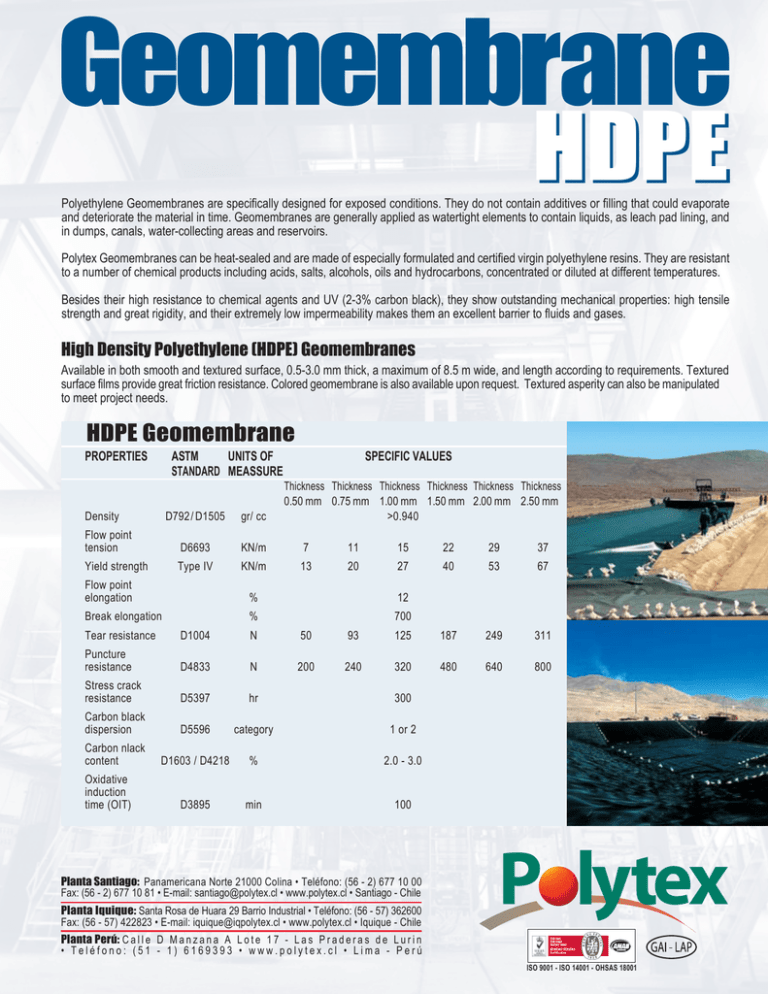

HDPE Geomembrane

Anuncio

Geomembrane HDPE Polyethylene Geomembranes are specifically designed for exposed conditions. They do not contain additives or filling that could evaporate and deteriorate the material in time. Geomembranes are generally applied as watertight elements to contain liquids, as leach pad lining, and in dumps, canals, water-collecting areas and reservoirs. Polytex Geomembranes can be heat-sealed and are made of especially formulated and certified virgin polyethylene resins. They are resistant to a number of chemical products including acids, salts, alcohols, oils and hydrocarbons, concentrated or diluted at different temperatures. Besides their high resistance to chemical agents and UV (2-3% carbon black), they show outstanding mechanical properties: high tensile strength and great rigidity, and their extremely low impermeability makes them an excellent barrier to fluids and gases. High Density Polyethylene (HDPE) Geomembranes Available in both smooth and textured surface, 0.5-3.0 mm thick, a maximum of 8.5 m wide, and length according to requirements. Textured surface films provide great friction resistance. Colored geomembrane is also available upon request. Textured asperity can also be manipulated to meet project needs. HDPE Geomembrane PROPERTIES ASTM UNITS OF STANDARD MEASSURE Density SPECIFIC VALUES Thickness Thickness Thickness Thickness Thickness Thickness 0.50 mm 0.75 mm 1.00 mm 1.50 mm 2.00 mm 2.50 mm >0.940 D792 / D1505 gr/ cc Flow point tension D6693 KN/m 7 11 15 22 29 37 Yield strength Type IV KN/m 13 20 27 40 53 67 Flow point elongation % 12 Break elongation % 700 Tear resistance D1004 N 50 93 125 187 249 311 Puncture resistance D4833 N 200 240 320 480 640 800 Stress crack resistance D5397 hr 300 Carbon black dispersion D5596 category 1 or 2 Carbon nlack content D1603 / D4218 % 2.0 - 3.0 D3895 min 100 Oxidative induction time (OIT) Planta Santiago: Panamericana Norte 21000 Colina • Teléfono: (56 - 2) 677 10 00 Fax: (56 - 2) 677 10 81 • E-mail: santiago@polytex.cl • www.polytex.cl • Santiago - Chile Planta Iquique: Santa Rosa de Huara 29 Barrio Industrial • Teléfono: (56 - 57) 362600 Fax: (56 - 57) 422823 • E-mail: iquique@iqpolytex.cl • www.polytex.cl • Iquique - Chile Planta Perú: C a l l e D M a n z a n a A L o t e 1 7 - L a s P r a d e r a s d e L u r i n • Teléfono: (51 - 1) 6169393 • www.polytex.cl • Lima - Perú ISO 9001 - ISO 14001 - OHSAS 18001 Geomembrane LLDPE Polyethylene Geomembranes are specifically designed for exposed conditions. They do not contain additives or filling that could evaporate and deteriorate the material in time. Geomembranes are generally applied as watertight elements to contain liquids, as leach pad lining, and in dumps, canals, water-collecting areas and reservoirs. Polytex Geomembranes can be heat-sealed and are made of especially formulated and certified virgin polyethylene resins. They are resistant to a number of chemical products including acids, salts, alcohols, oils and hydrocarbons, concentrated or diluted at different temperatures. Besides their high resistance to chemical agents and UV (2-3% carbon black), they show outstanding mechanical properties: high tensile strength and great rigidity, and their extremely low impermeability makes them an excellent barrier to fluids and gases. Linear Low Density Polyethylene (LLDPE) Geomembranes Available in thickness of 0.5-2.5mm, a maximum of 8.5 m wide, and length according to requirements. Minimum density of 0.939gr/cm3 makes it flexible enough to adhere to steep slopes. Polytex is producing co-extruded LLDPE, alloyed LLDPE, and hybrid LLDPE products to meet the challenges that fabricators, mining, and landfill caps require. These products range in thickness from .2 mm to 2.5 mm and up to 10 m wide rolls. Inquire at Polytex for its product group consisting of floating covers, films for fabricators, or thermal films used in mining applications. LLDPE Geomembrane PROPERTIES Density ASTM UNITS OF STANDARD MEASSURE D792 / D1505 gr/ cc SPECIFIC VALUES Thickness Thickness Thickness Thickness Thickness Thickness 0.50 mm 0.75 mm 1.00 mm 1.50 mm 2.00 mm 2.50 mm <0.939 Break point tension D6693 KN/m Break point elongation Type IV % Tear resistance D1004 N 50 70 Puncture resistance D4833 N 120 190 Break point multiaxial elongation D5617 % 30 Carbon black dispersion D5596 category 1 or 2 Carbon black content D1603 / D4218 % 2.0 - 3.0 D3895 min 100 Oxidative induction time (OIT) 13 20 27 40 53 66 100 150 200 250 250 370 500 620 800 Planta Santiago: Panamericana Norte 21000 Colina • Teléfono: (56 - 2) 677 10 00 Fax: (56 - 2) 677 10 81 • E-mail: santiago@polytex.cl • www.polytex.cl • Santiago - Chile Planta Iquique: Santa Rosa de Huara 29 Barrio Industrial • Teléfono: (56 - 57) 362600 Fax: (56 - 57) 422823 • E-mail: iquique@iqpolytex.cl • www.polytex.cl • Iquique - Chile Planta Perú: C a l l e D M a n z a n a A L o t e 1 7 - L a s P r a d e r a s d e L u r i n • Teléfono: (51 - 1) 6169393 • www.polytex.cl • Lima - Perú ISO 9001 - ISO 14001 - OHSAS 18001