Acero Strenx 1100

Anuncio

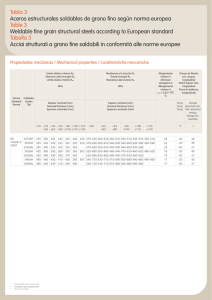

STRENX 1100 STRENX 1100 Ge eral Produ t Des ripio The high-strength structural steel at 1100 MPa St e ™ is a st u tu al steel ith a high ield st e gth at a i i u of bearing structures. Despite its st e gth, the ate ial is su p isi gl eas to eld a d e d. St e • • • • MPa. T pi al appli aio s i lude de a di g loade eits i lude: Good weldability with excellent HAZ strength and toughness E epio al o siste ithi a plate gua a teed lose tole a es High impact toughness which provides for good resistance to fractures Superior bendability and surface quality Dimension Range Strenx 1100 is available in plate thicknesses of 4 – 40 mm. Strenx 1100 is available in widths up to 3200 mm and lengths up to 14630 depe di g o thi k ess. Mo e detailed i fo aio o di e sio s is p o ided i the di e sio p og a Me ha i al Properies Thickness (mm) Yield strength 1 ) Rp0.2 (min MPa) Tensile strength 1 ) Rm (MPa) elo gaio a5 (min %) 4.0 - 4.9 1100 1250 - 1550 8 5.0 - 40.0 1100 1250 - 1550 10 1) For transverse test pieces according to EN 10 025. Impact Properies Grade Min transverse test, impact energy, Charpy V 10x10 mm tests specimens2) Strenx 1100 E 27 J/ - 40 0C Strenx 1100 F 27 J/ - 60 0C U less other ise agreed, tra s erse i pa t tesi g a ordi g to en - opio ill appl . For thi k esses et ee - . , su size Charp V-spe i e s are used. the spe iied i i u alue is the proporio al to the ross-se io al area of the spe i e o pared to a full-size spe i e 10 mm). 2) Data sheet strenx - - STRENX 1100 Che i al Co posiio C *) (max %) Si *) (max %) 0.21 0.50 The steel is g ai - ei ed. *) ladle a al sis Mn *) (max %) P (max %) S (max %) Cr *) (max %) Cu (max %) Ni *) (max %) Mo *) (max %) B *) (max %) 1.40 0.020 0.005 0.80 0.30 3 0.70 0.005 I te io al allo i g ele e ts. Maximum Carbon equivalent CET(CEV) . - . Thickness (mm) . - . . - . . - . 1100 E CET(CEV) 0.37 (0.57) 0.38 (0.58) 0.39 (0.62) 0.42 (0.73) 1100 F CET(CEV) - 0.40 (0.70) 0.40 (0.70) 0.42 (0.73) Tolerances Mo e details a e gi e i SSAB’s o hu es 4 -Ge e al p odu t i fo and Strenx™ Guarantees or on www.ssab.com. Thickness Tole a es a o di g to St e narrower tolerances. Thi k ess Gua a tees. St e aio St e , Ha do , A Gua a tees o a d Toolo -UK eets the e ui e e ts of EN 9 Class A, ut ofe s Length and Width According to SSAB’s dimension program. Tolerances conform to EN 10 029. Shape SSAB ofe s tole a es a o di g to EN 9. Flatness Tolerances according to Strenx Flatness Guarantees Class D, which are narrower than EN 10 029 Class N. Surface Properies According to EN 10 163-2 Class A, Subclass 3. Bending Tolerances according to Strenx Bending Guarantee Class C. Deli er Co diio s The deli e o diio is Q o QT Que hed o Que hed a d Te pe ed at ou dis eio . The plates a e deli e ed ith shea ed o the all ut edges. U t i ed edge ate ag ee e t. Deli e e ui e e ts a e fou d i SSAB’s o hu e 4 -Ge e al p odu t i fo aio St e , Ha do , A o a d Toolo -UK o o .ssa . o . Data sheet strenx - - STRENX 1100 Fa ri aio a d Other re o e daio s Welding, bending and machining Re o e daio s a e fou d i SSAB’s o hu es o .ssa . o o o sult Te h Suppo t, te hsuppo t@ssa . o . St e has o tai ed its e ha i al p ope ies ue hi g a d su se ue t te pe i g. The p ope ies of the deli e o diio a ot e etai ed ate e posu e to te pe atu es i e ess of ºC. App op iate health a d safet p e auio s ust e take he eldi g, ui g, g i di g o othe ise o ki g o this p odu t. G i di g, espe iall of p i e oated plates, a p odu e dust ith a high pa i le o e t aio . the UK e glish ersio of this do u e t shall pre ail i ase of dis repa . Do load the latest ersio of this do u e t at hardo , stre , Do ol, Dogal, Do e , toolo , Laser, ar o , ra or, Gree Coat are trade arks of ssaB te h olog aB, s ede .ssa . o