Metrohm Dosing Test

Anuncio

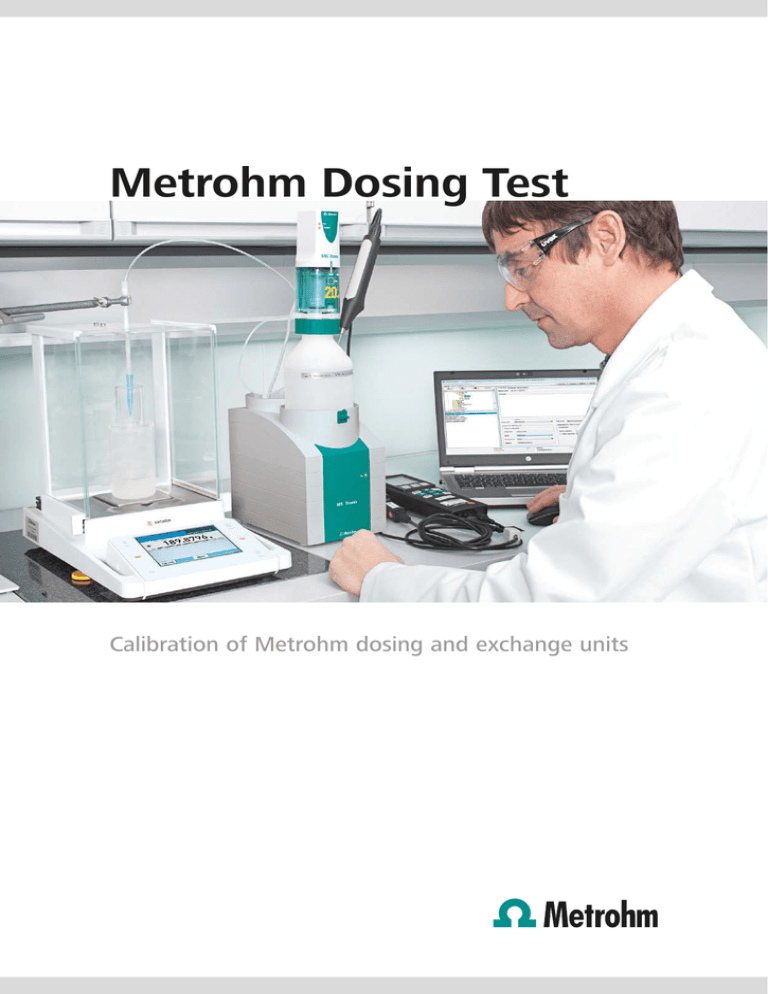

Metrohm Dosing Test Calibration of Metrohm dosing and exchange units Used every day – and always accurate ... 02 Everyday use Your Metrohm dosing or exchange unit operates reliably day in, day out, or even overnight if so configured. It al­­ ways dispenses an exact volume. The cylinder is filled with titrant before the sequence starts again. You base your decisions on the results obtained because you know that you can rely on the values delivered by your Metrohm titration system. Alcoholic KOH, for example, attacks the glass cylinder and can thus alter its inside diameter. Intensive use of the internal buret or just simply aging may also compromise the performance of the measuring system. The Metrohm Dosing Test The Metrohm Dosing Test has been developed to deal with this situation: your dosing or exchange unit is perio­ dically inspected to verify that its accuracy and precision are still within the required tolerances. But are these values absolutely reliable? Yes they are, provided that your Metrohm dosing or ex­­ change unit is new, or has been regularly serviced. Like any instrument exposed to chemicals or which has mov­ ing parts, or both in the case of a Metrohm buret, it may become less accurate over time. Furthermore, the Metrohm Dosing Test is carried out by specially trained Metrohm Service Engineers at your work­ ­place using recognized standards and procedures. The Metrohm Dosing Test can be conducted during an­­ nual servicing of the instrument, either as a component of a Metrohm Care Contract or «on demand» to mi­­nimize disruption to your laboratory workflow. ... for very demanding requirements Piston burets have very demanding requirements with respect to accuracy and precision of the dosed volumes, as defined in ISO standard 8655-3:2002 «Piston-operated volumetric apparatus – Part 3: Piston burettes». When they leave factory, Metrohm burets fulfill these strin­­gent requirements without exception, as confirmed by the corresponding quality certificate. This means you can rely on the accuracy and precision of your piston buret right from the start. The Metrohm Dosing Test checks that these require­ ments are still being fulfilled in your daily operations and confirms continuous compliance with the respective standards. Maximum permissible errors for motor-driven piston burets according to ISO 8655-3:2002: Nominal volume mL ≤ 1 2 5 10 20 50 Maximum permissible errors systematic random ± µL ± µL 6.0 1.0 10 2.0 15 5.0 20 7.0 40 14 100 25 03 One test method for every requirement 04 The Metrohm Dosing Test is based on a gravimetric method. This means that the dispensed water is weighed and the volume dosed is then calculated using the spe­ cific density of water. The calculated dosed volume is subsequently compared to the displayed volume. Procedure according to ISO 8655-6 In the procedure specified in the standard «ISO 8655­ 6:2002 Piston­operated volumetric apparatus – Part 6: Gravimetric methods for the determination of measure­ ment error», three different volumes are used in the test: •10%ofthenominalcylindervolume •50%ofthenominalcylindervolume •100%ofthenominalcylindervolume Ten individual measurements are carried out for each of these three volumes. The test liquid is water conforming with grade 3 as specified in ISO 3696. The systematic and the random measurement errors are calculated from the measured values. Metrohm Dosing Test, cumulative procedure The general conditions of the Metrohm Dosing Test cor­ respond to those of standard ISO 8655­6:2002. Details of the test conditions, the test procedure, and the calcula­ tionsaregiveninMetrohmApplicationBulletin283/1e. In the cumulative procedure, the test volumes are dis­ pensed from one cylinder filling without any refilling. The smallest test volume is exactly 10% of the cylinder volume, the largest is exactly 100%. The remaining 8 test volumes are randomly selected from the range between these two limits. This procedure ensures that the entire volume range of the buret is covered. The linearity of the dosed volume can thus be reliably checked. The accuracy of the results depends not only on exact determination of the mass, but on other parameters as well. These are primarily the temperature of the water and the ambient air as well as the barometric pressure. This is why the Metrohm Service Engineers are equipped with calibrated thermometers and barometers. Metrohm Dosing Test, repetitive procedure In the repetitive procedure of the Metrohm Dosing Test, one test volume is dispensed and then the cylinder is refilled. Each dosing thus starts with a cylinder that is completely full. Customer-specific Dosing Test The Customer­specific Dosing Test is carried out in accor­ dance with the procedure and general conditions speci­ fied in standard ISO 8655­6:2002. However, customers can select the following parameters: • The selected test volume can be any value between 10%and100%ofthenominalcylindervolume. • The number of repeated measurements can vary between3and10,andthisnumbercanbevaried for the individual test volumes. This enables compliance with customer­specific require­ ments, e.g. those specified in an SOP. Choosing the appropriate test procedure Procedure according to ISO 8655­6 Metrohm Dosing Test, cumulative procedure Metrohm Dosing Test, repetitive procedure Customer­specific Dosing Test Your advantages • Official procedure according to an internationally recognized standard • Based on ISO 8665­6:2002 • Checks the entire volume range • Quickest procedure • Based on ISO 8665­6:2002 • Checks the entire volume range • Simulates practical conditions • Complies with the requirements of your SOP • The buret can be checked in the volume range you need 05 Stay on the safe side 06 The Dosing Test gives you certainty – the certainty that your Metrohm buret is dispensing the displayed value. This in turn gives you assurance that you really can rely on your results, and that this will not cause problems during auditing. Once the Metrohm Dosing Test has been successfully completed, you will receive the corresponding certificate. This certificate confirms clearly and traceable that your buret continues to comply with the requirements as veri­ fied by the test, as well as the reference instruments used in the test. In short, you can focus on your work knowing that you canrely100percentontheaccuracyofyourMetrohm buret. Good to know The test includes inspection and maintenance of your Metrohm buret Every Metrohm Dosing Test includes inspection and main­­­­tenance of your Metrohm buret. The Metrohm Service Engineer checks the piston, cylin­ der, valve disc, connecting tubes, and other components for any signs of damage or wear, and then cleans and lubricates the parts as necessary. If the buret no longer complies with the requirements, the Metrohm Service Engineer can replace the corres­ pon­ding components directly on-site – and then repeats the Dosing Test. Inspection and maintenance of your drive unit (Dosino, Titrino, Titrando) The exchange unit or the dosing unit and the buret drive form a unit, and the complete system is checked during the Dosing Test. The drive unit itself is also a high-precision instrument, re­­­­­­gardless whether it is a Dosino, a Titrino or even a Titrando. The piston stroke of 50 mm or 80 mm is di­­vi­­ded into 10,000, respectively, 20,000 increments. Legend: Subsidiary Independent Distributor Needless to say, this stroke is directly related to the dosed volume. If the drive unit deviates from the spe­­­­cifi­cations, it directly compromises the result of the Dosing Test. Inspection and maintenance of your drive is thus worth­ while for several reasons: •No unpleasant surprises during the Dosing Test. •Error-free function of the drive unit, not only during the Dosing Test itself, but also during operation. •Maximum flexibility in combining the drive unit with an exchange unit resp. a dosing unit. Provided that all of your exchange, dosing, and drive units have been calibrated, any ex­­change or dosing unit can be combined with any drive unit. 07 Subject to change Layout Ecknauer+Schoch ASW, printed in Switzerland by Metrohm AG, CH-9100 Herisau 8.000.5088EN – 2015-01 www.metrohm.com