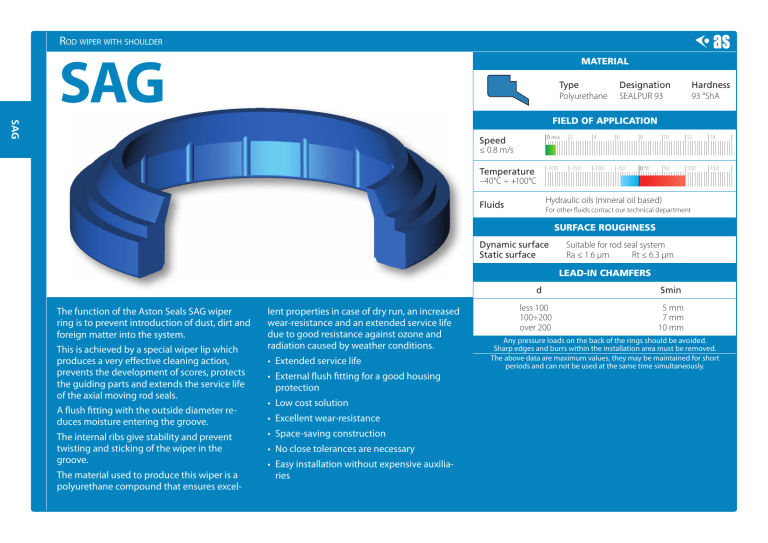

Rod wipeR with shouldeR SAG MATERIAL Type Polyurethane Designation SEALPUR 93 Hardness 93 °ShA SAG FIELD OF APPLICATION Speed ≤ 0.8 m/s 0 m/s 2 4 6 8 10 12 14 Temperature –40°C ÷ +100°C -200 -150 -100 -50 0 °C 50 100 150 Hydraulic oils (mineral oil based) Fluids For other fluids contact our technical department SURFACE ROUGHNESS Dynamic surface Static surface Suitable for rod seal system Ra ≤ 1.6 µm Rt ≤ 6.3 µm LEAD-IN CHAMFERS d The function of the Aston Seals SAG wiper ring is to prevent introduction of dust, dirt and foreign matter into the system. This is achieved by a special wiper lip which produces a very effective cleaning action, prevents the development of scores, protects the guiding parts and extends the service life of the axial moving rod seals. A flush fitting with the outside diameter reduces moisture entering the groove. The internal ribs give stability and prevent twisting and sticking of the wiper in the groove. The material used to produce this wiper is a polyurethane compound that ensures excel- lent properties in case of dry run, an increased wear-resistance and an extended service life due to good resistance against ozone and radiation caused by weather conditions. • Extended service life • External flush fitting for a good housing protection • Low cost solution • Excellent wear-resistance • Space-saving construction • No close tolerances are necessary • Easy installation without expensive auxiliaries less 100 100÷200 over 200 Smin 5 mm 7 mm 10 mm Any pressure loads on the back of the rings should be avoided. Sharp edges and burrs within the installation area must be removed. The above data are maximum values, they may be maintained for short periods and can not be used at the same time simultaneously. Rod wiper with shoulder SAG SAG Rounded and burr free r max 0.4 Part. SAG 6 SAG 7 SAG 10/A SAG 12 SAG 14/A SAG 16 SAG 16/A SAG 16/B SAG 18 SAG 20 SAG 22 SAG 24 SAG 25 SAG 25/A SAG 25/B SAG 28 SAG 30 SAG 30/A SAG 30/B SAG 32 SAG 35 SAG 36 SAG 38 SAG 40 d f7 D ±0.1 L +0.15 M H11 A ±0.1 6 7 10 12 14 16 16 16 18 20 22 24 25 25 25 28 30 30 30 32 35 36 38 40 10 11 16 20 20 24 20.7 20.7 26 28 30 32 33 33.6 31 36 38 36 47.5 40 43 44 46 48 2 2 2.6 4 2.6 4 3.7 2.2 4 4 4 4 4 5.5 2.4 4 4 4 3 4 4 4 4 4 9 10 14 18 18 22 19 19 24 26 28 30 31 31.4 29 34 36 34 45.5 38 41 42 44 46 1 1 1 1 1 1 0.8 0.8 1 1 1 1 1 4 1 1 1 1 1.5 1 1 1 1 1 r max 0.4 Part. d f7 D ±0.1 L +0.15 SAG 42 SAG 45 SAG 50 SAG 54 SAG 55 SAG 56 SAG 60 SAG 63 SAG 65 SAG 70 SAG 75 SAG 80 SAG 85 SAG 90 SAG 90/A SAG 97/B SAG 100 SAG 100/A SAG 110 SAG 110/A SAG 110/B SAG 117 SAG 118/B SAG 120 42 45 50 54 55 56 60 63 65 70 75 80 85 90 90 97 100 100 110 110 110 117 118 120 50 53 58 62 63 64 68 71 73 78 83 88 93 98 100 107 108 108 122 120 118 129 128 132 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5.5 7 4 6 5.5 5.5 4 5.5 7 5.5 M H11 A ±0.1 48 51 56 60 61 62 66 69 71 76 81 86 91 96 96 103 106 103.5 119 116 116 126 124 129 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 1 2 1.5 2 1 1.5 2 1.5 Part. d f7 D ±0.1 L +0.15 M H11 A ±0.1 SAG 120/A SAG 125 SAG 132/A SAG 137/A SAG 140/A SAG 140/B SAG 152/A SAG 172/A SAG 194/A 120 125 132 137 140 140 152 172 194 132 137 142 147 152 150 162 182 204 8.2 5.5 5.5 5.5 8.2 7 5.5 5.5 5.5 125 134 138 143 145 146 158 178 200 2.5 1.5 2 2 2.5 2 2 2 2 82.5 1.9 Inch sizes SAG 3000 76.2 86.2 3.1