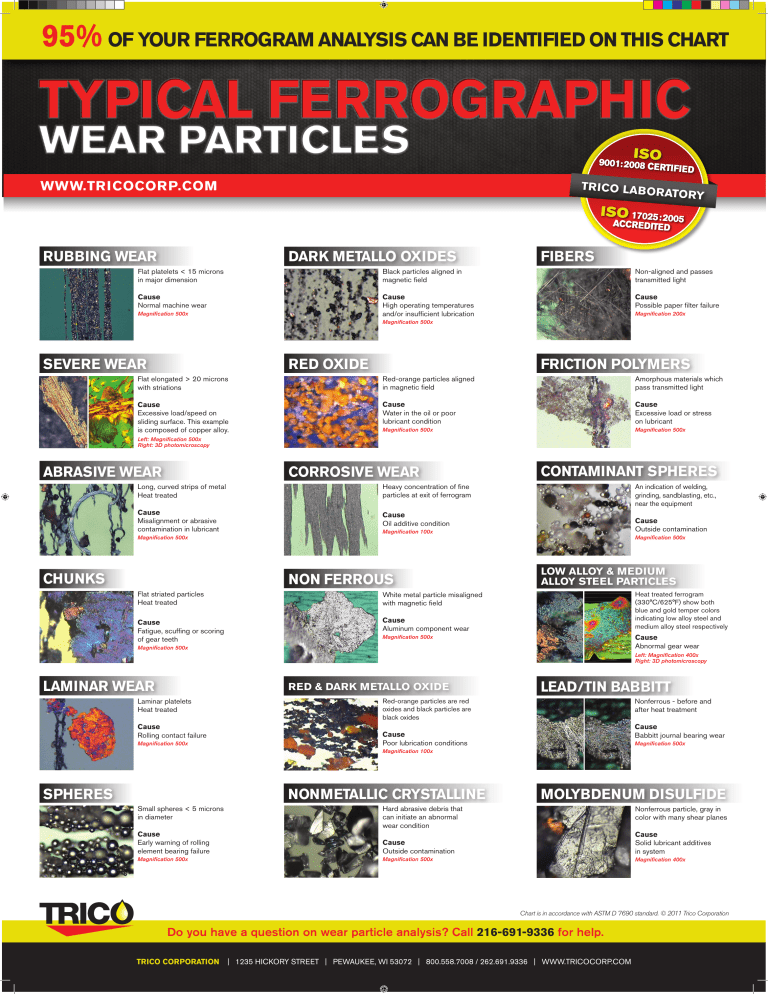

95% OF YOUR FERROGRAM ANALYSIS CAN BE IDENTIFIED ON THIS CHART TYPICAL FERROGRAPHIC WEAR PARTICLES www.tricocorp.com RUBBING WEAR DARK METALLO OXIDES FIBERS Flat platelets < 15 microns in major dimension Black particles aligned in magnetic field Non-aligned and passes transmitted light Cause Normal machine wear Cause High operating temperatures and/or insufficient lubrication Cause Possible paper filter failure Magnification 500x Magnification 200x Magnification 500x SEVERE WEAR RED OXIDE FRICTION POLYMERS Flat elongated > 20 microns with striations Red-orange particles aligned in magnetic field Amorphous materials which pass transmitted light Cause Excessive load/speed on sliding surface. This example is composed of copper alloy. Cause Water in the oil or poor lubricant condition Cause Excessive load or stress on lubricant Magnification 500x Magnification 500x Left: Magnification 500x Right: 3D photomicroscopy ABRASIVE WEAR CORROSIVE WEAR Long, curved strips of metal Heat treated Heavy concentration of fine particles at exit of ferrogram Cause Misalignment or abrasive contamination in lubricant Cause Oil additive condition Magnification 500x CHUNKS CONTAMINANT SPHERES An indication of welding, grinding, sandblasting, etc., near the equipment Cause Outside contamination Magnification 100x NON FERROUS Flat striated particles Heat treated White metal particle misaligned with magnetic field Cause Fatigue, scuffing or scoring of gear teeth Cause Aluminum component wear Magnification 500x LOW ALLOY & MEDIUM ALLOY STEEL PARTICLES Heat treated ferrogram (330°C/625°F) show both blue and gold temper colors indicating low alloy steel and medium alloy steel respectively Cause Abnormal gear wear Magnification 500x Magnification 500x Left: Magnification 400x Right: 3D photomicroscopy LAMINAR WEAR RED & DARK METALLO OXIDE Laminar platelets Heat treated Cause Rolling contact failure Magnification 500x LEAD/TIN BABBITT Nonferrous - before and after heat treatment Red-orange particles are red oxides and black particles are black oxides Cause Babbitt journal bearing wear Cause Poor lubrication conditions Magnification 500x Magnification 100x SPHERES NONMETALLIC CRYSTALLINE Small spheres < 5 microns in diameter MOLYBDENUM DISULFIDE Hard abrasive debris that can initiate an abnormal wear condition Nonferrous particle, gray in color with many shear planes Cause Early warning of rolling element bearing failure Cause Outside contamination Cause Solid lubricant additives in system Magnification 500x Magnification 500x Magnification 400x Chart is in accordance with ASTM D 7690 standard. © 2011 Trico Corporation Do you have a question on wear particle analysis? Call 216-691-9336 for help. Trico Corporation | 1235 Hickory Street | Pewaukee, WI 53072 | 800.558.7008 / 262.691.9336 | www.tricocorp.com