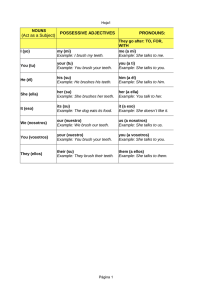

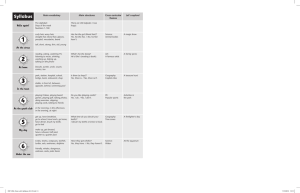

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/236591824 Regarding the Effect of the Rack-Cutter Fillet on the Undercutting of Gears Conference Paper · May 2012 DOI: 10.1007/978-94-007-6558-0_14 CITATIONS READS 0 304 3 authors: Ognyan Alipiev Sergey Antonov University of Ruse Angel Kanchev University of Ruse Angel Kanchev 110 PUBLICATIONS 111 CITATIONS 17 PUBLICATIONS 28 CITATIONS SEE PROFILE Tanya Grozeva University of Ruse Angel Kanchev 11 PUBLICATIONS 17 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: A research аnd Improvement оf Gantry Cranes Level-Luffing Jib Systems View project All content following this page was uploaded by Ognyan Alipiev on 03 June 2014. The user has requested enhancement of the downloaded file. SEE PROFILE POWER TRANSMISSIONS The 4th International Conference on Power Transmissions, June 20-23, 2012, Sinaia, ROMANIA REGARDING THE EFFECT OF THE RACK - CUTTER FILLET ON THE UNDERCUTTING OF GEARS Ognyan ALIPIEV 1, Sergey ANTONOV2, Tanya GROZEVA3 1, 2, 3 University of Ruse, BULGARIA oalipiev@uni-ruse.bg, santonov@uni-ruse.bg, tgrozeva@uni-ruse.bg Abstract. In this work a generalized approach for defining the phenomenon ”undercutting of involute teeth” is proposed, where besides the traditional boundary case, called “undercutting – type I”, additionally two more boundary cases, called “undercutting – type II” and “undercutting – type III” are included. According to this approach the nontraditional cutting – type II and type III is caused by the rack-cutter fillet, when the trajectories of some points cross respectively: 1) the radial line of the gear (the line connecting the gear centre and the starting point of the involute profile); 2) the involute profile of the cut teeth. The parametric equations of the so called ”boundary fillets” of the type II and type III of the rack-cutter are specified and in an evident state the additional boundary condition for avoiding the undercutting of teeth is drawn up. The maximum value of the radius of the the rack-cutter fillet at which the cut teeth are not undercut, is specified. Keywords. Gear, Involute profile, Undercutting of teeth, Rack-cutter fillet, 1. INTRODUCTION In the traditional theory of involute meshing (Litvin, 1968; Bolotovskii, 1986; GOST 16532–70, 1970; Colbourne, 1987; Alipiev et al., 2011) the condition that defines the nonundercutting of teeth is defined with the examination of the meshing of the rectilinear profile of the rack-cutter with an involute profile of the manufactured gear. In this case the undercutting of teeth, called by the authors „undercutting – type I ”, is avoided when the trajectories of all points of the rectilinear profile of the rack-cutter cross the line of action. When using the traditional approach the influence of the rack-cutter fillet on the teeth undercutting is not taken into account and the obtained results are correct only in cases when the radius of the rack-cutter fillet is not too large. When this radius exceeds a specified value (Alipiev, 2011) it might turn out that the traditional condition for nonundercutting is satisfied but in reality the involute gear teeth are undercut. For that reason, in the present work a new generalized method for defining the undercutting of gears is proposed, where together with the traditional boundary case (undercutting – type I ), two more boundary cases defined as „undercutting – type II ” and „undercutting – type III ” are taken into consideration. In these two additional cases the undercutting is done by the rack-cutter fillet and not by its rectilinear profile. Under this the undercutting – type II is characterized by the decrease of the tooth thickness at their bottom without cutting the involute profile, while by undercutting – type III, a part of the initial area of the involute profile is cut. 2. UNDERCUTTING OF TEETH AT MESHING OF AN INVOLUTE GEAR WITH THE RACK - CUTTER 2.1. Undercutting - type I (traditional case) The undercutting of teeth – type I of the involute gear is obtained when at its meshing with the rack-cutter (Fig. 1а), points of the rectilinear profile KE of the 2 Ognyan ALIPIEV, Sergey ANTONOV, Tanya GROZEVA Fig. 1. Conditions of Nonundercutting – type I a) X < Xmin; b) X > Xmin; c) X = Xmin tooth cutter are situated under the line of action AB. Then the trajectories of these points (lines parallel to the line n-n) do not cross the line of action AB (they cross its extension), as a consequence of which the basic theorem of meshing is not satisfied when realizing the contact between the pair profiles. In this case the rectilinear area КЕ of the rack-cutter becomes a non-operating area that penetrates into the bottom of the processed tooth and cuts a part of an involute profile. In order to avoid the undercutting – type I it is necessary that the tip line g-g of the rack-cutter cuts the line of action AB (Fig. 1b). Otherwise, when the crossing point L lies outside the line of action on the extension of the line PA (Fig. 1а), the cut teeth are undercut. This means that the condition for nonundercutting – type I generally can be expressed by the inequality (1) PA ≥ PL , and taking into account the specified distances marked on Fig. 1, the traditional condition for undercutting - type I finally is written in the following way (Litvin, 1968) x ≥ ha* − 0,5 z sin 2 α . (2) In the inequality (2) x = X / m is a shift (modification) coefficient of the rackcutter, ha* = ha / m – a coefficient of the height of the addendum, z – teeth number of the gear, α – pressure (profile) angle of the rack-cutter, m – a module of the gear. The smallest displacement X min of the rack-cutter, eliminating the undercutting – type I, is defined by the equation Regarding the effect of the rack-cutter fillet on… X min = xmin m = ( ha* − 0,5 z sin 2 α ) m . 3 (3) This displacement corresponds to the so called boundary case – type I (Fig. 1c), where the tip line g-g passes through the boundary point A (the point where the line of action contacts the base circle of a radius rb ). 2.2. Undercutting - type II and type III As already mentioned, the undercutting – type I and type II are caused by the rackcutter fillet AF (Fig.2) in the process of teeth cutting. When this fillet is a circle of a small radius ρ1 (Fig. 2a) the cut teeth are not undercut. Then the fillet fa of the gear teeth does not cross the radial line, passed from the centre О to the starting point a of the involute profile ае (at X=Xmin point a lies on the base circle of a radius rb ). Fig. 2. Types of undercutting of the rack-cutter fillet a) nonundercutting profile; b) undercutting – type II c); undercutting – type III At comparatively larger radius ρ2 of the fillet AF (Fig. 2b), an undercutting – type II is obtained, where the fillet fa of the cut tooth crosses (cuts) the radial line Оа, but does not cross the involute profile ае. This means that in the presence of undercutting – type II the tooth thickness at the bottom decreases without cutting an involute profile in the vicinity of its starting point a. When the radius ρ3 (Fig. 2c) of the rack-cutter fillet increases considerably, the fillet fq of the gear crosses the radial line Оа, as well as the involute profile. In this case besides the decrease of the tooth thickness at the bottom, the area aq of the involute profile ае is also cut. The essence of the undercutting – type II and type III is explained on Fig. 3, where the undercutting – type I is avoided by a positive displacement of the rack-cutter at a distance Xmin. At this boundary displacement, the tip line g-g of the rack-cutter crosses the line of action AB in its starting point A. In order to define the maximum radius of the rack-cutter fillet АF, corresponding to the boundary case where there is no undercutting – type II, on Fig. 3a additionally is drawn the curve qII, called a boundary fillet – type II. It is obtained as an envelope of the relative positions that take the radial line l (the line aO) of the gear in the plane of the rack-cutter, when realizing the meshing between the rectilinear profile АЕ of the rack of the involute profile ае of the gear. In other words the profiles l and qII are also conjugated profiles at rolling without sliding of the centroid line n-n of the а rack-cutter on the reference circle of the gear of a radius r. Knowing 4 Ognyan ALIPIEV, Sergey ANTONOV, Tanya GROZEVA the curve qII allows us to define the following boundary condition: the undercutting – type II is avoided if the real rack-cutter fillet АF is placed internally regarding the boundary fillet qII (in the material of the cutter). On Fig. 3a the curve АF is placed externally regarding the curve qII, as a result of which gear teeth are undercut – type II. Analogously the condition for nonundercutting – type III is defined by drawing a curve qIII (Fig. 3b), called a boundary fillet – type III. In this case the curve qIII is obtained as a trajectory (drawn in the plane of the rack-cutter) of the point а from the plane of the reference circle of a radius r, rolling without sliding on a reference circle on the line n-n. As point а lies on the internal side of the reference circle, the Fig. 3. Undercutting of teeth by rack-cutter fillet a) type II ; b) type III drawn trajectory represents a shortened epicycloid. The same curve qIII, connected without moving with the rack-cutter, can be considered also as a conjugated curve of the starting point а of the involute profile. This means that if the real rack-cutter fillet coincides with qIII, at each moment it will contact with point А and will not cut the involute profile aq. Therefore the undercutting – type III is avoided if the real rack-cutter fillet АF is placed internally regarding the boundary fillet qIII. In the case shown on Fig. 3b this condition is not satisfied and as a result the gear teeth are undercut – type III . 2.3. Еquations of boundary fillet curves Boundary fillet – type II . The equations of this curve are obtained using the theory of plane meshing [Litvin, 1968; Litvin, 2004], where one of the two meshed Regarding the effect of the rack-cutter fillet on… 5 profiles appears and the other one is obtained as an envelope of the relative positions which the specified profile occupies in the plane of the searched profile. In this case (Fig. 4) the specified profile is the radial line l of the gear and the searched profile is the boundary fillet qII of the rack-cutter. In order to solve the problem of the geometrical synthesis two mobile coordinate systems are introduced: XlOlYl – connected with the gear (the specified profile l); XII OYII – connected with the rack-cutter (the searched profile qII). As the axis OXII Fig. 4. A boundary fillet of the rack-cutter – type II (the centroid line) of the rack-cutter rolls without sliding on the reference circle (of a radius r) of the gear, the displacement s of XII OYII is synchronized with the rotation of XlOlYl at an angle φ, where s = r φ. The place of the contact points of profiles l and qII in the motionless plane, designed with K, A, etc. is defined as from the pitch point P perpendicular lines to the respective positions which the radial line l takes, are dropped. In fact the equations of the curve qII are derived by defining the place of the same contact points in the rectilinear moving coordinate system XII OYII. After executing the respective transformations and conversions [Litvin, 1968], the parametric equations of the boundary fillet – type II are finally written as follows: X II = r (ϕ − cos ϕ sin ϕ ) = X II (ϕ ) , (4) YII = − r sin 2 ϕ = YII (ϕ ) , where φ is the angular parameter of the curve, and r – the radius of the reference circle of the gear, calculated by the equation r =mz 2. (5) The obtained curve qII is divided by point А to two areas: AN and AM. On Fig. 4 it is seen that only the area AM appears as the real boundary rack-cutter fillet. This means that when drawing the real curve qII , the parameter φ gets an initial value of φ = α (point A) and increases in the direction from point А to point M. From the differential geometry it is known that the radius of a curvature ρ on each curve, specified as X=X(φ), Y=Y(φ), is defined from the equation ( X& 2 + Y& 2 ) 3 2 ρ = & && && & = ρ (ϕ ) , (6) ( XY − XY ) where X& , Y&, X&&, Y&& are the first and second derivatives to the parameter φ. 6 Ognyan ALIPIEV, Sergey ANTONOV, Tanya GROZEVA Taking into account that X& II = 2r sin 2 ϕ , X&& II = 4r sin ϕ cosϕ , Y&II = −2r sin ϕ cosϕ , Y&&II = −2r cos 2ϕ (7) for the equation of the radius of the curvature of the curve qII , it is finally obtained ρ II = 2 r sin ϕ = m z sin ϕ . (8) Boundary fillet – type III. It is obtained as a trajectory of the point A of the coordinate system XAOAYA connected with the gear (Fig. 5), drawn in a coordinate Fig. 5. A boundary fillet of the rack-cutter – type III system XIII OYIII , connected with the rack-cutter. The obtained trajectory qIII , as it was already explained, represents a shortened cycloid, whose parametric equations can be written as follows X III = rϕ − rb sin ϕ = X III (ϕ ) , (9) YIII = − r + rb cosϕ = YIII (ϕ ) , where rb is the radius of the base circle, defined by the formula rb = r cosα = 0,5m z cosα . (10) In the initial position of the coordinate systems, when at φ = 0, point А coincides with point А'', and at φ = α – with point А'. In that case, point А' appears as an inflection point, which divides the curve qIII in two parts: – a concave area NА' and a convex area А'M. In this case it should be taken into account that only area А'M is the real rack-cutter fillet – type III . The equation of the radius of the curvature of the curve qIII is obtained in analogous way as the curve qII , with the use of the equation (6). In this case the first and second derivatives of XIII and YIII to φ are defined from equations X& III = r − rb cosϕ , X&& III = rb sin ϕ , Y&III = − rb sin ϕ , Y&&III = − rb cosϕ , (11) and the radius of the curvature ρIII = ρIII (φ) of the curve qIII is obtained by the formula (r 2 − 2 r rb cos ϕ + rb2)3 2 m z(1 − 2 cos α cos ϕ + cos2 α)3 2 · = ρIII = (12) 2 cos α(cos α − cos ϕ) rb2 − r rb cos ϕ 2.4. Conditions of Nonundercutting - type II In order to clarify the causes by reason of which the rack-cutter fillet undercuts the gear teeth, on Fig. 6 both boundary curves qII and qIII are drawn simultaneously in Regarding the effect of the rack-cutter fillet on… 7 the current position where their common contact point coincides with the starting point А of the line of action АВ (the position where φ = α ). In this position the radial line ОАЕ (Fig. 6а), representing simultaneously a rectilinear profile of the rack-cutter, crosses the curve qIII in its inflection point, where in this case coincides with point А and appears as a contact point of ОАЕ with the curve qII . Fig. 6. Radius of the rack-cutter fillet From Fig. 6b it becomes clear that if the rack-cutter fillet is an arc of a circle of a small radius ρ1 there exists no undercutting – type II and type III, because in this case the arc AF1 lies on the internal side of curves qII and qIII . When the rack-cutter fillet is positioned between both curves qII and qIII (the arc AF2 of a radius ρ2>ρ1) an undercutting – type II appears, and when the rack-cutter fillet is placed between the curve qIII and the line ОЕ (the arc AF3 of a radius ρ3>ρ2) besides an undercutting – type II, an undercutting – type III is derived. In the case where the rack-cutter fillet is profiled on an arc from a circle, the following boundary condition is defined: the undercutting - type II is avoided if the radius of the fillet is smaller or equal to the radius of the curve ρII,A of the boundary fillet qII in point А. Since in point А of the curve qII the value of the angular parameter is φ = α, for the radius of the curve ρII,A in this point according to the equation (8), it is obtained ρ II, A = mz sin α . (13) Then the condition for the nonundercutting – type II , defined by the inequality ρ ≤ ρII,A , is written finally as follows ρ * ≤ z sin α , (14) where ρ*= ρ / m is a coefficient of the radius of the circle, on which the rack-cutter fillet is profiled. The condition (14) shows that the undercutting – type II depends only on the teeth number z of the gear and the profile angle α of the rack-cutter. In Table 1 the maximum values of the dimensionless coefficient ρ*max, are shown, corresponding to profile angles used in practice for different number of cut teeth. In order to avoid the undercutting – type II it is enough for the radius ρ, on which the rack-cutter fillet is profiled, to be smaller or equal to the respective value ρ*max , multiplied by the module m of the gear (ρ ≤ ρ*max m). From Table 1 it is seen that ρ*max increases when the pressure angle α and teeth number z are increased. Besides, from the specified values it becomes clear that if a standard rack-cutter is used, for which α=20° and ρ* = 0.38, the cut teeth are not undercut – type II and type III (at z = 5 and α=20° → ρ* max = 1.71). Ognyan ALIPIEV, Sergey ANTONOV, Tanya GROZEVA 8 * = z sin α Table 1. Maximum coefficient fillet radius of the rack-cutter – ρ max Number of teeth z 5 10 20 40 80 160 14°30' 1.252 2.504 5.008 10.015 20.030 40.061 Profile angle of the rack-cuter - α 15° 17°30' 20° 22°30' 25° 1.294 1.504 1.710 1.913 2.113 2.588 3.007 3.420 3.827 4.226 5.176 6.014 6.840 7.654 8.452 10.353 12.028 13.681 15.307 16.905 20.706 24.056 27.362 30.615 33.809 41.411 48.113 54.723 61.229 67.619 28° 30° 2.347 2.5 4.695 5.0 9.389 10.0 18.779 20.0 37.558 40.0 75.115 80.0 Here it is important to note that if the cut teeth are not undercut – type II, they are also not undercut – type III. Therefore the satisfying of the boundary condition (14) guarantees the nonundercutting of teeth of type II, as well as of type III. 3. CONCLUSION The carried out investigations connected to the undercutting of teeth of involute gears when cut by the rack-cutter, result in the following conclusions: 1. The undercutting of teeth is done from the rectilinear profile of the rack-cutter (traditional case – type I), as well as by the fillet, on which are cut the teeth of its cutting teeth crests (the non-traditional case) are cut. 2. The undercutting of teeth, caused by the rack-cutter fillet is found in two variants, defined in the present work as „undercutting – type II” and „undercutting – type III ”. 3. In the presence of the undercutting – type II the teeth thickness in their bottom is decreased without cutting their involute profile, and in the presence of undercutting – type III a part of the involute profile is additionally cut. 4. The condition for nonundercutting – type II is defined uniquely by two independent parameters: the number z of the cut teeth and the profile angle α of the rackcutter. 5. In order to avoid the undercutting of the involute teeth, it is necessary to satisfy the traditional condition (2) as well as the boundary condition (14). References ALIPIEV, O. L. (2011). Geometric design of involute spur gear drives with symmetric and asymmetric teeth using the Realized Potential Method, In: Mechanism and Machine Theory, Volume 46, Issue 1, pp.10-32. ALIPIEV, O., ANTONOV, S., GROZEVA, T. (2008). Determining the Position of Tooth Undercut Border Point in Involute Gears with Spur Teeth, Shaped by Rack-Cutter. In: Mechanics of Machines, Vol. 75, pp. 56-62, (in Bulgarian). BOLOTOVSKII, I. A. et al. (1986) Reference Book in Geometric Calculation of Involute and Worm Gearings, Mashinostroyenie, Moscow, (in Russian). COLBOURNE, J. R. (1987). The Geometry of Involute Gears, Springer–Verlag, New York. GOST 16532–70 (1970). Cylindrical Involute External Gear Pairs – Calculation of Geometry, Moscow, Russia. LITVIN, F. L. (1968). Theory of Gearing, Ed. Nauka, Moscow, (in Russian). LITVIN, F., FUENTES, A. (2004). Gear Geometry and Applied Theory, Cambridge University Press, Cambridge. View publication stats