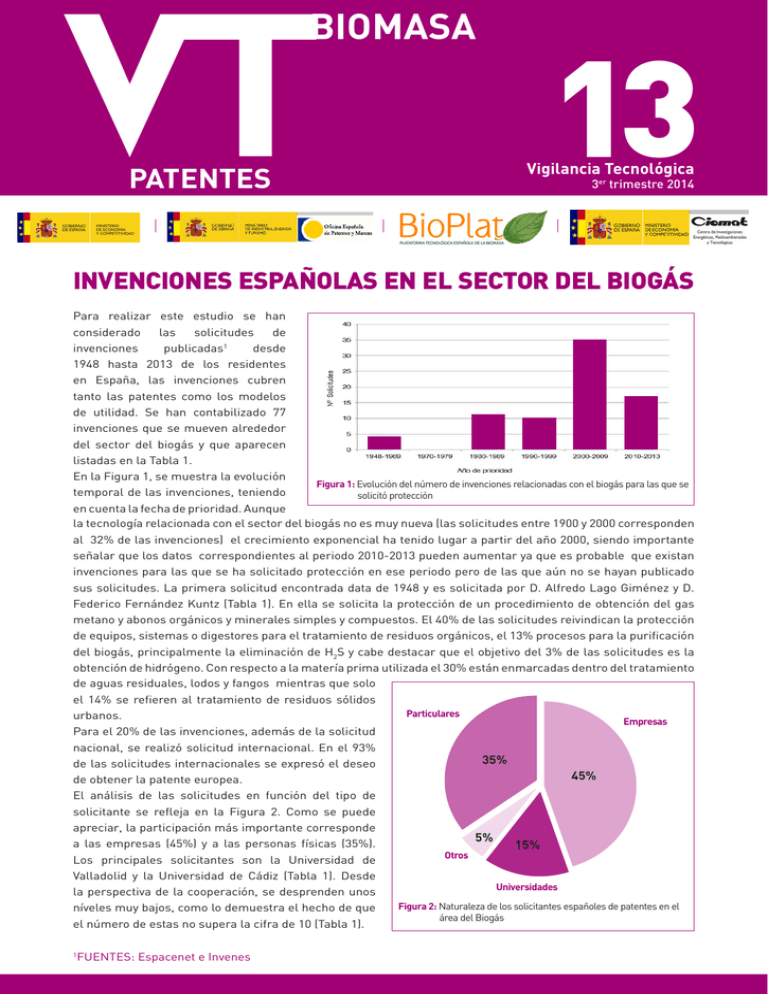

Boletín Vigilancia Tecnológica Biomasa (3er Trimestre

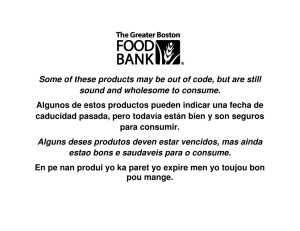

Anuncio