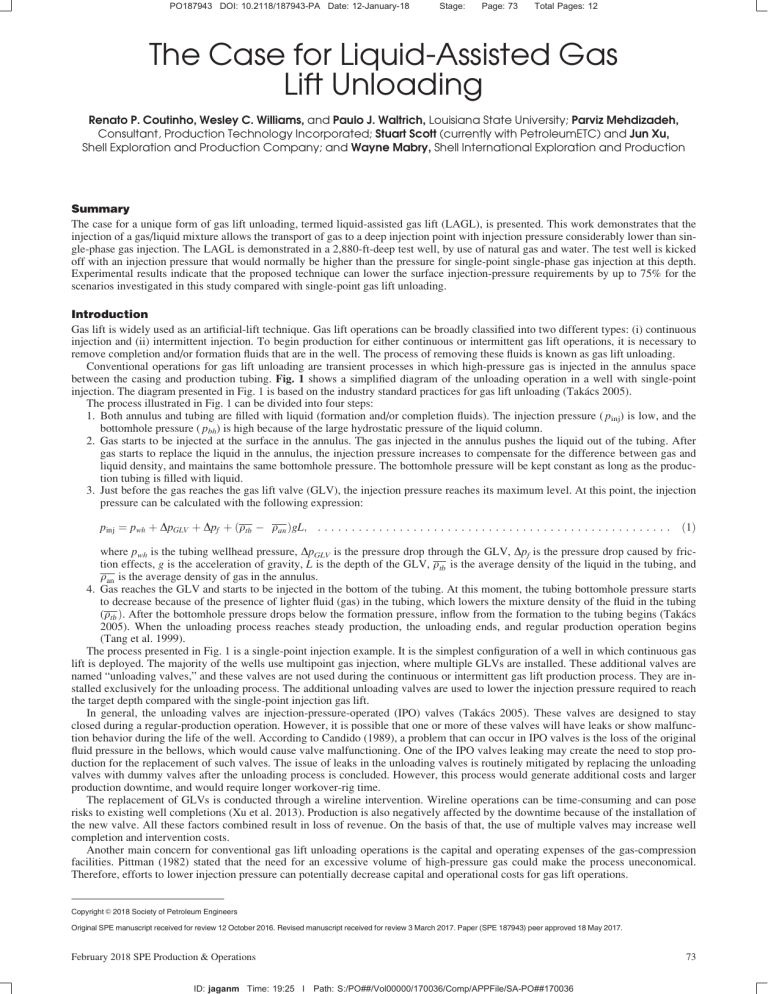

PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 73 Total Pages: 12 The Case for Liquid-Assisted Gas Lift Unloading Renato P. Coutinho, Wesley C. Williams, and Paulo J. Waltrich, Louisiana State University; Parviz Mehdizadeh, Consultant, Production Technology Incorporated; Stuart Scott (currently with PetroleumETC) and Jun Xu, Shell Exploration and Production Company; and Wayne Mabry, Shell International Exploration and Production Summary The case for a unique form of gas lift unloading, termed liquid-assisted gas lift (LAGL), is presented. This work demonstrates that the injection of a gas/liquid mixture allows the transport of gas to a deep injection point with injection pressure considerably lower than single-phase gas injection. The LAGL is demonstrated in a 2,880-ft-deep test well, by use of natural gas and water. The test well is kicked off with an injection pressure that would normally be higher than the pressure for single-point single-phase gas injection at this depth. Experimental results indicate that the proposed technique can lower the surface injection-pressure requirements by up to 75% for the scenarios investigated in this study compared with single-point gas lift unloading. Introduction Gas lift is widely used as an artificial-lift technique. Gas lift operations can be broadly classified into two different types: (i) continuous injection and (ii) intermittent injection. To begin production for either continuous or intermittent gas lift operations, it is necessary to remove completion and/or formation fluids that are in the well. The process of removing these fluids is known as gas lift unloading. Conventional operations for gas lift unloading are transient processes in which high-pressure gas is injected in the annulus space between the casing and production tubing. Fig. 1 shows a simplified diagram of the unloading operation in a well with single-point injection. The diagram presented in Fig. 1 is based on the industry standard practices for gas lift unloading (Takács 2005). The process illustrated in Fig. 1 can be divided into four steps: 1. Both annulus and tubing are filled with liquid (formation and/or completion fluids). The injection pressure ( pinj) is low, and the bottomhole pressure ( pbh) is high because of the large hydrostatic pressure of the liquid column. 2. Gas starts to be injected at the surface in the annulus. The gas injected in the annulus pushes the liquid out of the tubing. After gas starts to replace the liquid in the annulus, the injection pressure increases to compensate for the difference between gas and liquid density, and maintains the same bottomhole pressure. The bottomhole pressure will be kept constant as long as the production tubing is filled with liquid. 3. Just before the gas reaches the gas lift valve (GLV), the injection pressure reaches its maximum level. At this point, the injection pressure can be calculated with the following expression: pinj ¼ pwh þ DpGLV þ Dpf þ ðqtb qan ÞgL; . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ð1Þ where pwh is the tubing wellhead pressure, DpGLV is the pressure drop through the GLV, Dpf is the pressure drop caused by friction effects, g is the acceleration of gravity, L is the depth of the GLV, qtb is the average density of the liquid in the tubing, and qan is the average density of gas in the annulus. 4. Gas reaches the GLV and starts to be injected in the bottom of the tubing. At this moment, the tubing bottomhole pressure starts to decrease because of the presence of lighter fluid (gas) in the tubing, which lowers the mixture density of the fluid in the tubing (qtb Þ. After the bottomhole pressure drops below the formation pressure, inflow from the formation to the tubing begins (Takács 2005). When the unloading process reaches steady production, the unloading ends, and regular production operation begins (Tang et al. 1999). The process presented in Fig. 1 is a single-point injection example. It is the simplest configuration of a well in which continuous gas lift is deployed. The majority of the wells use multipoint gas injection, where multiple GLVs are installed. These additional valves are named “unloading valves,” and these valves are not used during the continuous or intermittent gas lift production process. They are installed exclusively for the unloading process. The additional unloading valves are used to lower the injection pressure required to reach the target depth compared with the single-point injection gas lift. In general, the unloading valves are injection-pressure-operated (IPO) valves (Takács 2005). These valves are designed to stay closed during a regular-production operation. However, it is possible that one or more of these valves will have leaks or show malfunction behavior during the life of the well. According to Candido (1989), a problem that can occur in IPO valves is the loss of the original fluid pressure in the bellows, which would cause valve malfunctioning. One of the IPO valves leaking may create the need to stop production for the replacement of such valves. The issue of leaks in the unloading valves is routinely mitigated by replacing the unloading valves with dummy valves after the unloading process is concluded. However, this process would generate additional costs and larger production downtime, and would require longer workover-rig time. The replacement of GLVs is conducted through a wireline intervention. Wireline operations can be time-consuming and can pose risks to existing well completions (Xu et al. 2013). Production is also negatively affected by the downtime because of the installation of the new valve. All these factors combined result in loss of revenue. On the basis of that, the use of multiple valves may increase well completion and intervention costs. Another main concern for conventional gas lift unloading operations is the capital and operating expenses of the gas-compression facilities. Pittman (1982) stated that the need for an excessive volume of high-pressure gas could make the process uneconomical. Therefore, efforts to lower injection pressure can potentially decrease capital and operational costs for gas lift operations. C 2018 Society of Petroleum Engineers Copyright V Original SPE manuscript received for review 12 October 2016. Revised manuscript received for review 3 March 2017. Paper (SPE 187943) peer approved 18 May 2017. February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 73 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 (1) (2) Stage: Page: 74 (3) Total Pages: 12 (4) Fig. 1—Gas lift unloading process for single-phase single-point injection. The use of the new LAGL concept discussed in this paper can eliminate or decrease the number of unloading valves (such as IPO valves), and also can decrease injection pressure. The LAGL Concept This paper proposes an alternative technique to perform the gas lift unloading process. In the LAGL, the injection fluid is a mixture of gas and liquid. The main objective of having the injection of a gas/liquid mixture is to increase the mixture density of the fluid in the casing annulus, which consequently decreases the necessary injection pressure for gas to reach a single GLV at the bottom of the well. Fig. 2 illustrates the unloading process for the LAGL, which uses the injection of gas and liquid (multiphase injection). This process is similar to the conventional unloading process. It can be divided into four steps: 1. Both annulus and tubing are filled with liquid (formation and/or completion fluids). The injection pressure (pinj) is low, and the bottomhole pressure (pbh) is high because of the large hydrostatic pressure of the liquid. 2. Multiphase fluid (gas/liquid mixture) is injected in the annulus, pushing part of the liquid out of the tubing. Bottomhole pressure would be the same as in Step 2 in Fig. 1. However, the injection pressure is lower than in Fig. 1 because of the higher fluidmixture density in the annulus, as a consequence of the injection of the gas/liquid mixture (see Eq. 1). 3. Gas/liquid mixture reaches the GLV and starts to flow upward in the tubing. The presence of gas in the tubing lowers the mixture density of the fluid in the tubing, which consequently decreases the bottomhole pressure. 4. After this point, the gas/liquid ratio (GLR) of the injected gas/liquid mixture is slowly increased to a point at which only gas is injected. At this moment, the LAGL unloading process ends, and the conventional gas lift process is started. (1) (2) (3) (4) (5) Multiphase injection Gas Fig. 2—Liquid-assisted gas lift unloading process. 74 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 75 Total Pages: 12 Fig. 3 presents the pressure profile during the unloading process for both conventional single-point gas lift unloading (single-phase gas) and LAGL unloading (multiphase mixture). Fig. 3 is a hypothetical example, and the parameters used to calculate the pressure gradients presented in this figure are listed in Table 1. Pressure (psi) Pressure (psi) 0 0 250 500 750 1,000 1,250 1,500 0 pwh pinj 500 pinj Gas gradient (annulus) 500 Liquid gradient (tubing) 750 1,000 1,250 1,500 pinj 500 LAGL fluid gradient (annulus) 1,000 1,000 Liquid gradient (tubing) Well Depth (ft) Well Depth (ft) 0 p 250 WH 1,500 1,500 Gas gradient (annulus) 2,000 2,000 ΔPvalve 2,500 2,500 ΔPvalve Flowing tubing pressure ΔPvalve 3,000 3,000 LAGL and single-point gas unloading Multipoint gas lift unloading Fig. 3—Schematic of the graphical valve spacing and pressure gradients. Parameter Unit Value Wellhead tubing pressure (psi) 100 Hydrostatic pressure gradient for the liquid (psi/ft) 0.433 Hydrostatic pressure gradient for the gas (psi/ft) 0.015 Pressure drop through GLV for single phase (psi) 50 Pressure drop through GLV for multiphase (psi) 150 Table 1—Parameters used in the schematic presented in Fig. 3. The pressure profile in Fig. 3a (red line) illustrates a theoretical example for the pressure profile for Step 3 of Fig. 1. The example presented in Fig. 3 assumes the geometry of the test well used in this study, as shown in Fig. 4. In addition to that, we assumed no pressure loss as a result of friction effects in the flow in the annulus and tubing, no-slip conditions between gas and liquid, using natural gas and water as working fluids, and considering gas-volume fraction for the multiphase injection fluid of 30%. In this example, the maximum required injection pressure for the LAGL method to unload the well is 600 psi. On the other hand, a pressure of 1,315 psi is required to complete the unloading process for single-point gas injection. The use of LAGL represents a reduction of more than 50% on the injection pressure compared with single-point gas injection. This simplified theoretical analysis shows that the injection of multiphase flow during the unloading process has the potential to significantly decrease the injection pressure for single-point gas lift unloading. Fig. 3b shows the unloading-valve string design for multipoint gas lift unloading. The example considers that the injection pressure available is 600 psi for the design presented in Fig. 3b. The design shows that three unloading valves are required to perform the unloading of the well with the available injection pressure. The extra valves would require additional costs. This additional cost can become higher in deep wells or in locations with lower injection pressure available. For the latter case, a larger number of unloading valves would be necessary. Multiple-point gas lift unloading is a well-developed and consolidated technique. However, in cases where technical (e.g., production of highly corrosive fluids) and economic aspects challenge the applicability of such a technique, the LAGL February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 75 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 76 Total Pages: 12 is a viable alternative to unload the well, applying low injection pressure with single-injection point. The LAGL technique also generates extra cost related to the liquid-pumping system, and, in a case-by-case economic analysis, it is needed to make the decision of which technique would be more efficient. Outflow line Gas Flare Gas injection Inflow line 2.88-in. ID Gas/liquid separator Gauge mandrel 1,648 ft Liquid Storage tanks 2,717 ft Gauge mandrel 2,728 ft 2,750 ft 5.50-in. OD 4.89-in. ID 2,788 ft 7.55-in. ID Fig. 4—Configuration of the test well used in this study. One point that requires special attention in the LAGL technique is the two-phase downward flow in the casing annulus. According to the authors’ knowledge, there are no studies in the literature about downward two-phase flow in annular pipes. Nevertheless, studies in downward two-phase flow in pipes can be found in the literature [Barnea et al. (1982a, 1982b); Hasan (1995); Hernandez et al. (2002); Almabrok et al. (2016)]. Almabrok et al. (2016) performed an extensive experimental study to characterize downward twophase flows in a 4-in.-inner-diameter (ID), 65.6-ft-long flow-loop system. In Almabrok et al. (2016), a wire-mesh sensor was used to characterize the gas/liquid void-fraction distribution. From their experimental observations, three flow regimes were defined: bubbly, intermittent, and annular. According to Barnea et al. (1982b), the most natural flow regime in downward two-phase flow in vertical pipes is the annular flow regime (falling film). Fig. 5 shows the flow-regime representation as experimentally observed by Almabrok et al. (2016). A brief description of these flow regimes is presented as follows: • Bubbly flow (Fig. 5a): Continuous downward liquid phase with dispersed gas bubbles. • Intermittent flow (Fig. 5b): As the gas velocity increases, gas bubbles coalesce into larger bubbles, which consequently increase the void fraction. The higher gas velocity creates an intermittent downward flow of large gas bubbles followed by large liquid slugs. • Annular flow (Fig. 5c): As the gas velocity increases even further, the liquid phase flows downward on the wall of the pipe as a falling film, with some liquid entrained in the downward flowing-gas core. The effectiveness of LAGL is directly related to the void fraction (a) in the two-phase flow in the annulus. Low void fraction will provide a large mixture density in the annulus (qan ¼ ql ð1 aÞ þ qg aÞ (Fig. 6b). As can be seen in Eq. 1, the larger the density in the annulus, the lower the injection pressure. It has been shown experimentally (Almabrok et al. 2016) that void fractions lower than 0.7 cannot be obtained for superficial liquid velocities lower than 1.5 ft/sec (Fig. 5b). Almabrok et al. (2016) show that the high void fractions for superficial liquid velocities lower than 1.5 ft/sec are consequences of the transition between intermittent and annular flow (falling film) regimes (Fig. 6a). Annular flow regime has the main characteristic of having high void fractions (a > 0.85). Barnea et al. (1982a) stated that the transition between intermittent flow and annular flow happens when the void fraction is higher than 0.65. In a more recent experimental work, Almabrok et al. (2016) confirmed that this transition occurs with the void fraction in the same order of magnitude as proposed by Barnea et al. (1982a). The experimental results presented by Almabrok et al. (2016) (see Fig. 6a) also indicate that if the liquid superficial velocity is lower than 1.5 ft/sec (for superficial gas velocities lower than 6 ft/sec), they observe annular flow regime in their experiments. For superficial gas velocities higher than 6 ft/sec, the transition between intermittent and annular flows seems to follow a straight line for the superficial velocities ratio of usg/usl ¼ 5 (or qg/ql ¼ 5). Testing the Multiphase Gas Lift Concept With a Field-Scale Test Well The concept of LAGL is validated in this study with a 2,788-ft-deep test well, at the Petroleum Engineering Research and Technology Transfer Laboratory (PERTT laboratory) at Louisiana State University. Field-Scale Test Well. The well configuration is presented in Fig. 4. This test well includes a 5.50-in.-outer-diameter (OD) and a 4.89in.-ID inner casing, and a 2.88-in.-OD and 2.00-in.-ID production tubing. A GLV mandrel is installed in the tubing at the depth of 2,717 ft, with a 44/64-in.-port-size orifice GLV. 76 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 Stage: Page: 77 Total Pages: 12 Flow direction PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 (a) Bubbly (b) Intermittent (c) Annular (falling film) ly bb Bu Void Fraction (%) usl (ft/sec) Intermittent 1.0 Annular 0.1 100 50 80 40 usl = 3.28 ft/sec usl = 1.57 ft/sec usl = 0.23 ft/sec 60 40 1.0 10.0 usg (ft/sec) (a) Flow-regimes map 20 10 20 0 0 0.1 30 Avarage Mixture Density (lb/ft3) Fig. 5—Flow regimes for downward two-phase flow in vertical pipes that are based on the experimental observations of Almabrok et al. (2016). 0 50 100 usg (ft/sec) (b) Effect of the superficial gas and liquid velocities on the void fraction Fig. 6—Flow-regimes map and effect of the superficial gas and liquid velocities on the void fraction for downward two-phase flow in a 4-in.-ID vertical pipe [modified from Almabrok et al. (2016)]. The well is equipped with temperature and pressure transducers at two different depths (1,648 and 2,728 ft) in both inner-casing and tubing sections. Pressure and temperature were also measured in the gas-injection line and in the outflow line at the surface. The waterflow rate injected in the well was measured with a magnetic flowmeter, and the gas-flow rate injected was measured with an orificeplate flowmeter. The fluids used in the experiments were natural gas and water. After water and natural-gas flow through the well, these fluids were separated downstream to the outflow line in a vertical separator. The natural gas was vented out to the flare, and the water was recirculated to the storage tank. Experimental Procedure. Two different sets of experiments were run in this study to evaluate the efficiency of the LAGL in field conditions. 1. The first set of experiments has the objective to characterize the flow of single-phase water through the test-well system. Tests with water would enable the evaluation of the pressure drop caused by friction in the GLV and flow through annulus and tubing (DpGLV and Dpf in Eq. 1). For the single-phase-flow experiments, the entire well (outer casing, inner casing, and tubing) is filled with water. In these experiments, seven different water-flow rates [44, 49, 55, 65, 69, 89, and 105 gal/min (gpm)] are injected in the inner casing by use of the gas-injection line. The water flows through the inner casing, through the orifice GLV, upward in the tubing and through the separator, and then returns to the water-storage tanks. 2. The second set of the experiments carried out had the objective of evaluating if the LAGL (e.g., injection of gas/liquid mixtures) is expected to lower the injection pressure during the unloading operation. For each experiment, the entire well was initially filled with water (to simulate formation or completion fluids). The inflow line was kept closed during the experiment, and the gas-injection line was used to inject the gas/liquid mixture in the inner annulus. The outflow line is connected to the gas/liquid separator. For each experiment, constant actual flow rates (e.g., flow rates at pressure and temperature of the injection lines) of water and natural gas are injected in the inner casing. The experimental-test matrix is presented in Table 2. All tests ended when the gas/liquid mixture reached the GLV at the bottom of the well. The tests are ended at this stage because the time that the gas/liquid mixture reaches the GLV is the time when the injection pressure should be the highest during the unloading process. February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 77 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 qg (acfd**) qg (agpm*) Case Number Total Pages: 12 qg,min (Mscf/D) qw (gpm) 34 11 20 29 11 30 35 12 40 2 5 Page: 78 qg,max (Mscf/D) 1 3 Stage: 962 4 25 15 50 5 31 12 60 6 120 11 20 7 70 40 40 8 48 11 45 9 60 15 50 10 53 15 55 10 1,925 11 72 25 60 12 294 70 20 274 80 30 13 20 14 2,887 229 60 40 15 209 60 50 16 271 90 70 *agpm = actual*** gallons per minute **acfd = actual cubic feet per day ***Actual flow rate is the actual volume of fluid at a specific in-situ conditions (pressure and temperature of the process). Table 2—Test matrix for well tests to evaluate the efficiency of the LAGL concept. Well-Test Results System Characterization for Single-Phase Water. The first component of the system that is analyzed with the single-phase-flow tests is the pressure drop through the GLV. Fig. 7 shows the experimental data for the pressure drop through the GLV for different waterflow rates being injected in the well. The pressure drop across the GLV was obtained by the subtraction of the pressure at the bottom of the inner casing (absolute pressure transducer that is 2,728-ft-deep in the inner casing) and the pressure at the bottom of the tubing (absolute pressure transducer that is 2,728-ft-deep in the tubing), as shown for the gauge mandrel in Fig. 4. In addition to that, Fig. 7 also shows the experimental-measurement uncertainty (uncertainty bars), on the basis of the accuracy of the pressure transducers used in the experiment. Differential Pressure (psi) 750 600 450 300 150 0 0 20 40 60 80 100 120 qw (gpm) Fig. 7—Differential pressure as a function of water-flow rate through the GLV. The error bars represent the measurement uncertainties. As noted in Fig. 7, the pressure drop increases for larger water-flow rates. These results are in accordance with other studies in the literature (Surbey et al. 1989). The downward flow in the annulus is another important part of the system that has to be analyzed, because it significantly affects the injection pressure. Fig. 8 shows the experimental results for the total pressure drop in the downward water flow through the annulus, and through the GLV. The results presented in Fig. 8 show the contribution to the total pressure drop from the pressure drop through the GLV, hydrostatic effects, and friction effects. The total pressure drop can be obtained by the sum of these three components. As can be seen in Fig. 8, for the single-phase water-flow test in the well, the hydrostatic effect accounts for more than 90% of the pressure change for the flow in the casing annulus. The friction loss is smaller for lower water-flow rates, and it increases for larger 78 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 79 Total Pages: 12 water-flow rates. However, even for the higher flow rates tested, the friction effects in the annulus and tubing are negligible compared with the hydrostatic effects. It also can be seen in Fig. 8 that the single-phase water flow through the GLV has a relevant contribution to the total pressure drop. This contribution is negligible for low water rates, but it becomes significant for high water-flow rates. –1,200 900 –900 Δp (Total) Δp (Hydro) 600 –600 Δp (Friction) Δp (GLV) 300 –300 0 Δp (Friction) and Δp (GLV) (psi) Δp (Total) and Δp (Hydro) (psi) 1,200 0 0 20 40 60 80 100 qw (bpm) Fig. 8—Pressure drop for the downward flow and flow through the GLV. Proof of Concept With a Field-Scale Test Well. To analyze the applicability of LAGL for unloading operations, a series of experiments was conducted with the test well in Fig. 5. The main objective behind the concept of LAGL is to decrease the injection pressure by injecting a gas/liquid mixture rather than single-phase gas (conventional gas lift concept). Fig. 9 shows the relationship of the injection pressure as a function of time for six combinations of gas and water flow rates, while using the concept of LAGL. Fig. 9 shows the results for two constant water-flow rates of 50 and 40 gpm, and for three different gas-flow rates: 5, 10, and 20 actual gpm (agpm). As can be seen in Fig. 9, at the beginning of each experiment, the injection pressure is constant. During the period of constant injection pressure, only water is injected, and the water-flow rate is kept constant. This initial single-phase water injection is important to guarantee that no trapped gas is in the well. After this initial period of single-phase water injection, gas injection starts. After gas starts to be injected into the well, the injection pressure starts to increase because of a decrease in the mixture density in the annulus (see Eq. 1). During the entire experiment, the actual gas- and water-flow rates are kept constant. The injection pressure keeps increasing as the gas phase goes deeper in the well, up to a point in time when the gas phase reaches the GLV and enters the tubing. When the gas phase reaches the GLV, it starts flowing upward through the tubing, and consequently, the injection pressure starts to decrease (gas in the tubing lowers the mixture density of the fluid in the tubing, which consequently decreases the injection pressure; see Eq. 1). At this point, the experiment is ended. The main result obtained in each experiment is the maximum injection pressure (pinj,max). Graphically, pinj,max can be identified by the inflection point toward the end of the test. Some experiments have a time interval with no data (e.g., Fig. 9c). The missing data were caused by a malfunctioning in the data-acquisition system during a small time interval. However, the missing data do not affect the main objective of the test, which is to obtain the pinj,max experimental value. The GLR of the injection fluid increases from Fig. 9a to Fig. 9c. The analysis of these three figures indicates that, during the unloading process, higher GLR for the injection fluid would increase the injection pressure. For a lower water-flow-rate injection (40 gpm), the same analysis can be obtained from Fig. 9d through Fig. 9f. Fig. 10 shows the volume of water injected, removed, and unloaded (e.g., the difference between the removed and injected amount) from the well as a function of time for three combinations of water- and gas-flow rates. The time zero in Fig. 10 represents the moment when the gas and water started to be injected into the well. These experimental results are plotted to times until the maximum injection pressure is reached. As can be seen in all three plots in Fig. 10, the volume of water removed (red dotted line) presents values always higher than the injected water volume (blue dashed line). It indicates that the volume of water that was originally in the well is unloaded (the difference between the volume removed and injected), because the unloaded water values are always positive for all three cases. For Fig. 10a (qw ¼ 50 gpm and qg ¼ 5 agpm), the unloaded volume is approximately 330 gal, whereas, for Figs. 10b and 10c, the values are approximately 320 and 710, respectively. The volumes of unloaded water in Fig. 10 indicate the effectiveness of the LAGL unloading process. Fig. 11 shows the experimental results for the maximum injection pressure as a function of the water-flow rate for a constant gasflow rate of 20 agpm. As can be seen from this figure, high maximum injection pressure is observed for low and high water rates, but it shows a point of minimum injection pressure for intermediate water-flow rates. This behavior on the maximum injection pressure can be explained with Eq. 1 and the experimental results from Bhagwat and Ghajar (2012). For lower water-flow rates (labeled as hydrostatically dominated flows in Fig. 11), void fraction in the casing annulus decreases as water-flow rates are raised, as a result of an increase in the fluid-mixture density. Eq. 1 shows that higher fluid-mixture density in the annulus will decrease injection pressure, if the friction terms are not significantly affected by the flow-rate changes. Bhagwat and Ghajar (2012) show that void fraction increases exponentially with slip ratio (usg/usl or qg/ql) for downward two-phase flows. However, as the water-flow rate keeps increasing (for a constant gas rate), friction effects start to become dominant in Eq. 1, and the injection pressure starts to increase for larger water-flow rates. For water-flow rates larger than approximately 50 gpm in Fig. 11, the pressure drop caused by friction is dominated by the pressure drop through the GLV. The friction pressure drop caused by the flow through the casing annulus is negligible for the conditions tested in this study (see Fig. 8). Fig. 12 presents the maximum injection pressure as a function of the water-injection rate for all cases tested. This figure presents the experimental results for three gas-injection flow rates (5, 10, and 20 agpm). The experimental results for all multiphase-injection curves have their profiles similar to the one presented in Fig. 11. For the three gas rates that are tested in this study, the water-injection rate that provides the minimum injection pressure (optimal-injection interval) is within the range of water-flow rate between 40 and 55 gpm. February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 79 800 700 700 600 500 400 pinj,max 300 200 100 Gas injection started 0 1,500 3,000 400 pinj,max 300 200 100 Gas injection started 4,500 0 2,000 Time (seconds) (a) qw = 50 gpm and qg = 5 agpm (d) qw =40 gpm and qg = 5 agpm 700 Injection Pressure (psi) 700 600 500 pinj,max 300 200 600 pinj,max 400 300 200 Gas injection started 0 0 1,500 3,000 4,500 0 1,250 Time (seconds) 2,500 3,750 Time (seconds) (b) qw = 50 gpm and qg = 10 agpm (e) qw = 40 gpm and qg = 10 agpm 800 pinj,max 700 pinj,max 700 Gas injection started Injection Pressure (psi) Injection Pressure (psi) 6,000 500 100 Gas injection started 0 800 4,000 Time (seconds) 800 100 Total Pages: 12 500 800 400 Page: 80 600 0 0 Injection Pressure (psi) Stage: 800 Injection Pressure (psi) Injection Pressure (psi) PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 600 500 400 300 200 Missing 100 experimental data 0 0 1,000 600 500 400 300 200 100 Gas injection started 0 2,000 Time (seconds) (c) qw = 50 gpm and qg = 20 agpm 3,000 0 1,000 2,000 3,000 Time (seconds) (f) qw = 40 gpm and qg = 20 agpm Fig. 9—Injection pressure as a function of time for water-and-gas injection rates at line (actual) condition. These figures show the relationship of the injection pressure as a function of time for six combinations of gas- and water-flow rates while using the concept of LAGL. The increase in the maximum injection pressure caused by lower fluid-mixture densities in the annulus can also be seen in Fig. 12, as the gas rate is increased. At a constant water-flow rate, the maximum injection pressure increases as the gas-flow rate increases. This behavior is a consequence of the change in the hydrostatic-pressure effects, which are predominant at low water-flow rates. When water-flow rates are higher than the optimal injection flow rates, the friction effects are predominant. Thus, higher gas-flow rates would create a larger frictional pressure drop. The major contribution for the total pressure drop caused by friction is a consequence of the flow through the GLV (see Fig. 8). The results presented in Fig. 12 can also be seen in Table 3. The values for standard gas-flow rate at injection-pressure condition are also presented in Table 3. One major conclusion from this analysis is that there is a narrow range for the water-flow rate required to obtain the optimal injection pressure. This narrow range for liquid-injection rates may increase the challenge for field application of the LAGL concept, because the liquid-flow rate would have to be monitored and controlled within a narrow margin to effectively deploy this technique in the field. Also, reliable simulation models would be recommended to optimize the application of this concept. Fig. 13 presents the calculated horsepower required to compress the gas and to pump the water for single-phase gas injection and LAGL. The power requirement for both techniques is evaluated as a function of the gas-flow rate. Two curves are presented for each 80 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 81 Total Pages: 12 plot: The red-dotted curve represents the power requirement for injection of single-phase gas (no liquid injected), and the blue-dashed curve represents the power requirement for the injection of liquid and gas. The liquid-injection flow rate selected (ql ¼ 50 gpm) is based on the optimal liquid-injection interval that is shown in Fig. 12. The injection pressure is 1,300 psi for the single-phase case (gl ¼ 0 gpm) in both plots in Fig. 13, which is the maximum-injection pressure required for the single-point gas injection during the unloading operation. For the LAGL case (ql ¼ 50 gpm), two different injection pressures are plotted: Fig. 13a shows the results for an injection pressure of 300 psi, and Fig. 13b shows the results for an injection pressure of 700 psi. 3,000 Water volume in (gallons) Water volume out (gallons) Unloaded water (gallons) Volume (gallons) Volume (gallons) 3,000 2,000 1,000 Water volume in (gallons) Water volume out (gallons) Unloaded water (gallons) 2,000 1,000 0 0 0 1,000 2,000 3,000 0 500 1,000 Time (seconds) 1,500 2,000 2,500 Time (seconds) (a) qw = 50 gpm and qg = 5 agpm (b) qw = 50 gpm and qg = 10 agpm Volume (gallons) 3,000 Water volume in (gallons) Water volume out (gallons) Unloaded water (gallons) 2,500 2,000 1,500 1,000 500 0 0 500 1,000 1,500 2,000 2,500 Time (seconds) (c) qw = 50 gpm and qg = 20 agpm Fig. 10—Experimental water volume injected, removed, and unloaded as a function of time, for three combinations of gas- and water-flow rates while using the concept of LAGL. 1,000 qg = 20 agpm pinj,max (psi) 900 800 Hydrostatically Friction 700 Optimal injection 600 500 10 20 30 40 50 60 70 80 qw (gpm) Fig. 11—Maximum injection pressure as a function of water-flow rate for gas-injection rate qg 5 20 agpm. The results presented in Fig. 13a show that, for gas-flow rates higher than 0.1 MMscf/D, the use of the LAGL would require lower horsepower than single-phase single-point gas injection. If the injection pressure for the LAGL is 700 psi (Fig. 13b), the LAGL would require lower horsepower for gas-flow rates higher than 0.25 MMscf/D. Thus, Fig. 13 shows that the use of the LAGL is thermodynamically more efficient than the single-phase single-point injection in conditions that require high gas-flow rates. For example, to minimize the injection pressure during the unloading for the case of Fig. 11, the experimental results in this figure show that the optimal liquid- and gas-flow-rate injection are 50 gpm and 0.2 MMscf/D, respectively. The maximum injection pressure for this case is approximately 700 psi. After comparing the experimental results in in Fig. 11 with the plot presented in Fig. 13b, it can be concluded that the LAGL technique requires slightly higher horsepower than the conventional single-point injection for this particular case. However, the injection pressure is lower for the LAGL than the pressure required for single-phase single-point injection to unload the well. It is important to notice that, although the horsepower requirement for the case in Fig. 11 is higher for the LAGL than February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 81 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 82 Total Pages: 12 for single-phase gas injection, the maximum injection pressure is still lower for the LAGL. These results clearly show that the use of LAGL is not always beneficial. However, the use of the LAGL can allow the well unloading with a compressor with lower pressure specifications. In fact, the gas compressor available in the facility in which the well tests were carried out for this study would only be able to unload the well with the LAGL technique, because the maximum working for this compressor was 1,000 psi. Exp qg = 5 agpm Exp qg = 10 agpm Exp qg = 20 agpm Pinj,max (psi) interval 900 injection Optimal 1,200 600 300 0 0 10 20 30 40 50 60 70 80 90 qw (gpm) Fig. 12—Maximum injection pressure as a function of water-flow rate for different gas-injection rates. qg (agpm) Case Number qw (gpm) qg (Mscf/D at pinj,max) pinj,max (psi) 1 20 34 454 2 30 29 379 40 35 268 5 3 4 50 25 328 5 60 31 378 6 20 120 742 7 40 70 531 45 48 342 8 10 9 50 60 449 10 55 53 372 11 60 72 501 12 20 294 979 13 30 274 875 40 229 758 15 50 209 728 16 70 271 902 20 14 Table 3—Actual gas- and liquid-flow rates, standard gas-flow rate at maximum injection pressure. The lines highlighted in red indicate the conditions for the tests that show the lowest injection pressure for a constant water-flow rate. 600 400 300 400 Lower HP for gas injection 300 200 200 100 100 Lower HP for LAGL 0 0.10 0.25 0.50 ql (gpm) 0 ql (gpm) 50 500 Horsepower 500 Horsepower 600 ql (gpm) 0 ql (gpm) 50 Lower HP for LAGL 0 0.75 1.00 qg (MMscf/D) (a) LAGL injection pressure: 300 psi 1.25 0.10 0.25 0.50 0.75 1.00 1.25 qg (MMscf/D) (b) LAGL injection pressure: 700 psi Fig. 13—Total horsepower (gas compressor 1 liquid pump) for combinations of liquid-flow rates (ql in gpm) and gas-flow rates (qg in MMscf/D). Single-phase gas-injection pressure is 1,300 psi. 82 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 83 Total Pages: 12 Conclusions This paper presented a new technique for gas lift unloading operations, termed in this study as LAGL. The main idea behind this new concept is to inject a gas/liquid mixture during the unloading process to lower injection pressure, and then to enable the use of a single gas lift valve at the bottom of the well, while reducing compression and GLV replacement costs. Conventional gas lift unloading operations use multiple valves and injection of single-phase gas. The use of single GLVs during unloading operations would decrease the number of potential leak points between casing and production tubing, by eliminating the multiple gas lift valves required on conventional unloading processes. The concept of LAGL was tested in this study with a field-scale test well. This well has a vertical depth of 2,880 ft. The working fluids used during the experimental tests are natural gas and water. The experimental results show that the injection pressure can be decreased significantly during unloading operations with the LAGL technique. The use of the LAGL technique can enable the reduction of the injection pressure from 1,200 psi (when injecting single-phase gas) to approximately 300 psi (when injecting gas/liquid mixtures). Field trials are still needed to truly prove the concept. The experimental results also show that the injection pressure is only reduced significantly for gas-/liquid-flow-rate ratios (qg/ql) lower than 2. For gas-/liquid-flow-rate ratios higher than 2, there is the appearance of the annular flow regime (falling liquid film) in the downward two-phase flow in the casing annulus, which generates high-void-fraction flow in the annulus. As a consequence of the high void fraction in the annulus, the fluid-mixture density is decreased, and larger injection pressures are required during the unloading process. These results are also supported by other studies in the literature about downward two-phase flow in vertical pipes. The main idea behind the concept of LAGL is to increase the mixture-fluid density in the annulus to enable lower injection pressures. For a better understanding of the flow behavior in the different components behind the LAGL, here it is suggested to investigate the following topics: downward two-phase flow in annulus (e.g., flow-regime maps and gas/liquid slippage), two-phase flow through gas lift valves (performance curves and erosion), and full simulation of the LAGL unloading process. For this purpose, a state-of-the-art flow loop has been built at Louisiana State University, and tests are currently being performed to investigate the effect of erosion caused by multiphase flow in gas lift valves, and to evaluate the performance of gas lift valves with different orifice sizes when submitted to two-phase flows. Nomenclature g ¼ acceleration of gravity, ft/sec2 L ¼ depth, ft pbh ¼ bottomhole pressure, psi pinj ¼ injection pressure, psi pinj,max ¼ maximum injection pressure, psi pwh ¼ wellhead pressure, psi qg ¼ gas-flow rate, gpm ql ¼ liquid-flow rate, gpm qw ¼ water-flow rate, gpm S ¼ slip ratio ug ¼ gas velocity, ft/sec ul ¼ liquid velocity, ft/sec usg ¼ gas superficial velocity, ft/sec usl ¼ liquid superficial velocity, ft/sec a ¼ void fraction, % Dpf ¼ pressure drop caused by friction, psi DpGLV ¼ pressure drop through the GLV, psi qan ¼ average density of gas in the annulus, lbm/ft3 qg ¼ gas density, lbm/ft3 ql ¼ liquid density, lbm/ft3 qtb ¼ average density of the liquid in the tubing, lbm/ft3 Acknowledgments The authors acknowledge the support of Shell Exploration and Production Company (SEPCo)– USA. The authors wish to thank Patrick Brady at SNL for discussions on experimental tracer studies in the published literature. References Almabrok, A. A., Aliyu, A. M., Lao, L. et al. 2016. Gas/Liquid Flow Behaviours in a Downward Section of Large-Diameter Vertical Serpentine Pipes. International Journal of Multiphase Flow 78: 2543. https://doi.org/10.1016/j.ijmultiphaseflow.2015.09.012. Barnea, D., Shoham, O., and Taitel, Y. 1982a. Flow-Pattern Transition for Downward Inclined Two-Phase Flow; Horizontal to Vertical. Chemical Engineering Science 37 (5): 735–740. https://doi.org/10.1016/0009-2509(82)85033-1. Barnea, D., Shoham, O., and Taitel, Y. 1982b. Flow-Pattern Transition for Vertical Downward Two-Phase Flow. Chemical Engineering Science 37 (5): 741–744. https://doi.org/10.1016/0009-2509(82)85034-3. Bhagwat, S. M. and Ghajar, A. J. 2012. Similarities and Differences in the Flow Patterns and Void Fraction in Vertical Upward and Downward TwoPhase Flow. Experimental Thermal and Fluid Science 39: 213–227. https://doi.org/10.1016/j.expthermflusci.2012.01.026. Candido, S. F. 1989. Offshore Production Systems in Deep Waters: Artificial Lift Methods and Flow Lines Design. Master’s thesis, Campinas State University (UNICAMP), Campinas, Brazil (May 1989). Hasan, A. R. 1995. Void Fraction in Bubbly and Slug Flow in Downward Two-Phase Flow in Vertical and Inclined Wellbores. SPE Prod & Fac 10 (3): 172–176. 5. SPE-26522-PA. https://doi.org/10.2118/26522-PA. Hernandez, A., Gonzalez, L., and Gonzalez, P. 2002. Experimental Research on Downward Two-Phase Flow. Presented at the SPE Annual Technical Conference and Exhibition, San Antonio, Texas, USA, 29 September–2 October. SPE-77504-MS. https://doi.org/10.2118/77504-MS. Pittman, R. W. 1982. Gas-Lift Design and Performance. Presented at the International Petroleum Exhibition and Technical Symposium, Beijing, China, 17–24 March. SPE-9981-MS. https://doi.org/10.2118/9981-MS. February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036 83 PO187943 DOI: 10.2118/187943-PA Date: 12-January-18 Stage: Page: 84 Total Pages: 12 Surbey, D. W., Kelkar, B. G., and Brill, J. P. 1989. Study of Multiphase Critical Flow Through Wellhead Chokes. SPE Res Eng 4 (2): 142–146. SPE15140-PA. https://doi.org/10.2118/15140-PA. Takács, G. 2005. Gas-Lift Manual. Tulsa, Oklahoma: PennWell (Reprint). Tang, Y., Schmidt, Z., Blais, R. N. et al. 1999. Transient Dynamic Characteristics of the Gas-Lift Unloading Process. SPE J. 4 (3): 268–278. SPE57659-PA. https://doi.org/10.2118/57659-PA. Xu, Z., Richard, B. M., and Kritzler, J. H. 2013. Smart Gas-Lift Valves Enhance Operation Efficiency of Offshore Wells. Presented at the SPE Annual Technical Conference and Exhibition, New Orleans, 30 September–2 October. SPE-166291-MS. https://doi.org/10.2118/166291-MS. SI Conversion Factors bbl 1.589873 ft 3.048* ft/sec 3.048 ft/sec2 3.048 ft3 2.83168 gal/min 2.27125 in. 2.54* lbm/ft3 1.60185 psi 6.894757 E01 ¼ m3 E01 ¼ m E01 ¼ m/s E01 ¼ m/s2 E02 ¼ m3 E01 ¼ m3/h Eþ00 ¼ cm Eþ01 ¼ kg/m3 Eþ00 ¼ kPa *Conversion factor is exact. Renato P. Coutinho is a research assistant and PhD-degree candidate in the Petroleum Engineering Department at Louisiana State University. Previously, he worked for 3 years as an assistant professor at the Center of Technological Education, Brazil, and was also a graduate research fellow sponsored by the National Petroleum Institute, Brazil, for 5 years. Coutinho’s research interests include multiphase-flow characterization, flow assurance, gas lift technologies, and production optimization. He has authored or coauthored more than 15 technical papers. Coutinho holds an MS degree in transportation engineering with a minor in petroleum engineering and a BS degree in chemical engineering, all from the Federal University of Ceara, Brazil. He is a member of SPE. Wesley C. Williams is a professional in residence at Louisiana State University. His research interests include wellbore hydraulics, fluid properties, and operational safety. Williams has authored or coauthored more than 30 technical papers and reports. He holds a doctorate degree in nuclear science and engineering from the Massachusetts Institute of Technology. Williams is a member of SPE. Paulo J. Waltrich is an assistant professor at Louisiana State University in the Craft & Hawkins Department of Petroleum Engineering. Previously, he worked at Whirlpool Corporation (in Brazil) in the Corporate Innovation and Technology division on the design and testing of innovative refrigeration systems, and at Petrobras America in flow-assurance assignments for a deepwater field in the Gulf of Mexico. Waltrich’s research interests include multiphase flow in pipes, artificial-lift systems, liquid loading in gas wells, worst-case-discharge calculations, flow assurance, and managed-pressure drilling. He has authored or coauthored more than 35 technical papers and holds one US patent. Waltrich holds BS and MS degrees in mechanical engineering from Federal University of Santa Catarina, and a PhD degree in petroleum engineering from Texas A&M University. He is a member of SPE and the American Society of Mechanical Engineers (ASME), and is an associate editor for the journal Multiphase Technology and Science. Parviz Mehdizadeh has been in the consulting practice since 1996. Previously, he worked at Conoco from 1962 to 1993. From 1989 to 1993, Mehdizadeh directed the development and testing of multiphase and water-cut meters for application to new asset developments within Conoco. He also directed the construction of the Conoco multiphase field-test facility in Lafayette, Louisiana, USA. For the next 15 years, Mehdizadeh was involved in field installations and performance testing of multiphase and conventional well-testing systems in various locations around the world. He holds a BS degree in physics, an MS degree in metallurgical engineering, and a PhD degree in chemical engineering and material science, all from the University of Oklahoma. Mehdizadeh served as the chair of the SPE 2004 Well Operations Program Subcommittee. Stuart L. Scott is the Director of Technology at Petroleum Emerging Technology Corporation (PetroleumETC). Previously, he worked at Shell E&P Company. From 2008 to 2016, Scott managed Shell’s deepwater artificial-lift technology program, and served for several years as Shell’s global artificial-lift/pumping principal technical expert. Before joining Shell, he held the Bethancourt Professorship of Petroleum Engineering at Texas A&M University, was a faculty member at Louisiana State University, and worked for Phillips Petroleum Company in a variety of roles. Scott holds a BS degree in petroleum engineering, an MS degree in computer science, and a PhD degree in petroleum engineering from the University of Tulsa. He is a Fellow of ASME, and holds the ASME Henry R. Worthington Medal for “eminent achievement in the evolving field of multiphase pumping.” Scott is a Distinguished Member of SPE. Jun Xu joined Shell in 2006 after working for Lufkin Automation, now a GE company. He was a production technologist working on the Artificial Lift Team in Shell P&T in Houston for 7 years before joining the Shell Unconventional Technology Excellence and Deployment Team in 2013. Xu has 25 years of experience in oil and gas, specializing in artificial-lift and gas-well deliquification. His research interests are focused on artificial-lift technology development and deployment; production-system optimization; and artificial-lift selection, design, modeling, and failure analysis. Xu holds a PhD degree in petroleum engineering from the University of Tulsa. He is a member of SPE. Wayne J. Mabry has been the Artificial Lift Team Lead at Shell International Exploration and Production, Houston, for 7 years. Previously, he worked at Schlumberger-Camco as the Gas Lift Business Development Manager, among other positions, for 18 years in the gas lift portion of the business. Mabry has been involved in development of American Petroleum Institute (API) and International Organization for Standardization (ISO) gas lift standards since 1984, and is currently the chairperson of API Subcommittee 19 (production equipment) and API Task Group 19G (gas lift equipment). He holds a BS degree in mechanical engineering from Texas A&M University. Mabry has been an SPE member since 1982 and is an SPE Life Member. 84 February 2018 SPE Production & Operations ID: jaganm Time: 19:25 I Path: S:/PO##/Vol00000/170036/Comp/APPFile/SA-PO##170036