Tendencias de la Industria de Agregados en el mundo

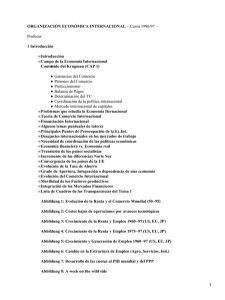

Anuncio

TENDENCIAS EN LA INDUSTRIA DE AGREGADOS PETREOS Agosto 2011 Perspectiva Global 2006 Production Data 7% 14% 5% 6% US Canada & Mexico 4% Western Europe China 13% Japan 16% Other Asia/Pacific Latin America Eastern Europe 6% Africa/Mid East 29% t pe rn id fr ic a/ M m er A in 2016 ro ic a ic La t E as te O th er A si a/ P ac if an Ja p a hi n C E ur op e te rn W es C an ad a & M U ex ic o S 2006 E as 12000 10000 8000 6000 4000 2000 0 A • Global output estimates: – 21.4bn tonnes in 2006 – 26.8bn tonnes in 2011 (?!) – 33.4bn tonnes in 2016 (??) Usage predicted to grow: – 3.3 tonnes/capita in 2006 – 3.9 tonnes/capita in 2011 – 4.6 tonnes/capita in 2016 E u • Source: Freedonia Study “World Construction Aggregates”, Dec 2007 Perspectiva Global 2006 Type of Aggregate 2006 Demand by Market 4% 12% Non-building Construction Sand 34% 29% Crushed Stone 17% Non-residential Building Gravel Residential Building Other 71% 33% 2006 Demand by Application 20% Concrete 39% Road Base Paving Asphalt 17% Other • Main breakdowns are: – Sand & Gravel 63%, Crushed Stone 33% – Infrastructure 71% – Concrete 39%, Roads 41% 24% Source: Freedonia Study “World Construction Aggregates”, Dec 2007 Una Industria Fragmentada Heidelberg + Hanson* Cemex + Rinker Vulcan + Florida Rock CRH Laf arge Martin Marietta Holcim Colas Tarmac Italcementi Rest of Industry • Top 10 global Aggregates producers account for (only) about 2.1bn tonnes! • This is only 10% of world output – meaning that the Aggregates sector is still relatively fragmented • Gradual further consolidation likely in years ahead, as Aggregates attract the major cement players Source: Freedonia & CRH data Agregados: Sector Estratégico • Strategic positioning, similar to cement (but no Climate Change issues!) • Hence strong development focus of the major players • Leading to higher acquisition costs! • Some analogies with oil? – Increasingly scarce resource in developed economies – Secure & steady market for future needs! Source: JP Morgan, Building Materials, Feb 2008 Unión Europea 30 Member Countries Represents Industry with: Sales of ~€20 billion Over 3 billion tonnes of aggregates per year 24,000 quarries & pits 16,000 companies 300,000 employed (including contractors) Precio Global de los Agregados • In developed economies, (US, UK and Australia) aggregate price increases have survived recessions, but did not necessarily keep pace with inflation Source: JP Morgan, Building Materials, Feb 2008 Precios de los Agregados en la UE • Significant price increases achieved up to 2006/2007 in many countries, particularly in Central Europe • Demand increased by 20% over last 10 years, thanks probably due to the EU enlargement! • Next 10 years? – Slower in W Europe – Stronger in C & E Europe – Residential down, though Commercial and Infrastructural up – Will prices hold up? Range of National Prices Euro/t Western Russia Switzerland Kazachstan Ukraine UK Norway Finland Sweden France Germany Belgium Netherlands Poland Romania Czech Republic Bulgaria Hungary Croatia Italy Spain France Portugal Turkey Slovakia Albania Macedonia 0 2 4 6 8 10 12 14 Source: “Aggregates Business Europe”, 2007 Producción de Agregados 2009 Total EU 2009 production was 3.25 billion tonnes Overall 51% crushed stone, 39% S&G, 2% marine, 6% recycled and 2% manufactured aggregates S O Z N Z U U E yp N ru or s w Fi ay nl A and us S tri w a ed Ir en e D la en nd m a N Bel rk et g h iu er m l G an er d s m G any re e C ce C ro z a S ech ti a w i t Re ze p rl a Fr nd an ce I t H a un ly S ga lo ry va P kia ol an S d P pai or n tu Tu g a l B rke ul y g ar ia U S K e R rb om ia an ia C Producción per Capita Tonnes/capita 2009 16.0 14.0 12.0 10.0 8.0 6.0 4.0 2.0 0.0 EU average was (only) 5.4t/c in 2009, Colombia 3t/c European output fell -11% in 2009, ~-10% in 2010 Comparativo Producción Tonnage Predictions 2010 v 2009 20% 10% -10% -20% B UK el gi u Fi m nl an P d ol an Tu d rk Fr ey a G nc er e m an N Cy y et he pru rl s an d S s er b A ia C us ze tr ch ia D Re en p m ar k I t S al lo y va H kia un ga r S y pa G in re P e ce or tu B ga ul l ga r Ir ia el R an om d an C ia ro at ia N or w S ay w S w ed it z e er n la nd 0% -30% -40% -50% There are a few “green shoots”, but overall further economic and tonnage declines in 2010 Has the EU now reached the bottom of the cycle? El cemento en España Producción y PIB percapita 16.0 14.0 Tonnes/capita Aggregates usage continues to grow as the economy grows Growth needs aggregates! Tonnes/Capita v GDP/capita 2009 12.0 Colombia 10.0 8.0 6.0 4.0 OZ 2.0 0.0 0 20 US 40 €000 GDP/capita 60 80 Proyecciones para los Estados Unidos Credit: U.S. Geological Survey Materiales de Demoliciones Amount of waste (Mt) Europe US Japan Construction and Demolition Waste (C&DW) 510 317 77 Municipal Waste 241 228 53 Global data on recycling is often based on best estimates The recent EU’s Bio-Intelligence Report did little better C&D materials = ~0.9-1.0t/capita Better called “materials” not “waste”! Agregados Reciclados Recycled Aggs as % National Demand 25% 20% 15% 10% 5% B UK N el et g h iu er m la G nd er s m an S Po y w la it n ze d rl an F d ra n A ce us R tr om ia an N ia or w F ay in l S an lo d va S ki w a ed en 0% Best performers are UK, Belgium & Netherlands Overall EU, only 6% of demand is recycled material If all countries recycled 100% = ~15% total demand Reciclaje en los Estados Unidos La Industria en Colombia • • • • • • • Unas 120 millones de toneladas en 2010 Más de150 millones proyectadas en 2012 Hoy 60 millones van por cemento 40% de los títulos mineros en el país Alta informalidad Sensible antigüedad del parque mecánico Empresas familiares entrando en la segunda generación El crecimiento del cemento en Colombia El reciclaje en Colombia Bogotá, Medellín y Cali: 12 millones de toneladas año Acceso a los recursos Planes Nacionales de Agregados • Finland – Minerals Strategy • France – “Livre Blanc”, 22 proposals for a sustainable aggregates industry to 2030 • Germany – founded “Deutsche Rohstoffagentur) • Lithuania – Strategy for Underground Minerals • Norway – developing national minerals strategy • UK – British Geological Survey coordinates Minerals & Planning issues El Plan Nacional de Agregados de Colombia Las Alianzas Estratégicas • UEPG was first industry to sign up to “Countdown 2010” in 2006 • UEPG was first to join the Business & Biodiversity (B@B) Platform in mid 2010 Buenas Prácticas en Biodiversidad Accidentes en el sector About 30 fatalities in the European aggregates industry/year About 200 fatalities in global aggregates industry/year Just on 60% of these were Contractors (20% each were Employees and Third Parties) Most common cause (50%) is Driving of Mobile Plant (trucks, loaders, etc) Two CSI initiatives adopted Prevención de Accidentes Developing Fatality and Accident Prevention Best Practice Disseminating through www.safequarry.com Major success with “Safer by Design Project”, now being promoted globally Working in parallel with the Australian EMESRT Safer by Design BEFORE AFTER Estructura de costos de la industria Typical Cost Breakdown Env & other overheads 5% Depreciation 9% Drill & blast 15% Electricity 10% Contract w ork 8% Fuel & lubricants 5% Plant hire 13% Wages 15% Maintenance mobile plant 10% Maintenance fixed plant 10% Costos del Transporte Source: JP Morgan/Martin Marietta data Algunos Indicadores en Europa • • • • • • • • • Total variable cost <€3/t Labour efficiency >15-20t/mh Explosives usage <150g/t Power consumption <3kWh/t Water consumption <150l/t Fuel use (quarry) <5kgCO2/t Fuel use (S&G) <3kgCO2/t Noise LAeq <55dB(A)/45dB(A) Vibration PPV <12mm/s Retos en Grandes Operaciones • Más productividad requiere inversión en tecnología, equipos, automatización, tierras, aseguramiento de reservas • Obtener las licencias ambiental, social y política • Construir infraestructura de transporte • Incremento de precio para recuperar inversiones y cubrir riesgos • La nueva unidad de negocio de la industria cementera Retos para más operaciones • • • • • • • • Mayores restricciones en el uso del suelo Mayor presión política, ambiental y social Obtener las licencias ambiental, social y política Costo cada día mayor para abrir nuevas Más estudios de factibilidad y viabilidad Más tiempo para ver resultados de la inversión Mayores dificultades logísticas y de transporte Dificultad para garantizar las economías de escala Tendencias • Mayor procesamiento y reprocesamiento para cumplir especificaciones (e.Transmilenios en Colombia) • Los productores de asfalto han subido especificaciones en los agregados • Incremento en precios de materias primas e insumos (e. Llantas, combustibles, lubricantes, metales, energía….todos!!) • Salarios altos para calificados y retención de empleados Tendencias Especiales • Dificultad en acceso físico a recursos cercanos • Disminución de informalidad e ilegalidad • Unificación normativa en cuanto a especificaciones • Competencia fuerte de las autorizaciones temporales • Optimización de modos de transporte • Mejoramiento continuo en HSEQ • Mejores TR y mejores estudios del sector en especial los ambientales • Agua, agregados y cambio climático: El futuro!! Proyección Gremial • • • • • • • Programa “una mirada hacia adentro” Diferenciación frente a la minería Más y mejor inteligencia de mercados Solo los mejores afiliados Tablero de indicadores Mejoramiento de productividad Gestión de innovación industrial