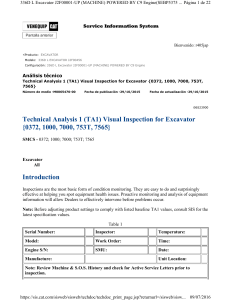

345C L Excavator SCN00001-UP (MACHINE) POWERED BY C13 Engine(SEBP53... Page 1 of 5 Previous Screen Welcome: t120jo1 Product: EXCAVATO R M odel: 345C L EXCAVATO R SCN 00200 Configuration: 345C L Excavator SCN00001-UP (M ACHINE) PO W ERED BY C13 Engine Operation and Maintenance Manual 345C UHD Excavator and 345C Mobile Hydraulic Power Unit Media Number -SEBU8445-02 Publication Date -01/06/2010 Date Updated -01/06/2010 i03972179 Maintenance Interval Schedule SMCS - 7000 Ensure that all safety information, warnings and instructions are read and understood before any operation or any maintenance procedures are performed. The user is responsible for the performance of maintenance, including all adjustments, the use of proper lubricants, fluids, filters, and the replacement of components due to normal wear and aging. Failure to adhere to proper maintenance intervals and procedures may result in diminished performance of the product and/or accelerated wear of components. Use mileage, fuel consumption, service hours, or calendar time, WHICH EVER OCCURS FIRST, in order to determine the maintenance intervals. Products that operate in severe operating conditions may require more frequent maintenance. Note: Before each consecutive interval is performed, all maintenance from the previous interval must be performed. Note: If Cat HYDO Advanced 10 hydraulic oil is used, the hydraulic oil change interval is extended to 3000 hours. S·O·S services may extend the oil change to a longer interval. Consult your Caterpillar dealer for details. When Required Adjustable Gauge Undercarriage Frame - Lubricate Air Conditioner/Cab Heater Filter (Recirculation) - Inspect/Replace Battery - Recycle Battery or Battery Cable - Inspect/Replace Boom Base Pins - Lubricate Bucket Linkage - Inspect/Adjust Bucket Tips - Inspect/Replace Bucket Tips - Inspect/Replace https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 02/03/2018 345C L Excavator SCN00001-UP (MACHINE) POWERED BY C13 Engine(SEBP53... Page 2 of 5 Cab Air Filter (Fresh Air) - Clean/Replace Camera - Clean/Adjust Circuit Breakers - Reset Engine Air Filter Primary Element - Clean/Replace Engine Air Filter Secondary Element - Replace Engine Air Precleaner - Clean Ether Starting Aid Cylinder - Replace Fuses - Replace Oil Filter - Inspect Track Adjustment - Adjust Window Washer Reservoir - Fill Window Wiper - Inspect/Replace Windows - Clean Every 10 Service Hours or Daily for First 100 Hours Boom and Stick Linkage - Lubricate Boom, Stick and Bucket Linkage - Lubricate Every 10 Service Hours or Daily Boom and Stick Linkage - Lubricate Cooling System Coolant Level - Check Engine Oil Level - Check Fuel System Water Separator - Drain Fuel Tank Water and Sediment - Drain Hydraulic System Oil Level - Check Indicators and Gauges - Test Radiator Core - Clean Seat Belt - Inspect Track Adjustment - Inspect Travel Alarm - Test Undercarriage - Check Every 10 Service Hours or Daily for Machines Used in Severe Applications Boom, Stick and Bucket Linkage - Lubricate Every 50 Service Hours or Weekly Boom, Stick and Bucket Linkage - Lubricate Expandable Pin - Tighten Every 100 Service Hours or 2 Weeks for Machines Used in Severe Applications Boom and Stick Linkage - Lubricate Every 100 Service Hours of Continuous Hammer Use Hydraulic System Oil Filter (Case Drain) - Replace Hydraulic System Oil Filter (Pilot) - Replace https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 02/03/2018 345C L Excavator SCN00001-UP (MACHINE) POWERED BY C13 Engine(SEBP53... Page 3 of 5 Initial 250 Service Hours Engine Valve Lash and Fuel Injector Timing - Check Final Drive Oil - Change Hydraulic System Filter Element (Fine Filtration) - Replace Hydraulic System Oil Filter (Case Drain) - Replace Hydraulic System Oil Filter (Pilot) - Replace Hydraulic System Oil Filter (Return) - Replace Swing Drive Oil - Change Every 250 Service Hours Cooling System Coolant Sample (Level 1) - Obtain Engine Oil Sample - Obtain Final Drive Oil Sample - Obtain Every 250 Service Hours or Monthly Adjustable Gauge Undercarriage Frame - Lubricate Belt - Inspect/Adjust/Replace Condenser (Refrigerant) - Clean Cooling System Hoses Inspect Final Drive Oil Level - Check Swing Bearing - Lubricate Swing Drive Oil Level - Check Every 250 Service Hours of Partial Hammer Use (50% of Service Hours) Hydraulic System Oil Filter (Case Drain) - Replace Hydraulic System Oil Filter (Pilot) - Replace Every 250 Service Hours of Continuous Hammer Use Hydraulic System Oil Filter (Return) - Replace Initial 500 Hours (for New Systems, Refilled Systems, and Converted Systems) Cooling System Coolant Sample (Level 2) - Obtain Every 500 Service Hours Cab Riser (Adjustable) Linkage - Lubricate Hydraulic System Oil Sample - Obtain Swing Drive Oil Sample - Obtain Every 500 Service Hours or 3 Months Engine Crankcase Breather - Clean Engine Oil and Filter - Change Fuel System - Prime Fuel System Primary Filter (Water Separator) Element - Replace https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 02/03/2018 345C L Excavator SCN00001-UP (MACHINE) POWERED BY C13 Engine(SEBP53... Page 4 of 5 Fuel System Secondary Filter - Replace Hydraulic System Filter Element (Fine Filtration) - Replace Every 500 Service Hours of Partial Hammer Use (50% of Service Hours) Hydraulic System Oil Filter (Return) - Replace Every 600 Service Hours of Continuous Hammer Use Hydraulic System Oil - Change Every 1000 Service Hours or 6 Months Battery - Clean Battery Hold-Down - Tighten Boom and Stick Linkage - Lubricate Hydraulic System Oil Filter (Case Drain) - Replace Hydraulic System Oil Filter (Pilot) - Replace Hydraulic System Oil Filter (Return) - Replace Swing Drive Oil - Change Every 1000 Service Hours of Partial Hammer Use (50% of Service Hours) Hydraulic System Oil - Change Every 2000 Service Hours or 1 Year Engine Valve Lash and Fuel Injector Timing - Check Engine Valve Rotators - Inspect Final Drive Oil - Change Hydraulic System Oil - Change Receiver Dryer (Refrigerant) - Replace Swing Gear - Lubricate Every Year Cooling System Coolant Sample (Level 2) - Obtain Every 3000 Service Hours or 18 Months Hydraulic System Oil - Change Every 3 Years After Date of Installation or Every 5 Years After Date of Manufacture Seat Belt - Replace Every 4000 Service Hours or 2 Years Hydraulic System Oil - Change https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 02/03/2018 345C L Excavator SCN00001-UP (MACHINE) POWERED BY C13 Engine(SEBP53... Page 5 of 5 Every 5000 Service Hours or 3 Years Hydraulic System Oil (If Equipped with Fine Filtration Filter) - Change Every 6000 Service Hours or 3 Years Cooling System Coolant Extender (ELC) - Add Every 12 000 Service Hours or 6 Years Cooling System Coolant (ELC) - Change Copyright 1993 - 2018 Caterpillar Inc. All Rights Reserved. Fri M ar 2 07:00:06 UTC+ 1100 2018 t120jo1 Private Netw ork For SIS Licensees. https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 02/03/2018