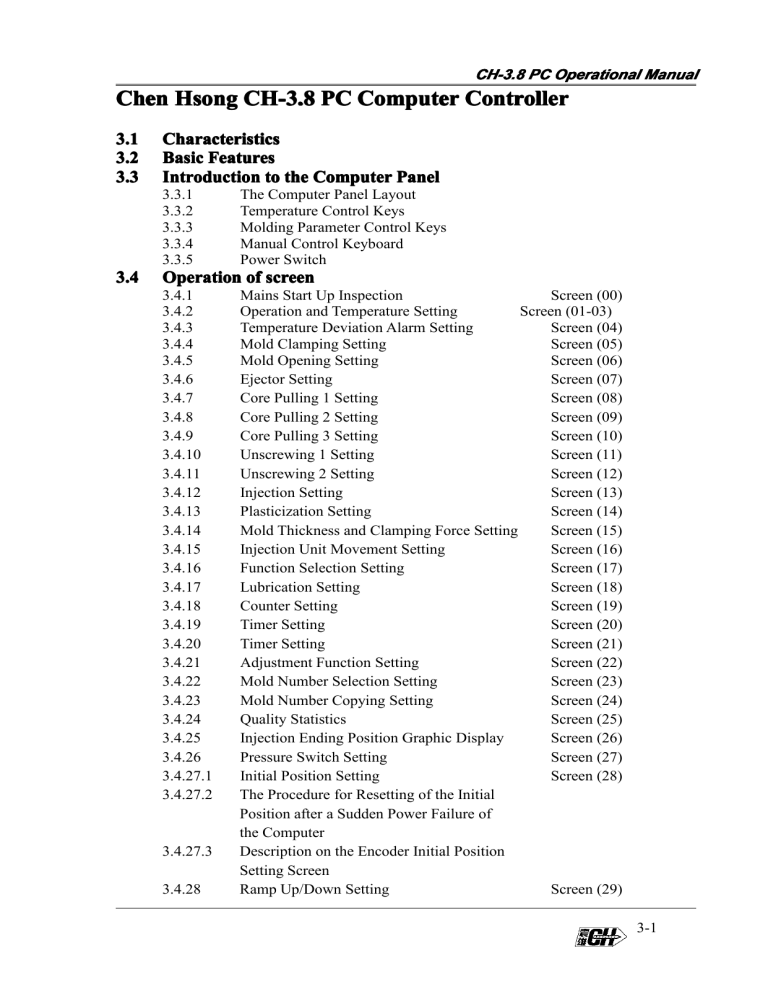

CH-3.8 PC Controller Operational Manual | Chen Hsong

Anuncio