FT IMPAC_FIBERGLASS_MIN

Anuncio

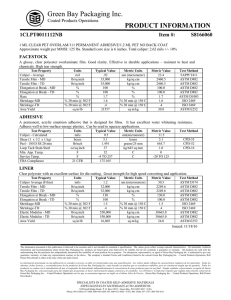

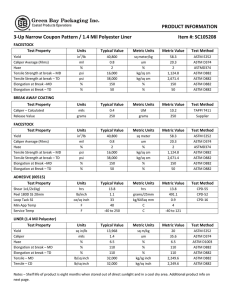

IMPAC Irish Green FIBERGLASS MINERAL SURFACE ROLL ROOFING River Stone Description: Arizona Sand IMPAC® Fiberglass Mineral Surfaced Roll Roofing is a glass fiber reinforced asphalt coated product with granular surface to protect against UV, weathering and physical damage. It is lightly coated with a mineral release material on the bottom side. Grand Canyon Granule Surface Usage: Modified Bitumen Glass Yarn Reinforced Polyester Modified Bitumen Polyethylen Film Fiberglass Mineral Surfaced Roll Roofing is a general purpose roofing product designed for use in new roofing and re-roofing installation utilizing hot mopping asphalt, cold process adhesives or mechanical fasteners. While frequently used for residential low-slope applications such as porches and carpots or as flashing material, it can also be used as a base sheet in commercial applications. PRESENTACIÓN Features and Benefits: Versatile and easy to handle Durable and cost-effective. Reinforced with glass fiber mat ensuring dimensional stability during installation. Specially formulated asphalt gives lasting performance. Minimal dead load weight Rolls lay flat and resist wrinkling for easy application. Low-slope residential and commercial use Granular surfacing available in multiple colors to complement most shingle applications. ROLLOS MEASURE 1.00 m width x 10.00 m long FINISH Gravel In specific cases request information from our technical department Important: All our products have been manufactured according to strict quality standards and fulfilling every reasonable precaution, the information we are providing is correct according to our experience, products as they are sell comply with the aims to which they are been manufactured. Nevertheless we can not be responsible for the variations in the use method or conditions to be applied by the buyer. Caution: Storage and Handling Fiberglass Mineral Surfaced Roll Roofing requires protection from damage and the weather. Constantly store rolls upright in a dry location and never more than two pallets high. When storing two pallets high, position a plywood sheet between pallets. The existing roof coating systems should be completely removed from the surface to be protected. The area to be coated must not have bulges that can damage the asphaltic membrane. Do not place heavy objects on the newly installed cloth without the suitable protection to prevent damage. During the installation with a gas blowtorch do not exceed in the flamed because it damages the reinforcement and the properties of the polymers that modify the asphalt. The application with blowtorch can only be fulfilled when the prime is dry. The IMPAC® prefabricated must not be stored exposed to heat, it should be stowed only in a vertical position and where the room temperature is not higher than 45°C. It is not resistant to oils neither solvents. Update: September/8/2010. These technical specifications replace any previous one up to this date. Visit our webpage www.impac.com.mx where you can find the current version. Subjected to changes without notice. www.impac.com.mx IP-PRE-MIN-NR00/0910 Aplicaction: All roofing materials must be kept clean and free of moisture prior to installation. Warm weather conditions are ideal for good adhesion.Application should be made when ambient temperatures are 50º F or higher. Deck must be free of voids, clean and dry. Cut membrane sheets into manageable lengths before installation. Apply over roof decks with inclines of not less than 2 inches per foot. Instal in a horizontal manner, overlapping a minimum of 2 inches on side laps and a minimum of 6 inches on end laps. To ensure product integrity, do not use in excess of 1/8 inch thickness of lap cement. Install flashings in cement before nailing in place. MINERALIZADO FIBRA DE VIDRIO GRAVILLA IMPAC FIBERGLASS MINERAL SURFACE ROLL ROOFING PROPERTIES MELTING POINT VALUE METHOD ASTMD-36 D-36 ASTM 212-110 -230ºC ºF 100 FIBERDEGLASS FIBRA VIDRIO INTERMEDIATE REINFORCEMENT RESISTANCE TO LONGITUDINAL STRAIN ASTM D-5147 ASTM D-5147 190 190 NN min. min. RESISTANCE TO TRANSVERSAL STRAIN ASTM D-5147 D-5147 ASTM 145 N N min. min. 145 ASTM D-5147 ASTM D-5147 30 -1 ºF ºC FLEXIBILITY FOR TEMPERATURE ACTUAL PERFORMANCE 8.9m2 m2 8.2 www.impac.com.mx IP-PRE-MIN-NR00/0910