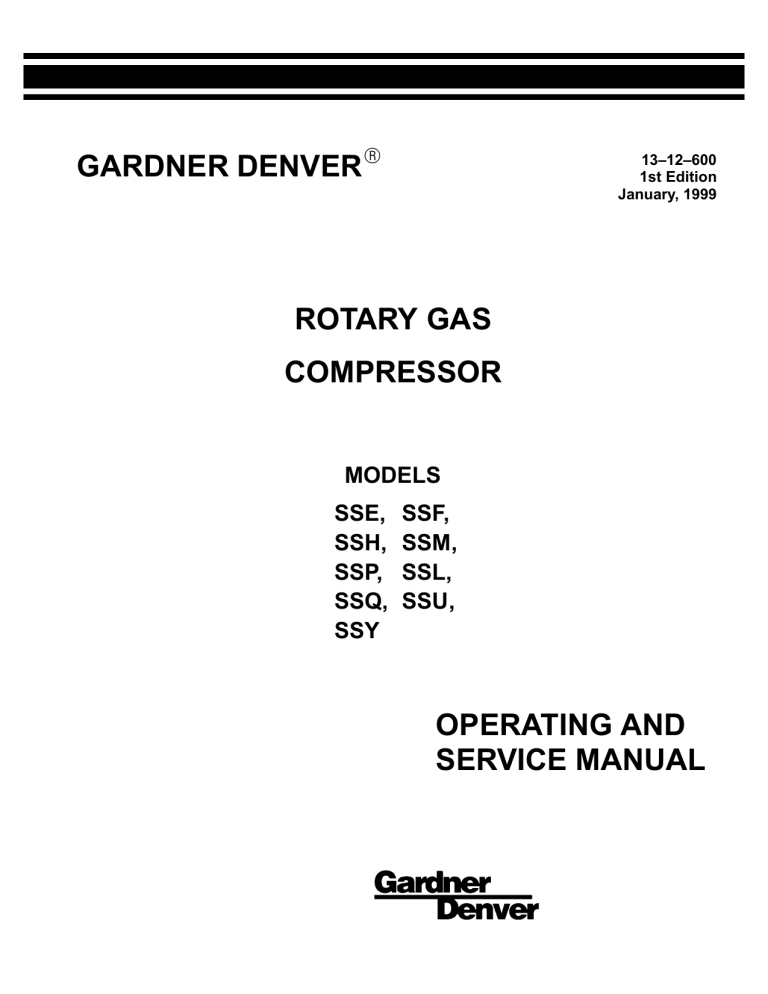

Operating and service manual compresor de gas garnder denver sspg

Anuncio