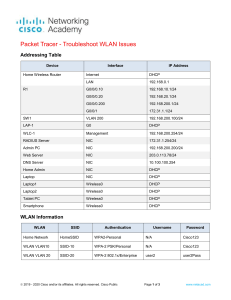

US 20140196515A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0196515 A1 Bloxham (43) Pub. Date: (54) APPARATUS AND METHOD FOR FORMING (30) J 11]. 17, 2014 Foreign Application Priority Data A SCREW FLIGHT Jul. 5,2011 (75) Inventor: Gregory John Bloxham, Beecroft (AU) (AU) .............................. .. 2011902667 Publication Classi?cation (51) (73) Assignee: ADVANCED SPIRAL TECHNOLOGY PTY LIMITED, Int. Cl. BZID 11/14 (52) us CL Castle Hill, New South Wales (AU) CPC .................................... .. 3210 11/14 (2013.01) USPC 72/67 14/130 837 (22) PCT Filed. JUL 5, 2012 This invention relates to an apparatus for forming a helical screW ?ight from a ?ight blank. The apparatus includes a base (86) PCT NO" PCT/AU2012/000803 mounted to the base and is con?gured to formineg engage the Mar. 27, 2014 blank corresponding to a predetermined pitch of the ?ight. ) A ............................................................ .. 1.N .: ( 21 (2006.01) pp 0 ’ _ ABSTRACT and an engaging means. The engaging means is movably § 371 (c)(1), (2), (4) Date: (57) blank so as to form a tWist in at least a portion of the ?ight 1 Patent Application Publication Jul. 17, 2014 Sheet 1 0f 17 US 2014/0196515 A1 Patent Application Publication Jul. 17, 2014 Sheet 2 0f 17 US 2014/0196515 A1 OFILTLER l 4 / / /// "4 h H. O O m /K\| r LU / / 5m, E (D g. '> o. 2. o / \ “MR— Patent Application Publication - HIDRA _ u LI Jul. 17, 2014 Sheet 3 0f 17 con. FILTER \ _ . . 1 US 2014/0196515 A1 /|SOLATION SWITCH I EMERGENCY SWITCH LINEAR GUIDE , \ ‘ > ° 29‘ \5 I, /'LINEAR GUIDE 30’ 4' L.H. SIDE VIEW FIGURE 3 HYDRAULIC 1 __ ELECTRICAL TOUCH ggalTEOL - PLATE 2 . , (15) _ I ' , ’ l H I: 28 - o I Q I 4/ _ ll \ J _ 12 s l ' \ (15) I INTERFACE PLATE I FRONT ELEVATION HGURE4 I SIGHT GUAGE SCREEN E SIDE DIE ' SIDE DIE, ' Patent Application Publication GUIDE 12—95 Jul. 17, 2014 Sheet 4 0f 17 I . I:5 US 2014/0196515 A1 GUIDE my i Patent Application Publication Jul. 17, 2014 Sheet 5 0f 17 Inner Diameter "ID" "Outer Diameter "OD" FIGUREG US 2014/0196515 A1 Patent Application Publication I Jul. 17, 2014 Sheet 6 0f 17 _ Flight Pitch "PT" I HGURE7 Flight Thickness "TH" FIGUREB US 2014/0196515 A1 Patent Application Publication ' BENDTINUTKREI'NCSEURTE Jul. 17, 2014 Sheet 7 0f 17 US 2014/0196515 A1 Patent Application Publication Jul. 17, 2014 Sheet 8 0f 17 US 2014/0196515 A1 3. MOVE THE RULE TO LINE-UP THE SCRIBE AND CENTRE LINES THEN LOCK IN PLACE BY TIGHTENING BOLTS 4. LOOSEN BOLTS . 08 CL _2_0 09 09 0v os llllllllllllll'I?llInwllllllll 30 H Ilmmll'llullll so so 70 so 29. I l 1. CHECK THAT SCRIBE LINE / '7 5 > IS LINED UP WITH DIE MID PLATE CENTRE Ll E! IF'YES THEN ROCEED TO NEXT PAGE 2. LOOSEN BOLTS IF NO THEN FOLLOW POINTS 2 AND 3 HGURE10 Patent Application Publication Jul. 17, 2014 Sheet 9 0f 17 FIGURE 11 US 2014/0196515 A1 Patent Application Publication Jul. 17, 2014 Sheet 10 0f 17 US 2014/0196515 A1 1. RULE GUIDE MUST BE FREE, TO MOVE WITH IN CHANNEL A 511 100110 120130 140150160 7018 190 00 2J0 22012 3. SLIDE THE RULE ASSEMBLY UP - OR DOWN UNTIL BASE OFFSET 2' bb'fFHURPU'EELT'igUE'TDEBiggE MEASUREMENT IS ACHIEVED ‘ OFFSET) MEASUREMENT FIGURE 12 Patent Application Publication Jul. 17, 2014 Sheet 11 0f 17 5 i US 2014/0196515 A1 1. LOCK RULE. 0 ASSEMBLY O 22 20 AV ® > _ l 7‘ ' v 01 ° 1 ' O O / 2. REMOVE RULE GUIDE HGURE13 i 20 Patent Application Publication , ~ Jul. 17, 2014 Sheet 12 0f 17 _ 4' ‘ SELECT AND INSERT APPROPRIATEV (DIE SIDE PLATE) AS PER (FLIGHT DIE CONFIGURATION PROGRAM) INTO BACK PLATE CHANNELS HGURE14 US 2014/0196515 A1 Patent Application Publication Jul. 17, 2014 Sheet 13 0f 17 3. LOCK (DIE SIDE PLATE) INTO POSITION 1. SLIDE SDIE SIDE PLATE TOWARDS RULE / 2. UNTIL CONTACT BETWEEN DIE SIDE PLATE) AND RULE ED E 19"} 20 / 24 FIGURE .15 US 2014/0196515 A1 Patent Application Publication Jul. 17, 2014 Sheet 14 0f 17 US 2014/0196515 A1 I. ADJUST THE DISTANCE BETWEEN SUPPORT BRACKET) AND RULE EDGE ALONG (DIE SIDE LATE) TOP EDGE TO MATCH THE (SUPPORT OFFSET) MEASUREMENT \ 2. LOCK (SUPPORT BRACKET) ‘ FIGURE 16 Patent Application Publication Jul. 17, 2014 Sheet 15 0f 17 US 2014/0196515 A1 1. ADJUST THE DISTANCE BETWEEN SUPPORT BRACKET) AND RULE EDGE ALONG (DIE SIDE LATE) TOP EDGE TO MATCH THE (SUPPORT OFFSET) MEASUREMENT .21 6 /7 5\’ v7\\‘/7 \ mmmlmmm all“): WIMIOQIWIO'IUEIUZIDHMI MOI llllllllllll lllllomulllllllllllllllllll @y N2. LOCK (SUPPORT BRACKET) FIGURE 17 Patent Application Publication Jul. 17, 2014 Sheet 16 0f 17 US 2014/0196515 A1 2. | > 17 < 15 6 FormGa 5 . 0‘; _ | 21' o oE 12 ‘ HGURE18 2 6 5 HollGap Aif“1521 o t g 12 28 E Extract Gap HGUREZO . Patent Application Publication Jul. 17, 2014 Sheet 17 0f 17 US 2014/0196515 A1 \a\ SIDE PLATE ANGLE ‘ i LLSIDE PLATE LENGTH+_> ‘ FIGURE 21 Jul. 17, 2014 US 2014/0196515 A1 APPARATUS AND METHOD FOR FORMING A SCREW FLIGHT FIELD OF THE INVENTION [0001] This invention relates generally to the ?eld of mate rials handling equipment. More particularly, the present invention relates to screw or auger ?ights (particularly sec annular) wherein the annulus shapedblank has an inner diam eter and an outer diameter. The engaging means is preferably adapted to twist the portion of the annulus about a mean radius line of the annulus. It will be appreciated by those skilled in the art that, by twisting the blank about its mean radius line, undesirable rounding or rolling across the cross section of the blank is substantially avoided. tional ?ights) and to an apparatus and method of forming such [0014] ?ights. sides of the blank such that forming movement of the engag ing means forms a twist in at least a portion of the ?ight blank. [0015] In some embodiments, the engaging means includes primary engaging means for engaging the blank at at least two BACKGROUND OF THE INVENTION [0002] Any discussion of the prior art throughout the speci ?cation should in no way be considered as an admission that such prior art is widely known or forms part of common general knowledge in the ?eld. [0003] Screw or auger ?ights are typically used in bulk handling industries for e?iciently moving ?uid, granular or semi-solid material. Rotation of the ?ight causes the material to be conveyed along the surface of a spiralled coil section. [0004] The means and method of manufacturing conven tional sectional screw ?ights involves pressing each section of ?ight between a set of appropriately shaped dies. Each section of ?ight is then typically welded to a shaft in sequence to form The engaging means preferably engages opposed spaced apart positions, whereby the primary engaging means is con?gured to cause relative movement between the at least two engaged positions so as to form the twist in the blank. [0016] In certain preferred embodiments, the primary engaging means includes two pairs of (primary) side plates. Each side plate is preferably a die formed plate having an engaging portion such as, for example, an engaging edge or surface for engaging the blank. Each side plate is preferably. arranged so as to extend in a direction which is substantially normal to the mean radius line of the blank. a complete conveyor screw. [0017] Preferably, each pair of side plates has a ?rst ?xed plate and a second movable plate, the second plate being [0005] movable relative to the ?xed plate. The conventional die pressing method has a number of inherent disadvantages. These disadvantages include that, [0018] depending on the thickness of the blank material used, is it often necessary to repeat the die pressing operation several times in order to conform the shape of the annulus to the shape of the dies between which the blank is pressed. The require ment to repeat the pressing cycle necessarily adds to the costs of production of screw ?ights produced via this method. means includes secondary engaging means for engaging the blank at at least one position in between the primary engaging means. The secondary engaging means preferably engages In some preferred embodiments, the engaging the blank at a central or mid-point between the primary engaging means. Preferably, the secondary engaging means includes a pair of mid-plates. The mid-plates preferably [0006] Furthermore, the blank typically undergoes plastic include a ?xed mid-plate and a movable mid-plate, the mov deformation during the pressing process which can lead to inaccuracy in ?ight pro?les outside of desired manufacturing able mid-plate being movable relative to the ?xed mid-plate. [0019] The ?xed plates of both the primary and secondary tolerances. Such variations away froth desired manufacturing tolerances necessarily lead to inferior products and a resulting engaging means are preferably mounted to a mounting means such as a mounting frame connected to the base. Preferably, reduction in product performance and lifespan. the mounting means includes a receiving formation for [0007] receiving each ?xed plate. The receiving formation prefer ably includes a pair of spaced apart channels, grooves, slots, In addition, for each particular size and pitch for a ?ight, two sets of dies are needed if both left and right hand ?ights are to be produced, further adding to the costs of using dies to form screw ?ights. [0008] It is also di?icult to produce accurate dies which will ridges, or other suitable formation for receiving the ?xed side plates, and a central receiving formation (e.g. channel) for receiving the ?xed mid-plate. produce a ?ight of a particular size and pitch. Accordingly, it [0020] is typically necessary to use an iterative process of trial and error whereby several sets of dies are produced, tested and tion for mounting the plate in or on or otherwise to the receiv modi?ed until the desired properties of a ?ight can be achieved from the die set. [0009] It is an object of the present invention to overcome or ameliorate one or more of the disadvantages of the prior art, or at least to provide a useful alternative. SUMMARY OF THE INVENTION [0010] According to a ?rst aspect of the invention, there is provided an apparatus for forming a helical screw ?ight from Preferably, each ?xed plate has a mounting forma ing formation. The mounting formation of each plate is pref erably complementary in shape to that of the receiving formation. For example, the mounting formation and the receiving formation may be con?gured as a tongue-and groove type arrangement. [0021] In certain embodiments, securing means is provided for securing each ?xed side plate in position, relative to the mounting means. The securing means preferably includes one or more locking screws for holding the mounting forma a ?ight blank, the apparatus including: tion (e. g. tongue) in the associated channel. Preferably, each receiving formation is con?gured to enable the associated [0011] [0012] mined position along the length of the receiving formation. a base; and engaging means movably mounted to the base, the engaging means being con?gured to formingly engage the blank so as to form a twist in at least a portion of the ?ight blank corresponding to a predetermined pitch of the ?ight. [0013] Preferably, the ?ight blank is in the form of an annulus, more preferably, an open ended annulus (e.g. a pen ?xed plate to be selectively mounted at a desired or predeter For example, the ?xed plates can be slid along the associated channel and then locked in the desired position. [0022] Preferably, a locking means such as, for example, a lock-bolt is provided for locking the ?xed mid-plate in posi tion, relative to the mounting means. Jul. 17, 2014 US 2014/0196515 A1 [0023] The movable plates of the primary engaging means and the secondary engaging means are preferably mounted to a movable frame, the frame being movably mounted to the base to enable relative movement between the ?xed plates and the movable plates. [0024] The movable frame preferably has a mounting for mation for mounting the movable plates. Preferably, the mounting formation of the movable frame corresponds to (e. g. mirrors) the mounting formation of the ?xed mounting frame such that the engaging portion of each pair of ?xed and movable plates is substantially aligned. That is, the pairs of side plates and the pair of mid-plates are preferably in engag plates and the mid-plate in a counter-clockwise direction, or vice versa. Again, it will be appreciated that side plates can be mounted to achieve the desired direction of rotation for pro ducing either a right-hand or left-hand twist in the blank. [0030] Each side plate (?xed and movable) is generally trapezoidal in shape, wherein its engaging edge is tapered relative to its mounting formation. To achieve the desired rotation of the blank at the point held between the side plates, the ?rst pair of side plates are arranged such that the tapered edges of the ?xed and movable plates in the ?rst pair are ing alignment. substantially parallel and extend at a negative angle (or posi tive angle for opposite hand formation). Similarly, the second pair of side plates are arranged such that the tapered edges of [0025] the ?xed and movable plates in the second pair are substan The receiving formations are preferably arranged such that the pairs of side plates are angled relative to one another. Preferably, the side plates are con?gured such that the relative angle therebetween is less than 180 degrees. In certain preferred embodiments, the side plates are arranged to have an angle of approximately 60 degrees therebetween. It will be appreciated that the primary engaging members are not limited to being angled at 60 degrees, but could, in other embodiments, be angled at any suitable angle less than 180 degrees. For example, the side plates can be angled at approximately 30, 45, 65, 75, 90, 105, 120, 135 or 145 degrees relative to each other. [0026] Preferably, a support means is associated with the side plates for supporting the ?ight blank, in use. The support means is preferably con?gured to support the outer diameter of the blank. Preferably, the support means includes a ?rst support bracket mountable to a ?xed side plate of a ?rst pair tially parallel and extend at a positive angle (or negative angle for opposite hand formation). [0031] It will therefore be appreciated that, due to the tapered engaging edges of the side plates, the relative linear movement between the ?xed and movable side plates results in a rotation of the part of the blank between the plates about the mean radius line to produce the desired twist in the blank. [0032] In at least one preferred embodiment, the actuating means is con?gured such that the apparatus operates with a forming force in the range of 0 to 60 tonne at 200 bar (2,900 psi), and the forming speed is within the range of 0 to 80 mm/ s. Embodiments operating within these parameters can be suitable for forming a helical screw from a blank having a thickness in the range of 1 mm to 300 mm. [0033] According to a second aspect of the invention, there is provided a method of forming a helical screw ?ight, the of primary engaging side plates and a second support bracket method including: mountable to a movable side plate of a second pair of primary [0034] providing a ?ight blank of a predetermined size; and engaging side plates. Each support bracket is preferably selectively adjustably positionable relative to the associated [0035] formingly engaging the blank so as to form a twist in side plate and secured thereto by a suitable locking means such as one or more locking elements (e.g. screws). It will be appreciated that the support brackets can be selectively mounted to the desired side plates, depending on whether a right-hand or left-hand helical screw ?ight is to be formed by at least a portion of the ?ight blank, the twist substantially corresponding to a predetermined pitch of the ?ight. [0036] Preferably, the method includes twisting at least a portion of the blank generally about a mean radius line of the blank. [0037] Preferably, the method includes engaging the blank the apparatus. [0027] The moveable frame is preferably moved by an with primary engaging means at at least two spaced apart actuating means. The actuating means preferably includes a to cause relative movement between the at least two engaged positions so as to form the twist in the blank. hydraulically driven cylinder, the hydraulic cylinder being positions, whereby the primary engaging means is con?gured selectively movable between an extended position and a [0038] retracted position for moving the movable frame and thus the engaging means for engaging the blank at at least one position movable plates of the primary and secondary engaging in between the primary engaging means, whereby the means. Preferably, the hydraulic cylinder has a cylinder rod engaged portion of the blank on one side of the secondary engaging means is twisted in a ?rst direction and the engaged portion of the blank on the other side of the secondary engag ing means is twisted in a second opposed direction. which is con?gured to cause linear movement of the movable frame when the cylinder rod extends or retracts. [0028] To facilitate the forward and backwards linear movement of the movable frame, the movable frame and base [0039] The method preferably includes using a secondary Preferably, the method includes determining the are preferably ?tted with guide means. Preferably, the guide size of the blank from at least one of a desired pitch, outer means includes at least one front guide bar and at least one diameter, inner diameter, and thickness of the formed helical rear guide bar extending from the movable frame. The at least one front guide bar is arranged to pass through an aperture in a front guide plate and the at least one rear guide bar is arranged to pass through an aperture in a rear guide plate. In screw ?ight. one particularly preferred embodiment, there is provided two front guide bars and two rear guide bars. [0029] Preferably, a ?rst pair of side plates is con?gured to rotate the portion of the blank between that pair of side plate and the mid-plate (i.e. secondary engaging means) in a clock wise direction, and a second pair of side plates is con?gured to rotate the portion of the blank between that pair of side [0040] According to a third aspect of the invention, there is provided a screw (or auger) ?ight which has been manufac tured in accordance with the method of the second aspect of the invention. [0041] According to a fourth aspect of the invention, there is provided a method of setting up an apparatus for forming a helical screw ?ight from a ?ight blank, the method including: [0042] securing a central engaging means to the apparatus; [0043] aligning a set up device with the central engaging means;