Technologies of elimination and concentration of

Anuncio

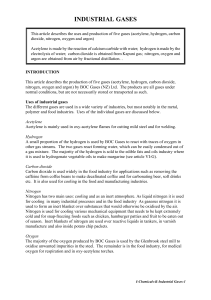

INDEX Technologies of elimination and concentration of nitrogen Maria Cruz García González Technological Agriculture Institute of Castilla y León 1. About the Technological Agriculture Institute of Castilla y León 2. Current activity and experience in the management and treatment of livestock manure 3. Technologies of elimination and concentration of nitrogen MANEV project kick of meeting. Zaragoza, 13-14 of April 2011 About ITACyL About ITACyL ¾ITACYL is a Public Body of the Regional Ministry of Agriculture and Livestock of Castilla y León (Spain) STRUCTURE REGIONAL MINISTRY OF AGRICULTURE AND LIVESTOCK FUNCTIONS ASSIGNED ITACYL (JCYL Law 7/2002, 03/05/2002) ¾Applied Research and Technological Development of the Agro-Food Sector ¾Certification of the Quality of Entities operating into the Regional Agro-Food system ¾Research in Food Quality and Food Safety General Directorate ¾Infrastructures and technical development of Land actions of general interest Deputy Directorate for Research and Technology About ITACyL R&D Central offices Livestock Research Area Innovation and Process Optimisation Area Unit for Herbaceous Crops Pig Research Centre Optimisation and Industrial Processes Unit The Unit for Woody and Horticultural crops Meet Technology Centre Biofuel and Bioproducts Research Line Enological Station Dairy Technology Centre Aquaculture Research Center Deputy Directorate for Administration and Finance RTD Centres along the region of Castilla y León Molecular Biology Lab Phisico-Chemical Lab Technology Transfer and Dissemination Other Livestock Research (cattle, ovine, goat) Deputy Directorate for Agricultural Infrastructures About ITACyL Research and Technology Dep. Directorate Agricultural Research Area Deputy Directorate for Food Quality and Safety (Zamadueñas) -80 ha : experimental fields, greenhouses, climatic chambers. Biofuels and bioproducts centre (Villarejo del Órbigo, León) Dairy technology center -F-Q, Molecular Biology and Microbiology laboratories. - Pilot plant for the research in innovative process and products. Meat technology center (Guijuelo) Livestock and agroo-food waste treatment research line Wine technology center (Rueda) Swine research center (Hontalbilla) Other livestock unit Aquaculture research center (in the start-up) Facilities and Equipment CURRENT ACTIVITY AND EXPERIENCE IN THE MANAGEMENT AND TREATMENT OF LIVESTOCK MANURE Laboratory for wastewater, pig manure, poultry litter and other livestock manures analisis. Analisis: pH, EC, tCOD, sCOD, BOD5, TKN, ammonia, nitrates, nitrites, organic matter, moisture, TSS, VSS, TS, VS, total and soluble phosphate Hontalbilla 30marzo.igx Facilities and Equipment Pilot plants facility Hontalbilla pig´s manure treatment plant Tanque de membranas pH Tanque pulmón Almacenamiento de permeado SBR-MBR Tª pH OD Aireación SBR Contenedor de fangos Naves de cebo S/L dporo = 300micras dporo =500micras S/L Fosa almace_ namiento Tanque de homogeneización aireación Lechoneras Experience in the Management and Treatment of Livestock Manure Experience in the Management and Treatment of Livestock Manure • 2 European Union Funding Projects Manev (Life+), Sustavino (7th FP) Centro para el Desarrollo Tecnológico Industrial • Spanish Government Funding Projects 3 INIA, 1 INIA Agreement, 4 funding dissemination activities, 1 Rural Network (Feader), 2 CDTI funding projects in collaboration with 2 companies • Other Research Projects 5 Collaboration Projects with Universities (León and Valladolid Universities) 5 Companies Funding Projects Centro para el Desarrollo Tecnológico Industrial Manev activities location CyL Vulnerable Zones R+D Farm Centre Castilla and Leon 5 Vulnerables Zones 10 Vulnerables Zones 13 municipality 65 municipality CyL Vulnerable Zones Solid-liquid separation unit Biological treatment Chemical treatment of the biological effluent Technologies of elimination and concentration of nitrogen Solids storage Technologies Technologies to remove nitrogen from wastewater Technologies to concentrate nitrogen from wastewater • Nitrification-denitrification • Aerobic treatment • Anammox • Evaporation (liquid) and Drying (solid) • Stripping and absortion • Membrane filtration Technologies to remove nitrogen Nitrification-denitrification Nitrification: 2NH4+ + 3O2 Ö 2NO2- + 4H+ + 2H2 2NO2- + O2 Ö 2NO3- 4.57 g O2 / g N-NH4+ 7.14 g CaCO3 / g N-NH4+ Denitrification: 6NO3- + 5CH3OH Ö 3N2 + 5CO2 + 7H2O+ 6OH- 3.57 g CaCO3 / g N-NO34.6 g DBO5 / g N-NO3- Technologies to remove nitrogen Technologies to remove nitrogen Nitrification-denitrification Advantages Disadvantages • Nitrogen removal • Medium-high investment costs • Organic matter removal • Exploitation costs dependent on aeration consumption • Odour reduction • Process afected by toxic compounds Oxidation channel. BAT´s Document, 2003 Burton and Turner, 2003 Treated liquid manure Sludge Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 Bardenpho system. Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 Technologies to remove nitrogen Technologies to remove nitrogen Anammox Anammox Advantages Disadvantages • Nitrogen removal NH4+ + 1.31 NO2− + 0.066 HCO3− + 0.13 H+ Ö N2 + 0.26 NO3− + 0.066 CH2O0.5N0.15 + 2 H2O • OM reduction is necessary in order to avoid process inhibition • Low energy costs • Partial nitritation is necessary • Low sludge production • Process control is difficult Anammox bacteria can oxidize ammonia in anaerobic conditions, using nitrite as electron acceptor and producing N gas. Partial nitritation is necessary. PN Technologies to concetrate nitrogen Technologies to concetrate nitrogen Aerobic digestion Advantages Anammox Evaporation and drying Disadvantages • Organic nitrogen is concentrated in the sludge for land application • High exploitation costs due to aeration consumption • Solids settlement improvement • Foam formation These are processes by which water is removed from manure through evaporation Liquids Solids • Organic matter removal BAT´s Document, 2003 Burton and Turner, 2003 Evaporator • Pathogens and odour reduction Aerobic Digestion Condensed Air Condenser Dryed product Condensed Dryer Concentrated Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 Technologies to concetrate nitrogen Stripping Evaporation and drying Advantages Disadvantages • Volume reduction, easy transportation • High investment and exploitation costs • Nutrients recovery in the concentrated final product • Acid reagents are used to lower pH • Reduction in ammonia emissions from the dry product • Organic matter reduction is required to avoid pollution in the condensed water • Pathogens removal • Acid and alkali reagents are used • Reduction in mineral fertilizer application • It is necessary a previous manure treatment in order to remove organic matter • Not affected by toxic compounds Acidic water • System affected by the hererogeneity of manure, foam formation and corrosion Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 BAT´s Document, 2003 Burton and Turner, 2003 Disadvantages • Nitrogen recovery • Stripping by steam: Foam formation and sedimentation of solids • The final product quality is important in order to market it Absortion Advantages Technologies to concetrate nitrogen Burton and Turner, 2003 Ammoniacal water • It is necessary to market the final product Treated liquid manure Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 Technologies to concetrate nitrogen Technologies to concetrate nitrogen Membrane filtration • Nitrogen recovery • Pathogens removal • Enlarged and transportable technology • High flow treatment Technology Disadvantages Advantages Cost range (€/Tn treated substrate) • It is necessary a previous manure treatment, to remove OM and solids Nitrification-denitrification • Membrane fouling, chemical cleaning 0.5-2.1 Partial treatment 2.5-5.2 SL separation Anammox 13.31 dump leachate (partial nitritation+anammox+termic drying) Aerobic digestion 0.7-2 aeration in the storage tank 2.7-4 aeration in a separation tank Evaporation and drying 2.3 • High maintenance costs • Automatic operation Permeate Burton and Turner, 2003 Stripping Membrane filtration Physical or chemical pretreatment Concentrated purge Cleaning backstream system Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 15 sedimentation and reverse osmosis Source: Guía de los tratamientos de las deyecciones ganaderas. 2004 BAT´s Document, 2003 Burton and Turner, 2003 PhD Thesis, Girona, 2008