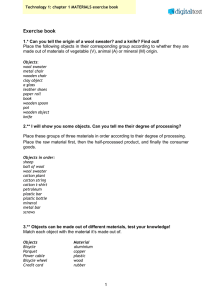

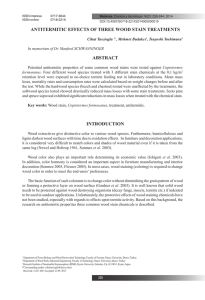

Building and Environment 44 (2009) 1162–1170 Contents lists available at ScienceDirect Building and Environment journal homepage: www.elsevier.com/locate/buildenv Optimization model for the selection of materials using a LEED-based green building rating system in Colombia Daniel Castro-Lacouture a, *, Jorge A. Sefair b, Laura Flórez b, Andrés L. Medaglia b a b Building Construction Program, College of Architecture, Georgia Institute of Technology, 280 Ferst Drive, Atlanta, GA 30332, USA Centro de Optimización y Probabilidad Aplicada (COPA), Departamento de Ingenierı́a Industrial, Universidad de los Andes, Bogotá D.C., Colombia a r t i c l e i n f o a b s t r a c t Article history: Received 16 May 2008 Received in revised form 6 August 2008 Accepted 19 August 2008 Buildings have a significant and continuously increasing impact on the environment because they are responsible for a large portion of carbon emissions and use a considerable number of resources and energy. The green building movement emerged to mitigate these effects and to improve the building construction process. This paradigm shift should bring significant environmental, economic, financial, and social benefits. However, to realize such benefits, efforts are required not only in the selection of appropriate technologies but also in the choice of proper materials. Selecting inappropriate materials can be expensive, but more importantly, it may preclude the achievement of the desired environmental goals. In order to help decision-makers with the selection of the right materials, this study proposes a mixed integer optimization model that incorporates design and budget constraints while maximizing the number of credits reached under the Leadership in Energy and Environmental Design (LEED) rating system. To illustrate this model, this paper presents a case study of a building in Colombia in which a modified version of LEED is proposed. 2008 Elsevier Ltd. All rights reserved. Keywords: Green building Material selection Sustainable building rating systems Building design Mixed integer linear programming 1. Introduction Buildings have an enormous and continuously increasing impact on the environment, using about 40% of natural resources extracted in industrialized countries [1], consuming nearly 70% of electricity and 12% of potable water [2], and producing between 45 and 65% of the waste disposed in landfills [3]. Moreover, they are responsible for a large amount of harmful emissions, accounting for 30% of greenhouse gases, due to their operation, and an additional 18% caused indirectly by material exploitation and transportation [3–5]. At the same time, the bad quality of indoor environments may cause health problems to employees in office buildings, thus, decreasing productivity [6]. 1.1. Emergence of green buildings In order to mitigate the impact of buildings along their life cycle, Green Building (GB) has emerged as a new building philosophy, encouraging the use of more environmentally friendly materials, the implementation of techniques to save resources and reduce * Corresponding author. Tel.: þ1 404 385 6964; fax: þ1 404 894 1641. E-mail addresses: daniel.castro@coa.gatech.edu (D. Castro-Lacouture), j-sefair@ uniandes.edu.co (J.A. Sefair), l.florez403@egresados.uniandes.edu.co (L. Flórez), amedagli@uniandes.edu.co (A.L. Medaglia). 0360-1323/$ – see front matter 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.buildenv.2008.08.009 waste consumption, and the improvement of indoor environmental quality, among others [2,7]. This would result in environmental, financial, economic, and social benefits. As an illustration, savings in operation and maintenance costs in GBs can be realized through the installation of high-efficiency illumination and insulation systems [8] or through an appropriate material selection process that considers, for instance, the daylight roof reflection [2,9]. Other benefits of GBs related to indoor environmental quality improvements are the reduction on health costs and the increase on employees’ productivity [8,10,11] through their perceived satisfaction towards work areas [6]. Furthermore, intangible benefits, such as the building and builder’s goodwill, and perceived added value must also be considered [8,12,13] because they could guide the decisions of investors and future owners [10,13]. Despite their demonstrated benefits, GBs are not yet perceived as attractive projects because most builders associate green features with expensive technologies that add cost (e.g., photovoltaic panels, grey water reuse systems) [14,15]. However, a careful design process and a comprehensive material selection method, rather than an elevated investment in technology, may be enough to achieve desired environmental goals at a lower cost. In fact, some evidence supports the lack of difference between the average investment cost per square foot for some GBs, such as academic buildings, laboratories, community centers, and ambulatory care facilities, and that of non-green buildings with the same characteristics [14]. Moreover, GBs provide better returns in the long run D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 [8,10,11], recovering up to 10 times the green premium through the realization of expected benefits [11]. The success of a GB depends on the quality and efficiency of the installed green systems. If the building lacks these essential features, it will neither accomplish the environmental goals nor generate the estimated benefits. Thus, the market requires a common way to differentiate GBs from traditional buildings through the use of standard, transparent, objective, and verifiable measures of green, which assure that the minimum green requirements have been reached. 1.2. Green building rating systems Many methodologies have been developed to establish the degree of accomplishment of environmental goals, guiding the planning and design processes. In these earlier stages of the construction process, planners can make decisions to improve building performance at very little or no cost, following the recommendations of the decisionmaking tool. The first of such tools was the Building Research Establishment Environmental Assessment Method (BREEAM) [16]. After that, other methodologies, such as Green Star from Australia [17], the Comprehensive Assessment System for Building Environmental Efficiency (CASBEE) from Japan [18], the Building and Environmental Performance Assessment Criteria (BEPAC) from Canada [19], and the Leadership in Energy and Environmental Design (LEED) from the United States [20] were developed and are currently widely applied. Very comprehensive inventories of available tools for environmental assessment methods can be found in Ding [21], the Whole Building Design Guide [22], and the World Green Building Council [23]. Although the existing methods and tools have an extended use, LEED has established strong credibility among the experts [1,21], increasing its affiliates. According to Bowyer [24], in April of 2007, the LEED system was comprised of 7500 companies and organization members, validating its importance as the standard environmental performance measure of a building [3,8] and becoming a reference system for the design, construction, and operation of GBs beyond the U.S. [1,12,15,25]. Adaptations of the LEED system have been applied or are in the process of implementation in Brazil and Mexico [26], two of the largest developing economies in the Western hemisphere. Furthermore, the LEED system is being proposed as a reference framework for countries in which there is no current method of building environmental assessment, such as the case of Colombia [27], where a national council for sustainable construction is being formed to start operations in 2008 [23,28]. Like many of the available rating systems, the LEED rating system is based on credits and points [29]. Through each credit, the system evaluates the performance of the candidate building and awards points if the requirements are reached in a variety of areas such as sustainable sites, indoor environmental quality, and materials and resources. Although these categories should not be treated separately, but rather as a whole, it has been stated that materials are the most-significant topic in a building study [30], reducing the environmental footprint through the correct choice and substitution of materials [7]. According to the LEED rating system [29], the selection of environmentally responsible materials considers material accessibility by encouraging the use of materials extracted, processed, and manufactured regionally, and, at the same time, promoting the development of regional economies. The LEED system also encourages the use of high recycled content, rapid renewable cycle, and low-emitting contaminant materials which aim to reduce their impact on the environment and indoor air quality of the building. As a result, the design of a GB requires a comprehensive process for material selection that considers not only the previously described standards but also design and budget requirements that are key factors for the success of the building. 1163 1.3. Selection of materials The material selection problem has been treated extensively in the literature through many approaches, such as multiobjective optimization [31,32], ranking methods [33,34], index-based methods [35,36], and other quantitative methods like cost–benefit analysis [37]. However, current literature in the building domain lacks a standard method that may help the decision-maker select the more-appropriate materials while at the same time looking at the accomplishment of environmental goals and meeting design and budgetary requirements. This gap is observed in spite of cost being a common reason for the bankruptcy of many GB projects [15,21] given that materials reach up to 20–30% of the total building cost [8]. This article proposes a mixed integer linear program (MILP) that improves green construction decision-making through the selection of materials. The model considers both design and budget constraints to address realistic scenarios experienced by the decision-maker. In addition, the model includes soft constraints that describe the LEED requirements pertaining to the selection of materials, which may or may not be satisfied. The number of satisfied constraints constitutes the objective function to maximize. In other words, the model attempts to maximize the number of satisfied LEED constraints while also satisfying design and budget constraints. To illustrate the operation of the model, a case study of an office building construction project in Colombia is discussed. This article is organized as follows. Section 2 describes the LEED credits considered. Section 3 presents the optimization model. Section 4 addresses the case study of a building in Colombia, describing the data sources used, and presenting the results and sensitivity analysis of the case study. Finally, Section 5 concludes the paper and outlines the future research. 2. LEED-based rating system for material selection Credits in the proposed LEED-based rating system are based on those credits in the existing LEED rating system for new construction and major renovations that are related to material selection [29]. Through each credit, the proposed rating system evaluates the performance of the candidate building in terms of the characteristics of the materials, such as the contribution to the heat island effect, proportion of recycled content, distance from the supplier or producer to the project site, and emissions of indoor pollutants (see Table 1). For each criterion, the rating system awards points if the requirements are reached, accounting a number of 11 available points. The requirements of the proposed LEED-based rating system are adapted for the specific situation of the Colombian market. For instance, in Colombia, because specifications on available materials state only the total recycled content, those credits related to recycled content do not differentiate between pre-consumer or postconsumer recycled content. Thus, credits 4.1 and 4.2 in the area of materials and resources (see Table 1) state that, in order to award points, the total recycled content should constitute a minimum portion of the total cost of the materials for the project, requiring a minimum 10% for credit 4.1 and 20% for credit 4.2. Credits regarding regional materials (credits 5.1 and 5.2 in the area of materials and resources) are also adapted to take into account a more-convenient distance from the place where materials are extracted, harvested, recovered, or manufactured to the project site. However, it is not possible to track the origin of the components for most available materials, manufacturing requirements do not consider the proportion of the final product manufactured in the region, but only that at least one process has been conducted in the same region of the project. As LEED states, the aim of these credits is not only to reduce the environmental effects caused by 1164 D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 Table 1 LEED-based credits considered in the materials selection problem Credit Area Name Intent 7.2 (Points: 1) Sustainable sites Heat island effect, roof Reduce heat islands 4.1 (Points: 1) Materials and resources Recycled content – 10% 4.2 (Points: 1) Recycled content – 20% 5.1 (Points: 1) Regional materials, 10% extracted, processed & manufactured regionally 5.2 (Points: 1) Regional materials, 20% extracted, processed & manufactured regionally 6 (Points: 1) Rapidly renewable materials 7 (Points: 1) Certified wood 4.1 (Points: 1) Indoor environmental quality Low-emitting materials, adhesives & sealants 4.2 (Points: 1) Low-emitting materials, paints & coatings 4.3 (Points: 1) Low-emitting materials, carpet systems 4.4 (Points: 1) Low-emitting materials, composite wood & agrifiber products Description Use roofing materials having a solar reflectance index (SRI) equal to or greater than 78 for lowsloped roofs (2:12) or 29 for steep-sloped roofs (>2:12). These values must be used for a minimum of 75% of the roof surface. Increase demand for building Use materials with recycled content such that products that incorporate recycled the content constitutes at least 10% (based on content materials, reducing impacts cost) of the total value of the materials in the from extraction and processing of project. Only include materials permanently virgin materials. installed in the project, except mechanical, electrical, plumbing components and specialty items such as elevators. The recycled fraction of the assembly (by weight) is multiplied by the cost of assembly to determine the recycled content value. Use materials with recycled content such that content constitutes an additional 10% beyond Credit 4.1 (total of 20%, based on cost) of the total value of the materials in the project. Increase demand for building Use building materials or products that have materials and products that are been extracted, harvested or recovered, as well extracted and manufactured within as manufactured, within the same region of the the region, supporting local project site for a minimum of 10% (based on economies and reducing the cost) of the total materials value. Only include environmental impacts resulting materials permanently installed in the project, from transportation. except mechanical, electrical, plumbing components and specialty items such as elevators. Use building materials or products that have been extracted, harvested or recovered, as well as manufactured, within the same region of the project site for an additional 10% beyond Credit 5.1 (total of 20%, based on cost) of the total materials value. Reduce the use and depletion of Use rapidly renewable building materials and finite raw materials and long-cycle products (made from plants that are typically renewable materials by replacing harvested within a ten-year cycle or shorter) for them with rapidly renewable 2.5% of the total value of all building materials materials. and products used in the project, based on cost. Encourage environmentally Use a minimum of 50% (based on cost) of woodresponsible forest management. based materials and products, which are certified (e.g., Forest Stewardship Council’s -FSC), for wood building components (e.g., structural framing and general dimensional framing, flooring, sub-flooring, wood doors, and finishes). Only include materials permanently installed in the project. Reduce the quantity of indoor air All adhesives and sealants used on the interior contaminants that are odorous, of the building shall comply with the volatile irritating and/or harmful to the organic compounds (VOC) limits provided in comfort and well-being of installers USGBC (2005) page 65. and occupants. Paints and coatings used on the interior of the building shall comply with the volatile organic compounds (VOC) limits provided in USGBC (2005) page 67. All carpet installed in the building interior shall meet the product requirements of the Carpet and Rug Institute’s Green Label Plus program. Composite wood and agrifiber products used on the interior of the building shall contain no added urea-formaldehyde resins. Laminating adhesives used to fabricate on-site and shopapplied composite wood and agrifiber assemblies shall contain no added ureaformaldehyde resins. Source: Adapted from USGBC [29]. transportation, but also to support regional economies. Credits promoting the use of rapidly renewable materials (credit 6 in the area of materials and resources), certified wood (credit 7 in the area of materials and resources), and low-emitting materials (credits 4.1, 4.2, 4.3, and 4.4 in the area of indoor environmental quality) are considered as stated in the LEED system for new construction and major renovations [29]. Credit 7.2 in the area of sustainable sites considers the solar reflectance index as the only criteria for roofing materials. 3. Mixed integer optimization model for material selection This section presents the proposed mixed integer model for material selection. Let S be the set of building systems (e.g., wood D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 finishes, floors, walls, roofs), T the set of types of materials, and Jj the subset of materials that are used in system j˛S. Let F ¼ MA WMP WMC WMW WMW WMR be a partition based on the types of materials, where MA represents the set of adhesives and sealants, MP the set of paints and coatings, MC the set of carpet systems, MW the set of composite wood and agrifiber products permanently installed in the building, MW the set of composite wood and agrifiber products temporally installed in the building during the construction process, and MR the set of roofing materials. Note that F ¼ W Mt , where Mt1 XMt2 ¼ B for t1 st2 ; t1 ; t2 ˛T. t˛T j Let Qn be a category of materials such that one or more of these materials can be selected to complete a fraction or the whole system NðjÞ j j. Consequently, Jj ¼ Wn ¼ 1 Qn , where N(j) is the maximum number of categories in the system j. Finally, the set of credits under the proposed LEED-based system, according to Section 2, is expressed by L. The available budget for materials in the building systems in S is denoted by the parameter b. The dimension (length, area, or volume units) of system j is expressed by dj and the cost per unit of material is denoted by ci. The number of points earned if credit k˛L is accomplished is pk. The recycled content of material i as a percentage of the total weight is expressed by ri. Let vi be the content of volatile organic compounds (VOC) of the material i˛MA WMP measured in [g/L] for adhesives, sealants, and paints. Let v_ i be the emission factor of volatile organic compounds (VOC) of the material i˛MC measured in [mg/m2 h] for carpets. The maximum allowed content of VOC (in [g/L]) of a material i˛MA WMP is denoted by vui. The maximum allowed emission factor of VOC (in [mg/m2 h]) of a material i˛MC is denoted by v_ ui. The minimum and maximum fraction of the system j˛S that can be built using one of the materials from category Qnj , are denoted by lnj and unj ð0 lnj unj 1Þ, allowing the designer to impose his/her requirements. The maximum number of materials from category Qnj that can be selected to build system j is Knj. The constant G takes a value much greater than zero ðG[0Þ and it is used in some of the constraints as a penalty term. Binary parameters are also defined to describe some properties of materials: ei takes the value of 1 if the material was extracted, recovered, manufactured, or processed in the same region that the project, it takes the value of 0, otherwise; hi takes the value of 1 if the material i˛MW WMW is made by rapidly renewable materials (see Table 1), it takes the value of 0, otherwise; fi takes the value of 1 if the material i˛MW has a certification of responsible forest management (e.g., Forest Stewardship Council’s – FSC), it takes the value of 0, otherwise; mi takes the value of 1 if the material i˛MW WMA does not contain urea–formaldehyde resins, it takes the value of 0, otherwise; and si takes the value of 1 if material i˛MR accomplishes the required minimum solar reflectance index according to the desired slope (see Table 1), it takes the value of 0, otherwise. The proposed model identifies the materials and their required amount as a fraction of the system. Let xij ð 0Þ be the fraction of system j˛S that is built using material i. The binary variable yi takes the value of 1 if the material is used (in any building system); it takes the value of 0, otherwise. Let zk be a binary variable that takes the value of 1 if credit k˛L is accomplished, as is stated in the Table 1; it takes the value of 0, otherwise. The proposed mixed integer program follows: max X pk zk i˛Qnj xij unj ; j˛S; n ¼ 1; 2; .; NðjÞ (3) i˛Qnj j˛S; i˛Jj xij yi ; X xij ¼ 1; (4) j˛S (5) ci dj xij b (6) i˛Jj X X j˛S i˛Jj X si xij 0:75z1 ; j˛S (7) i˛Jj XMR 0 0:10@ XX 1 0 ci dj xij A @ j˛S i˛Jj 0 0:20@ XX 1 0 ci dj xij A @ j˛S i˛Jj 0 0:10@ X X X X 0:20@ X X 1 0 ci dj xij A @ 0:025@ 1 0 ci dj xij A @ 0:5@ XX X 1 X ri ci dj xij A þGð1z3 Þ (9) X X 1 ei ci dj xij A þ Gð1 z4 Þ (10) X X 1 ei ci dj xij A þ Gð1 z5 Þ (11) j˛S i˛Jj 1 0 ci dj xij A @ j˛S i˛Jj 0 (8) j˛S i˛Jj j˛S i˛Jj 0 ri ci dj xij A þGð1z2 Þ j˛S i˛JyMW j˛S i˛Jj 0 1 X j˛S i˛Jj yMW X XX 1 hi ci dj xij A þGð1z6 Þ (12) j˛S i˛Jj 1 0 ci dj xij A @ j˛S i˛Jj XMW X X 1 fi ci dj xij A þ Gð1 z7 Þ j˛S i˛Jj XMW (13) vi yi vui þ ð1 z8 ÞG; i˛MA (14) vi yi vui þ ð1 z9 ÞG; i˛MP (15) v_ i yi v_ ui þ ð1 z10 ÞG; subject to, X yi Knj ; 1165 (1) k˛L lnj X j˛S; n ¼ 1; 2; .; NðjÞ (2) yi ð1 mi Þ ð1 z11 ÞG; i˛MC i˛MW (16) (17) 1166 xij 0; D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 j˛S; i˛Jj (18) carpentry, and wood carpentry; 5) carpets used on floors of common areas; 6) roofs; 7) glass; and 8) window assemblies. Additionally, the building design specifies a low-sloped roof. i˛F (19) 4.1. Data sources yi ˛f0; 1g; zk ˛f0; 1g; k˛L (20) As is shown in Eq. (1), the model seeks to maximize the number of points awarded by the accomplishment of LEED-based credits. The set of constraints (2) allows the decision-makers to impose lower and upper limits on the fraction of each system built using materials from a specific category while constraints (3) allow the decision-makers to impose a maximum number of materials that can be selected to build each system. If the decision-maker would like to determine the fraction of system j that must be built using j materials from category Qn, then he/she could set lnj ¼ 0 and unj ¼ 1. On the other hand, if the decision-maker sets lnj ¼ unj, then the j fraction of system j built using materials from category Qn is fixed. Constraints (4) articulate the variables representing the fraction of the materials used, with the corresponding binary variables that specify that a given material is used. The set of constraints in Eq. (5) states that the entire system (100%) must be completed. The budget constraint shown in Eq. (6) limits the amount of money available to purchase materials for the systems in S. Constraints (7)–(17) consider the LEED-based requirements stated in Table 1. The constraints shown in Eq. (7) represent credit 7.2 from the area of sustainable sites, which states that 75% of the roof area must be built using materials complying with the required solar reflectance index. Credit 4.1, from the area of materials and resources, is considered in Eq. (8) and requires that at least 10% of the total cost of materials in the project should be allocated to materials with recycled content. Constraint (9) represents credit 4.2 from the area of materials and resources, and reflects an additional 10% of the cost invested in materials with recycled content. Notice that if constraint (9) is satisfied, then constraint (8) is also satisfied. Credits 5.1 and 5.2, promoting the purchase of regional materials, are considered in constraints (10) and (11), respectively. Likewise, if constraint (11) is satisfied, then constraint (10) is also satisfied. Constraint (12) shows the requirements stated in credit 6 from the area of materials and resources, motivating the use of rapidly renewable materials. Credit 7, from the area of materials and resources, is considered in Eq. (13) and encourages the use of certified wood. Constraints (14) and (15) show the recommended maximum VOC content for adhesives and sealants, paints, and coatings, respectively, while constraint (16) shows the maximum VOC emission factor for carpet systems. Constraint (17) contains the requirements in credit 4.4 from the area of indoor environmental quality. It discourages the use of materials containing urea–formaldehyde resins. Finally, constraints (18) enforce non-negativity conditions on the fractions, while constraints (19) and (20) state the binary nature of the decisions regarding material use and the accomplishment of the LEED credits. 4. A numerical example based on a case study The case study is based on the application of the model in an 11story office building with an area of 6000 m2 in Bogotá, Colombia. The estimated total budget for materials is about USD 183,500. A total of eight systems are considered: 1) wood carpentry used in the building interior, including doors and wood finishes; 2) wood temporally used during construction, such as slabs, timbers, rolls, and laminates for walls and exterior finishes; 3) adhesives and sealants; 4) paints, coatings, vinyl, and varnishes used in the building interior for ceilings, walls, parking spaces, metallic The environmental properties required by the LEED-based system of Section 2 are mainly obtained using Building for Environmental and Economic Sustainability software – BEES [38]. Although BEES is not the only source available in the literature, it provides reliable information for a wide range of construction materials. However, some of the materials available in the Colombian market, as well as some material properties required by the LEED system [39], are not included in BEES. Thus, we also use local studies [40] to complement the main data source. The information regarding systems and materials is shown in Table 2. The recycled content for adhesives and sealants, carpets, and paints is obtained from BEES software, while the same information for wood components, construction wood, glass, roof, and windows is obtained from a study in Motta [40], which provides an inventory of properties for local materials. Information regarding regional materials, renewable time, urea–formaldehyde content, and certified-wood labels comes directly from the suppliers. The volatile organic compound (VOC) emissions for carpets are estimated using BEES software and, for similar products not available in BEES, they are obtained from the California Indoor Air Quality Program [41]. The maximum allowed emission of VOC for carpets is obtained from the Carpet and Rug Institute [42]. The VOC content for paints, adhesives, and sealants are obtained through BEES software and free online databases. Maximum limits for VOC content for adhesives and sealants, paints, and carpets are considered as stated in USGBC [29]. The solar reflectance index (SRI) for roofing materials is estimated using similar materials from Energy Star [43]. Finally, the cost per unit of dimension for each material is obtained from a local directory of prices. 4.2. Optimal selection of materials Table 3 shows the results of the model, where the column labeled xij indicates the fraction of each system to be built from the selected materials. For instance, to build the wood components system, the model suggests the use of 40% of wood component 2, 20% of wood component 3, and 40% of wood component 4. Although these results show the fraction of the system that should be built using a specific material, they can also be used to quantify the required amount of each material. For instance, the model suggests purchasing 67.59 m of wood component 2, 230.77 gal of paint 3 and 91.34 m2 of glass 3. Furthermore, the results provided by the model can also be used to obtain a detailed purchase plan. As shown in Table 3, once the costs of all materials are estimated, the total cost is USD 183,353. Although the solution shown in Table 3 satisfies budget and design constraints, it satisfies only 5 out of the 11 LEED-based constraints. In other words, the solution awards 5 out of the 11 points available, but fails to achieve the points in credit 7.2 from sustainable sites, credits 4.2 and 7 from materials and resources, and those from credits 4.2, 4.3 and 4.4 related to indoor environmental quality. This number of awarded points may be insufficient to obtain a green certification, so a further analysis to determine how to award more points will add value to the decision-making process. As stated in the literature, a crucial factor that can preclude the achievement of green goals is the available budget [15]. A scarce budget may not allow the model to select more convenient materials to satisfy all LEED-based constraints, limiting the number of awarded points. To determine the additional funding required for D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 1167 Table 2 System and materials information System (j) dj Wood components Construction (wood) 168.97 (m) 8768.64 (m) Adhesives and sealants 5.01 (gal) Paint 288.46 (gal) Carpet 17.22 (m2) Roofs 542.9 (m2) 91.344 (m2) Glass Windows 1059.35 (m2) Material (i) lnj unj wood component 1 wood component 2 wood component 3 wood component 4 wood component 5 construction wood 2 construction wood 3 construction wood 4 construction wood 5 construction wood 1 sealant 1 sealant 2 sealant 3 sealant 4 sealant 5 paint 1 paint 2 paint 3 paint 4 paint 5 carpet 1 carpet 2 carpet 3 carpet 4 carpet 5 roof material 1 roof material 2 roof material 3 roof material 4 roof material 5 glass 1 glass 2 glass 3 glass 4 glass 5 window 1 window 2 window 3 window 4 window 5 20% 40% 10% 40% 20% 60% 20% 40% 10% 50% 20% 70% 0% 100% 60% 80% 10% 30% 0% 100% 10% 15% 75% 90% 0% 100% 30% 50% 30% 90% 10% 30% ci (USD) ri ei vi v_ i vui v_ ui hi fi mi si 62.01 32.93 22.97 33.35 119.5 9.7 6.55 7.11 35.93 16.82 24.37 16.83 9.39 17.28 39.83 28.4 19.85 6.84 20.75 33.57 25.02 33.24 6.35 13.89 52.25 22.41 14.17 3.9 5.5 7.1 72.9 27.79 10.1 28.83 123.2 35.4 30.54 8.85 38.87 487.7 35% 0% 0% 0% 40% – – – – – 0% 0% 0% 0% 0% 50% 0% 0% 0% 76% 6% 6% 0% 49% 66% 95% 75% 20% 70% 80% 95% 85% 75% 75% 100% 25% 10% 0% 0% 30% 0 0 0 1 1 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 – – – – – – – – – – 700 850 550 300 25 0 150 250 100 0 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 215 180 700 605 0 – – – – – – – – – – – – – – – – – – – – – – – – – 750 750 250 250 250 150 100 150 250 50 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 500 500 500 500 500 – – – – – – – – – – – – – – – 0 0 1 1 1 1 0 1 0 1 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 1 0 0 0 1 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 1 0 1 0 1 – – – – – 1 0 0 0 1 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 1 1 0 0 1 – – – – – – – – – – obtaining extra LEED-based points, the model presented in Eqs. (1)–(20) can be slightly modified as follows. First, let h be the desired number of awarded points; then, the new constraint which guarantees that at least a number of h points are awarded follows: The objective function changes to account for the minimum amount of money required to reach the desired number of points. The new objective function follows: X min pk zk h (21) k˛L Table 3 Materials required in the optimal solution System Material xij Quantity Cost Wood components (m) wood component 2 wood component 3 wood component 4 construction wood 3 construction wood 4 construction wood 1 sealant 1 paint 3 paint 4 carpet 3 roof material 2 roof material 3 glass 3 window 1 window 3 window 5 Total cost 40% 20% 40% 40% 10% 50% 100% 80% 20% 100% 10% 90% 100% 30% 60% 10% 67.59 33.79 67.59 3507.46 876.86 4384.32 5.01 230.77 57.69 17.22 54.29 488.61 91.34 317.81 635.61 105.94 2226 776 2254 22,974 6235 73,744 122 1578 1197 109 769 1906 923 11,250 5625 51,665 183,353 Construction (wood) (m) Adhesives and sealants (gal) Paints (gal) Carpet (m2) Roof (m2) Glass (m2) Windows (m2) X X ci dj xij (22) j˛S i˛Jj In summary, the resulting model is comprised of objective function (22) subject to constraints (2)–(21), except budget constraint (6), which is no longer necessary. The modified model determines the minimum amount of money required to achieve the desired number of credits indicated by h. To reveal the existing trade-off between money and LEED points, we devise an iterative scheme to explore the complete scope of all the combinations of LEED-based points subject to a given budget. According to this scheme, the model is solved several times, increasing the value of the parameter h one point at a time, up to the maximum points available. In this case study, the modified model is solved seven times, varying the parameter h from 5 to 11, that is, from the maximum number of points achieved with the original model up to the maximum number of points available. The compromise between awarded points and budget is shown in Fig. 1. Points A, B, C, and D show an opportunity to gain extra LEED points with a relatively low effort in terms of cost. On the other hand, points E, F, and G require a higher increase in cost to gain extra LEED points, suggesting a more careful analysis to determine their convenience (e.g., cost–benefit). Each one of these 1168 D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 11 G 10 F LEED-based points 9 H E 8 D 7 C 6 B 5 A 4 180,000 185,000 190,000 195,000 200,000 205,000 210,000 The modified model unveils the non-dominated points (A, B, C, and D in Fig. 1). These efficient points represent the cheapest alternative for each level of LEED-based score. To illustrate the concept of efficiency (non-domination), let us compare points H and E in Fig. 1. Even though both points achieve a solution with a LEED-based score of 9, point H is more expensive than point E, thus based on cost, solution E dominates H. Although in this case the cost criterion is used to select the best alternative, other criteria such as material availability and material delivery time from the supplier can be considered to break ties among a set of alternatives with the same number of LEED-based points. It is worthwhile to note that a scarce budget is not the only reason why a low number of LEED points can be awarded. Material constraints can restrict the capacity of the model to award points, limiting its choice of alternatives. In the case in point, if none of the available wood-based materials is certified, then credit 7 from the materials and resources area will be impossible to comply with. Design constraints can also affect the number of awarded points. To illustrate this case, if the design constraints reduce the solution space such that the model is forced to select some specific materials, then the model might not be able to substitute lower-quality materials with higher-quality ones. Budget (USD) 4.3. Sensitivity analysis Fig. 1. Existing trade-off between LEED-based points and budget. points represents a given set of materials and their extent of use. For instance, point A corresponds to the results presented in Table 3, while point B represents a different choice of materials that adds an extra LEED point to those awarded in point A. This increment from 5 to 6 points implies the compliance with credit 4.3 from the indoor environmental quality area, but demands an addition of just USD 321 to the current budget. In contrast, moving from a solution represented by point F to that of point G (from 10 to 11 LEED points), implies the compliance with credit 4.2 from the materials and resource area, which requires a significant addition to the budget of USD 11,291. These results show the general rule that as more points are awarded, it is more expensive to add a marginal point. The amount required of each material at point G is shown in Table 4. Note that this solution differs widely from that suggested in Table 3. For instance, the use of new materials, such as wood component 1, paint 1, and carpet 1, helps to award the total number of available points, but requires a significant addition to the budget. The primary goal of the proposed model is to maximize the number of earned LEED-based points, selecting the best materials and determining their extent of use. However, changes in market conditions such as government policies, material prices, and material availability, can affect the optimal solution. The study of the effect of these external changes will provide the decisionmaker with valuable information to take better decisions under a constantly changing environment. In recent years, the forest policy in Colombia is receiving ever increasing attention given that certified timber production has become an alternative economic activity for small producers of illicit crops [44]. According to the Colombian Ministry of Environment, Housing and Territorial Development, more than USD 1M has been assigned to support sustainable forest plans in some regions in Colombia [45]. Given those policies it is reasonable to assume that the LEED-based rating system will double the points awarded to credit 7 from the materials and resources area, motivating the use of certified wood while contributing to alleviate a deep social problem. Let us assume an available budget of USD 186,000 which is enough to reach the point C presented in Fig. 1, where seven LEEDbased points are earned (see Table 5). After running the model with the new budget under the new forest policy, there are some Table 4 Materials required in the eleven-LEED point solution (point G) System Material xij Quantity Cost Wood components (m) wood component 1 wood component 3 wood component 5 construction wood 3 construction wood 4 construction wood 1 sealant 1 paint 1 paint 5 carpet 1 roof material 2 roof material 5 glass 5 window 1 window 3 window 5 Total cost 40% 20% 40% 40% 10% 50% 100% 80% 20% 100% 10% 90% 100% 30% 60% 10% 67.59 33.79 67.59 3507.46 876.86 4384.32 5.01 230.77 57.69 17.22 54.29 488.61 91.34 317.81 635.61 105.94 4191 776 8077 22,974 6235 73,744 122 6554 1937 431 769 3469 11,254 11,250 5625 51,665 209,072 Construction (wood) (m) Adhesives and sealants (gal) Paints (gal) Carpet (m2) Roof (m2) Glass (m2) Windows (m2) Table 5 LEED-based points awarded given changes in model parameters Credit Area 7.2 Sustainable sites 4.1 Materials and 4.2 resources 5.1 5.2 6 7 4.1 Indoor 4.2 environmental 4.3 quality 4.4 Total LEED-based points Points awarded at point C (Fig. 1) Points awarded motivating the use of certified wood Points awarded increasing material prices by 1% 1 1 1 1 1 1 1 1 1 2 1 1 1 1 7 8 6 1 1 1 1 1 1 D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 1169 Table 6 Comparison of optimal solutions given a change in the LEED-based points System Optimal solution at point C (Fig. 1) Optimal solution motivating the use of certified wood Optimal solution increasing material prices by 1% Material Material Quantity Cost Material Quantity Cost wood component 1 wood component 3 wood component 4 construction wood 3 construction wood 4 construction wood 1 sealant 1 paint 3 paint 4 carpet 1 roof material 2 roof material 3 glass 3 window 1 window 3 window 5 Total cost 67.59 33.79 67.59 3507.46 876.86 4384.32 5.01 230.77 57.69 17.22 54.29 488.61 91.34 317.81 635.61 105.94 4191 776 2254 22,974 6235 73,744 122 1578 1197 431 769 1906 923 11,250 5625 51,665 185,640 wood component 2 wood component 3 wood component 4 construction wood 3 construction wood 4 construction wood 1 sealant 1 paint 3 paint 4 carpet 1 roof material 2 roof material 3 glass 3 window 1 window 3 window 5 Total cost 67.59 33.79 67.59 3507.46 876.86 4384.32 5.01 230.77 57.69 17.22 54.29 488.61 91.34 317.81 635.61 105.94 2248 784 2277 23,204 6,297 74,482 123 1594 1209 435 777 1925 932 11,363 5681 52,181 185,511 Wood components Quantity Cost wood component 2 67.59 2226 wood component 3 33.79 776 wood component 4 67.59 2254 Construction (wood) construction wood 3 3507.46 22,974 construction wood 4 876.86 6235 construction wood 1 4384.32 73,744 Adhesives and sealants sealant 1 5.01 122 Paint paint 3 230.77 1578 paint 4 57.69 1197 Carpet carpet 1 17.22 431 Roofs roof material 2 54.29 769 roof material 5 488.61 3469 Glass glass 3 91.34 923 Windows window 1 317.81 11,250 window 3 635.61 5625 window 5 105.94 51,665 Total cost 185,238 changes in the accomplished credits. Credit 7.2 from the sustainable sites area is replaced by credit 7 from the materials and resources area (see Table 5). The comparison between the optimal solutions (see Table 6) shows that roof material 5 is substituted by roof material 3, which is cheaper and does not comply with the solar reflectance index requirements. Conversely, the wood component 2, which does not comply with the certified forest requirement, is substituted by wood component 1. These exchanges help the model to comply with credit 7 from the materials and resources area within the same budget. That is, most of the savings generated by the roof materials exchange are used to buy a more expensive yet certified wood component. It is worth mentioning that under lower budget levels the model is not able to exchange materials. The availability and price of materials can also affect the optimal solution. For instance, if certified wood components (1 and 5) are unavailable in the market, it is impossible to comply with credit 7 from the materials and resources area. Moreover, if the price of the materials increases by 1%, which seems to be a slight change, the number of LEED-based credits decreases from seven (point C in Fig. 1) to six. Table 5 shows how under this scenario, the model output fails to comply with credits 7.2 from the sustainable sites area and credit 7 from the materials and resources area. The optimal solution is shown in Table 6, where roof material 5 is replaced by roof material 3, which is cheaper but does not comply with the solar reflectance index requirement. Although the optimal quantities are the same, the total cost of each material (except for roofs) is 1% higher, consuming a bigger portion of the budget. As a result, a material substitution is needed, buying a cheaper material and consequently losing a LEED-based credit. 5. Concluding remarks Although many approximations to the material selection problem have been proposed in the literature, the outlined model is the only one that incorporates design, budget, and environmental requirements simultaneously to determine a better set of materials and their extent of use in green buildings. The model allows the user to freely include preferred materials and design parameters through design constraints, without enforcing a restrictive (even costly) environmental solution. A widely applied rating system is used to determine the level of accomplishment of environmental goals. However, the rating system is adapted to the specific situation in Colombia to reflect the situation of its construction market. The reality-based case study illustrates the application of the model in a building in Colombia. The decision-makers can obtain a detailed purchase plan that describes the materials that should be used and their extent of use. The solution of the model also provides the total cost of the materials. Moreover, the model can be adapted to show the amount of additional money required to obtain extra LEED credits, providing decision-makers with the necessary steps to improve the green performance of building projects. The results of the case study show the importance of the availability of green materials. If materials with desirable properties are not available, LEED-based requirements are nearly impossible to meet. In the case of the Colombian market, the LEED-based system is highly dependent on the use of materials with a low content or emission factor of volatile organic composites (VOC) and a high content of recycled constituents. Materials with these characteristics are scarce and expensive. Similarly, other materials, such as certified wood, are not widely available, nor do they come with information about their origin and properties. As no regulations currently require manufacturers to report data, the lack of information about materials – some characteristics are unknown even to the manufacturers – will continue to challenge LEED-based systems. The case study shows that the budget can determine the success of green building projects, many of which are abandoned due to insufficient funds [15]. The results demonstrate that sometimes a slight budget addition may lead to a significant increment of earned points. Finally, the trade-off analysis also shows that the marginal cost of an additional LEED point may be expensive, depending on the price of the materials involved in the extra credit. The proposed model is based on a modified LEED rating system for building evaluation in Colombia, where the GB movement is at its birth and still emerging. Given the limitations of the Colombian construction market, a LEED-based rating system was selected as the more realistic first step towards green building evaluation. The booming GB culture will attract builders and designers to improve their early green practices by using tools like the proposed LEEDbased rating system. Although this method is easy to adopt by builders due to the transparency of its requirements and the reduced data complexity, its application must be considered as a first phase towards a more robust environmental building design. The maturity of the GB market in Colombia will improve data availability and quality, helping designers apply not only green rating systems, but more sophisticated assessment methods of environmental impact such as life cycle analysis (LCA). 1170 D. Castro-Lacouture et al. / Building and Environment 44 (2009) 1162–1170 Acknowledgments This work was partially funded by the Industrial Engineering Department and the Masters Internship Fund of the School of Engineering at Universidad de los Andes. We also thank Fair Isaac Corporation for providing us with access to Xpress-MP’s optimization products under the Academic Partner Program subscribed with Universidad de los Andes. Finally, we express our deep appreciation to the construction company Pérez Arciniegas S.A. (Payc S.A.) for sharing with us valuable information related to the case study. References [1] Pulselli RM, Simoncini E, Pulselli FM, Bastianoni S. Emergy analysis of building manufacturing, maintenance and use: Em-building indices to evaluate housing sustainability. Energy and Buildings 2007;39(5):620–8. [2] Wang W, Zmeureanua R, Rivard H. Applying multi-objective genetic algorithms in green building design optimization. Building and Environment 2005;40(11):1512–25. [3] Yudelson J. The green building revolution. Washington, D.C.: Island Press; 2008. [4] Keysar E, Pierce AR. Decision support tool for green building: facilitating selection among new adopters on public sector projects. Journal of Green Building 2007;2(3):153–71. [5] Venkatarama Reddy BV, Jagadish KS. Embodied energy of common and alternative building materials and technologies. Energy and Buildings 2003;35(2):129–37. [6] Ries R, Bilec M, Gokhan NM, Needy KL. The economic benefits of green buildings: a comprehensive case study. The Engineering Economist 2006;51(3):259–95. [7] Thormark C. The effect of material choice on the total energy need and recycling potential of a building. Building and Environment 2006;41(8):1019–26. [8] Ross B, Lopez-Alcala M, Small III AA. Modeling the private financial returns from green building investments. Journal of Green Building 2006;2(1):97–105. [9] Moeck M, Yoon JY. Green buildings and potential electric light energy savings. Journal of Architectural Engineering 2004;10(4):143–59. [10] Edwards B, editor. Green buildings pay. 2nd ed. London; New York: Spon Press; 2003. [11] Kats G. The cost and financial benefits of green buildings: a report to California’s sustainable building task force. Sacramento, CA: Sustainable Building Task Force; 2003. [12] Muse A, Plaut JM. An inside look at LEED: experienced practitioners reveal the inner workings of LEED. Journal of Green Building 2006;1(1):3–8. [13] Baker G. Certification impacts private sector. Environmental Design and Construction 2006;9(6):80–2. [14] Matthiessen LF, Morris P. The cost of green revisited: reexamining the feasibility and cost impact of sustainable design in the light of increased market adoption. Davis Langdon; 2007. Retrieved February 7, 2008, from www. davislangdon.com. [15] Sherwin D. Reducing the cost of green. Journal of Green Building 2006;1(1):46–54. [16] Baldwin R, Yates A, Howard N, and Rao S. BREEAM (Building Research Establishment Environmental Assessment Method) 98 for offices. Watford, UK; 1998. [17] GBCA (Green Building Council of Australia). GBCA website; 2008. Last accessed from http://www.gbca.org.au/on on April 21st, 2008. [18] CASBEE (Comprehensive Assessment System for Building Environmental Efficiency). CASBEE website; 2008. Last accessed from http://www.ibec.or.jp/ CASBEE/english/index.htm on April 21st, 2008. [19] Cole RJ, Rousseau D, Theaker GT. Building environmental performance assessment criteria (BEPAC). Vancouver: BEPAC Foundation; 1993. [20] USGBC (United States Green Building Council). LEED – Leadership in energy and environmental design: green building rating system, version 1.0. US Green Building Council; 1999. [21] Ding GKC. Sustainable construction: the role of environmental assessment tools. Journal of Environmental Management 2008;8(1):451–64. [22] WBDG (Whole Building Design Guide). WBDG website; 2008. Last accessed from http://www.wbdg.org/ on April 21st, 2008. [23] WGBC (World Green Building Council). WGBC website; 2008. Last accessed from http://www.worldgbc.org/ on April 21st, 2008. [24] Bowyer JL. Green building programs: are they really green? Forest Products Journal 2007;57(9):6–17. [25] France C. How to successfully implement LEED: documentation challenges and solutions. Journal of Green Building 2007;2(4):3–13. [26] Lockwood C. Building the green way. Harvard Business Review June 2006:1–9. [27] Espinosa JP, Echeverry D. Aplicabilidad del sistema LEED en el entorno colombiano. Research Memorandum No. ICYA 2002-003. Bogotá, Colombia: Departamento de Ingenierı́a Civil, Universidad de Los Andes; 2005. Retrieved April 11, 2008, from http://hdl.handle.net/1992/198. [28] Muńoz, D. Impulsan la construcción sostenible. Diario La República. December 14, 2007. [29] USGBC (United States Green Building Council). LEED for new construction & major renovations (Reference guide version 2.2). Washington, D.C; 2005. Retrieved February 7, 2008, from http://www.usgbc.org/. [30] San-Jose JT, Garrucho I, Losada R, Cuadrado J. A proposal of environmental indicators towards industrial building sustainable assessment. International Journal of Sustainable Development and World Ecology 2007;14(2):160–73. [31] Sirisalee P, Ashby MF, Parks GT, Clarkson PJ. Multi-criteria material selection in engineering design. Advanced Engineering Materials 2004;6(1–2):84–92. [32] Ashby MF. Multi-objective optimization in material design and selection. Acta Materialia 2000;48(1):359–69. [33] Jee DH, Kang KJ. A method for optimal material selection aided with decision making theory. Materials & Design 2000;21(3):199–206. [34] Chan JWK, Tong TKL. Multi-criteria material selections and end-of-life product strategy: grey relational analysis approach. Materials & Design 2007;28(5):1539–46. [35] Holloway L. Materials selection for optimal environmental impact in mechanical design. Materials & Design 1998;19(4):133–43. [36] Giudice F, La-Rosa G, Risitano A. Materials selection in the life-cycle design process: a method to integrate mechanical and environmental performances in optimal choice. Materials & Design 2005;26(1):9–20. [37] Farag M. Quantitative methods of materials selection. In: Kutz M, editor. Handbook of materials selection. New York: Wiley; 2002. [38] Lipiatt BC. BEES 4.0 – building for economic and environmental sustainability (technical manual and user guide). National Institute for Standards and Technology; 2007. Retrieved February 7, 2008, from www.fire.nist.gov. [39] Scheuer C, Keoleian GA, Reppe P. Life cycle energy and environmental performance of a new university building: modeling challenges and design implications. Energy and Buildings 2003;35(10):1049–64. [40] Motta G. Materiales de Construcción y Ecoeficiencia. Master’s degree thesis. Bogotá, Colombia: Departamento de Ingenierı́a Civil y Ambiental, Universidad de los Andes; 2002. [41] IAQ (California Indoor Air Quality Program). IAQ website; 2008. Last accessed from http://www.cal-iaq.org/ on April 29th, 2008. [42] CRI (Carpet and Rug Institute). CRI website; 2008. Last accessed from http:// www.carpet-rug.org/ on April 29th, 2008. [43] Energy Star. Roof products list; 2008. Last accessed from http://www. energystar.gov/ia/products/prod_lists/roofs_prod_list.pdf on April 29th, 2008. [44] USAID (United States Agency for International Development). Summary of the alternative development program. Bogotá, Colombia; 2007. Retrieved July 29, 2008, from http://www.usaid.gov. [45] MAVDT (Ministerio del Medio Ambiente, Vivienda, y Desarrollo Territorial – Ministry of Environment, Housing and Territorial Development). Convenio Forestal; 2008. Retrieved July 29, 2008, from http://www.minambiente.gov. co/.