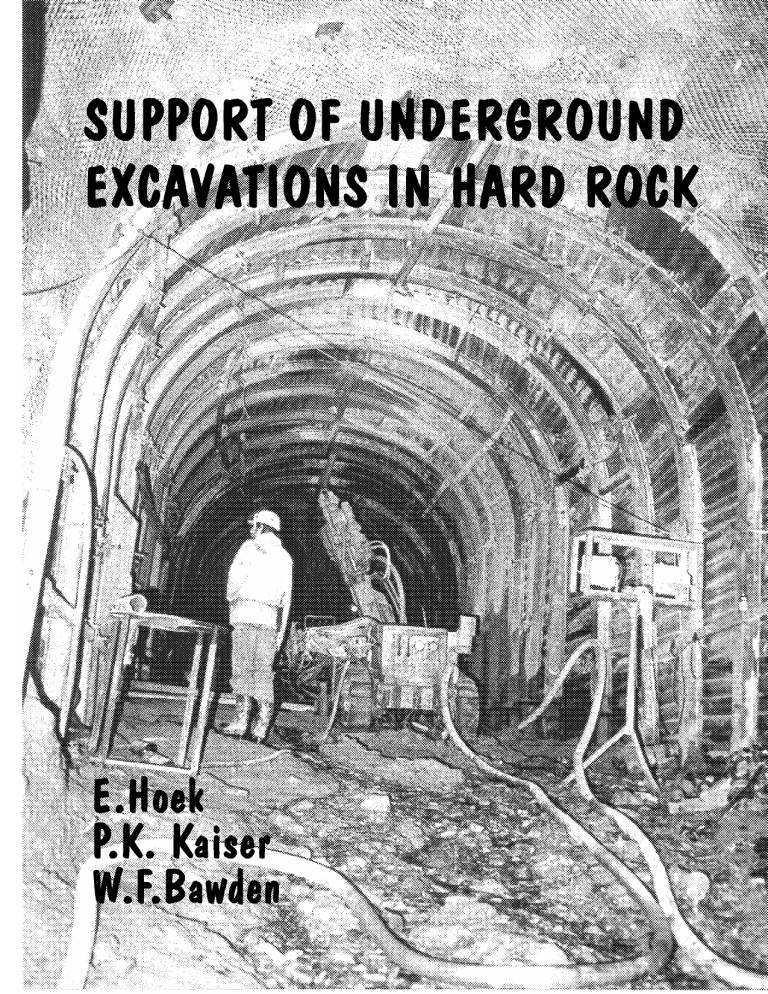

4. Support of underground excavations in hard rock, Hoek, E. ; Kaiser, P. & Bawden, W.F. (1995).

Anuncio