Austempered ductile iron with dual matrix structures

Anuncio

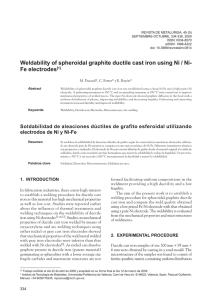

REVISTA MEXICANA DE FÍSICA S55 (1) 48–51 MAYO 2009 Austempered ductile iron with dual matrix structures C. Valdés, M.J. Pérez López, M. Figueroa, and L.E. Ramı́rez División de Estudios de Posgrado e Investigación, Instituto Tecnológico de Saltillo, Blvd. V. Carranza 2400, Saltillo, Coah., México, 25280, Phone: +52(844) 438 9539, e-mail: mjperez@its.mx, Recibido el 29 de agosto de 2008; aceptado el 8 de diciembre de 2008 In the present work were evaluated the microstructural changes and mechanical properties exhibited by ductile iron when it was heat treated in the intercritical region (α + γ) and then austempered at 375◦ C. For this purpose, ductile iron specimens were heated to the austenitizing temperature in the range of 780 to 830◦ C for 90 minutes and then austempered at 375◦ C for 60 minutes. This treatment was aimed to induce a duplex structure constitued of pro-eutectoid ferrite and ausferrite. A comparison of the properties exhibited by the heat treated ductile iron with conventionally processed ductile irons austenitized at 860◦ C, indicated that the material strength was not significantly modified. However, the impact strength and elongation show appreciable improvements. The enhanced in both properties of the heat treated ductile iron with and without alloying elements (1Ni-0.24Mo) was related to the presence of a duplex matrix. In particular, the best results of impact strength were found when the ductile irons were heat treated in the intercritical region between 800 - 830◦ C and austempered at 375◦ C. Impact strength of 130 - 145 J and 100 - 140 J were obtained for unalloyed and alloyed ductile iron, respectively. These results are comparable with fully ferrite structure (intercritical heating at 780◦ C) and higher than totally ausferrite structure (austenitizing at 860◦ C). Keywords: Ductile iron; duplex structure; ausferrite; intercritical heating; mechanical properties. En este trabajo se estudiaron los cambios microestructurales y en propiedades mecánicas de hierros dúctiles sometidos a austenitización parcial en la región intercrı́tica (α + γ) y posteriormente austemperizados. Para ello, muestras de hierros dúctiles fueron sometidas a calentamiento a temperaturas en el intervalo de 780 a 830◦ C por 90 minutos y austemperizadas a 375◦ C por 60 minutos. El tratamiento anterior promueve la formación de una estructura duplex consistente en ferrita proeutectoide y ausferrita. Una comparación con las propiedades que presentan los hierros dúctiles sometidos a tratamiento de austemperizado convencional (austenitizados a 860◦ C) mostró que la resistencia mecánica no presentó cambios significativos, mientras que la elongación y resistencia al impacto se incrementaron de manera apreciable. La mejora en ambas propiedades en hierros no aleados y aleados al 1Ni-0.24Mo sometidos a tratamiento térmico se relaciona con la presencia de una estructura duplex. En particular, los mejores niveles de resistencia al impacto se obtuvieron cuando los hierros dúctiles fueron calentados en la región intercrı́tica a temperaturas comprendidas entre 800 a 830◦ C y austemperizados a 375◦ C. Con resistencias el impacto de 130 - 145 J y 100 a 140 J para el hierro no aleado y aleado respectivamente, los resultados anteriores son similares a los obtenidos en el hierro de estructura completamente ferrı́tica (austenitizado parcialmente a 780◦ C) y superiores al de un hierro con una estructura completamente ausferrı́tica (austenitizada a 860◦ C). Descriptores: Hierro dúctil; estructura duplex; ausferrita; calentamiento intercrı́tico; propiedades mecánicas. PACS: 81.05.Bx; 81.40.Gh; 81.70.Bt 1. Introduction Austempered ductile iron (ADI) has been extensively investigated in the last decade because of their excellent mechanical properties [1-3]. The unique combination of ADI’s properties has been attributed to the acicular morphology (αg- ferrite and γHC – high carbon austenite) obtained by austempering. This microstructural constituent is known as ausferrite, unlike bainite, a constituent found in steels, which consists of ferrite and carbide phases. During austempering, the relatively high Si contents present in the nodular iron effectively hinder the precipitation of carbide phases retaining relatively large amounts of γHC . The high-C austenite is thermally instable and prolonged periods at the austempering temperatures or subsequent exposure to high temperatures promote the decomposition of γHC into α-ferrite and carbides. This reaction is undesirable as it leads to degradation of the exhibited properties, particularly the ADI toughness and ductility [4-5]. The role of the alloying elements on the reaction kinetics and microstructural stability at the austempering temperatures has been widely investigated [1,2,6]. In particular, the effect of time and temperature on the exhibited phases and their relative volume fractions [4-5], as well as on their overall effect on the resultant mechanical properties [1-5]. Even though, ADIs posses a good combination of mechanical properties, there is increasing demand in the automotive industry for ADIs with increasing ductility without affecting the ADI strength. Recent works [7-10] have suggested that optimal ductility can be achieved through the development of dual-phase microstructures (ferrite-ausferrite or ferrite-martensite) induced by heat-treating. In particular, in ADIs, duplex microstructures are obtained by intercritical annealing (partial austenitization) in the (α + γ) region followed by austempering at 250-400◦ C. Kobayasi [7] has found that in ADIs, a superior combination of strengthductility properties is achieved by having a ferrite-ausferrite matrix when compared with conventional ductile irons. In addition, Rousiere [8] has found that in ductile irons with a 49 AUSTEMPERED DUCTILE IRON WITH DUAL MATRIX STRUCTURES TABLE I. Average chemical composition of ductile irons. Chemical composition, wt.% Cast iron C Unalloyed TABLE III. Volume fraction of pro-eutectoid ferrite, martensite and ausferrite in the ductile irons. Mo Ni 3.79 3.09 0.45 0.014 0.046 0.028 —- Si Mn S P Mg —- Type of iron Feature ◦ Unalloyed (7% of graphite) Type of iron Unalloyed 1Ni-0.24Mo Structure Mechanical Property % pearlite 11 42 % ferrite 82 50 % graphite 7 8 Nodules/mm2 135 160 Nodularity 92 95 Yield Strength (Mpa) 350 250 UTS (MPa) 404 370 Impact Strength ( J) 83 19 % elongation 15 5.3 αp temperature volume 1Ni-0.24Mo 3.41 2.58 0.47 0.040 0.026 0.084 0.24 1.02 TABLE II. Phase composition and properties of as-cast ductile iron. Intercritical 1Ni-0.25Mo (8% of graphite) Ausferrite volume ( C) fraction fraction 780 93 0 800 85 8 830 51 42 780 23 69 800 13 79 830 9 83 ferrite-ausferrite matrix both, the tensile strength and elongation are twice as high as those corresponding to ductile iron with a ferritic matrix. Finally, published results indicate that ADIs with dual-structures (ferrite-ausferrite matrix) exhibit superior mechanical properties to the ones exhibited by ductile iron with ferrite-martensite matrices [9-10]. Even though austempering leads to appreciable improvements in the ADI mechanical properties, there is hardly any information on the effect of the pro-eutectoid ferrite on the mechanical properties as a function of intercritical annealing conditions. Hence, in the present work, an attempt is made to elucidate the effect of intercritical annealing on the exhibited mechanical properties of ADI unalloyed and alloyed with 1Ni-0.24Mo. 2. Experimental procedure The chemical composition of the experimental ductile irons is given in Table I. The ductile irons were processed in a high frequency induction furnace and the raw materials were steel scrap, iron returns, graphite, electrolythic Ni, and Fe-Mo alloy. The nodularization process was carried out in a tundish cover reactor employing Fe-Si-5% Mg. After inoculation using a Fe-Si (75%) alloy, the molten metal was poured in Y shaped sand molds according to the ASTM A897M-90 standard. Tensile specimens of 6.4 mm in diameter (ASTM-897M-90) and un-notched impact specimens of 10×10×55 mm (ASTM-397-91) were machined from the bottom portion of the Y blocks. The heat treatment for all the nodular irons consisted of annealing at the intercritical temperature of 780, 800 and 830◦ C for 90 minutes followed F IGURE 1. As-cast microstructures a) unalloyed ductile iron and b) 1Ni-0.24Mo ductile iron. by austempering at 375◦ C for 60 min and then water quenching. Tensile testing was carried out at room temperature in an universal testing machine at a cross-head speed of 1 mm/min. Impact testing was carried out in a Charpy testing machine of 325 J capacity. A minimal of three specimens were tested in Rev. Mex. Fı́s. S 55 (1) (2009) 48–51 50 C. VALDÉS, M.J. PÉREZ LÓPEZ, M. FIGUEROA, AND L.E. RAMÍREZ F IGURE 3. Mechanical properties in as-cast and heat treatment condition a) ultimate tensile strength and yield strength, b) percent elongation and c) impact strength. ments in as-cast samples included nodule count, graphite size and amount phases (graphite, ferrite and pearlite) and for heat treatment samples quantitative measurements of volume percent of pro-eutectoid ferrite (αp ) and ausferrite were made. 3. 3.1. F IGURE 2. Microstructural changes as a function of intercritical temperature in unalloyed ductile iron austempered at 375◦ C: a) 780◦ C, b) 800◦ C and c) 830◦ C. each heat treated condition. Image analysis was employed to quantitatively evaluate the microstructure. Typical measure- Results and discusion Microstructure The nodular graphite morphology in the experimental ductile irons was totally spherical (≥ 90%) with a nodule count of 135 to 160 nodules/mm2 and a graphite volume percent of 7 to 8. Two different starting matrix microstructures were obtained by as-cast irons. A ferritic phase with a small islands of pearlite structure for unalloyed ductile iron Fig. 1a and a ferrite-pearlite mixture of the bull eye type for alloyed ductile iron Fig. 1b, in this case the presence of Ni increases the amount of pearlite strucutre. A summary of the microstructural features, including exhibited properties in the experimental nodular irons are given in Table II. Heating in the intercritical region between 780 – 830◦ C gave rise to an initial structure consisting of pro-eutectoid ferrite and austenite (αp + γ), with various amounts of αp in Rev. Mex. Fı́s. S 55 (1) (2009) 48–51 AUSTEMPERED DUCTILE IRON WITH DUAL MATRIX STRUCTURES each nodular iron Table III depending on the heating temperature and chemical composition. During heating, the austenite phase nucleates and grows at the α/Fe3 C interfaces of the pearlite localized in the eutectic cell. Apparently, the presence of higher amounts of pearlite in the alloyed ductile iron promotes higher amount of austenite during heating and then ferrite volume fraction decreases. Also the presence of alloying elements (Ni and Mo) close the interval temperatures between A1 -Af , (where A1 is the minimal temperature to start austenite transformation during heating and Af is the highest temperature at which ferrite is still stable) these leading to a higher austenite volume fraction due to higher nucleation and growth of the austenite phase. During isothermal holding at the austempering temperature (375◦ C), the austenite phase (γ), formed at intercritical region, transforms into ferrite and high carbon austenite (γHC ). Ausferrite preferentially forms at the cell boundaries developing a semi-continuous network towards the interior of the eutectic cell depending on the amount of austenite (γ). Figure 2 shows the microstructure as a function of intercritical heating temperatures for unalloyed ductile iron and in Table III are given the relative amounts of the present phases in each condition. Notice that all of the cases, when the pro-eutectoid ferrite was present, it surrounded the graphite nodules. In addition, the microstructure of unalloyed ductile iron heating in the intercritical region at 780◦ C was fully ferritic. In this conditions, the duplex structure was not obtained. 3.2. Mechanical Properties Figure 3 shows the ultimate tensile strength (UTS), yield strength (YS), percent elongation and impact strength in the ADIs. In general, any variations in mechanical properties with the intercritical heating temperature can be attributed to the type and volume fractions of present phases. For both irons, the UTS and yield strength increase when increasing 1. H. Bayati and R. Elliott, Materials Science and Technology 11 (1995) 284. 2. N. Darwish and R. Elliott, Materials Science and Technology 9 (1993) 882. 3. M.J. Pérez et al., Wear 260 (2006) 879. 4. M. Grech et al., AFS Transactions 2 (1991) 338. 5. A.S. Hamid and R. Elliott, Materials Science and Technology 12 (1996) 780. 6. M.M. Cisneros et al., Int. Journal of Cast Metals Research 11 (1999) 425. 51 the amount of ausferrite structure, while the elongation and toughness exhibit the best values when the heating in the intercritical temperatures were between 800-830◦ C. Notice that when unalloyed iron was intercritical annealing at 780◦ C, showed the best values of elongation and impact strength due to spheroidal graphite is embedded in a fully ferritic matrix see Fig. 2a. In addition, when the ductile irons were treated at a traditional austempering, which is carried out by heating at 860◦ C and austempering at 375◦ C, the structure was totally ausferritic, in these cases the elongation and the impact energy decreased. Apparently, promoting the development of pro-eutectoid ferrite is an effective way to increase the ductility and impact strength in austempered irons with duplex structures. Alternatively, the ausferrite structure is relatively strong and can effectively restrict the deformation of pro-eutectoid ferrite under tensile stressing. In turn, this can lead to a reduction in the exhibited ductility as the ausferritic network becomes increasingly continuous. 4. Conclusions Microstructural features and mechanical properties of austempered ductile iron with duplex matrix unalloyed and alloyed with 1Ni-0.24 Mo were studied by optical microscopy, tensile and impact test. The results shown: As-cast microstructure was constituted by a ferritepearlite mixture of the bull-eye type with an average of graphite nodularity of 93%. UTS, elongation and impact strengh strongly depend on amounts of pro-eutectoid ferrite (αp ) and ausferrite present after heat treatment. Unalloyed and 1Ni-0.24Mo ductile iron treated in the intercritical region between 800 - 830◦ C, exhibited the highest impact strength from 140 to 145 J and from 100 to 130 J, respectively, due to presence of duplex matrix structure. 7. T. Kobayashi and S. Yamada, Metallurgical and Materials Trans. A 27 (1996) 1961. 8. D. Rousiere and J. Aranzabal, Metallurgical Science and Technology 18 (2000) 24. 9. A.M. Rashidi and M. Moshrefi-Torbati, Materials Letters 45 (2000) 203. 10. M. J. Pérez et al., Proc. of Eigth Int. Sy. Sc. & Processing of Cast Iron, CHINA (2006) 139. Rev. Mex. Fı́s. S 55 (1) (2009) 48–51