![10995 Technical Manual[031-060]](http://s2.studylib.es/store/data/008965585_1-ffd92ad6bfefaba79e8f4f2b9b762c4c-768x994.png)

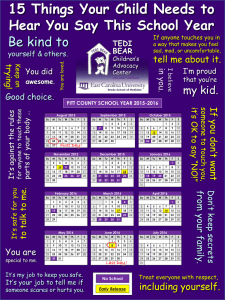

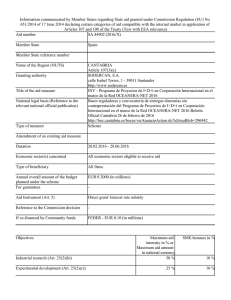

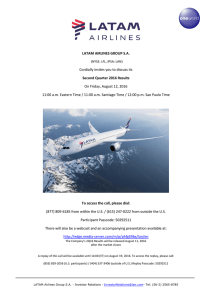

System description Switch cabinet Part No. 015157 For details see electrical diagram Weight Dimensions (W x H x D) ~ 56 kg ~ 600 x 600 x 250 mm General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 UV-disinfection plant For details see 4.4.3 "UV-disinfection plant (A-1-C-180)" on page 31 and orderspecific documentation in chapter „Components“. Empty weight ~ 3,5 kg Length ~ 928 mm Feeding pump (A-1-P-050) For details see order-specific documentation. Exemplary illustration: CONSUMPTION FLOCCULANT The consumption of flocculant amounts to ~ 40 ml/h at nominal load. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 21 (42) System description AMBIENT CONDITIONS The plant is designed for operation • • • in shipping routes with seawater, freshwater and brackish water at a max. ambient temperature of 55° C (+131° F) and 90% relative humidity Roll- and pitch angle up to 22.5° The HL-Cont PLUS 0125 plant may not be used in flammable and explosive atmosphere and areas! PLANT CAPACITY/DESIGN General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 The sewage treatment plant is intended to treat 3000 Liters of grey and black water per day. The treatment plant can handle up to 12 persons, considering 240 liters of wastewater (black and grey water) per person per day. 22 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 Installation 4. INSTALLATION The installation instructions in this document refers to sewage treatment plant of type HL-Cont PLUS 0125 according to drawings: • • • Piping and Instrumentation Diagram (P&ID): 01-012-00000-2-00000 Also refer to order-specific P&ID! Dimensional Drawing Sewage Treatment Plant: 01-012-00006-0-01000 Dimensional Drawing Dosing Station: 01-000-00078-0-01000 4.1 TRANSPORT General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Transport has to be done with appropriate carrying straps. Take care that the attached components will not get damaged by mechanical stress of the straps! Where necessary a traverse must be used to ensure that the carrying straps remain vertical under load and will not damage any of the components. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 23 (42) Installation 4.2 MOUNTING The HL-Cont PLUS 0125 has to be mounted upright onto appropriate horizontally frames/panels or baseplates. Spacing for fastening holes see 4.4 "Drawings" on page 27. Any kind of welding at tanks/container/vessels of the sewage treatment plant will cause damage to the coating inside of the tank! If the ship's piping is made of CuNiFe, the sewage treatment plant's piping will have to be properly isolated. In order to permit ready access to all parts requiring service, it is recommended to consider the following spaces. min. 200 mm UV-disinfection plant Dosing Station min. 250 mm min. 500 mm • • • • 24 (42) The Dosing Station has to be mounted directly at the plant assembly group and should not be mounted at a higher level as the plant assembly group. UV-disinfection plant (A-1-C-180) has to be horizontally mounted directly at the plant assembly group. For mounting and changing of UV lamp adequate free space must be ensured. The separate delivered Feeding pump (A-1-P-050) has to be mounted in a way that suction height is not more than 2,5 m. Please refer to order-specific components documentation in the appendix. The separate delivered optional Macerator (A-1-Z-080) has to be mounted vertically with drive upwards or horizontally with outlet positioned upwards. Please refer to order-specific components documentation in the appendix. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 min. 200 mm Installation 4.3 PIPING AND HOSE CONNECTIONS The reference codes in brackets (…) refer to section 3.3 "Standard Piping and Instrumentation diagram (P&ID); 01-012-00000-2-00000" on page 14. INLET BLACK AND GREY WATER (A-1-R-001) • • Loose flange DIN 2642, aluminum, DN 25, PN 10 Inlet sewage from Feeding pump (A-1-P-050) OUTLET CLEAR PHASE (A-1-R-105) • • Loose flange DIN 2642, aluminum, DN 25, PN 10 For connection to be made to inlet (A-1-R-106) of UV-disinfection plant (A-1-C180) OUTLET SLUDGE (A-1-R-033) • Loose flange DIN 2642, aluminum, DN 15, PN 10 FLUSHING WATER CONNECTION (A-1-R-400) • To be connected to Pneumatic valve, cleaning flotation tank (A-1-B-402) The Flushing water connection (A-1-R-400) has to be connected to the on-board seawater or fresh water supply. At FLUSHING WATER CONNECTION (A-1-R-400) a pressure between 2 bar and 3.5 bar is required. A minimum flow of 8 Liter per minute must be ensured. Optional the sewage treatment plant can be delivered with a Dry running protection & cleaning pump (A-1-P-450) and Strainer, seawater (A-1-F-480), if not or no sufficient on-board seawater/freshwater supply is possible. General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 DOSING VALVE, FLOCCULANT (A-1-V-300) • • R 1/2“ (8x5 mm hose connector) DIN 2999 To be connected to outlet of Dosing pump, flocculant (A-1-P-350) VENT, FLOTATION TANK (A-1-R-600) • R 1/2“ i (inside thread) DIN 2999 This aeration connection can keep open or be connected to the on-board ventilation system. CONNECTION WORKING AIR (A-1-R-500) • R 1/2" i (inside thread) DIN 2999 A minimum pressure of 6 bar compressed air, quality min. according to DIN ISO 8573-1 class 4, is required. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 25 (42) Installation OPTIONAL 3-WAY VALVE, DISCHARGE (A-1-V-204) • 2 x Flange DN 25, PN 16 May differ, please refer to order-specific Piping- and Instrumentation Diagram. OPTIONAL DISCHARGE PUMP (A-1-P-251) • G 1" i (inside thread) May differ, please refer to order-specific Piping- and Instrumentation Diagram. General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 When the optional Discharge pump (A-1-P-251) is fitted, a non return valve on outlet of Discharge pump (A-1-P-251) and on the Outlet UV-disinfection plant (A-1-R-107) each is required. 26 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 Installation 4.4 DRAWINGS 4.4.1 ASSEMBLY GROUP SEWAGE TREATMENT PLANT Designation and reference code of piping connections see also 3.1 "Overview" on page 9. Flushing water connection (A-1-R-400) Pneumatic valve, cleaning flotation tank (A-1-B-402) Inlet black and grey water (A-1-R-001) General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Service cock (A-1-B-103) Outlet Sludge (A-1-R-033) Outlet clear phase (A-1-R-105) Figure above: Drawing 01-012-00006-0-01000 Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 27 (42) Installation JZ HZ Figure above: Drawing 01-012-00006-0-01000 28 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 JZ HZ Installation HZ JZ General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Figure above: Drawing 01-012-00006-0-01000 Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 29 (42) Installation 4.4.2 ASSEMBLY GROUP DOSING STATION [ Figure above: Drawing 01-000-00078-0-01000 30 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Installation 4.4.3 UV-DISINFECTION PLANT (A-1-C-180) Ø = 42 mm 928 mm R1“ 2 2 1 4 R1“ 3 850 mm Qty. Part No Description 1 1 011096 UV set 2500 230E 90W M + 1/2" - with muffle for probe valve 1/2“ - with cable (10 m) - with UV lamp 2 2 008248 Pipe clamp SRS 0542 PP 42;5;DIN3015;Teil1;PP 3 1 004767 Angle 90° 304 90° R 1/2"i/a, W.-Nr.1.4571/1.4408 4 1 001783 Ball valve with sealed elbow ZG311023-PROBE General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Pos. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 31 (42) Installation 4.5 OPTIONS Following options may be part of the Sewage Treatment Plant if ordered. The design is order-specific and will be documented inside of the order-specific Technical Manual. Please refer to order specific Plant Components List and P&ID at introduction of the Technical Manual and order-specific documentation in chapter „Components“. DRY RUNNING PROTECTION & CLEANING PUMP (A-1-P-450) • • Dry running protection & cleaning pump (A-1-P-450) Strainer, seawater (A-1-F-480) A A-1-F-480 A-1-P-450 2 - 3,5 bar G 1 1/2" o PP 1 1/4" i LEVEL SENSOR, HOLDING TANK (A-1-CL-063) inlet vent Grease separ inlet B Galley waste, fat, LH LS ships holding tank - 0,2 bar DN32 LL 32 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 A-1-CL-063 Installation LEVEL SENSOR, SLUDGE TANK (A-1-CL-261) vent B inlet ships sludge tank LH A-1-CL-261 LS LL DISCHARGE STATION Discharge pump (A-1-P-251) 3-way valve, discharge (A-1-V-204) - 0,2 bar • • - 0,2 bar C min. 2,0 bar M A-1-V-204 A-1-P-251 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 GREASE SEPARATOR (A-1-B-650) D A-1-B-650 Grease separator Galley waste, fat, oil Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 33 (42) Installation SEWAGE TANK AERATION SYSTEM FOR SHIPS HOLDING TANK LL E Detail: A-0-R-054 A-0-A-380 A-0-P-350 A-0-CL-360 CL A-0-V-580 * A-0-B-330 Inlet Vent compressed air quality min. acc. to DIN EN 779 Filter grade F7 A-0-R-067 ** holding tank FIT A-0-CF-810 * A-0-A-841*** G 34 " i • • • • • • • 34 (42) Suction set, antifoam agent (A-0-A-380) Aeration unit, Sewage tank (A-0-A-841) Container, antifoam agent (A-0-B-330) Air flow control (A-0-CF-810) Level sensor, antifoam agent (A-0-CL-360) Dosing pump, anti-foam (A-0-P-350) Compressor (A-0-V-580) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 G 38 " o Installation MACERATOR (A-1-Z-080) F A DN32/ R3"o DN40/ DN32 A-1-P-050 A-1-Z-080 4.6 ELECTRICAL CONNECTIONS The power supply must correspond with voltage and frequency given in the order confirmation and the Technical Data. Otherwise the correct function of the plant is not guaranteed and/or serious damages can occur. • • • General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 • All power supply lines for switch cabinet and separate components must be designed sufficiently regarding fuses and wire cross section. All electrical connections must be in accordance with the electrical diagrams and in accordance with national rules/regulations. Main power supply for HL-Cont PLUS 0125 has to be connected to the separate mounted switch cabinet. From separate mounted switch cabinet the terminal box at Sewage Treatment Plant and separate mounted components have to be connected. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 35 (42) Installation ELECTRICAL CONNECTION TO BE MADE BY THE CUSTOMER Connection to separate mounted components: - Optional Macerator (A-1-Z-080) - Feeding pump (A-1-P-050) - Dosing pump, flocculant (A-1-P-350) - Level sensor, flocculant (A-1-CL-360) - UV-disinfection plant (A-1-C-180) Switch Cabinet Terminal Box Main Power Supply COMMON ALARMS AND WARNINGS Common alarms and common warnings for external use are to be tapped according to the order-specific electrical diagram. 36 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 Connections to separate mounted components: - Optional Dry running protection & cleaning pump (A-1-P-450) - Optional 3-way valve, discharge (A-1-V-204) - Optional Level sensor, sludge tank (A-1-CL-261) - Optional Level sensor, holding tank (A-1-CL-063) Initial commissioning 5. INITIAL COMMISSIONING After all installation work of all components has been completed check tank and piping for foreign objects (bolts, nuts, etc.). 1. Please read the operating and maintenance instruction carefully. 2. Check the serial number on type plate of the Sewage Treatment Plant with that one given in the plant certificate. They must be the same. 3. Check the following points: – correct connection of all piping. – correct direction of rotation of the pumps. – pressurized air and sea/fresh water supply is present. – correct position of external valve. Ensure that all electrical connections are carried out according to the relevant safety regulations. The electrical power supply must correspond with voltage and frequency specified in the order confirmation and Technical Data. 4. Switch on the plant with main switch on switch cabinet. 5. Replenish the plant with process water (sea water or fresh water) using the cleaning program of and wait until the program stops automatically. 6. Check the filling level in Container, flocculant (A-1-B-330), replenish if necessary. 7. Check dosing adjustment of the Dosing pump, flocculant (A-1-P-350) for following value: 40 ml/h. After this procedure the sewage treatment plant is ready for use an can be started in AUTOMATIC MODE. Values for flocculant dosing rate are applicable for initial commissioning and have to be adjusted during operation of the plant when required. General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 • • • • It is recommended to adjust the dosing rate at first to 40 ml/h. Actual conditions of sewage have also to be taken into consideration. After 30 minutes a sample can be taken at Sample cock (A-1-B-102) and has to be checked against floating particles. Before checking the clear phase sample let the sample quieten down for about 10 minutes so that gas bubble can escape. After 10 minutes the clear phase sample can be checked against floating particles. Clear phase is allowed to be slightly cloudy but should contain only a small amount of floating particles. If clouding/turbidity is too high, the dosing rate of flocculant has to be increased. This verification/procedure has to be repeated till clear phase sample contains only less amount of floating particles out of the sewage. After once having adjusted the dosing rate wait at least 30 minutes before taking the next sample. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 37 (42) Operating/control elements 6. OPERATING/CONTROL ELEMENTS Operation via Touch Panel is described in separate document/chapter „Operation of Touch Panel". Bei der Lehmkuhle 4 D-21279 Hollenstedt - Germany Tel: +49-(0)4165 / 2211-0 E-Mail: Service@HamannAG.com www.HamannAG.com Sewage treatment plant Type: HL-CONT PLUS 0125 Operation of Touch Panel This instruction includes important safety information and instructions for commissioning, operation and maintenance of the sewage treatment plant. It is essential therefore, that the responsible specialist refers to it before starting any work at the plant as well as prior to commissioning. Furthermore, this instruction must always be available on site. With reservation of technical modification General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 1 (22) 38 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 Maintenance 7. MAINTENANCE 7.1 SCHEDULED MAINTENANCE Besides a daily visual check no additional activities at the HL-Cont PLUS 0125 are required, because any cleaning and flushing procedures are automatic and independent operations. Check the following during visual inspection: • • • Leakages Abnormal noises Sufficient level of flocculant in its container Maintenance activities to be performed for the components of the plant (pumps, valves,...), are described in the respective documentation, which can be found in the appendix of this manual. The nuts of the cover from saturator are to be tighten with 200 Nm if they have been unscrewed. 7.2 DRAINING THE PLANT Please refer to document/chapter „Operation of Touch Panel". For draining the plant completely, the following steps are to be performed. • • • General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 • • • • • • • • • The plant has to be in MANUAL MODE. Pressure release valve (A-1-H-004) has to be opened. Increase the opening rate of the valve step by step until saturator pressure is 0 bar. When the saturator pressure at the Pressure gauge, saturator (A-1-CP-061) indicates 0 bar, the Ball valve, manual drain (A-1-B-203) can be opened. Keep the Pressure release valve (A-1-H-004) open. Open the 3-way valve, sludge (A-1-V-201). Check that Ball valve, outlet sludge (A-1-B-202) is open. Open bleeding valve below Pressure gauge, saturator (A-1-CP-061). Start the Sludge pump (A-1-P-250). The draining requires a few minutes. After complete draining the Sludge pump (A-1-P-250) must be stopped. Open Service cock (A-1-B-103) for emptying/discarding of residues. Enter the value 0% for Pressure release valve (A-1-H-004). Leave MANUAL MODE. The 3-way valve, sludge (A-1-V-201) moves automatically back to its primary position. • Close Ball valve, manual drain (A-1-B-203), Service cock (A-1-B-103) and bleeding valve below Pressure gauge, saturator (A-1-CP-061). 7.3 CLEANING AT DOWN TIME LONGER THAN TWO WEEKS All pipings after macerator, saturator, flotation tank, sludge compartment tank and sludge pump are to be cleaned. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 39 (42) Maintenance The cleaning cycle has to be activated. Obey the instruction on the display. • Time: approx. 30 minutes Prior to this the Ball valve, inlet sewage (A-1-B-002) must be closed. Pneumatic valve, dry running protection (A-1-B-401) opens. The plant operates in normal overboard mode without flocculant but with UV-treatment. At this the Cleaning injector/nozzle, flotation tank (A-1-A-480) opens every 5 minutes. WINTER HOLDING TIME Cleaning program • Time: approx. 30minutes with subsequent manual draining General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 After completed cleaning procedure the plant has to be drained manually (see "Draining the plant" on page 39). 40 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 Components list and consumable 8. COMPONENTS LIST AND CONSUMABLE 8.1 COMPONENTS LIST • Please refer to introduction of the order-specific Technical Manual for order-specific Plant Components List with part numbers and reference code. Plant components list HAMANN AG 'HVFULSWLRQ 'DWH 2UGHU 6HZDJH7UHDWPHQW3ODQW VHW +/&2173OXV &6 7KLVOLVWLQFOXGHVWKHPDLQSODQWFRPSRQHQWVZLWKWKHLUSDUWQXPEHUDQGUHIHUHQFHFRGH Part No. Description Reference code 6HZDJH7UHDWPHQW3ODQW +/&2173/86 'RVLQJVWDWLRQ / &RQWUROV\VWHP6HZDJH7UHDWPHQW3ODQW +/&RQW3OXV5$/ (FFHQWULFVFUHZSXPS 0'/ OKKRUL]a9+]VWXGSRV ZD\YDOYHGLUHFWDFWLQJ '*'*'1 :D\VROHQRLGYDOYH 97.')4 89VHW ZRVHQVRUPXIIOHZLWKRXWHO%DOODVW (:0 &HQWULIXJDO3XPS &%9+=3K.:3 : W W L $3 $% $9 $& $3 $ ) Figure above: Example for order specific Plant Components List Detailed spare part lists for individual components of the plant (spare parts for pumps, valves, etc.) please refer to the components documentation in the annex of the Technical Manual. General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 8.2 CONSUMABLES Quantity Designation Type Part-No. 1 Canister = 30 kg Flocculant with polymer EKOFLOC APH; 30 kg in canister 013517 1 Canister = 30 kg Flocculant AQUATOP LC-2115 005383 HAMANN AG recommends above flocculant for an optimal cleaning process. Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 41 (42) Appendix 9. APPENDIX On the following pages are: • • General_Information_HL-Cont plus_0125_014736_e1.fm / 10.5.2016 • Chapter „Operation of Touch Panel“ Chapter „Components“ with documentation of assembled plant components (pump, valve, sensor,...) Chapter „Electrical Circuit Diagram" 42 (42) Sewage treatment plant HL-Cont PLUS 0125 Part No. 014736 Bei der Lehmkuhle 4 D-21279 Hollenstedt - Germany Tel: +49-(0)4165 / 2211-0 E-Mail: Service@HamannAG.com www.HamannAG.com Sewage treatment plant Type: HL-CONT PLUS 0125 Operation of Touch Panel This instruction includes important safety information and instructions for commissioning, operation and maintenance of the sewage treatment plant. It is essential therefore, that the responsible specialist refers to it before starting any work at the plant as well as prior to commissioning. Furthermore, this instruction must always be available on site. With reservation of technical modification 1 (22) CONTENT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 SWITCH CABINET AND TOUCH PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 FUNCTION KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 EXTENDED VISUALISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 AUTOMATIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 STATE OF SINGLE COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 OPERATING MODES IN AUTOMATIC MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ENTRY OF NUMERICAL VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 PARAMETER MASK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 DISCHARGE MASK (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 AUTOMATIC DISCHARGE FROM SHIPS HOLDING TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 MANUAL DISCHARGE FROM SHIPS HOLDING TANK OR SLUDGE TANK . . . . . . . . . . . . . . . . . . 18 ALARM AND WARNING INDICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Sewage treatment plant HL-CONT PLUS 0125 3 (22) Sewage treatment plant HL-CONT PLUS 0125 4 (22) Operation 1. OPERATION This description is valid for • • Software version V 3.01.01. Plant type: HL-CONT PLUS 0125 1.1 SWITCH CABINET AND TOUCH PANEL Operation and monitoring of HL-CONT PLUS 0125 is done via Touch Panel positioned at the front side of the switch cabinet. • • All power supply lines for switch cabinet and separate components must be designed sufficiently regarding fuses and wire cross section. All electrical connections must be in accordance with the electrical diagrams and in accordance with national rules/regulations. Operation, monitoring, and adjustments for HL-CONT PLUS 0125 are to be performed by the Touch Panel as follows: Switch cabinet Status display for plant Software version Value display Steuerung_HL-CONT_Plus_0125_e1.fm / 27.4.2016 Function keys Status display for single components FUNCTION KEYS • : Start/Stop of sewage treatment • : Manual operation for individual components • : Start of cleaning procedure • • : List of alarm and warning messages – : Alarm message is present – : Warning message is present : Adjustment/setting of parameter Sewage treatment plant HL-CONT PLUS 0125 5 (22) Operation • : Selection of discharge function (optional) Once the sewage treatment plant is switched on with main switch, at first the operating system will boot and then control program starts. It is not allowed to change the IP-address, because operating of the plant will be no longer possible. If the boot procedure is ready, the basic mask appears on the display. Now it is possible • to start automatic mode by pressing the START key • • • to start manual mode by pressing the key to start cleaning procedure by pressing the CLEAN key to enter history list of fault and warning messages by pressing the HISTORY REPORT key • to enter mask for general parameter entry by pressing the key – Level switch points for Sludge Tank and Holding Tank – Parameter for UV-disinfection plant 1 (A-1-C-180) and Cleaning injector/nozzle, flotation tank (A-1-A-480) • – Level switch points for Holding Tank for transfer release signal (optional) to enter mask for operation of discharge function by pressing the DISCH key (optional) Steuerung_HL-CONT_Plus_0125_e1.fm / 27.4.2016 Individual symbols and function keys faded out if plant is set to automatic mode by pressing the START key. 6 (22) Sewage treatment plant HL-CONT PLUS 0125 Operation 1.2 EXTENDED VISUALISATION By pressing on a component (see example above) the following detailed visualization appears: key the mask will be closed again. Steuerung_HL-CONT_Plus_0125_e1.fm / 27.4.2016 By pressing onto Sewage treatment plant HL-CONT PLUS 0125 7 (22) Operation 1.3 AUTOMATIC OPERATION 1.3.1 START To get into automatic operation press START key. State of plant press START If fault messages are present the HISTORY REPORT key changes into ALARM key and is displayed in red. It is not possible to set the plant into automatic mode then. If the START filling level at ship‘s holding tank is not reached, the plant will go into STANDBY MODE and not into TREATMENT MODE. As soon as START filling level at ship‘s holding tank is reached again, the plant will go into TREATMENT MODE. 8 (22) Sewage treatment plant HL-CONT PLUS 0125 Steuerung_HL-CONT_Plus_0125_e1.fm / 27.4.2016 State of individual components