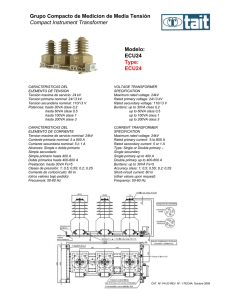

Ficha Ficha Tecnica / Data / Data Sheet

Anuncio

Electrorefining and Electrowinning and Electrowinning Capping Boards Ficha Tecnica Ficha Tecnica / Data / Data Sheet Sheet INTRODUCTION In the hydrometallurgical industry, it is of common practice to refine metal by electrolysis in electrolytic cells especially designed for this purpose. The metals that are refined are usually conventional metals like copper, zinc, nickel,cobalt or precious metals like silver, platinum or gold, and others. It is also of common practice to use metal plates as anodes or cathodes or both. These metal plates most often weigh several hundred pounds, have a given thickness and include the metal to be refined or used to carry the electric current. Once installed, the plates usually hang on lateral sidewalls of the electrolytic cells. In use, these heavy plates are immersed into the cells in parallel relationship and are used as anodes, cathodes or both, depending on the affinity and properties of the metal being refined. In order to precisely and properly position the electrodes, it is of common practice to place a member called a “capping board” onto the top surface of each lateral sidewall of the cells. These capping boards are used to position the plates with respect to each other. They are j / / g also used as electric insulators between adjacent cells and/or each electrode and/or the ground. In practice, the capping boards are used not only as supports to position the electrodes, but also as supports to avoid damage to the masonry or concrete forming the lateral sidewalls of the cells during the insertion and removal of the heavy electrodes. As mentioned herein above, the insulating capping boards are used to hold the electrodes at very precise positions. They are also often used in combination with other components of the electrolytic apparatus, such as electrically conductive contact bars (Bus bars) whose purpose is to allow electrical connection between the ends of the anodes and cathodes located in the adjacent cells. Thus, the combined use of capping boards and contact bars has the particularity of allowing insulation and distribution of electric current at the same time. use of capping boards and contact bars has the particularity of allowing insulation and distribution of electric current at the same time. The capping boards may also be precisely arranged in relation to other components, depending on the specific electrolytic process or cell arrangement. The installation of capping boards also presents numerous difficulties, as both the capping boards and the electrical plates are often large, heavy and awkward to handle. In addition, the precision fit of the capping board with respect to the plate and cell dimensions requires certain manufacturing standards and implies certain limits on the form and construction of the capping board. Capping Boards pp g • Custom Designs ‐ Electrowinning ‐ Electrorefining • Accurate Positioning ‐ Excelent Dimensional Tolerances • High Grade Materials High Grade Materials ‐ High Compression High Compression Strenght ‐ High Electrical Resistance ‐ High Chemical Resistance ‐ High Temperature High Temperature Resistance Mechanical Test Thermal Test Dimensional Check Impact Test Chemical Test Resistencia Quimica Resistencia Quimica ‐ %Weight H2SO4: 15 ‐ 90% ‐ Temperature : 20 ‐ 70 ºC ‐ Time: 240 hrs. Thermal Test Temperature (300ºC) Thermal Test Temperature Test : 300ºC 300 C Test Duration : 24 hrs. Test Capping Test Capping Boards Thermal Test Impact Test Thermo – Chemical Capping Boards Test Test Parameters Test Parameters ‐ Weight Concentration H2SO4: 90% ‐ Temperature : 70 ºC ‐ Time : 200 hrs. Standard Material Cell Material Polimeric Concrete Exma High Grade Material Test Parameters - Weight Concentration H2SO4: 90% - Temperature : 70 ºC - Time : 200 hrs. Test Parameters - Weight Concentration H2SO4: 90% - Temperature : 20 ºC - Time : 1000 hrs. Xo : : Exma Exma High Grade Material Rangos Usos Material High Grade Material Capping Boards % Weight H2SO4 20ºC 20 C 30ºC 30 C 50ºC 50 C 70ºC 70 C 5 o.k o.k o.k o.k 15 o.k o.k o.k o.k 30 o.k o.k o.k o.k 50 o.k o.k o.k o.k 75 o.k o.k o.k o.k 90 o.k o.k o.k - Low Surface Discoloration loss0.02% 02% - Mass loss0 - Good Impact Resistance - Thermal Resistance 260ºC Capping Boards Electrowinning Sistema Sistema Barras Alta Densidad Corriente Ánodo Equalizado Barras Alta Densidad Corriente Ánodo Equalizado Capping Boards Electrowinning Check Capping Boards Electrowinning Sistema Barras Corriente Anodo Sistema Barras Corriente Anodo Equalizado Capping Boards Electrowinning Sistema Barras Corriente Anodo Sistema Barras Corriente Anodo ‐ Catodo Equalizado Capping Boards Electrowinning Sistema Barras Corriente Anodo Sistema Barras Corriente Anodo Equalizado Capping Boards Electrowinning Barra Spool p Capping Boards Electrorefinacion Capping Boards Electrowinning Alto Grado