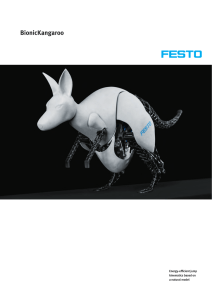

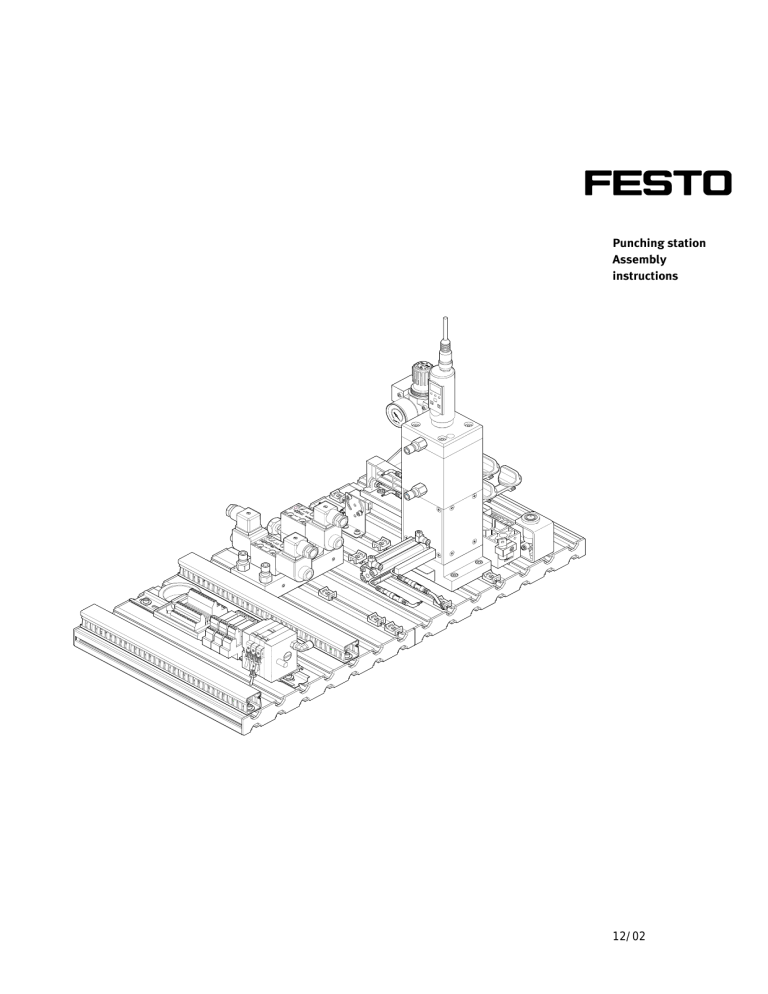

Punching station Assembly instructions 12/02 Intended use This station has been developed and produced solely for vocational and further training purposes in the field of automation and communication. The company undertaking the training and/or the instructors is/are to ensure that trainees observe the safety precautions described in the manuals provided. Festo Didactic herewith excludes any liability for damage or injury caused to trainees, the training company and/or any third party, which may occur if the system is in use for purposes other than purely for training, unless the said damage/injury has been caused by Festo Didactic deliberately or through gross negligence. Description MONT.ANLEIT Designation: D:MP-MA-S-STANZ-1-GB Status: 12/2002 Author: Frank Ebel Graphics: Doris Schwarzenberger, Albert Sigel Layout: 12/2002 © Festo Didactic GmbH & Co., D-73770 Denkendorf, 2002 Internet: www.festo.com/didactic e-mail: did@festo.com The copying, distribution and utilisation of this document, as well as the communication of its contents to others without the express authorisation of Festo Didactic is prohibited. Offenders will be held liable for the payment of damages. All rights reserved, in particular the right to carry out patent, utility model or ornamental design registration 2 © Festo Didactic GmbH & Co. • Punching station Contents 1. Notes on safety ________________________________________________ 5 2. Short description_______________________________________________ 6 3. 3.1 3.2 Views and tools ________________________________________________ 8 Views ________________________________________________________ 8 Required tools _________________________________________________ 9 4. 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 Assembling the station _________________________________________ 10 Step 1 _______________________________________________________ 10 Step 2 _______________________________________________________ 11 Step 3 _______________________________________________________ 12 Step 4 _______________________________________________________ 13 Step 5 _______________________________________________________ 14 Step 6 _______________________________________________________ 15 Step 7 _______________________________________________________ 16 Step 8 _______________________________________________________ 17 © Festo Didactic GmbH & Co. • Punching station 3 Contents 4 © Festo Didactic GmbH & Co. • Punching station 1 Notes on safety In the interests of your own safety, please observe the following safety instructions: General • Trainees must only work on a station under the supervision of an instructor. • Observe the data in the data sheets for the individual components, particularly all safety instructions! Electrical • Electrical connections are to be wired-up or disconnected only when the power supply is turned off! • Use only extra-low-voltages of up to max. 24 V DC. Pneumatic • Do not exceed the maximum permissible pressure of 8 bar (800 kPa). • Do not switch on the compressed air supply until you have established and secured all tubing connections. • Do not disconnect air lines under pressure. • Particular care is to be taken when switching on the compressed air supply. Cylinders may advance or retract as the compressed air is switched on. Hydaulics • Do not exceed the permissible pressure of 6 MPa (60 bar) • Prior to commissioning a hydraulic control system, check that all return lines have been connected and that all tubing connections have been securely attached. • First, switch on the electrical power supply unit and then the hydraulic power pack. • Do not dismantle the circuit unless pressure has been relieved from the hydraulic components. • Couplings must be connected and disconnected only under zero pressure! Mechanical • Attach all components securely on the mounting plate. • No manual intervention is to take place unless the machine is at rest. © Festo Didactic GmbH & Co. • Punching station 5 Notes on safety 6 © Festo Didactic GmbH & Co. • Punching station 2 Short description View Punching station The punching process comes under the heading of form changing. Processes of this type are : Reshaping , seperating and joining.Seperating includes cutting processes, drilling, grinding and non-cutting processes such as sharing, where differentation is made between open and closed cutting line. Punching comes under the processes with closed cutting line. The Punching station is a production unit. The production process is divided into steps, i.e. feeding and processing. Each step is carried out by one module. © Festo Didactic GmbH & Co. • Punching station 7 Short description The function of the Punching station is • To seperate out a workpiece from the cover magazine module (punching station ) • To punch a hole in the worpiece The Punching station consists of the following • Punching module • Cap magazine module (punching) • Profile plate • Trolley • Control console • PLC board View of the combination Robot–Assembly–Punching 8 © Festo Didactic GmbH & Co. • Punching station 3 Views and tools 3.1 Views Punching station, plan view Punching station, side view © Festo Didactic GmbH & Co. • Punching station 9 Views and tools Punching station, front view 3.2 Required tools Tube spanner, 9 x 10 Open ended spanners, 6 x 7, 12 x 13, 22 x 24 Slot-head screwdriver, 3.5 Allen key, 5 10 © Festo Didactic GmbH & Co. • Punching station 4 Assembling the station Step 1 1 14. Nut 13. 12. 11. 10. 9. 8. 7. 6. 5. 4. 3. 2. 1. 1 Profile plate © Festo Didactic GmbH & Co. • Punching station 11 Assembling the station Step 2 2.1 (2x) 2.5 2.2 (4x) 2.3 (4x) 2.6 (2x) 2.7 (2x) 2.4 (4x) 12 2.1 Cable duct 2.2 Socket-head screw 2.3 Washer 2.4 T-head nut 2.5 Top-hat rail 2.6 Socket-head screw 2.7 Washer 2.8 T-head nut 2.8 (2x) © Festo Didactic GmbH & Co. • Punching station Assembling the station Step 3 5. 2 3. 1. 2 Mounting the electrical system © Festo Didactic GmbH & Co. • Punching station 13 Assembling the station Step 4 8 13. 10. 3 14. 7. 7 (2x) 7. 6 (6x) 4 (3x) 5 14 © Festo Didactic GmbH & Co. • Punching station Assembling the station 3 I/O terminal 4 Relay (3 x) 5 CP valve terminal 6 Cable fixture (6 x) 7 Connector (2 x) 8 Service unit 9 Fibre optic device 10 Valve block Punching (hydraulics) © Festo Didactic GmbH & Co. • Punching station 15 Assembling the station Step 5 Position of cable fixtures Position valve block Punching (hydraulics) Position fibre optic device 16 © Festo Didactic GmbH & Co. • Punching station Assembling the station Step 6 11. 9. 13. 10. 9. 12 4. 2. 11 (9x) 11 Cable fixture (9 x) 12 Pressure indicator, pneumatic © Festo Didactic GmbH & Co. • Punching station 17 Assembling the station Step 7 Position of cable fixtures 18 © Festo Didactic GmbH & Co. • Punching station Assembling the station Step 8 15 12. 11. 10. 13 13 Hydraulic punching module 14 Cable fixture 15 Cap magazine module (Punching) © Festo Didactic GmbH & Co. • Punching station 14 19 Assembling the station Step 9 Position cable fixture Position Hydraulic punching module Position Cap magazine module (Punching) Assemble fibre optic cables at Cap magazine module (Punching) 20 © Festo Didactic GmbH & Co. • Punching station Assembling the station Step 9 Station fully assembled © Festo Didactic GmbH & Co. • Punching station 21 5 Alterations of the Robot station Take the magazin barrel out of the mounting bracket Dismantle the service unit © Festo Didactic GmbH & Co. • Punching station 22 6 Alterations of the Assembly station Assemble cap holder © Festo Didactic GmbH & Co. • Punching station 23