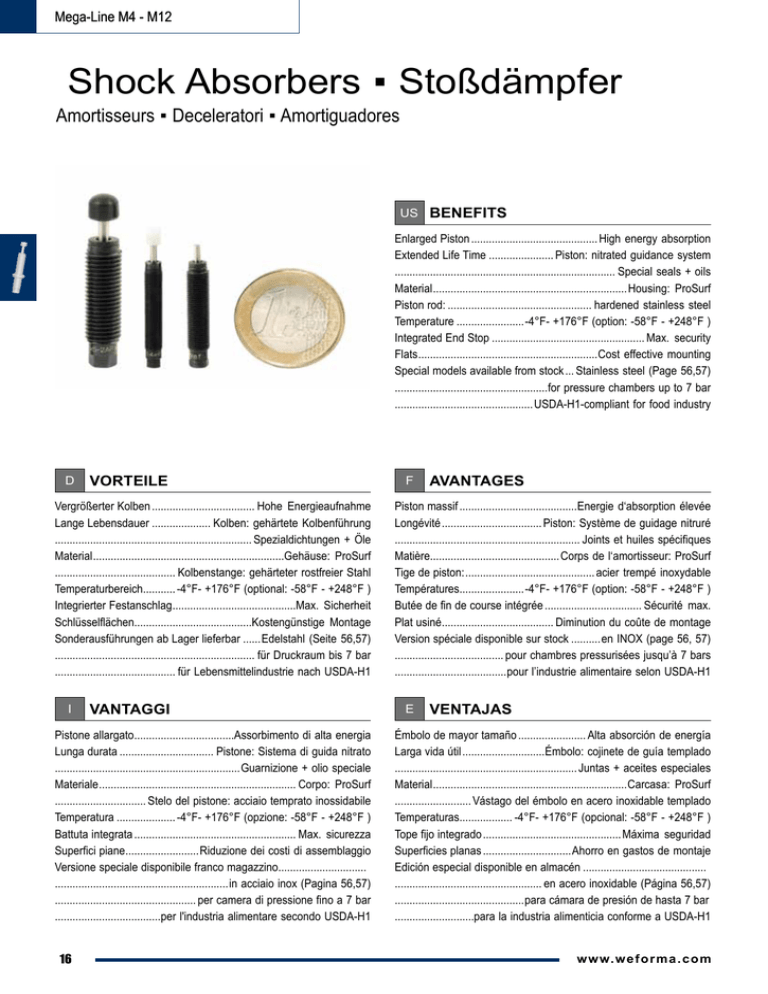

Shock Absorbers Stoßdämpfer

Anuncio