The Use of Intelligent Systems to Support the Decision–Making Process in Lean Maintenance Management

Anuncio

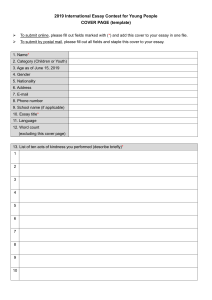

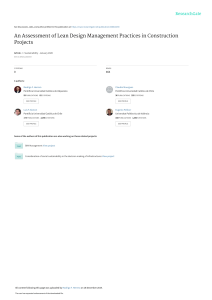

13th IFAC Workshop on Intelligent Manufacturing Systems 13th IFAC Workshop on Manufacturing Systems Available online at www.sciencedirect.com 13th IFAC Workshop on Intelligent Intelligent Manufacturing Systems August 12-14, 2019. Oshawa, Canada 13th IFAC Workshop on Intelligent Manufacturing Systems August 12-14, 2019. Oshawa, Oshawa, Canada August 12-14, 2019. Canada 13th IFAC Workshop on Intelligent Manufacturing Systems August 12-14, 2019. Oshawa, Canada August 12-14, 2019. Oshawa, Canada ScienceDirect IFAC PapersOnLine 52-10 (2019) 148–153 The Use of Intelligent Systems to Support the Decision–Making Process The Use of Intelligent Systems to the Decision–Making Process The Use of of Intelligent Intelligent Systems Systems to to Support Support the Decision–Making Process The Use Support the Decision–Making Process in Lean Maintenance Management The Use of Intelligent Systems to Support the Decision–Making Process in Lean Maintenance Management in Lean Maintenance Management in Lean Maintenance Maintenance Management Management in Lean Katarzyna Antosz*, Lukasz Pasko**, Arkadiusz Gola*** Katarzyna Lukasz Pasko**, Pasko**, Arkadiusz Gola*** Gola*** Katarzyna Antosz*, Antosz*, Lukasz Pasko**, Arkadiusz Katarzyna Antosz*, Lukasz Arkadiusz Gola*** Katarzyna Antosz*, Lukasz Arkadiusz Gola*** * Rzeszow Mechanical Pasko**, * Rzeszow University University of of Technology, Technology, Faculty Faculty of of Mechanical Engineering Engineering and and Aeronautics, Aeronautics, Poland Poland * Rzeszow University of Technology, Faculty of Mechanical Engineering and Aeronautics, Poland (e-mail: katarzyna.antosz@prz.edu.pl). * Rzeszow University of Technology, Faculty of Mechanical Engineering and Aeronautics, Poland (e-mail: katarzyna.antosz@prz.edu.pl). (e-mail: Faculty katarzyna.antosz@prz.edu.pl). * Rzeszow University of Technology, of Mechanical Engineering and Aeronautics, Poland ** Faculty (e-mail: katarzyna.antosz@prz.edu.pl). ** Rzeszow Rzeszow University University of of Technology, Technology, Faculty of of Mechanical Mechanical Engineering Engineering and and Aeronautics, Aeronautics, Poland Poland ** Rzeszow University of Technology, Faculty of Mechanical Engineering and Aeronautics, Poland (e-mail: katarzyna.antosz@prz.edu.pl). (e-mail: lpasko@prz.edu.pl). ** Rzeszow University of Technology, Faculty of Mechanical Engineering and Aeronautics, Poland (e-mail: lpasko@prz.edu.pl). (e-mail: lpasko@prz.edu.pl). ***** Rzeszow Faculty ofofMechanical Engineering andInformation, Aeronautics, Poland LublinUniversity Universityof ofTechnology, Technology, Institute Technological Systems (e-mail: lpasko@prz.edu.pl). *** Lublin Institute of Systems of of Information, Information, Poland Poland *** Lublin University University of of Technology, Technology, Institute of Technological Technological Systems of Poland (e-mail: lpasko@prz.edu.pl). (e-mail: a.gola@pollub.edu.pl)} *** Lublin University of Technology, Institute of Technological Systems of Information, Poland (e-mail: a.gola@pollub.edu.pl)} (e-mail: a.gola@pollub.edu.pl)} *** Lublin University of Technology, Institute of Technological Systems of Information, Poland (e-mail: a.gola@pollub.edu.pl)} Abstract: Manufacturing Manufacturing companies companies(e-mail: continually aim at at increasing increasing the the performance performance and and effectiveness effectiveness of of a.gola@pollub.edu.pl)} Abstract: continually aim Abstract: Manufacturing companies continually aim at increasing the performance and effectiveness of maintenance processes. The emphasis is put on the elimination of unexpected failures which generate unAbstract: Manufacturing companies continually aim at increasing the performance and effectiveness of maintenance processes. The emphasis is put on the elimination of unexpected failures which generate unmaintenance processes. The emphasis is put on the elimination of unexpected failures which generate unAbstract: Manufacturing companies continually aim at increasing the performance and effectiveness of necessary costs and production losses. The element that has has an an impact impact on the the efficiency efficiency of maintenance maintenance is maintenance processes. The emphasis is putelement on the elimination of unexpected failures which generate unnecessary costs and production losses. The that on of is necessary costs and production losses. The element that has an impact on the efficiency of maintenance is maintenance processes. The emphasis is put on the elimination of unexpected failures which generate unnot only the selection of an appropriate conservation strategy and the use of appropriate methods and necessary costs and production losses. Theconservation element thatstrategy has an impact onuse the of efficiency of maintenance is not only the selection of an appropriate and the appropriate methods and not only the selection of an appropriate conservation strategy and the use of appropriate methods and necessary costs and production losses. The element that has an impact on the efficiency of maintenance is tools to support the decision-making process in this this area. area.strategy The aim aimand of this this workofis isappropriate to present present the the possibility not only the selection of an appropriate conservation the use methods and tools to support the decision-making process in The of work to possibility tools to support the decision-making process in this area. The aim of this work is to present the possibility not only the selection of an appropriate conservation strategy and the use of appropriate methods and of using intelligent systems to support decision-making processes in the the implementation ofpossibility the Lean Lean tools to support the decision-making process in this area. The aim of this work is to present theof of using intelligent systems to decision-making processes in implementation the of using intelligent systems to support support decision-making processes in the implementation ofpossibility the Lean tools to support the decision-making process in this area. The aim of this work is to present the Maintenance concept, which allows to increase the operational efficiency of the company's technical inof using intelligent systems to support decision-making processes in the implementation of the Lean Maintenance concept, which to the efficiency the inMaintenance concept,systems which allows allows to increase increase the operational operational efficiency ofimplementation the company's company's technical technical inof using intelligent to support decision-making processes in theof of the Lean frastructure. Maintenance concept, which allows to increase the operational efficiency of the company's technical infrastructure. frastructure. Maintenance concept, which allows to increase the operational efficiency of the company's technical infrastructure. Keywords: decision –– making process, maintenance management, Maintenance, logic, decifrastructure. © 2019, IFAC (International Federation Automatic Control) HostingLean by Elsevier Ltd. All fuzzy rights reserved. Keywords: decision process, management, Lean Maintenance, fuzzy logic, Keywords: decision – making making process,ofmaintenance maintenance management, Lean Maintenance, fuzzy logic, decidecision tree, the theory of rough sets Keywords: decision – making process, maintenance management, Lean Maintenance, fuzzy logic, decision tree, theory rough sion tree, the thedecision theory of of rough sets sets Keywords: – making process, maintenance management, Lean Maintenance, fuzzy logic, decision tree, the theory of rough sets sion tree, the theory of rough sets These activities activities are are related related to to the elimination elimination of of losses, e.g. e.g. These 1. These activities are in related to the the elimination of losses, losses, e.g. 1. INTRODUCTION INTRODUCTION failures occurring maintenance (Clarke et al., 2010). 1. INTRODUCTION These activities are in related to the elimination of losses, e.g. failures occurring maintenance (Clarke et al., failures occurring in maintenance (Clarke et al., 2010). 2010). 1. INTRODUCTION These activities related to the elimination of appropriate losses, e.g. Moreover, theseare activities require the use of of For the last few decades, maintenance was thought as unnecfailures occurring in maintenance (Clarke et appropriate al., 2010). 1. INTRODUCTION Moreover, these activities require the use For the last few decades, maintenance was thought as unnecMoreover, these activities require the use of appropriate For the last few decades, maintenance was thought as unnecfailures occurring in maintenance (Clarke et al., 2010). methods and andthese toolsactivities to support the decision making process essary an enterprise management. That because issue Moreover, require the use making of appropriate For thein last few decades, maintenance wasis thought asthe unnecmethods tools to the process essary in an enterprise management. That is because issue methods andthese toolsactivities to support support the decision decision process essary inlast an few enterprise management. That isthought because the issue Moreover, require the2018, use making of appropriate For the decades, maintenance was asthe unnec(Jasiulewicz-Kaczmarek and Żywica, Valis and Mawas limited to the specific functions that are normally used in methods and tools to support the decision making process essary in an enterprise management. That is because the issue (Jasiulewicz-Kaczmarek and Żywica, Żywica, 2018, making Valis and and Mawas limited to the functions that are normally used in and 2018, Valis Mawas limited to the specific specific functions that are normally used in (Jasiulewicz-Kaczmarek methods and2018). tools to support the decision process essary in ansituations enterprise management. That is because the issue zurkiewicz, emergency such as machine failures (Gola, 2019). (Jasiulewicz-Kaczmarek and Żywica, 2018, Valis and Mawas limited to the specific functions that are normally used in zurkiewicz, 2018). emergency situations such functions as machine machine failures (Gola, used 2019). 2018). emergency situations such as failures (Gola, 2019). (Jasiulewicz-Kaczmarek Żywica, 2018, Valis and Mawas limitedthis to the specific that are normally in zurkiewicz, In the the literature, literature, there are areand different solutions concerning the However, practice is no longer acceptable because the zurkiewicz, 2018).there emergency situations such as machine failures (Gola, 2019). In different solutions concerning the However, this practice is no longer acceptable because the In the literature, are different solutions concerning the However, this practice is no longer acceptable because the 2018).there emergency situations such as machine failures (Gola, 2019). zurkiewicz, supporting decision processes in maintenance management. importance of maintenance has been recognised as a strategic the literature, there are different solutions concerning the However, this practice is no acceptable asbecause the In decision processes in management. importance of maintenance maintenance haslonger been recognised recognised strategic supporting decision processes in maintenance maintenance management. importance of has been aa strategic In the work literature, there are different solutions concerning the However,ofthis practice is no longer acceptable asbecause the supporting In the the (Taghipour et al., al., 2011), the authors authors present how how element income for enterprises. decision processes in maintenance management. importance ofgenerating maintenance has been recognised asNowadays, a strategic supporting In work (Taghipour et 2011), the present element of generating income for enterprises. Nowadays, In the work (Taghipour et al., 2011), the authors present how element of generating income for enterprises. Nowadays, supporting decision processes in maintenance management. importance of maintenance has been recognised as a strategic to identify identify and prioritizeetcritical critical devices to mitigate functionmaintenance is considered aa key that influences In the workand (Taghipour al., 2011), the to authors present how element of generating income for element enterprises. Nowadays, to prioritize devices mitigate functionmaintenance is element that influences to identify prioritize devices mitigate functionmaintenance is considered considered a key key element that Nowadays, influences In the workand (Taghipour etcritical al.,a 2011), the to authors present how element of competitiveness generating income forcost enterprises. al failures. The authors used multi-criteria decision-making company’s as its constitutes the main to identify and prioritize critical devices to mitigate functionmaintenance is considered as a key element that influences al failures. The authors used a multi-criteria decision-making company’s competitiveness its cost constitutes the main al failures. The authors used a multi-criteria decision-making company’s competitiveness as its cost constitutes the main to identify and prioritize critical devices to mitigate functionmaintenance is considered a key element that influences to prioritize and to propose appropriate part of operational costs of Thus, an al failures. The authorsdevices used a multi-criteria decision-making company’s competitiveness asanitsenterprise. cost constitutes the unexmain model model to prioritize and to appropriate part of operational costs of Thus, an unexmodel to The prioritize devices and ‘preventive to propose propose appropriate part ofsystem operational costs ofasan anitsenterprise. enterprise. Thus, an unexal failures. authorsdevices used a multi-criteria decision-making company’s competitiveness cost constitutes theoffered main maintenance strategies including maintenance’ pected failure may influence the quality of the model to prioritize devices and to propose appropriate part of operational costs of an enterprise. Thus, an unexmaintenance strategies including ‘preventive maintenance’ pected system failure may influence the quality of the offered maintenance strategies including ‘preventive maintenance’ pected system failure may influence the quality of the offered model to prioritize devices and to propose appropriate part of operational costs of an enterprise. Thus, an unexand ‘user training’. Moreover, in the works (Bashiri et product, the availability of machines or tools, the environmaintenance strategies including ‘preventive maintenance’ pected system failure may influence the quality of the offered and ‘user training’. training’. Moreover, in the the works (Bashiri (Bashiri et al., al., product, the availability availability ofinfluence machines orquality tools,ofthe the environand ‘user Moreover, in works et al., product, the of machines or tools, maintenance strategies including ‘preventive maintenance’ pectedand system failure may the theenvironoffered 2011; Zhaoyang et al., 2011, Galar et al., 2012), the ment an operator (Sobaszek et al., 2017; Burduk and and ‘user training’. Moreover, in the et works (Bashiritheet imal., product, the availability of machines or tools, the environ2011; Zhaoyang et al., 2011, Galar al., 2012), imment and an operator (Sobaszek et al., 2017; Burduk and 2011; Zhaoyang et al., 2011, Galar et al., 2012), the imment and an operator (Sobaszek et al., 2017; Burduk and and ‘useroftraining’. Moreover, in the works (Bashiri et al., product, the 2015, availability ofetmachines or tools, the environ- portance preventive the maintenance Jagodziński, Szwarc al., 2019). implementation Zhaoyang et al.,maintenance 2011, Galarin et al., 2012), themanimment and an2015, operator (Sobaszek et al.,The 2017; Burduk and 2011; portance of preventive maintenance in the maintenance manJagodziński, Szwarc et al., 2019). The implementation portance of preventive maintenance inthe theal., maintenance manJagodziński, Szwarc eta al., 2019). implementation 2011; Zhaoyang et al., 2011, Galar et 2012), thebased imment andManufacturing an2015, operator (Sobaszek etimpact al.,The 2017; Burduk and agement process of equipment and of risk of Lean had great the change of portance of preventive maintenance inthe the role maintenance manJagodziński, 2015, Szwarc eta al., 2019). Theon implementation agement process of equipment and role of risk based of Lean Manufacturing had great impact on the change of agement process of equipment and the role of risk based of Lean Manufacturing had a great impact on the change of portance of preventive maintenance in the maintenance manJagodziński, 2015, Szwarc et al., 2019). The implementation was shown. perceiving the role of had maintenance in an on enterprise. This agement process of equipment and the role of risk based of Lean Manufacturing a great impact the change of maintenance maintenance was perceiving the role maintenance in enterprise. This maintenance was shown. shown. perceiving the role of of had maintenance in an anmanagement enterprise. This agement process of et equipment and the role propose of risk to based of Lean Manufacturing a great impact on the change of In the work (Zeineb al., 2017), the authors use philosophy is currently a preferably used conmaintenance was shown. perceiving the role of amaintenance in anmanagement enterprise. This In the work (Zeineb et al., 2017), the authors propose to use philosophy is currently preferably used conIn the work (Zeineb et al., 2017), the authors propose to use philosophy is currently a preferably used management conmaintenance was shown. perceiving the role of maintenance in an enterprise. This the Analytical Hierarchy Process, the technique for order cept in enterprises. A number of organisations have started In the work (Zeineb et al., 2017), the authors propose to use philosophy is currently a preferably used management conthe Analytical Hierarchy Process, the technique for order cept in enterprises. A number of organisations have started the Analytical Hierarchy Process, the technique for order cept in enterprises. A number of organisations have started In the work (Zeineb et al., 2017), the authors propose to use philosophy is currently a preferably used management conpreference by similarity to ideal solution, and the mathematiusing “lean tools” mainly in order to reduce losses in producthe Analytical Hierarchy Process, the technique for order cept in enterprises. A number of organisations have started preference by similarity similarity to Process, ideal solution, solution, and the the mathematimathematiusing “lean tools” mainly in order to reduce losses in producpreference by to ideal and using “lean tools” mainly in order to reduce losses in producthe Analytical Hierarchy the technique for order cept in enterprises. A number of organisations have started cal optimization to determine the criticality of equipment, to tion (Gornicka and Burduk, 2018). However, it beby similarity to ideal andofthe mathematiusing “lean tools” in order reduce losses in produccal optimization to determine determine thesolution, criticality equipment, to tion (Gornicka andmainly Burduk, 2018).to However, it quickly quickly be- preference cal optimization to the criticality ofthe equipment, to tion and Burduk, 2018). it quickly bepreference by similarity to ideal solution, and mathematiusing(Gornicka “lean tools” mainly in order to However, reduce in losses in producrank the maintenance strategies and to select the optimal came apparent that the presence of losses manufacturing optimization to determine the criticality of equipment, to tion (Gornicka and Burduk, 2018). However, it quickly be- cal rank the maintenance strategies and to select the optimal came apparent that the presence of losses in manufacturing rank the maintenance strategies and to select the optimal came apparent that the presence of losses in manufacturing cal optimization to determine the criticality of equipment, to tion (Gornicka and Burduk, 2018). processes However,such it quickly be- maintenance strategy taking into consideration the total processes is influenced by auxiliary as, among rank the maintenance strategies and to select the optimal came apparent that the presence of losses in manufacturing maintenance strategy taking into consideration the total processes is influenced influenced by auxiliary processes such as, among among maintenance strategy taking into total processes is by auxiliary as, rank the maintenance strategies andconsideration to select thethe optimal came apparent that the presence ofprocesses lossesorganisations in such manufacturing maintenance cost. In the work (Wang et al., 2006), the auothers, maintenance. That is why, some have maintenance cost. strategy taking into consideration thethetotal processes is influencedThat by auxiliary processes such as, among In work (Wang et al., 2006), auothers, is why, some organisations have maintenance In the the work (Wang ettool al., to 2006), auothers, maintenance. maintenance. ismethods why, processes some organisations have maintenance strategy taking into consideration thethetotal processes is influencedThat by auxiliary suchof as,mainteamong thors used used the thecost. Monte Carlo simulation forecast the started implementing lean in the area cost. In the work (Wang ettool al., to 2006), the auothers, maintenance. That ismethods why, some organisations have maintenance thors Monte Carlo simulation forecast the started implementing lean in the area of maintethors used the Monte Carlo simulation tool to forecast the started implementing lean methods in the area of maintemaintenance cost. In the work (Wang et al., 2006), the auothers, maintenance. That is why, some organisations have risk of equipment failures. According to (Cruz et al., 2012), nance defined as Lean Maintenance. thors used the Monte Carlo simulation tool to forecast the started implementing lean methods in the area of mainte- risk of equipment failures. to tool (Cruz al., 2012), nance as ofused equipment failures. According (Cruz etforecast al., 2012), nance defined as Lean Lean Maintenance. Maintenance. thors the Monte CarloAccording simulation to et the starteddefined implementing lean methods in the area of mainte- risk in the the equipment maintenance processto the focus should be risk of equipment equipment maintenance failures. According tothe (Cruz et al., 2012), nance defined as 2. Lean Maintenance.REVIEW in process focus should be LITERATURE in the equipment maintenance process the focus should be risk of equipment failures. According to (Cruz et al., 2012), nance defined as 2. Lean Maintenance. 2. LITERATURE LITERATURE REVIEW REVIEW paid on the risk caused by equipment failure. In the work in the equipment maintenance process the focus should be paid onequipment the risk risk caused caused by equipment equipment failure. In should the work work the failure. the in theon maintenance process the focusIn be 2. is LITERATURE REVIEW activities aimed paid (Jamshidi et al., al., 2015) theby authors applied, among others, the Lean Maintenance Maintenance a concept concept implementing implementing paid on the risk2015) caused by equipment failure. Inothers, the work 2. LITERATURE REVIEW (Jamshidi et the authors applied, among the Lean is a activities aimed (Jamshidi et al., 2015) the authors applied, among others, the Lean Maintenance is a concept implementing activities aimed paid on the risk caused by equipment failure. In the work fuzzy failure modes and effects analysis method to prioritize at increasing increasing the efficiency efficiency and effectiveness of technical technical et al., 2015) authors applied, amongtoothers, the Lean Maintenance is a conceptand implementing activities aimed (Jamshidi fuzzy failure modes andthe effects analysis method prioritize at the effectiveness of modes and analysis method prioritize at increasing the efficiency and effectiveness of technical (Jamshidi et al., theeffects authors applied, among others, the Lean Maintenance is a concept implementing activities aimed fuzzy devicesfailure and to 2015) facilitate the classification classification of to devices for infrastructure (Jasiulewicz and Saniuk, 2018). fuzzy failure modes and effects analysis method to prioritize at increasing the efficiency and effectiveness of technical devices and to facilitate the of devices for infrastructure (Jasiulewicz andand Saniuk, 2018). of technical devices and modes to facilitate the classification of to devices for infrastructure and Saniuk, 2018). fuzzy failure and effects analysis method prioritize at increasing (Jasiulewicz the efficiency effectiveness devicesbyand to facilitate the reserved. classification of devices for infrastructure (Jasiulewicz and Saniuk, 2018).of Automatic Control) Hosting 2405-8963 © 2019, IFAC (International Federation Elsevier Ltd. All rights devices and to facilitate the classification of devices for infrastructure (Jasiulewicz and Saniuk, 2018). Peer review under responsibility of International Federation of Automatic Copyright@ 2019 IFAC 148Control. Copyright@ 2019 IFAC IFAC 148 10.1016/j.ifacol.2019.10.037 Copyright@ 2019 148 Copyright@ 2019 IFAC 148 Copyright@ 2019 IFAC 148 2019 IFAC IMS August 12-14, 2019. Oshawa, Canada Katarzyna Antosz et al. / IFAC PapersOnLine 52-10 (2019) 148–153 maintenance activities based on their criticality. In the work (Bayar et al., 2016) the authors propose to use ontologies and multi-agent systems as an approach for disruptions and risks monitoring. The system was designed to support a decision making process. In the work (Carnero, 2016) the author proposes to use a multicriteria decision making approach to improve maintenance policies in a healthcare organization where the condition of healthcare equipment may influence human life. In turn, in the work (Li et al., 2014) the authors incorporated machine learning techniques together with the distributed learning and hierarchical analytical approaches to explore historical and real-time data concerning railway conditions and to predict failures. Additionally in the work (Loska, 2013) the methodology of operational modelling of the decision-making process with the use of scenario methods was proposed. Although there are many methods and tools supporting the decision making process in maintenance management, but in the current research, the use of intelligent systems which are dedicated to support the implementation of the Lean Maintenance concept is often not taken into consideration. The main goal of this work was to present the possibility of using intelligent systems to support decision-making processes in the Lean Maintenance concept, which, allows to increase the operational efficiency of the company's technical infrastructure. The third section of the article presents the results of research on the use and effectiveness of Lean Maintenance in production enterprises. The aim of the research was to gather information on technical infrastructure management systems in enterprises, with particular emphasis on Lean Maintenance methods and tools as well as the ability to identify factors affecting the efficiency of their application. The fourth section presents the use of artificial intelligence methods (decision trees and the theory of rough sets) to search for dependencies between specific activities implemented as part of the Lean Maintenance implementation and the obtained effects. The last section of this paper concludes the work and presents its limitations and as well as the future research. 149 results of the studies were shown in the work (Antosz and Stadnicka, 2014). Based on the studies conducted in the enterprises of podkarpackie voivodship and their results considering the identification of the ways of technical infrastructure management, on the activities undertaken as part of the Lean Maintenance implementation in enterprises as well as the assessment of the effectiveness of the technical infrastructure management ways of enterprises, it was able to draw the following conclusions: - The analysed enterprises identify different kinds of wastes in the technical infrastructure management process. In order to eliminate wastes more and more enterprises implement Lean Maintenance philosophy. - The companies that have identified the wastes such as machine failures or long changeover times plan to implement or have implemented different Lean Maintenance methods and tools related to the machine use and the improvement of the organization of work stands. - The number of enterprises that implement TPM is becoming smaller. Mostly, medium enterprises resign from the implementation of the TPM method. - The research proved that most companies decided to implement TPM because of high machine failure rate, and the TPM system is most often implemented on all machines if the mean time to repair ranges between 1 to 8 hours. - The enterprises realize different activities in terms of the TPM method implementation. The presented results show that in large enterprises the kind of activities within this method implementation has practically not changed. - The most common problems that appear during the TPM implementation include the lack of skilled workers to eliminate irregularities on machines and the lack of engagement of the top management into the activities related to TPM. - Enterprises implement 5S method increasingly. However, less and less companies declare to have implemented 5S in the whole enterprise. They notice benefits from the implementation of 5S method, and its effectiveness is mainly assessed with 5S audits. - The results show that the knowledge and use of the SMED (Single Minute Exchange of Die) method have not significantly changed for the last few years. SMED is most often implemented in small and micro enterprises. However, only among large companies there were such companies that analysed all changeovers. Enterprises most often assess the effectiveness of the SMED method by the changeover time reduction. - Most of the analysed enterprises still don’t use the OEE (Overall Equipment Effectiveness) indicator. This indicator is used in medium enterprises. It is most frequently used in the enterprises where a single production is used and in the enterprises from aviation, metalworking and automotive industries. The lowest values of the OEE indicator, below 30%, are obtained in small enterprises, in the metalworking industry and in the enterprises with Polish capital. 3. THE ASSESSMENT OF LEAN MAINTENANCE EFFECTIVENESS CONCEPT IN ENTERPRISES – STUDY RESULTS The first stage of the study was to collect information considering the systems of technical infrastructure management, in particular, the methods and tools of Lean Maintenance such: TPM (Total Productive Maintenence), SMED (Single Minute Exchange of Die), 5S and OEE (Overall Equipment Effectiveness) indicator, and the possibility to identify the factors that influence the effectiveness of their use. The studies were carried out in 150 manufacturing enterprises in podkarpackie voivodship in two stages: stage I – years 2010 to 2014 and stage II in years 2014 to 2017. The surveyed enterprises were classified according to the following criteria: an organisation size, a production type, an industry, an ownership type, capital, a company’s condition and the type of the owned machines. Among the analysed enterprises, there were ones that realized a few production types or operated in a few industries. The detailed 149 2019 IFAC IMS 150 August 12-14, 2019. Oshawa, Canada Katarzyna Antosz et al. / IFAC PapersOnLine 52-10 (2019) 148–153 - Large enterprises achieved the greatest benefits from implementing Lean Maintenance tools. In most of the analysed areas they achieved higher benefits than expected. Additionally, the statistical analysis with using chi square test of the obtained results, allowed to identify the factors that influence the Lean Maintenance implementation effectiveness. On the basis of the studies it was drawn the following conclusions: the factors that influence the use of Lean Maintenance methods and tools are: the enterprise size, industry and the capital owned, the factors that influence the SMED method implementation are: the company’s condition, the kind and means of supervising, and the type of machines owned, the factors that influence the 5S method implementation are: the company’s condition and kind of supervision, the main factor influencing the TPM method implementation is the type of machines owned, the activities realized within the TPM method implementation depend mainly on the type of ownership and the company’s condition, the classification of machines and spare parts realized within TPM depends on the company’s size, its capital, type of the machines owned and kind of supervision., the reduction of changeover times depends on an enterprise type, the OEE value depends on the ownership type, enterprise industry and mean time to repair, the reduction of unexpected downtimes depends on the implementation of the SMED method and the type of machines owned. The studies allowed to identify the factors that influence the achieved results after the Lean Maintenance implementation in enterprises. It should be noted that the studies often showed that single factors don’t have a significant impact on the studied areas, although their interaction with other factors may have a substantial impact on the analysed area. However, the problem is that analysing a process with so many variables is very difficult. Therefore, it was proposed the concept of using the method of building and analysing decision trees, and the theory of rough sets for the quantitative interpretation of the degree Lean Maintenance is used. turing enterprises. The 13 decision rules were generated for predicting the value of the variable “OEE value”. In order to assess the quality of the generated decision rules, the rules were validated. The aim of the validation was to prove in a documented manner and in accordance with the assumptions that the generated decision rules actually lead to the planned results. Fig. 1. Calculation of the OEE indicator in enterprises. The assessment of the developed decision rules was conducted in the following stages: re-conducting the surveys in 20 randomly chosen enterprises, developing an expert system based on the generated decision rules (within the framework programme PC-Shell of Aitech Sphinx suite), using the survey results to study general classification ability of the generated decision rules with the developed expert system, and assessing qualitatively the obtained results with quality classification measures. The structure of the created knowledge base in the expert system consists of two blocks: facets and rules. The facet block is used to declare the decision attributes and their values. Decision attributes are explanatory variables placed in the nodes of the decision tree. In addition, for each decision tree, the so-called the result attribute (target attribute) that represents the result of the system inference. After completing the inference, the application presents the determined value of the resulting attribute "OEE value" placed in a separate window. On the figure 2 the result of the expert system consultation window is presented. On the figure 3 the window of justifying the result of applying the expert system is presented. The quality analysis consisted of developing binary matrices of errors for the classifier for the classes that most commonly appear in the conducted studies. In the developed binary matrices, the class analysed at a particular moment was assumed positive (TP – true positive) while the remaining classes were negative (TN – true negative). 4. DECISION TREE AND THE THEORY OF ROUGH SETS TO SUPPORT THE DECISION – MAKING PROCESS IN LEAN MAINTENANCE MANAGEMENT Decision tree (classification) were developed for decision variable: the average value of OEE after the Lean Maintenance implementation. The indicator is one of the indicators recommended in the literature for the assessment of the efficiency of the machines owned and the TPM implementation. It was designed a classification tree for enterprises which were analysed a given indicator and implemented the TPM method. It was developed a classification tree for a dependent variable – an average value of OEE – 24 out of the studied group of enterprises. The study results shows, that most of the analysed enterprises still don’t use the OEE indicator (stage I: 60,38%, stage II: 73,96%). This indicator is used for all machines merely by a few percent of the enterprises (stage I: 7,55%, stage II: 5,21%) (Fig. 1). The developed classifier allowed to generate a set of decision rules that may be the basis for determining the directions and effects of the Lean Maintenance implementation in manufac150 2019 IFAC IMS August 12-14, 2019. Oshawa, Canada Katarzyna Antosz et al. / IFAC PapersOnLine 52-10 (2019) 148–153 Fig. 2. The result of the expert system consultation window. of the lack of an answer in the survey. The rough set theory uses decision tables that include a higher number of items. Therefore, it considers a greater number of data while generating the rules. This fact allowed to discover new relations between the explaining and explained variables that had not been discovered with the decision trees. The decision rules were generated based on the proposed algorithm LEM2 (Learning from Examples Module, version 2), together with RSES software. Then, the assessment of their correctness was done. It was conducted the assessment of the developed decision rules in the following stages: generating a decision table and error matrix, developing an expert system based on the generated decision rules, application of the obtained results of the survey for examining a general classification ability, applying the obtained survey results for examining a general classification ability of the generated decision rules with the developed expert system, and assessing the quality of the obtained results with quality classification measures. Fig. 3. The window of justifying the result of applying the expert system. Table 1 and 2 present error matrices for the classifier - the value of OEE for the two most-emerging classes: 30-50% and 70-85%. Based on a binary matrix of errors, we can designate numerical indicators (Table 3). In detail, these indicators have been presented and discussed, among others in the works (Costa et al., 2007, Fawcelt, 2006; Sokolova and Lapalme, 2009). Table 3. Indicators used to test the quality of classifier (Pasko and Setlak, 2016). Ind. Designation Formula TP TN Acc Acc accuracy, TP TN FP FN overall error FP FN Err Err rate, TP TN FP FN true positives TP TPR TPR rate, TP FN Table 1. Matrix of errors for the classifier value of OEE indicator - 30 - 50% class. Real classes TP TN TP 7 0 Predicted classes TN 0 13 Table 2. Matrix of errors for the classifier value of OEE indicator - 70-85% class. Real classes TP TN 151 TNR Predicted classes TP TN 5 1 2 12 PPV The obtained indicator values for the assessment of classification measure, e.g. of an error (Err) at the level of 0,00 to 0,15 proved high usefulness of the developed classifiers, and thereby, their possibility to apply them by manufacturing enterprises for the effectiveness assessment of the Lean Maintenance methods and tools implementation. The rough set theory was used to assess the degree of the Lean Maintenance application. The conducted studies described are based on the same input data sets as were used for decision tree. However, it was suggested a means of improving the accuracy of the obtained assessment through incorporating the incomplete data. Data considered organisational and technical area of activity of the most enterprises. Applying the rough set theory allowed to extend the group of the considered enterprises, what increased the scope of the data used for calculating and for the inference process. For instance, while generating the decision rules for the described variable “an average OEE value” with a decision tree, 24 enterprises were taken into consideration. Applying the rough set theory allowed to increase the group of the considered enterprises to 34. The additional 10 enterprises were described with a variable set, of which at least one variable doesn’t have a designated value as a result NPV FPR FDR FNR true negatives rate, positive predictive value, negative predictive value false positive rate false discovery rate, false negatives rate TNR TN TN FP PPV TP TP FP NPV TN TN FN FPR FP 1 TNR FP TN FDR FP FP TP FNR FN 1 TPR TP FN MCC Matthew’s correlation coefficient MCC F1 F1-score F1 J Youden’s statistic J TP TN FP FN (TP FN )(TP FP)( FN TN )( FP TN ) 2 PPV TPR PPV TPR J TPR TNR 1 The figure 4 presents the RSES program window with the error matrix for the classification of learning objects based on the decision rules generated by the LEM2 algorithm for the variable "Average value of OEE". 151 2019 IFAC IMS 152 August 12-14, 2019. Oshawa, Canada Katarzyna Antosz et al. / IFAC PapersOnLine 52-10 (2019) 148–153 gence methods (decision tree and the theory of rough sets) to apply them in manufacturing enterprises for the effectiveness assessment of the Lean Maintenance methods and tools implementation is presented. The positive results obtained during the conduct of the described research lead to the conclusion that the activities in these areas should be continued. In particular, they ought to be: studies considering the assessment of the effectiveness of using other methods and tools recommended in the literature within the Lean Maintenance implementation, the possibility of extending functionality designed in a computer application, the use of other methods of data exploration for generating decision rules and comparing their classification quality. Fig. 4. The RSES program window with the error matrix for the variable "Average value of OEE". The indicator values obtained for examining the classifier quality, e.g. the error (Err) at the level of 0,10 and Acc at the level of 0,90 to 1,00, proved high usefulness of the decision rules generated with the rough sets, and, thereby, their applicability by manufacturing enterprises for the assessment of the Lean Maintenance effectiveness. Table 4 shows the comparison of the achieved values of the indicators used for the assessment of the classifier quality for the models obtained with decision tree (DT) and rough set theory (RST). Table 4. Comparison of the achieved values for the models obtained with the decision trees (DT) and the rough set theory (RST). Indicators Acc TPR TNR PPV NPV MCC F1 J Err FPR FDR FNR REFERENCES Antosz, K. (2018). Maintenance – identification and analysis of the competency gap. Eksploatacja i Niezawodnosc – Maintenance and Reliability, vol. 20 (3), pp. 484– 494. Antosz, K., Stadnicka, D. (2014). The results of the study concerning the identification of the activities realized in the management of the technical infrastructure in large enterprises. Eksploatacja i Niezawodnosc-Maintenance and Reliability. vol. 16 (1), pp.112-119. Bashiri, M., Badri, H., Hejazi, T.H. (2011). Selecting optimum maintenance strategy by fuzzy interactive linear assignment method. App. Math. Mod. vol. 35 (1), pp. 152164. Bayar, N., Darmoul, S., Hajri-Gabouj, S., Pierreval, H. (2016). Using immune designed ontologies to monitor disruptions in manufacturing systems. Com in Ind, vol. 81, pp. 67-81. Burduk, A., Jagodziński, M. (2015). Assessment of Production System Stability with the Use of the FMEA Analysis and Simulation Models. In: Jackowski K., Burduk R., Walkowiak K., Wozniak M., Yin H. (eds) Intelligent Data Engineering and Automated Learning – IDEAL 2015. Lecture Notes in Computer Science, vol. 9375. Springer, Cham, pp. 216-223. Carnero, M.C., Gomez, A. (2016) A multicriteria decision making approach applied to improving maintenance policies in healthcare organizations. BMC Med Inform Decis Mak, vol. 16, Springer, London. Clarke, G., Mulryan, G, Liggan P. (2010), Lean Maintenance – A Risk-Based Approach, Pharmaceutical Engineering, The Official Magazine of ISPE, 30(5), pp. 1-6. Costa E.P., Lorena A.C., Carvalho A.C.P.L.F., Freitas A.A. (2007). A review of performance evaluation measures Quantitative techniques for medical equipment maintenance management for hierarchical classifiers. Evaluation Methods for Machine Learning II: papers from the AAAI-2007 Workshop, AAAI Press, pp.182÷196. Cruz, A.M., Rincon A. M.R. (2012). Medical device maintenance outsourcing: Have operation management research and management theories forgotten the medical engineering community? A mapping review. Eur. J. Op. Res. vol. 221(1), pp. 186-197. Fawcelt T. (2006). An introduction to ROC analysis. Pattern Recognition Letters, Vol. 27(8) Elsevier, New York, pp. 861÷874. Classifier: an average OEE value Marked class 30-50% 70-85% DT RST DT RST 1,00 0,90 0,85 0,90 1,00 1,00 0,83 1,00 1,00 0,88 0,86 0,86 1,00 0,60 0,71 0,75 1,00 1,00 0,92 1,00 1,00 0,73 0,66 0,80 1,00 0,75 0,77 0,86 1,00 0,88 0,69 0,86 0,00 0,10 0,15 0,10 0,00 1,00 0,67 1,00 0,00 0,40 0,29 0,25 0,00 0,00 0,17 0,00 The indicators that achieved more favourable values were marked green. When the values achieved for particular indicators were identical, they were marked yellow. While analysing the presented results, it should be noticed that the models generated with the rough set theory achieved much better results than in decision trees. The decision rules indicated only better values for all indicators in OEE classifier for the 30-50% class. The obtained results prove the possibility to apply decision trees and the rough set theory for supporting the decision making process in Lean Maintenance management. 6. CONCLUSIONS The work presents the possibility of using intelligent systems to support decision-making processes in the Lean Maintenance management. In the work the use of artificial intelli152 2019 IFAC IMS August 12-14, 2019. Oshawa, Canada Katarzyna Antosz et al. / IFAC PapersOnLine 52-10 (2019) 148–153 Galar, D., Gustafson, A., Tormos, B., Berges, L. (2012). Maintenance decision making based on different types of data fusion, Eksploatacja i Niezawodnosc-Maintenance and Reliability, vol. 2, pp. 135-144. Gola, A. (2019). Reliability analysis of reconfigurable manufacturing system structures using computer simulation methods. Eksploatacja i Niezawodnosc – Maintenance and Reliability, 21 (1): 90–102. Gornicka, D., Burduk, A. (2018). Improvement of Production Processes with the Use of Simulation Models. in Intelligent Systems and Computing vol.657, pp. 265-274. Jamshidi, A., Rahimi, S.A., Aitkadi, D., Ruiz, A. (2015). A comprehensive fuzzy risk-based maintenance framework for prioritization of medical devices. App. Soft Comp. vol. 32, pp. 322-334. Jasiulewicz-Kaczmarek M., Saniuk, A. (2018), How to make maintenance processes more efficient using lean tools? Book Series: Advances in Intelligent Systems and Computing, , Springer, Cham, vol. 605, pp. 9 – 20. Jasiulewicz-Kaczmarek, M., Żywica P. (2018). The concept of maintenance sustainability performance assessment by integrating balanced scorecard with non-additive fuzzy integral. Eksploatacja i Niezawodnosc – Maintenance and Reliability, 20 (4): 650–661. Li, H.F., Parikh, D., He, Q., Qian, B.Y., Li, Z.G., Fang, D.P., Hampapur, A. (2014). Improving rail network velocity: A machine learning approach to predictive maintenance. Transportation Research Part C-Emerging Technologies, vol. 45, pp. 17-26. Loska A. (2013). Exploitation assessment of selected technical objects using taxonomic methods. Eksploatacja i Niezawodnosc – Maintenance and Reliability, 15(1), pp. 1-8. Pasko Ł., Setlak G. (2016). Badanie jakości predykcyjnej segmentacji rynku. Zeszyty Naukowe Politechniki Śląskiej, Seria Informatyka, 37, 1 (123): 83-97 (in polish). Sobaszek Ł., Gola A., Kozłowski E. (2017). Application of survival function in robust scheduling of production jobs, [in:] Ganzha M., Maciaszek M., Paprzycki M., Proceedings of the 2017 Federated Conference on Computer Science and Information Systems (FEDCSIS), IEEE, New York, pp. 575-578. Sokolova M., Lapalme G. (2009). A systematic analysis of performance measures for classification tasks. Information Processing and Management, Vol. 45 (4), pp. 427÷437. Szwarc E., Bocewicz G., Banaszak Z., Wikarek J. (2019) Competence allocation planning robust to unexpected staff absenteeism, Eksploatacja i Niezawodnosc - Maintenance and Reliability vol. 21(3), pp. 440-450. DOI: 10.17531/ein.2019.3.10 Taghipour, S., Banjevic, D., Jardine, A. (2011). Prioritization of medical equipment for maintenance decisions. J. Oper Res Soc, vol. 62 (9), pp. 1666–1687. Valis D., Mazurkiewicz D. (2018) Application of selected Levy processes for degradation modelling of long range mine belt using real-time data, Archives of Civil And Mechanical Engineering, vol. 18(4), pp. 1430-1440. 153 Wang, B., Furst, E., Cohen, T., Keil, O.R., Ridgway, M., Stiefel, R. (2006). Medical Equipment Management Strategies. Biom. Instr.Tech., vol. 40(3), pp.233-237. Zeineb, B. H., Malek, M., Ahmad, Al H., Ikram, K., Faouzi, M. (2017). Quantitative techniques for medical equipment maintenance management. Eur. J. of Ind. Eng., vol. 10(6), pp. 703-723. Zhaoyang, T., Jianfeng L., Zongzhi W., Jianhu Z. Weifeng H. (2011). An evaluation of maintenance strategy using risk based inspection. Saf. Sci. vol. 49 (6), pp. 852-860. 153