higher flow rate than MPA 1/2. Highly modular valve terminal MPA-L Plastic sub-bases. Up to 32 valve positions/coils, expandable in small increments. Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 7 Modular electrical terminal CPX A world-wide unique platform for function integration, including electrical I/O, standard, proportional and servopneumatics, sensors and compact vision systems and motion control. Fieldbus direct connection Space-optimised connection of valve terminals using directly integrated fieldbus node. Advantage: Everything from a single source – and optimised pneumatic diagnostics. Decentralised installation system CPI Highly modular control and energy supply concept with a single transition point for all common fieldbuses and Ethernet protocols. Fieldbus/Ethernet Designed to be more communicative! Festo supports all established fieldbus systems. For a high degree of integration of electric, pneumatic and motion control functions on a single platform and from a single source. Allows comprehensive diagnostics and condition monitoring, pre-processing and seamless integration into your control system. Bus node CTEU Impressively simple fieldbus technology: For fieldbus-capable valve terminals for the price of a multi-pin solution. Optional adapter CAPC as a small installation system. AS-interface components Extremely simple, economical and flexible installation and control of distributed individual valves, sensors and safety technology. A single source for pneumatic as well as electrical components. IO Link/I-Port Standardised point-to-point communication link for diagnostics and parameterization of sensors, actuators, valves and valve terminals. The I-Port is a Festo-specific communication link with integrated Festo Plug and Work®-concept. For ultra-simple system assembly and commissioning. Electrical connection technology Perfectly matched: The modular system NEBU for connecting cables. After-Sales Service Hot line, spare parts service, repair service, emergency service or on-site technical customer service – as a single service or as a modular service package. Energy Saving Services Achieve energy and other cost savings of up to 60% together with increased productivity – an investment that will generally pay for itself within a short time. 7 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 8 Attractive solutions – from every point of view The whole is greater than the sum of its parts. Whoever takes this rule to heart becomes stronger. Just like us at Festo. We always aim to use our individual strengths to create a holistic solution. Our customers greatly appreciate this. Here are just a few examples: 8 Individual control elumatec GmbH, Mühlacker, Germany Advanced function integration Beck Automation AG, Oberengstringen, Switzerland Decentralization as a magic formula KUKA Systems GmbH, Augsburg, Germany A good appearance is important for successful sales! This also applies to aluminium and plastic profiles, as the manufacturer elumatec knows: “Our machines need to be fast and precise and also sensitive.” This is why elumatec chooses Festo valve terminal technology. “In order to be able to actuate cylinders with different pressures, we use the functionality of Festo products for creating of pressure zones and for the vertical stacking of modules.” If a company wishes to develop stylish solutions, it needs inventive but also reliable partners. “Festo is just such a partner,” explains Christian Beck, one of the managing partners of the Swiss company Beck Automation AG. This company supplies handling robots for the in-mould labeling process. For Beck, international service is just as important as excellence in technology. Solar modules on a 10-second high-speed tuning cycle to produce crystalline photovoltaic modules. Trimming, taping on the fly and framing are undertaken by fully-automatic robotic systems. Festo pneumatic proportional technology ensures that the contact pressure of the tape roller is correct. The decentralised electro-pneumatic control chain with CPX/MPA directly on the robot tool makes the process faster and more reliable and saves energy. Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 9 Commissioning and maintenance: As easy as child’s play CeraCon GmbH, Weikersheim, Germany Reducing costs with ready-toinstall control cabinets Ziemann Group, Ludwigsburg, Germany Seminar on higher plant efficiency Karlsberg Brauerei GmbH, Homburg, Germany People seldom give a thought to foam seals, but these provide reliable protection from air, dust and humidity. CeraCon’s new one-component system and proportional technology from The Ziemann Group in Ludwigsburg develops and builds brewery installations for clients worldwide. The extremely economical operation of these installations allow breweries to One important concept for increasing machine availability and reducing downtime is Total Productive Maintenance, or TPM. This is used by, for example, the brewery Karlsberg Brauerei GmbH in Homburg to achieve a continuous increase in plant efficiency. The Festo Didactic seminar “Fundamentals of Total Productive Maintenance (TPM)” provided the company with an introduction to this concept. Festo is generating innovation in the seal industry. During the preparation and dosing of the materials, a valve terminal CPX/MPA with diagnostic functionality forms a bridgehead to the master machine control system. Standardised networking and a neat installation structure, easy implementation and high function density provide benefits for CeraCon as commissioning and maintenance become as easy as child’s play. run production operations with extremely low life-cycle costs. In designing these installations, Ziemann concentrates totally on its own core competences. Control cabinets for the production systems in the brewing rooms and refrigerated areas are supplied by Festo as readyto-install units. These control the pneumatic process valves and provide individual diagnostics for each valve. A pressure measurement module on each valve manifold checks the supply pressure. Our range of products and services provide everything you need: • Complete portfolio for every requirement • Clear installation concepts, also for combined installations • Comprehensive ncentrated services covering everything from engineering to after sales • Support tools for all phases from engineering to operation, e.g. for correct dimensioning • Attractive electrical and pneumatic concepts • Maximum function integration • Diagnostic and condition monitoring packages 9 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 10 Reducing the cost of electrical and motion control solutions Within the overall costs of an installation, the costs of the components themselves are often the smallest item. You can therefore reduce overall costs by planning ahead. Below you will find some hints and tips that will help you to get more out of your budget. Technological optimization for more economic production 1. Concentration of a number of valves and I/O on one point with central installation Example of CPX/VTSA with Profibus: • Price per channel for 4 5/2-way valves 100% • Price per channel for 16 5/2-way valves 40% less • Price per channel for 32 5/2-way valves 50% less 2. More performance – greatly reduced price per channel on high-capacity I/O modules • 8 digital inputs instead of 4: price per channel 40% less • 16 digital inputs instead of 8: 25% less • 8 digital outputs instead of 4: 15% less • 4 analogue inputs instead of 2: 20% less Example of CPX/MPA with Profibus: • Price per channel for 16 3/2-way valves 100% • Price per channel for 32 3/2-way valves 16% less • Price per channel for 128 3/2-way valves 28% less More channels per modules means, for example, overhead costs with decentralised valve terminals which are up to 34% lower! 10 Deal with one component instead of over 200. In factory and process automation, it is possible to optimize overall costs and increase reliability. For example, with well-thoughtout control cabinet concepts, even for high-volume production. 3. Concepts with a protected installation area: lower protection class possible, fewer connections • IP20 connection system CageClamp for control cabinets. Flexible, reliable, fast • Multi-pin connectors in control cabinets save hardware costs • CageClamp IP20 on machines and in safety covers AK-8KL for CPX gives IP65/67 • Pneumatic multi-pin connector for CPV or VTUG saves a vast amount of installation work • Protective cover CAFR – for electric shock protection without a control cabinet 4. Benefit from higher productivity A decentralised machine concept requires greater investment. But it can speed up cycle times by 10%, thus making the investment pay for itself within just a few weeks. Diagnostic functions are also well worthwhile and improve the total cost of ownership (TCO) of your end customers (see point 5, page 12). With remote maintenance, for example, you can offer completely new types of service concepts or maintenance contracts and new forms of guarantees. Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 11 Electrical criteria and motion control Electrical criteria Centralised Decentralised On-site (Fieldbus Direct) Hybrid No. of valves No. of digital I/O 8 ... 128 Preferred tubing length < 3 m 32 ... 128 Distance between modules up to 8 - 10 m 2 … 32 (48) … 512 Bandwidth 2 4 Bandwidth Bandwidth 8 16 32 Typical 8 64 128 512 Fieldbus I/O 16 Typical 8 ASi I/Os Typical Bandwidth 32 64 128 512 Fieldbus I/O 8 16 Typical Bandwidth 32 64 128 512 Fieldbus I/O 8 16 32 Typical 64 128 512 Fieldbus I/O • Analogue I/O • Temperature measurement • Pressure measurement • Displacement measurement Yes Yes Yes Yes – – – – – – – – Yes Yes Yes Yes I/O parameterizable Yes – – Yes (local I/O) Motion control for electric drives • Asynchronous • Synchronous • 2.5 D Up to 31 Up to 8 Up to 8 – – – – – – Up to 31 Up to 8 Up to 8 Motion cont. servopneumatic drives • Soft-Stop end-position cushioning • Positioning system Up to 8 Up to 8 – – – – Up to 8 Up to 8 – Yes Yes Yes – Yes Yes Yes, with CPX Yes Yes – – – Yes Yes Yes Yes Yes Yes Yes Yes Yes – – – Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes – – – Yes Yes Yes Yes – Yes – Yes – – – – Yes Yes Yes Yes (local I/O) Yes Yes (local I/O) Yes Yes Yes • IO Link/I-Port • Fieldbus • Ethernet • Fieldbus and Ethernet in combination • Pre-processing (front-end control) - CEC-C1 diagnostics - CEC-M1 motion - PC Worx Diagnostic functions • LEDs • Hand-held control unit • Module-oriented • Channel-oriented • CMS • Limit values • SMS/e-mail alarm • CPX web monitor • CPX-FMT maintenance tool 11 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 12 Reducing the cost of pneumatic components and safety technology Technology that delivers greater economy 1. Saving flow rate by up to 50% The principle is to be as close as possible to the application; e.g. by mounting on handling units or robots. 2. Optimizing cycle times by up to 30% Will fast valves or a higher flow rate boost performance? A precise answer is provided by a simulation which also takes into account tubing cross-section and length. 3a. Optimizing installation space by up to 70% The closer valves and I/O modules are to the application, the less installation space is required. What is more, a multipin connector can be up to 40% smaller than a fieldbus connector. 3b. Optimizing installation space by up to 50% Halve the installation width by installing higher-capacity I/O modules (see point 2, page 10). 3c. Optimizing installation space: Decentral I/O modules for three platforms • Compact – minimal installation space • Robust – aluminium housings with metal threads • Economical – high channel density Do you know our integrated technology? It offers system solutions that deliver maximum performance with minimal dimensions. These are ideal wherever a compact neat design or fast installation and maintenance is important. 12 4. Function integration for demonstrable efficiency gains of up to 60% Modules for temperature measurement, manual pressure regulators, pressure sensors or proportional valves can now be ordered fully integrated, pre-assembled and tested on CPX/MPA. This saves space and simplifies installation, commissioning and programming. 5. Optimised machine utilization through diagnostics There is a wide choice of diagnostic functions and diagnostic depth, with optimization of the strategic diagnostic approach. Herer are a few examples: • Reducing downtime by a factor of 8 with channeloriented diagnostics. Allows immediate detection of the type of fault and its location. • The valve terminal MPA is more reliable, safer and more economical thanks to serial linking, special Festo valve ASICs and pressure sensors. • CPX Web Monitor – optional for all valve terminals connected to CPX via Ethernet. Comprehensive diagnostics without programming costs using standard browsers. • Condition Monitoring Systems for preventive maintenance to avoid breakdowns. Only from Festo: specially for valves! A further benefit: our Condition Monitoring Service. This continuously monitors critical processes and avoids unplanned downtime. This service can be matched exactly to your requirements and we can also provide support during implementation. Ask our specialists! Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 13 Pneumatic criteria and safety technology Pneumatic criteria Centralised MPA VTSA Decentralised MPA CPV On-site* No. of valves 1 … 128 1 … 32 2 … 32 4/6/8 8 ... 48* Flow rate 360 700 900 700 1400 1800 3000 4500 360 700 200** 400 800 1600 Vertical stacking • Manual regulator • Flow control plate • Pressure shut-off plate • Air supply plate Yes – Yes – Yes Yes Yes Yes Yes Yes Yes – Valve size mix • 2 sizes • 3 sizes • 4 sizes • 5 sizes Yes – – – Yes Yes Yes Yes Yes Yes Yes Yes Function integration • Pressure sensor • Proportional pressure regulator • Single-channel valve diagnostics • CMS valves • Voltage zones, electrically isolated Safety technology • Interlock function • Valves for press control, with two-channel interlinking • Valves for manual clamps • Valves for lifting/turning cylinders • Valves with piston rod sensing • Soft start and exhaust valve • Switch-off concepts up to performance level d (cat. 3) • Profisafe switch-off module up to performance level e (cat. 3) and SIL 3 Hybrid MPA VTSA CPV 1 … 32 + decentral MPA/CPV up to 480 4 … 512 – 360 – 700 – 900 10 ... 1600* 700 1400 1800 3000 4500 200** 400 800 1600 – Yes – – Yes* Yes* Yes* – Yes – Yes – Yes Yes Yes Yes – Yes – – Yes – – – – – – – – – – – Yes – – – Yes Yes Yes Yes – – – – – – Yes – – – – – – – – – – – – Yes* Yes Yes Yes Yes – – Yes – – – – – Yes Yes – – – Yes Yes – – – – Yes – – – – Yes* – – – – Yes – – – – – – – Yes Yes Yes Yes Yes – – – – – – – – – – – – – – – – – – – – Yes Yes Yes Yes Yes – – – – – Yes Yes – – – Yes Yes – * Depending on the valve terminal range CPV, MPA-L, VTUB, VTUG, VTOC 1 … 512 ** CPV-SC, IP40 13 Ventilinseluebers_en.qxp 28.07.2011 13:23 Uhr Seite 14 We enjoy a challenge! Our in-house research and development department is fully equipped with state-of-the-art the devices it needs to create objective-oriented innovations in all our major competence areas – electronics, pneumatics, motion control and industrial networking. Award-winning! In recognition of its capacity for innovation, Festo was accorded the German Future Award 2010 from the Federal German President. We feel that there is a part of this award in each of our new products, thus reflecting Festo’s intention that each product represents the optimum in terms of functionality and futureoriented technology. Our great inspiration is bionics – unravelling nature’s original archetype to discover the fundamental technical principle and creating a bionic adaptation fit for an industrial application. The latest electronics from Festo. Several hundred people work at Festo in its electronics development department, in specialised laboratories, in research and in Festo’s own electronics production operations. We produce well over one million printed circuit boards each year and test these to the strictest standards. This ensures that our valve terminals can be integrated perfectly into industrial communication systems – and that you can rely on us to supply start-of-the-art technology. Future-oriented technology. This means many innovative catalogue products, tested under real-life conditions, for your benefit. www.festo.de Gewinner 2010 14 Virtual reality – for faster design work … … and dependable production. Our research and development department uses this technology to simulate and optimize fluidic processes. This reduces time to market – and enables complex connections to be precsiely calculated in advance. The quality of Festo’s product portfolio and production operations … … ensures we can deliver maximum process reliability and performance in pneumatics, electrical engineering and networking. Ventilinseluebers_en.qxp 28.07.2011 13:24 Uhr Seite 15 A brief tour of our facilities 1. Mechanical engineering • Tensile/compression tests … … in accordance with DIN EN 10002 to ensure that the materials meet our demanding requirements even at extreme temperatures. • Corrosion resistance … … in accordance with DIN EN 50018, DIN EN 50021 and an internal Festo standard to ensure hard-wearing finishes for metallic surfaces and selected plastics. • Vibration/shock tests In accordance with FN942017-5 and DIN/IEC 68. 2. Electrical engineering Certified EMC laboratory Conformity testing of everything up to and including fully assembled valve terminals in accordance with the EMC directives 89/336 EEC and 2004/108EC. Festo’s in-house EMC laboratory also acts as an accredited test facility! 3. Acoustics, analysis • Sound measurement Whisper-quiet pneumatic products in accordance with Festo’s own standard and DIN 45635-1 or ISO 3745 is created in our sound measurement toom, which is a certified and authorized test facility. • Microscopes and X-rays Analysis of material samples and identification of consequential faults using a scanning electron microscope, a laser scanning microscope and X-ray examination. • Spectral analysis Detects the smallest particles and invisible elements such as contamination in oils. 4. Climatic tests Continuous hot/cold cycle In accordance with Festo standards: how long will mechanical and electronic components last at ambient temperatures of between -40 and +150 °C? 5. Fire and water Water jet tests to verify protection class IP65/67 in accordance with Festo’s own standard, DIN EN 60529 and NEMA 250 to ensure that these components will survive a harsh industrial environment. 6. Clean room classes Festo products are tested in our own Competence Center to ensure they comply with VDI guideline 2083 or Federal Standard 209 F Airborne. The result: Many inexpensive Festo products can also be used in clean rooms. 7. Endurance tests In accordance with various Festo standards. In order to ensure maximum process reliability, valves, valve terminals, electrical I/O and fieldbus interfaces, together with plugs, cables and tubing/fitting combinations, are exhaustively tested by bending, stretching and connecting/ disconnecting. 8. Explosion protection Festo carries out testing and certification of pneumatic and electrical explosion-proof products, for example in accordance with the directive 94/9/EC or EN 60079. For the latest information, declarations of conformity and other documentation, see www.festo.com/en/ex Systematic innovation 15 Ventilinseluebers_en.qxp 28.07.2011 13:24 Uhr Seite 16 Festo worldwide Finland Festo OY Mäkituvantie 9 P.O. Box 86 01511 Vantaa Tel. +358 (09) 87 06 51, Fax +358 (09) 87 06 52 00 E-mail: info_fi@festo.com Australia Festo Pty. Ltd. Head Office (Melbourne) 179-187 Browns Road P.O. Box 261 Noble Park Vic. 3174 Call Toll Free 1300 88 96 96 Fax Toll Free 1300 88 95 95 Tel. +61(0)3 97 95 95 55, Fax +61(0)3 97 95 97 87 E-mail: info_au@festo.com France Festo Eurl ZA des Maisons Rouges 8 rue du clos sainte Catherine 94360 Bry-sur-Marne Tel. +33 (0) 820 20 46 40 (numéro indigo), Fax +33 (0) 820 20 46 41 E-mail: info_fr@festo.com Austria Festo Gesellschaft m.b.H. Linzer Straße 227 1140 Wien Tel. +43 (0)1 910 75-0, Fax +43 (0)1 910 75-250 E-mail: automation@festo.at Belarus IP Festo Masherov avenue, 78 220035 Minsk Tel. +375 (0)17 204 85 58, Fax +375 (0)17 204 85 59 E-mail: info_by@festo.com Belgium Festo Belgium sa Rue Colonel Bourg 101 1030 Bruxelles Tel. +32 (0)2 702 32 11, Fax +32 (0)2 702 32 09 E-mail: info_be@festo.com Belgium Festo Belgium nv Kolonel Bourgstraat 101 1030 Brussel Tel. +32 (0)2 702 32 11, Fax +32 (0)2 702 32 09 E-mail: info_be@festo.com Brazil Festo Brasil Ltda Rua Guiseppe Crespi, 76 KM 12,5 - Via Anchieta 04183-080 São Paulo SP-Brazíl Tel. +55 (0)11 50 13 16 00, Fax +55 (0)11 50 13 18 68 E-mail: info_br@festo.com Bulgaria Festo EOOD 1592 Sofia Bul. Christophor Kolumb 9 Tel. +359 (0)2 960 07 12, Fax +359 (0)2 960 07 13 E-mail: info_bg@festo.com Canada Festo Inc. 5300 Explorer Drive Mississauga, Ontario L4W 5G4 Tel. +1 (0)905 624 90 00, Fax +1 (0)905 624 90 01 E-mail: info_ca@festo.com Chile Festo S.A. Avenida Américo Vespucio, 760 Pudahuel Santiago Tel. +56 2 690 28 00, Fax +56 2 690 28 60 E-mail: info.chile@cl.festo.com China Festo (China) Ltd. 1156 Yunqiao Road, Jinqiao Export Processing Zone, Pudong, 201206 Shanghai Tel. +86 21 60 81 51 00, Fax +86 21 58 54 03 00 E-mail: info_cn@cn.festo.com Colombia Festo Ltda. Autopista Bogotá - Medellín Km 6 (costado sur) Tenjo, Cundinamarca Tel. +57 (1) 865 77 88, Fax +57 (1) 865 77 88 Ext.287 E-mail: mercadeo@co.festo.com Croatia Festo d.o.o. Nova Cesta 181 10000 Zagreb Tel. +385 (0)1 619 19 69, Fax +385 (0)1 619 18 18 E-mail: info_hr@festo.com Czech Republic Festo, s.r.o. Modřanská 543/76 147 00 Praha 4 Tel. +420 261 09 96 11, Fax +420 241 77 33 84 E-mail: info_cz@festo.com Germany Festo AG & Co. KG Postfach 73726 Esslingen Ruiter Straße 82 73734 Esslingen Tel. +49 (0)711 347 0, Fax +49 (0)711 347 26 28 E-mail: info_de@festo.com Greece Festo Ltd. 40 Hamosternas Ave. P.C. 11853 Athens Tel. +30 210 341 29 00, Fax +30 210 341 29 05 E-mail: info_gr@festo.com Hong Kong Festo Ltd. 6/F New Timely Factory Building, 497 Castle Peak Road, Kowloon, Hong Kong Tel. + 852 27 43 83 79, Fax + 852 27 86 21 73 E-mail: info_hk@festo.com Hungary Festo Kft. Csillaghegyi út 32-34. 1037 Budapest Hotline +36 1 436 51 00 Tel. +36 1 436 51 11, Fax +36 1 436 51 01 E-mail: info_hu@festo.com India Festo Controls Private Ltd. 237B, Bommasandra Industrial Area, Bangalore Hosur Highway, Bangalore 560 099 Tel. +91 (0)80 22 89 41 00, Fax +91 (0)80 27 83 20 58 / 27 83 33 62 E-mail: info_in@festo.com Indonesia PT. Festo JL. Sultan Iskandar Muda No. 68 Arteri Pondok Indah Jakarta 12240 Tel. +62 (0)21 27 50 79 00, Fax +62 (0)21 27 50 79 98 E-mail: info_id@festo.com Lithuania Festo, UAB Partizanų 63M 50306 Kaunas Lietuva Tel. +370 (8)7 32 13 14, Fax +370 (8)7 32 13 15 E-mail: info_lt@festo.com Slovenia Festo d.o.o. Ljubljana IC Trzin, Blatnica 8 1236 Trzin Tel. +386 (0)1 530 21 00, Fax +386 (0)1 530 21 25 E-mail: info_si@festo.com Malaysia Festo Sdn. Berhad 10 Persiaran Industri Bandar Sri Damansara Wilayah Persekutuan 52200 Kuala Lumpur Tel. +60 (0)3 62 86 80 00, Fax +60 (0)3 62 75 64 11 E-mail: info_my@festo.com South Africa Festo (Pty) Ltd. 22-26 Electron Avenue P.O. Box 255 Isando 1600 Tel. +27 (0)11 971 55 00, Fax +27 (0)11 974 21 57 E-mail: info_za@festo.com Mexico Festo Pneumatic, S.A. Av. Ceylán 3, Col. Tequesquináhuac 54020 Tlalnepantla Estado de México Tel. +52 (01)55 53 21 66 00, Fax +52 (01)55 53 21 66 55 E-mail: festo.mexico@mx.festo.com Spain Festo Pneumatic, S.A.U. Avenida Granvia, 159 Distrito Económico Granvia L'H 08908 Hospitalet de Llobregat Barcelona Tel.: 901243660, Fax: 902243660 Tel. +34 93 261 64 00, Fax +34 93 261 64 20 E-mail: info_es@festo.com Netherlands Festo B.V. Schieweg 62 2627 AN Delft Tel. +31 (0)15 251 88 99, Fax +31 (0)15 251 88 67 E-mail: info@festo.nl Sweden Festo AB Stillmansgatan 1 Box 21038 200 21 Malmö Tel. +46 (0)20 38 38 40, Fax +46 (0)40 38 38 10 E-mail: order@festo.se New Zealand Festo Ltd. 20 Fisher Crescent Mount Wellington Auckland Tel. +64 (0)9 574 10 94, Fax +64 (0)9 574 10 99 E-mail: info_nz@festo.com Nigeria Festo Automation Ltd. Motorways Centre, First Floor, Block C Alausa, Ikeja, Lagos Tel. +234 (0)1 794 78 20, Fax +234 (0)1 555 78 94 E-mail: info@ng-festo.com Norway Festo AS Ole Deviks vei 2 0666 Oslo Tel. +47 22 72 89 50, Fax +47 22 72 89 51 E-mail: info_no@festo.com Peru Festo S.R.L. Amador Merino Reyna 480 San Isidro Lima Tel. +51 (1) 219 69 60, Fax +51 (1) 219 69 71 E-mail: festo.peru@pe.festo.com Iran Festo Pneumatic S.K. # 2, 6th street, 16th avenue, Km 8, Special Karaj Road P.O.Box 15815-1485 Teheran 1389793761 Tel. +98 (0)21 44 52 24 09, Fax +98 (0)21 44 52 24 08 E-mail: Mailroom@festo.ir Philippines Festo Inc. Festo Building KM 18, West Service Road South Superhighway 1700 Paranaque City Metro Manila Tel. +63 (0)2 776 68 88, Fax +63 (0)2 823 42 19 E-mail: info_ph@festo.com Ireland Festo Limited Unit 5 Sandyford Park Sandyford Industrial Estate Dublin 18 Tel. +353 (0)1 295 49 55, Fax +353 (0)1 295 56 80 E-mail: info_ie@festo.com Poland Festo Sp. z o.o. Janki k/Warszawy ul. Mszczonowska 7 05090 Raszyn Tel. +48 (0)22 711 41 00, Fax +48 (0)22 711 41 02 E-mail: info_pl@festo.com Israel Festo Pneumatic Israel Ltd. P.O. Box 1076 Ha'atzma'ut Road 48 Yehud 56100 Tel. +972 (0)3 632 22 66, Fax +972 (0)3 632 22 77 E-mail: info_il@festo.com Portugal Festo – Automação, Unipessoal, Lda. Rua Manuel Pinto De Azevedo, 567 Apartado 8013 4109-016 Porto Contact Center: 707 20 20 43 Tel. +351 22 615 61 50, Fax +351 22 615 61 89 E-mail: Info@pt.festo.com Italy Festo SpA Via Enrico Fermi 36/38 20090 Assago (MI) Tel. +39 02 45 78 81, Fax +39 02 488 06 20 E-mail: info_it@festo.com Japan Festo K.K. 1-26-10 Hayabuchi Tsuzuki-ku Yokohama 224-0025 Tel. +81 (0)45 593 56 10 / -5611, Fax +81 (0)45 593 56 78 E-mail: info_jp@festo.com Denmark Festo A/S Islevdalvej 180 2610 Rødovre Tel. +45 70 21 10 90, Fax +45 44 88 81 10 E-mail: info_dk@festo.com Korea South Festo Korea Co., Ltd. 470-1 Gasan-dong Geumcheon-gu Seoul #153-803 Tel. +82 (0)2 850 71 14, Fax +82 (0)2 864 70 40 E-mail: info_kr@festo.com Estonia Festo OY AB Eesti Filiaal Laki 11B 12915 Tallinn Tel. +372 666 15 60, Fax +372 666 15 61 E-mail: info_ee@festo.com Latvia Festo SIA A. Deglava iela 60 1035 Riga Tel. +371 67 57 78 64, Fax +371 67 57 79 46 E-mail: info_lv@festo.com Romania Festo S.R.L. St. Constantin 17 010217 Bucuresti Tel. +40 (0)21 310 31 90, Fax +40 (0)21 310 24 09 E-mail: info_ro@festo.com Russia OOO Festo-RF Michurinskiy prosp., 49 119607 Moscow Tel. +7 495 737 34 00, Fax +7 495 737 34 01 E-mail: info_ru@festo.com Singapore Festo Pte. Ltd. 6 Kian Teck Way Singapore 628754 Tel. +65 62 64 01 52, Fax +65 62 61 10 26 E-mail: info@sg.festo.com Slovakia Festo spol. s r.o. Gavlovicová ul. 1 83103 Bratislava 3 Tel. +421 (0)2 49 10 49 10, Fax +421 (0)2 49 10 49 11 E-mail: info_sk@festo.com Switzerland Festo AG Moosmattstrasse 24 8953 Dietikon ZH Tel. +41 (0)44 744 55 44, Fax +41 (0)44 744 55 00 E-mail: info_ch@festo.com Taiwan Festo Co., Ltd. Head Office 24450 9, Kung 8th Road Linkou 2nd Industrial Zone Linkou Dist., New Taipei City Taiwan, R.O.C. Tel. +886 (0)2 26 01-92 81, Fax +886 (0)2 26 01 92 86-7 E-mail: festotw@tw.festo.com Thailand Festo Ltd. 67/1 Phaholyothin Rd., T. Klong 1, A. Klongluang Pathumthani 12120 Tel. +66 29 01 88 00, Fax +66 29 01 88 30 E-mail: info_th@festo.com Turkey Festo San. ve Tic. A.S. Tuzla Mermerciler Organize Sanayi Bölgesi 6/18 34956 Tuzla - Istanbul/TR Tel. +90 (0)216 585 00 85, Fax +90 (0)216 585 00 50 E-mail: info_tr@festo.com Ukraine Festo Ukraina DP Festo vul. Borisoglebskaya,11 04070, Kiev Tel. +380 (0)44 239 24 30, Fax +380 (0)44 463 70 96 E-mail: orders_ua@festo.com United Kingdom Festo Limited Applied Automation Centre Caswell Road Brackmills Trading Estate Northampton NN4 7PY Tel. ++44 (0)1604 / 66 70 00, Fax ++44 (0)1604 / 66 70 01 E-mail: info_gb@festo.com United States Festo Corporation (New York) 395 Moreland Road P.O. Box 18023 Hauppauge, NY 11788 Call Toll-free 800/993 3786 Fax Toll-free 800/963 3786 Tel. +1(631) 435 08 00, Fax +1(631) 435 80 26 E-mail: customer.service@us.festo.com Venezuela Festo C.A. Av. 23 esquina con calle 71 N° 22-62, Edif. Festo. Sector Paraíso Maracaibo - Venezuela Tel. +58 (261) 759 11 20/759 41 20/759 44 38, Fax +58 (261) 759 04 55 E-mail: festo@festo.com.ve Vietnam Festo Co., Ltd (Cong Ty Tnhh Festo) No. 206 Tran Nao Street Ward Binh An District 2 Ho Chi Minh City Tel. +84 (0)8 740 69 09, Fax +84 (0)8 740 69 10 E-mail: info_vn@festo.com 135237 en 2011/07 Argentina Festo S.A. Edison 2392 (1640) Martínez Prov. Buenos Aires Tel. +54 (011) 4717 82 00, Fax +54 (011) 47 17 82 82 E-mail: info@ar.festo.com