This manual explains the servo/spindle tuning so that the configured machine will be ready for the mechanical

adjustment.

Note that retuning is necessary when performing the following items:

- Roundness measurement

- Synchronous tapping adjustment

- Adjustment for the shortest and optimum acceleration/deceleration

- Actual machining test

Refer to the following manuals.

MDS-D/DH Series Instruction Manual (IB-1500025)

MDS-D-SVJ3/SPJ3 Series Instruction Manual (IB-1500193)

MS Configurator Instruction Manual (IB-1500154)

CAUTION

1. Items related to servo tuning

Keep the axis from collision when moving it.

2. Items related to spindle adjustment

Do not adjust when possible risks associated with adjustment procedures are not thoroughly taken into

consideration.

Before tuning, ensure the safe operation at the maximum rotation speed.

Be sure to break in the machine before tuning.

Be careful when touching rotating section, or your hand may be caught in or cut.

Changing of parameters has to be done carefully.

CONTENTS

1 Introduction ..................................................................... 1

1.1 Aims of Servo/Spindle Tuning.................................................................................... 2

1.2 General Description of Servo Axis Control................................................................. 3

1.3 Speed loop gain ......................................................................................................... 4

1.4 Position loop gain....................................................................................................... 6

1.5 Relation of Speed Loop Gain and Position Loop Gain............................................... 8

1.6 Load inertia ................................................................................................................ 9

1.7 Resonance frequency ................................................................................................ 9

1.8 Acceleration/Deceleration Time Constant.................................................................. 9

1.9 General Description of Spindle Control.................................................................... 10

1.10 NC Screen.............................................................................................................. 11

1.10.1 Parameter Screen........................................................................................... 11

1.10.2 Drive Monitor Screen ...................................................................................... 12

1.11 MS Configurator ..................................................................................................... 13

2 Servo Tuning Procedure .............................................. 15

2.1 Flow of Servo Tuning ............................................................................................... 16

2.2 Setting Initial Parameters ......................................................................................... 17

2.2.1 Servo Parameters ............................................................................................. 17

2.2.2 Axis Specifications Parameters ........................................................................ 17

2.2.3 Machine Error Compensation Parameters........................................................ 18

2.3 Setting Resonance Frequencies .............................................................................. 19

2.4 Measuring Load Inertia Ratio ................................................................................... 22

2.5 Setting the Speed Loop Gain ................................................................................... 24

2.6 Setting the Position Loop Gain................................................................................. 28

2.7 Setting the Acceleration/Deceleration Time Constant.............................................. 30

2.8 Measuring Waveforms and Tuning .......................................................................... 32

2.8.1 Waveform Examples after Tuning..................................................................... 32

3 Spindle Tuning Procedure ........................................... 37

3.1 Flow of Spindle Tuning............................................................................................. 38

3.2 Setting Initial Parameters ......................................................................................... 39

3.3 Checking the Operation and Tuning ........................................................................ 40

3.3.1 Checking the Operation toward Maximum Rotation Speed .............................. 40

3.3.2 Setting the Acceleration/Deceleration Time Constant ...................................... 41

3.3.3 Tuning in Orientation......................................................................................... 43

3.4 Measuring Waveforms ............................................................................................. 44

3.4.1 Waveforms in Acceleration/Deceleration .......................................................... 44

3.4.2 Waveform in Orientation ................................................................................... 45

3.4.3 Others ............................................................................................................... 45

3.5 Waveform Examples and Tuning Methods .............................................................. 46

3.5.1 Waveforms in Acceleration/Deceleration .......................................................... 46

3.5.2 Waveform in Orientation ................................................................................... 52

1

Introduction

1

MITSUBISHI CNC

1 Introduction

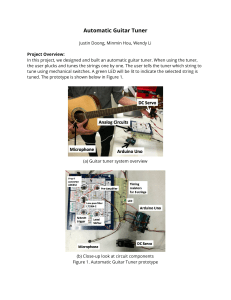

1.1 Aims of Servo/Spindle Tuning

Servo/spindle tuning aims at the following two points:

(1) To achieve machine's high performance

Servo/spindle parameter standard values allow a machine to successfully operate in spite of some

inertia. However, conditions connected to the motor (inertia, machine's configuration and specifications

(accuracy-oriented or efficiency-oriented), etc.) are not involved in the values. Therefore, the machinespecific optimum setting is required.

(2) To find and solve problems

Waveforms are not irrelevant to the machine's faults, unsatisfactory machining results or servo/spindle

alarms.

As the inertia increases, the current value will also increase. If machining surface is not good, the

factors may be shown in the waveform (if not shown, mechanical factor will be assumed). If an alarm

occurs, an abnormal waveform will be surely found. Thus, problems and countermeasures (retuning,

replacing of machine parts or mechanical readjustment) will be clarified by measuring waveforms and

tuning.

Tuning is also used as a "life extension measure": if a machining failure occurs due to mechanical

friction, the machine is basically not allowed to operate until the parts are replaced. However, tuning

under the current state allows the machine to be used in the meanwhile.

2

Servo/Spindle Tuning Guide

1.2 General Description of Servo Axis Control

1.2 General Description of Servo Axis Control

Servo axis control is to keep the axis at the cyclically-commanded position (at every communication cycle

between NC and servo amplifier) and at the commanded feedrate (rotation speed).

During axis stop

Control

No rotation.

Keep the commanded position!

Machine

Table

Disturbance (pushing force)

Tension (returning force)

Tension is produced to keep the commanded position.

During axis movement

Control

Follow the commanded position

and rotation speed!

Machine

Disturbance (pushing force)

Table

Tension (returning force)

As the command will not change in spite of dropping rotation speed,

tension is produced to regain the commanded rotation speed and position.

In the example above, the tension against the disturbance (the force to regain the speed and position by

passing a current through the motor) is controlled by speed loop gain and position loop gain.

3

MITSUBISHI CNC

1 Introduction

1.3 Speed loop gain

Speed loop gain is the response speed to regain the commanded speed when the motor speed deviates due

to cutting load and the like.

Comparison at the speed deviation

When speed loop gain is

increased

When the speed loop gain

is decreased

Responsiveness

Command speed will be quickly regained.

Machining will be less affected by speed deviation factors (load change. etc), producing

smoother rotation.

Command speed will be slowly regained.

Machining will be easily affected by speed

deviation factors (load change. etc), producing rougher rotation.

Machining result

Machining result will be like the one when

the torque (power) has been increased.

(Ex: The machining surface is improved.)

Machining result will be like when the

torque (power) has been decreased.

(Ex: The machining surface gets worse.)

Setting the higher speed loop gain is a key of servo tuning.

Will the highest speed loop gain lead the best machining?

If the speed loop gain is too high or too low, the following cases will occur.

(a) When too good responsiveness (too high gain) is set for the machine with small weight and

friction which regains the commanded speed with a small force:

The regained speed will exceed the commanded speed. If the responsiveness against the

excessive speed is too sharp, oscillation will eventually occur.

-> Vibrations with high frequency will occur. The speed deviation will be rather larger.

Continuous vibration with high frequency is called "oscillation". The higher the speed loop

gain is, the more the oscillation is likely to occur; the lower, the less.

(Waveform example) Speed feedback - Position droop waveform

Narrow vibrations are distributed on the whole.

4

Servo/Spindle Tuning Guide

1.3 Speed loop gain

(b) When too little responsiveness (too low gain) is set for the machine with large weight and

friction which requires a large force to regain the commanded speed:

The response to regain the commanded speed will be slow.

-> Vibrations with low frequency will occur. The speed deviation will not be reduced (the

commanded speed will be hardly regained).

Constant unstable waveform with low frequency is called "fluctuation".

(Waveform example) Speed feedback - Position droop waveform

5 or 6 waves have occurred in 1 or 2 second(s).

Set the appropriate speed loop gain corresponding to the inertia ratio (weight ratio) to the motor.

5

MITSUBISHI CNC

1 Introduction

1.4 Position loop gain

Position loop gain is the responsiveness in time; how quickly the motor reaches the commanded position

(spped) when a different command is issued.

Comparison when a different rotation speed is commanded

Responsiveness

Position (speed) will be quickly changed.

When position loop gain is

Response to the rotation change will be

increased

faster.

Position (speed) will be slowly changed.

When the position loop

Response to the rotation change will be

gain is decreased

slower.

Machining result

Machining result will be like when the time

constant has been shorten. (Ex: The

shape (size, etc) is accurate.)

Machining result will be like when the time

constant has got longer. (Ex: The shape

(size, etc) is inaccurate.)

Setting the higher position loop gain is also a key of servo tuning.

Will the highest position loop gain lead the best machining?

If the position loop gain is too high or too low, the following cases will occur.

(a)

When too good responsiveness (too high gain) is set for the machine with small rigidity

(loader and the like, whose weight balance is not good)

-> The machine vibrates at the change of the command speed, or overshoot occurs at

acceleration/deceleration.

"Overshoot" means that the machine's position exceeds the commanded position at a

speed change (acceleration -> constant speed or deceleration -> stop).

(Waveform example) Speed feedback - Position droop waveform

Overshoots happen at the circled points.

6

Servo/Spindle Tuning Guide

1.4 Position loop gain

(b) When too little responsiveness (too high gain) is set for the machine with rigidity (machine

whose weight balance is good, or light and small machine)

-> The machine will work slowly. The machining accuracy will deteriorate.

(Waveform example) Position command - Position feedback waveform

(A) When position loop gain is appropriate

(B) When position loop gain is low

Set the appropriate position loop gain corresponding to the machine's configuration and the inertia

ratio.

7

MITSUBISHI CNC

1 Introduction

1.5 Relation of Speed Loop Gain and Position Loop Gain

As explained so far, speed loop gain is the responsiveness to the speed deviation, and position loop gain is

the responsiveness to the command speed change.

If an overshoot occurs after increasing the position loop gain, the overshoot can be eliminated by increasing

the speed loop gain, because the overshoot is related to the speed deviation.

In reverse, if an overshoot occurs at acceleration/deceleration, the overshoot can be eliminated by

decreasing the position loop gain and applying slow accelecation/deceleration, because the acceleration/

deceleration means a change of command speed.

Which is set first?

Considering the following features, set the speed loop gain first, then set the position loop gain.

Speed loop gain

Standard speed loop gain is determined by measuring

the inertia ratio.

Axis-specific setting is available (because each axis has

a different inertia ratio.)

Upper limit is determined by the inertia ratio. Setting over

the upper limit is impossible.

Position loop gain

Determined by the mechanical structure, as well as the inertia ratio. Whether the value is high or low is only judged

by moving the axis.

Adjustment among interpolation axes is required.

For interporation axes, upper limit is determined by the

speed loop gain.

Set the speed loop gain first. Then set the position loop gain considering the determined speed

loop gain and the mechanical structure.

8

Servo/Spindle Tuning Guide

1.6 Load inertia

1.6 Load inertia

Inertia is physical quantity to express load amount. In servo control, load inertia (diameter, friction, etc.),

which is converted into motor axis, is more important than load weight. Servo response is in proportion to

speed loop gain and in inverse proportion to load inertia. It is essential to know the load inertia amount when

determining appropriate speed loop gain.

Load inertia

In servo tuning, measure the load inertia first. Then determine the standard speed loop gain

accoriding to the inertia.

1.7 Resonance frequency

"Resonance" is a large vibration when machine and motor's own vibration frequencies affect each other.

All machines have a resonance point and the resonance of ball screw is a serious problem. Resonance has

to be suppressed as it prevents the speed loop gain from being raised.

Notch filter is installed on servo and it suppresses the resonance. However, resonance frequency has to be

set for each machine to set parameters.

Vibration waveform

Recognizing resonance frequency and suppressing resonance for raising the speed loop gain is a

key in servo tuning.

1.8 Acceleration/Deceleration Time Constant

Shorter and smoother acceleration/deceleration is also important.

When the position loop gain is adjusted, acceleration/deceleration time constant should also be adjusted,

because the position loop gain is related to the time to complete positioning.

Set the time constant with parameters. The values should be set so that the maximum current at

acceleration/deceleration will not exceed the maximum current command value.

Set the acceleration/deceleration time constant so that the current value will not exceed the

maximum current command value.

9

MITSUBISHI CNC

1 Introduction

1.9 General Description of Spindle Control

Spindle control is largely divided into two types.

Control 1: Always follows the commanded rotation speed with the maximum power of spindle

amplifier and motor

-> Only the responsiveness to the commanded speed is provided, which is mainly

controlled by speed loop gain.

Spindle always follows the maximum power; the position and acceleration/deceleration time constant

need not to be considered.

The catch-up time difference is due to the power of spindle amplifier and motor, as well as the inertia

(weight, friction and centrigugal force) of an object to rotate.

It is like when a man who carries a burden runs 100m at full speed.

Power of spindle amplifier and motor = The man's ability

A burden = machine's inertia

To run faster (to shorten the acceleration/deceleration time), raising the ability (increasing the power of

spindle amplifier and motor) and reducing the burden (decreasing the inertia) are required. As reducing

the burden (inertia) is hardly possible, raising the ability (increasing the power) should be considered.

The adjustment of spindle's speed loop gain is the same as that of servo axis.

Control 2: Like servo axis, follows the commanded position

-> Controlled by speed loop gain and position loop gain.

In the following operations, spindle is controlled similarly as servo axis.

(a)Orientation (Stop at fixed position)

(b)Spindle/ C axis control

(c)Synchronous tap control

(d)Spindle synchronization

Spindle must stop at a fixed position, which requires the control

according to the commanded position.

Spindle is controlled like a servo C axis (rotation axis), which

requires the position control all the time including acceleration/

decelertion.

Spindle and servo axis (Z axis) are simultaneously controlled.

(When the pitch 1mm is commanded, spindle is controlled to

rotate once per 1mm of Z axis movement. Position control is required all the time including acceleration/decleration.

Spindles (or spindle and servo axis) are controlled to be at the

commanded speed and postition all the time including acceleration/deceleration.

These operations require the time constant setting according to the inertia.

10

Servo/Spindle Tuning Guide

1.10 NC Screen

1.10 NC Screen

The following screens are mainly used in servo/spindle tuning.

1.10.1 Parameter Screen

Parameters are displayed and set.

How to display the parameter screen and set a value

(1) Press

key to display the Mainte screen.

(2) Select [Mainte] and then [Psswd input] menus.

(3) Enter "MPARA" in the setting area and press the INPUT key.

(4) Select [Param] menu.

(5) Select [Param number] menu. Enter the parameter No. in the setting area and press the

INPUT key. The cursor moves to the entered parameter position.

(6) Enter a value and press the INPUT key.

The menus on the parameter screen ([Servo param], [Spindle spec param] and [Spindle param])

are also available for the parameter display.

11

MITSUBISHI CNC

1 Introduction

1.10.2 Drive Monitor Screen

The diagnosis information from the drive section can be monitored with this screen.

How to display the drive monitor screen

(1) Press

key to display the Diagn screen.

(2) Select [Drv mon] menu.

(3) Select [Servo unit] to display the servo monitor screen. Select [Spindle unit] to display the

spindle monitor screen.

12

Servo/Spindle Tuning Guide

1.11 MS Configurator

1.11 MS Configurator

With MS Configurator, the servo parameters can be automatically adjusted by activating the motor with test

NC programs or vibration signals, and analyzing the machine characteristics. Data measurement function is

also provided.

Cable H200

In this manual, MS Configurator is used in servo tuning to sample waveforms.

13

2

Servo Tuning Procedure

15

MITSUBISHI CNC

2 Servo Tuning Procedure

2.1 Flow of Servo Tuning

Start

Setting Initial Parameters

Refer to 2.2

Setting Resonance Frequencies

Refer to 2.3

Set the resonance frequency of filter to

suppress resonance.

Measuring the Load Inertia Ratio

Refer to 2.4

Perform an axis reciprocation with G00

(Rapid traverse) at full stroke to measure

the load inertia ratio.

Setting the Speed Loop Gain

Refer to 2.5

Set the speed loop gain according to the

measured load inertia ratio. Then check

for any unusual noise or vibration.

Setting the Position Loop Gain

Refer to 2.6

Set the parameters for position loop gain.

Then check for any mechanical vibration.

Setting the Acceleration/Deceleration

Refer to 2.7

Adjust the acceleration/deceleration time

constants at G00 and G01 so that the

current does not exceed the maximum

current command value.

Refer to 2.8

Execute G01 (cutting feed) and then G00

(rapid traverse), measuring waveforms

and tuning.

Time Constant

Measuring Waveforms and Tuning

End

16

Servo/Spindle Tuning Guide

2.2 Setting Initial Parameters

2.2 Setting Initial Parameters

2.2.1 Servo Parameters

(1) Set standard values in the servo parameters

on the axes for tuning.

Refer to "List of standard parameters for each

servomotor" of the servo drive unit's Instruction

Manual.

(2) Set all the following compensation/filter/

resonance frequency parameters to "0

(Disabled)".

No.

Parameter name

Setting

#2227

SV027 (SSF1)

Servo function selection 1

Set "4000"

#2233

SV033 (SSF2)

Servo function selection 2

Set "0000"

#2238

SV038 (FHz1)

Notch filter frequency 1

Set "0"

#2246

SV046 (FHz2)

Notch filter frequency 2

Set "0"

#2283

SV083 (SSF6)

Servo function selection 6

Set "0"

#2287

SV087 (FHz4)

Notch filter frequency 4

Set "0"

#2288

SV088 (FHz5)

Notch filter frequency 5

Set "0"

(3) Enable the speed feedback filter to eliminate

high-frequency vibration noise.

No.

#2217

Parameter name

SV017

(SPEC1)

Servo specification selection 1

Setting

Change "00*0" to "00*8"

2.2.2 Axis Specifications Parameters

(1) Temporarily disable the backlash

compensation. Take a note of the axis'

original set values in "#2011" and "#2012".

Then set both to "0".

No.

Parameter name

Setting

#2011

G0back

G0 backlash

Set "0"

#2012

G1back

G1 backlash

Set "0"

Be sure to take a note and set the original values

back after tuning.

(2) Enable the feed forward gain. Set "#2139" to

"1" to apply the conventional feed forward

control.

No.

#2139

Parameter name

omrff_off

Setting

Set "1: Temporarily disable".

OMR-FF invalid

17

MITSUBISHI CNC

2 Servo Tuning Procedure

2.2.3 Machine Error Compensation Parameters

Temporarily disable the machine error

compensation. Take a note of the axis'

original set value of "#4006 (, #4016,

#4026...)". Then set it to "0".

No.

#4006

(#4016,

4026...)

Parameter name

sc

Compensation scale factor

Setting

Set "0"

Be sure to take a note and set the original values

back after tuning.

18

Servo/Spindle Tuning Guide

2.3 Setting Resonance Frequencies

2.3 Setting Resonance Frequencies

Parameters to set

No.

Parameter name

Setting

#2205

SV005 (VGN1)

Speed loop gain 1

Set a speed loop gain

#2238

SV038 (FHz1)

Notch filter frequency 1

Set a resonance frequency

#2246

SV046 (FHz2)

Notch filter frequency 2

Set a resonance frequency (When SV038

has already been set)

#2233

SV033 (SSF2)

Servo function selection 2

Set the depth of notch filter 2

* Set for each axis.

Set the resonance frequency of filter to suppress resonance.

Attach the cover to the table and take the workpiece off before setting.

Keep the axis from collision when moving it.

(1) Display the servo monitor screen.

(2) Move the axis by handle/JOG feed. Check for

any unusual noise or vibration.

If unusual noise or vibration occurs:

(1) See the resonance frequency on the servo

monitor screen. ("AFLT frequency")

19

MITSUBISHI CNC

2 Servo Tuning Procedure

(2) Display the parameter screen. Set the resonance

frequency in "#2238 SV038".

(3) Display the parameter screen. Set "(speed

loop gain standard parameter value) + 50" in

"#2205 SV005".

For the standard parameter value, refer to "List

of standard parameters for each servomotor" of

the drive unit's Instruction Manual.

20

Servo/Spindle Tuning Guide

2.3 Setting Resonance Frequencies

(4) Move the axis by handle/JOG feed again.

Check for any unusual noise or vibration.

If no noise or vibration occurs:

Set the standard parameter value in SV005.

If any noise or vibration occurs:

(1) See the resonance frequency on the servo

monitor screen. ("AFLT frequency")

(2) Display the parameter screen. Set the frequency

in "#2238 SV038" (or "#2246 SV046" when

"#2238" has already been set).

(3) Move the axis again. If no noise or vibration

occurs, set the standard parameter value in

SV005.

Before setting SV046, set "#2233 SV033" to

"**8*".

If the displayed frequency is almost the same as

SV038 frequency (within ±30Hz):

Set "#2233 SV033" smaller as follows;

"***0"(- ∞ ) -> "***2"(-18.1db) -> "***4" (-12.0db) ->

"***6" (-8.5db)...

Confirm the resonance frequency ("AFLT

frequency") shows "0" or different value from

SV038 on the servo monitor screen.

If the resonance frequency is unstable ("AFLT

frequency" shows more than ±10 deviation):

Lower the SV005 value until the frequency is

stabilized.

If the resonance frequency still exists after both

SV038 and SV046 settings:

Lower the SV005 value until the frequency shows

"0".

If the frequency is over 900Hz (a keening noise

is heard), the amount may not be displayed. In

such a case, set "1125", "2250" or "900" in

SV038 (or SV046).

(5) Move the axis by rapid traverse with override

100%. Check for any unusual noise or

vibration.

If any problem occurs, take the same measures

as (4).

21

MITSUBISHI CNC

2 Servo Tuning Procedure

2.4 Measuring Load Inertia Ratio

Parameters to set

No.

Parameter name

#2232

SV032 (TOF)

#2004

#2005

#2235

#2237

Setting

Torque offset 1

Set the unbalance torque of vertical axis

G0tL

G0 time constant (linear)

G0t1

G0 time constant (primary delay)

Set a time constant for rapid traverse acceleration/deceleration

SV035 (SSF4) Servo function selection 4

SV037 (JL)

Load inertia scale

Set "1" in bitF. "0000" is changed to "8000".

Set a load inertia

* Set for each axis.

Perform an axis reciprocation with G00 (Rapid traverse) at full stroke to measure the load inertia ratio.

(1) Set an unbalance torque in "#2232 SV032"

on vertical axis when used.

Move the axis at about F1000 and measure the

load current on the servo monitor screen. Then

apply the following formula.

Unbalance torque = {(+ Feed load current (%)) +

(- Feed load current (%))} / 2

(2) Prepare an MDI/memory operation of rapid

traverse with override 100%.

(Ex.) G00 feed for reciprocation of 200mm with onesecond dwell time

*Apply the maximum travel amount for a short

stroke less than 200mm.

Always use MDI or memory operation. JOG or

Rapid feed does not provide an average inertia

value in a constant cycle.

(3) Carry out a test run with the program

prepared in (2). During the test run, see the

maximum current value shown in "Max

current 2 (or 3)" on the servo monitor screen.

22

Servo/Spindle Tuning Guide

2.4 Measuring Load Inertia Ratio

(4) Set the time constant so that the maximum

current value stays between 150 and 200

(%).

Adjust the "#2004/#2005" value until "Max

current 2 (3)" shows "150 to 200" at

acceleration/deceleration.

(5) Stop the run and set the display of load inertia

ratio on the servo monitor screen.

Display the parameter screen. Set "1" in

"#2235 SV035/bitF". ("0000" is changed to

"8000".)

Complete the step (4) before (5).

Slowly raising the feedrate after (5) will add

extra 15 to 30 minutes to stabilize the inertia

display.

(6) Set the feedrate to 100% and run the (2)

program for about 15 minutes.

During the run, see the load inertia ratio on

the servo monitor screen.

Run the program until the load inertia ratio is

stabilized "with 1% or less deviation in five

reciprocations".

(7) Take a note of the load inertia ratio stabilized

in (6). Then stop the run.

(8) Display the parameter screen. Set the noted

inertia ratio in "#2237 SV037".

(9) Cancel the load inertia ratio display. Set "1"

in "#2235 SV035/bitF". ("*000" is changed to

"0000".)

23

MITSUBISHI CNC

2 Servo Tuning Procedure

2.5 Setting the Speed Loop Gain

Parameters to set

No.

Parameter name

#2205

SV005

(VGN1)

Setting

Speed loop gain 1

Set a speed loop gain

#2238

SV038 (FHz1) Notch filter frequency 1

Set a resonance frequency

#2246

SV046 (FHz2) Notch filter frequency 2

Set a resonance frequency (When SV038

has already been set)

* Set for each axis.

Set the speed loop gain according to the measured load inertia ratio. Then check for any unusual noise or

vibration.

If any vibration occurs, set a resonance frequency again.

Attach the cover to the table and take the workpiece off before setting.

Keep the axis from collision when moving it.

(1) Determine the speed loop gain according to

the load inertia ratio in "#2237 SV037".

Refer to "Standard VGN1 graph" below and set

the motor-specific speed loop gain.

(2) Set "(determined value in (1)) + 50" in "#2205

SV005".

(3) Execute the handle, JOG and then Rapid

operation.

If no noise or vibration occurs:

Set the determined value in (1) in "#2205 SV005".

If any noise or vibration occurs:

(1) See the resonance frequency on the servo

monitor screen. ("AFLT frequency")

(2) Display the parameter screen. Set the frequency

in "#2238 SV038" (or "#2246 SV046" when

"#2238" has already been set).

(3) Move the axis again. If no noise or vibration

occurs, set the determined value in (1) in SV005.

Refer to the chapter of "Setting Resonance

Frequencies" written before.

24

Servo/Spindle Tuning Guide

2.5 Setting the Speed Loop Gain

Reference

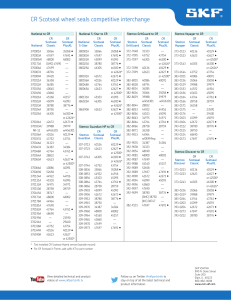

MDS-D/DH Series Standard VGN1 graph (servo motor HF, HF-H Series)

[ HF75, HF54

[ HF-H75, HF-H54

]

]

[ HF105, HF104, HF154

[ HF-H105, HF-H104, HF-H154

Isolated motor

Standard

VGN1

Isolated motor

600

600

500

500

400

400

300

300

200

200

100

100

0

100

200

300

400

500

600

0

100

[ HF204, HF354

[ HF-H204, HF-H354

]

]

Isolated motor

400

500

600

]

]

Isolated motor

600

500

500

400

400

300

300

200

200

When OSA166 used

When OSA 105 used

100

200

300

[ HF453, HF703

[ HF-H453, HF-H703

600

0

100

200

Load inertia magnification (%)

Load inertia magnification (%)

Standard

VGN1

]

]

300

400

500

When OSA166 used

When OSA105 used

100

600

0

100

200

300

400

500

Load inertia magnification (%)

Load inertia magnification (%)

25

600

MITSUBISHI CNC

2 Servo Tuning Procedure

MDS-D/DH Series Standard VGN1 graph (servo motor HP, HP-H Series)

[ HP54, HP154, HP224

[ HP-H54, HP-H154, HP-H224

]

]

[ HP104

[ HP-H104

Isolated motor

Standard

VGN1

Isolated motor

600

600

500

500

400

400

300

300

200

200

100

100

0

100

200

300

400

500

600

0

100

Load inertia magnification (%)

[ HP204, HP354, HP454

[ HP-H204, HP-H354, HP-H454

]

]

400

500

600

]

]

Isolated motor

600

500

500

400

400

300

300

200

200

When OSA166 used

When OSA105 used

100

200

300

[ HP704, HP903, HP1103

[ HP-H704, HP-H903, HP-H1103

600

0

100

200

Load inertia magnification (%)

Isolated motor

Standard

VGN1

]

]

300

400

500

When OSA166 used

When OSA105 used

100

600

0

100

200

300

400

500

Load inertia magnification (%)

Load inertia magnification (%)

26

600

Servo/Spindle Tuning Guide

2.5 Setting the Speed Loop Gain

MDS-D-SVJ3 Series Standard VGN1 graph (servo motor HP, HP-H Series)

[ HF75, HF54

]

[ HF105, HF104, HF154

Isolated motor

Standard

VGN1

Isolated motor

600

600

500

500

400

400

300

300

200

200

100

100

0

100

200

300

400

500

600

[ HF204, HF354

]

Isolated motor

600

500

400

300

200

When OSA166 used

When OSA 105 used

100

0

100

200

300

400

500

0

100

200

300

400

500

Load inertia magnification (%)

Load inertia magnification (%)

Standard

VGN1

]

600

Load inertia magnification (%)

27

600

MITSUBISHI CNC

2 Servo Tuning Procedure

2.6 Setting the Position Loop Gain

Parameters to set

No.

Parameter name

Setting ratio

#2203

SV003 (PGN1)

Position loop gain 1

#2204

SV004 (PGN2)

Position loop gain 2

#2257

SV057 (SHGC)

SHG control gain

#2208

SV008 (VIA)

Speed loop lead compenSet "1900", the standard value, in SHG control

sation

700 to 2500

#2215

SV015 (FFC)

Acceleration rate feed forSet "100", the standard value, in SHG control

ward gain

0 to 300

#1194

H_acdc

Time constant 0 for handle feed

1

Standard

setting

range

Setting example

8

3

6

18

21

23

26

33

38

47

18 to 70

48

56

61

70

88

101

125

48 to 186

108

126

138

156

198

228

282

108 to 420

Set "0" when using time constant for G01 in manual handle feed

mode

* Set for each axis. Interpolation axes (synchronously controlled) must have the same lowest value.

Set the parameters for position loop gain. Then check for any mechanical vibration. SHG control changes

the position loop to a high-gain by smoothly compensating the servo system position loop through a delay.

This allows the settling time to be reduced and a high precision to be achieved. (SHG: Smooth High-Gain)

This manual explains the setting with SHG control.

Use the setting example above for the SHG control parameters (SV003, SV004 and SV057). When

the axis is synchronized with spindle (in synchronous tap or spindle/C axis control), the spindle will

have automatically-calculated values (SV003 : SV004 : SV057 = 1: 8/3 :6). Set the calculated

values (rounded to the nearest integer) for the servo axis accordingly.

(1) Set the following parameters using

"SV003=33" settings.

SV003 (PGN1): "33"

SV004 (PGN2): "88"

SV008 (VIA): "1900"

SV015 (FFC): "100"

SV057 (SHGC): "198"

"SV003=33" settings are normally used.

"SV003=26" settings are used for the system

with scale specifications, rotary axis, gear or belt

drive, which is more vibratable than semi-closed

one. "SV003=9" settings can be used for the

system with longer machine end such as loader

axis or especially arm axis.

28

Servo/Spindle Tuning Guide

2.6 Setting the Position Loop Gain

(2) Execute the handle, JOG and then Rapid

operation. Check for any mechanical

vibration at acceleration/deceleration.

When any vibration occurs at acceleration/

deceleration:

Decrease SV003, SV004 and SV057 values,

keeping the ratio 1 : 8/3 : 6, until the vibration

disappears.

Setting the longer time constant will also

eliminate the vibration. However, if the vibration

still exists while the maximum current value at

the acceleration/deceleration is down to 50% or

less, time constant does not help suppress the

vibration. Then set the lower SHG control gain.

When the vibration occurs only in the handle feed:

Set "0" in "#1194 H_acdc (Time constant 0 for

handle feed)". Then set the longer time constant for

G01.

For the G01 time constant setting, use "#2007"

or "#2008" according to the acceleration/

deceleration mode.

(3) When using multiple axes, carry out these

adjustments for each axis.

Interpolation axes must have the same position

loop gain value. Set the same lowest value for

all the interpolation axes.

29

MITSUBISHI CNC

2 Servo Tuning Procedure

2.7 Setting the Acceleration/Deceleration Time Constant

Parameters to set

No.

Parameter name

Setting

#2001

rapid

Rapid traverse rate

Set the rapid traverse feedrate for each axis

#2002

clamp

Cutting feedrate for clamp function

Set the maximum cutting feedrate for each

axis

#2004

G0tL

G0 time constant (linear)

#2005

G0t1

G0 time constant (primary delay)

#2007

G1tL

G1 time constant (linear)

#2008

G1t1

G1 time constant (primary delay)

Set a time constant for rapid traverse acceleration/deceleration

Set a time constant for cutting acceleration/

deceleration

* Set for each axis. When setting "#2007" or "#2008" for multiple axes, set the same lowest value for all

the axes.

Adjust the acceleration/deceleration time constants at rapid traverse (G00) and cutting feed (G01) so that

the current does not exceed the maximum current command value ("max.").

(1) Display the parameter screen. Set a rapid

traverse rate (G00) in "#2001", a cutting

feedrate (G01) in "#2002".

(2) Display the servo monitor screen.

(3) Move the axis in MDI or memory mode at the

rapid traverse rate (G00) and the maximum

cutting feedrate (G01).

(4) See "Max current 2 (or 3)" on the servo

monitor screen. Confirm that the current peak

value at the acceleration/deceleration does

not exceed the "max." (or 70% of the "max."

in cutting feed).

"Max current 1" shows the current peak value

after the power ON. "Max current 2 (or 3)"

shows the instantaneous peak value of load

current.

30

Servo/Spindle Tuning Guide

2.7 Setting the Acceleration/Deceleration Time Constant

For the maximum current command value

("max."), refer to the chart below.

When the current exceeds the "max.":

Set the longer time constant.

When the current is below the "max.":

Shortening the time constant is allowed.

When the current is below the "max.", vibration

occurred by shortening the time constant:

Adjust the time constant so that the vibration does

not occur.

Set the time constant in any of the parameters

"#2004" to "#2008".

(5) When using multiple axes, carry out these

adjustments for each axis.

G01 time constant ("#2007" or "#2008") must be

the same among all the axes. Set the same

lowest value for all the axes.

Reference:

Maximum current command value when adjusting acceleration/deceleration time constant

Motor

model

HF75

HF105

HF54

HF104

HF154

HF204

HF354

HF453

HF703

HF903

MDS-D Series (200V)

Max. current

Motor

command

model

value

Within 350%

HP54

Within 270%

HP104

Within 420%

HP154

Within 504%

HP204

Within 378%

HP354

Within 340%

HP454

Within 331%

HP704

Within 298%

HP903

Within 238%

HP1103

Within 291%

Max. current

command

value

Within 306%

Within 262%

Within 434%

Within 312%

Within 320%

Within 311%

Within 216%

Within 215%

Within 184%

Motor

model

HF-H75

HF-H105

HF-H54

HF-H104

HF-H154

HF-H204

HF-H354

HF-H453

HF-H703

HF-H903

MDS-DH Series (400V)

Max. current

Motor

command

model

value

Within 350%

HP-H54

Within 270%

HP-H104

Within 420%

HP-H154

Within 504%

HP-H204

Within 378%

HP-H354

Within 312%

HP-H454

Within 331%

HP-H704

Within 298%

HP-H903

Within 238%

HP-H1103

Within 291%

MDS-D-SVJ3 Series (200V)

Max. current

Motor model

command value

HF75

437

HF105

337

HF54

525

HF104

439

HF154

472

HF204

356

HF354

290

31

Max. current

command

value

Within 306%

Within 262%

Within 434%

Within 312%

Within 320%

Within 311%

Within 216%

Within 215%

Within 184%

MITSUBISHI CNC

2 Servo Tuning Procedure

2.8 Measuring Waveforms and Tuning

Execute G01 (cutting feed) and then G00 (rapid traverse), measuring waveforms and tuning.

In each mode, sample the waveforms in the following order:

(1) Speed feedback- Position droop waveform (deviation between the command and the position feedback)

(2) Speed feedback - Current feedback waveform

Tuning is for achieving good machining results. In order to achieve good machining results, it is

essential to keep the stable droop or the waveform without overshoot or fluctuation, especially in

G01 (cutting feed). After realizing the stability, try shortening the time constant (or tact time) and

improving the responsibility (or accuracy). Thus, a position droop waveform should be firstly

sampled to confirm that the servo motor’s rotation is stable.

For the waveform measurement, refer to "MS Configurator Instruction Manual" (IB-1500154).

2.8.1 Waveform Examples after Tuning

The following shows the waveforms measured by MS Configurator.

These are the examples in G01 (cutting feed). The result will be the same in G00 (rapid traverse).

As for G00, however, the allowable fluctuation is 5μm. In other mode, the allowance is should be

1μm (3μm during the axis travel)

Check the points in both forward and backward travels.

Speed feedback - Position droop waveform

Point 3

Point 1

Point 2

32

Servo/Spindle Tuning Guide

2.8 Measuring Waveforms and Tuning

Point 1: At acceleration -> constant speed:

Make sure there is no overshoot or delay in

feed (more than 3μm).

"Delay in feed" is a waveform where the feed

seems to stop once and move again.

Tuning method

(1) Set the longer time constant.

(2) If the peak current value shows 50% or less, set

the lower position loop gain (SV003, SV004 and

SV057). After confirming the stable waveform,

shorten the time constant.

Point 2: At constant speed:

Make sure there is no fluctuation (over 3μm)

except cyclic vibration.

Tuning method

Set the higher speed loop gain (SV005).

If any cyclic vibration is found, sample a

waveform at a different feedrate. If the vibration

cycle changes depending on the feedrate,

mechanical factor (such as core deflection) may

be affecting the vibration.

Point 3: At deceleration -> stop:

Make sure there is no overshoot or delay in

feed (more than 1μm).

Tuning method

(1) Set the longer time constant.

(2) If the peak current value shows 50% or less, set

the lower position loop gain (SV003, SV004 and

SV057). After confirming the stable waveform,

shorten the time constant.

33

MITSUBISHI CNC

2 Servo Tuning Procedure

Speed feedback - Current feedback waveform

Point 4

Point 5

34

Servo/Spindle Tuning Guide

2.8 Measuring Waveforms and Tuning

Point 4: Make sure there is no current value

exceeding the "max."

For the "max." value, refer to the chart in the

chapter 2.7.

Tuning method

(1) Set the longer time constant.

(2) If the peak current value shows 50% or less, set

the lower position loop gain (SV003, SV004 and

SV057). After confirming the stable waveform,

shorten the time constant.

Point 5: At constant speed:

Make sure there is no fluctuation (more than

3μm).

Tuning method

Set the higher speed loop gain (SV005).

If any cyclic vibration is found, sample a

waveform at a different feedrate. If the vibration

cycle changes depending on the feedrate,

mechanical factors (such as core deflection)

may be affecting the vibration.

Check for any change (up and down) of current

value as well during the axis travel. Especially

on horizontal axis, the load current change may

be caused by mechanical factors (such as

guides’ crossing angle).

35

3

Spindle Tuning Procedure

37

MITSUBISHI CNC

3 Spindle Tuning Procedure

3.1 Flow of Spindle Tuning

Keys of spindle tuning

(1) Always check the waveform while tuning.

(Note) At a point of May, 2008, MS Configurator’s spindle waveform measure functions don’t support

all the models or all kinds of data. For exact spindle tuning, waveforms should be sampled

from spindle amplifier's D/A output, using a measure device such as a waveform recorder.

When using such a device, set the time axis range to either 20ms/DIV or 50ms/DIV. With the

range 100ms/DIV or more, the device will not sample an accurate waveform.

(2) Tune the spindle at every rotation speed, not only at the maximum.

As rotation speed changes, torque (power) will also change.

(3) Repeat accelerations/decelerations when sampling waveforms.

As temperature changes, friction may also change due to heat expansion, etc.

(4) Always mount the chuck before tuning.

Results may differ due to the chuck weight.

CAUTION

1.

2.

3.

4.

5.

Do not adjust when possible risks associated with adjustment procedures are not

thoroughly taken into consideration.

Before tuning, ensure the safe operation at the maximum rotation speed.

Be sure to break in the machine before tuning.

Be careful when touching rotating section, or your hand may be caught in or cut.

Changing of parameters has to be done carefully.

Start

Setting Initial Parameters

Refer to 3.2

Checking the Operation and Tuning

Refer to 3.3

Checking the Operation

Tuning in Orientation

Setting the Acceleration/

Deceleration Time Constant

(Tuning in other operations)

Rotate the spindle up to the maximum rotation

speed. Check for any fluctuation in rotation or

vibration in the waveform.

Repeat accelerations/decelerations. Sample

waveforms both in room temperature and in high

temperature for tuning.

Take this tuning method when using orientation.

Execute orientations from the maximum rotation

speed, every rotation speed and from 180 degrees

position. Sample waveforms and tune the spindle in

each orientation.

Tune the spindle in the other operation such as

spindle/C axis control.

End

38

Servo/Spindle Tuning Guide

3.2 Setting Initial Parameters

3.2 Setting Initial Parameters

(1) Set the following parameters: "#3001 slimit1"

to "#3137 stap_ax_off" according to the

machine's specifications; "#13001 SP001" to

"#13256 SP256" according to the "Parameter

setting list" from MITSUBISHI.

(2) Set the following filter-setting parameters to

"0".

No.

Parameter name

Setting

#13038

SP038 (FHz1)

Notch filter frequency 1

Set "0"

#13046

SP046 (FHz2)

Notch filter frequency 2

Set "0"

#13087

SP087 (FHz4)

Notch filter frequency 4

Set "0"

#13088

SP088 (FHz5)

Notch filter frequency 5

Set "0"

Follow the parameter setting list. As long as the

spindle inertia is within 3-fold (in almost all

machining centers), the operation will have no

problem with standard values from the list. If the

inertia exceeds 3-fold (in lathe system with

chuck, etc.), set "#13005 SP005" to "200"

instead of "150".

39

MITSUBISHI CNC

3 Spindle Tuning Procedure

3.3 Checking the Operation and Tuning

Parameters to set

No.

Parameter name

#13001

SP001 (PGV)

#13005

SP005

(VGN1)

Setting

Position loop gain Non-interpolation mode

Start with "15" ("5" in lathe system)

Speed loop gain 1

Change the value when a problem occurs

even if SP001 is lowered to "5"

3.3.1 Checking the Operation toward Maximum Rotation Speed

Rotate the axis with gradually raising the rotation speed toward the maximum.

Check for any rough rotation or fluctuation in the waveform.

Before tuning, ensure the safe operation at the maximum rotation speed.

At the first rotation command since the power ON, the rotation speed is raised up to the "#3109

zdetspd (Z phase detection speed)" speed. The speed will be raised up to the commanded

speed after Z phase detection. If the rotation speed has not been raised for a long time, check

the PLG.

(1) Display the parameter screen and set "15"

("5" in lathe system) in "#13001 SP001".

(2) Rotate the spindle with gradually raising the

rotation speed (1000 to 2000 r/min at a time).

Check for any fluctuation in the following

waveforms at every rotation speed.

(a) Speed - Phase current waveform

(b) Speed - Current feedback waveform

(Ex.) Run the following program with executing single

blocks.

S1000 M3;

S2000;

S3000;

:

S**; (**: Max. rotation speed (Smax value))

M5

Watch the waveform in the recorder during the

run. Check only the constant speed rotation

waveform.

When any fluctuation occurs during constant speed

rotation:

(1) Stop the operation and raise the speed loop gain

(SP005).

(2) Restart the operation with the speed at which the

fluctuation occurred. Check the waveform.

(3) If the fluctuation still exists, lower the speed loop

gain.

40

Servo/Spindle Tuning Guide

3.3 Checking the Operation and Tuning

3.3.2 Setting the Acceleration/Deceleration Time Constant

Repeat accelerations/decelerations. Sample waveforms both in room temperature and in high temperature

for tuning.

(1) Display the spindle monitor screen. Wait until

the spindle temperature goes down to the

room temperature.

Spindle temperature is shown in "Temperature".

(2) Sample waveforms in acceleration/

deceleration at room temperature.

Execute "stop --> maximum rotation speed"

for sampling them.

(Ex.) Run the following program with executing single

blocks.

S8000 M3;

M5

Dwell time setting is also available if the speedstabilized time is confirmed.

For how to sample waveforms, refer to the later

chapter of "Measuring Waveforms".

(3) Repeat accelerations/decelerations until the

temperature on the spindle monitor screen

reaches around 80 C°.

(4) Sample waveforms in acceleration/

deceleration at 80 C°.

Execute "stop --> maximum rotation speed"

for sampling them.

For how to sample waveforms, refer to the later

chapter of "Measuring Waveforms".

41

MITSUBISHI CNC

3 Spindle Tuning Procedure

(5) Compare the waveforms between (2) and (4).

Apply the temperature at which the waveform

shows worse. Tune the spindle in

acceleration/deceleration toward/from the

maximum rotation speed.

When both waveforms are similarly not good:

(1) Start tuning at the temperature with shorter

deceleration time.

(2) Then, tune at the other temperature.

When both waveforms are good:

Choose the temperature with shorter deceleration

time for tuning.

For checking waveforms and tuning, refer to the

later chapter of "Waveform Examples and

Tuning Methods".

(6) Decrease the rotation speed (1000 to 2000 r/

min at a time). Tune the spindle at every

rotation speed.

Execute "stop --> rotation speed" and sample

waveforms for tuning at every rotation speed.

For checking waveforms and tuning, refer to the

later chapter of "Waveform Examples and

Tuning Methods".

(7) After completing tunings at every rotation

speed, raise the position loop gain. Set "33"

("15" in lathe system) in "#13001 SP001".

(8) Execute accelerations/decelerations, sample

waveforms and tune the spindle at every

rotation speed toward the maximum.

Start with the lowest rotation speed. Then

gradually raise the speed.

When an overshoot occurs:

Lower the position loop gain (SP001) until no

overshoot is found.

When an overshot occurs even if SP001 is lowered to

"5":

(1) Set "200" and "100" in "#13005 SP005". Sample

each two sets of waveforms.

(2) Compare the waveforms. Choose the SP005

value with less problem.

42

Servo/Spindle Tuning Guide

3.3 Checking the Operation and Tuning

3.3.3 Tuning in Orientation

Parameters to set

No.

Parameter name

#13016

SP016 (DDT)

#3107

ori_spd

Setting

Phase alignment deceleration rate

Set the single-rotation position alignment

deceleration rate for orientation stopping

Orientation command speed

Set the spindle speed during orientation

command

Take this tuning method when using orientation.

Execute orientations from the maximum rotation speed, every rotation speed and from 180 degrees position.

Sample waveforms and tune the spindle in each orientation.

(1) Execute an orientation from the maximum

rotation speed. Sample waveforms and tune

the spindle.

(a) Execute with a tool (workpiece) of the

largest weight that allows the spindle

maximum rotation speed.

(b) Execute with the tool (workpiece) of the

largest weight allowed to be mounted to

the spindle.

For how to sample waveforms, refer to the later

chapter of "Measuring Waveforms".

For checking waveforms and tuning, refer to the

later chapter of "Waveform Examples and

Tuning Methods".

(2) Execute orientations from every rotation

speed (every 1000 to 2000 r/min). Sample

waveforms and tune the spindle.

(3) Confirm the standard value "100" is set in

"#3107 ori_spd".

Be sure to set "#3107". Otherwise, an orientation

from stop is not possible.

(4) Execute an orientation from 180 degrees

position. Sample waveforms and tune the

spindle.

(a) Mount a tool (workpiece) of the largest

weight allowed to be mounted to the

spindle.

(b) Stay the spindle at the orientation

position.

(c) Rotate the spindle to 180 degrees

position.

(d) Execute an orientation.

43

MITSUBISHI CNC

3 Spindle Tuning Procedure

3.4 Measuring Waveforms

Sample waveforms in the following order for tuning.

(1) Waveforms in acceleration/deceleration (at maximum rotation speed and every rotation speed)

(2) Waveforms in orientation (from maximum rotation speed, every rotation speed and from stop)

(3) Others (in synchronous tap, spindle synchronization and spindle/C-axis control)

(Note 1) As spindle power characteristics (base rotation speed, rated output max. speed, instantaneous

rating, etc.) will change depending on the rotation speed, waveforms at each speed are required in

addition to those at max. speed. However, for the waveform type noted later as "Sampled at

maximum rotation speed only", waveforms at each speed are not required because the problem

shows most clearly at the highest speed.

(Note 2) At a point of May, 2008, MS Configurator’s spindle waveform measure functions don’t support all

the models or all kinds of data. For exact spindle tuning, waveforms should be sampled from

spindle amplifier's D/A output, using a measure device such as a waveform recorder.

When using such a device, set the time axis range to either 20ms/DIV or 50ms/DIV. With the range

100ms/DIV or more, the device will not sample an accurate waveform.

3.4.1 Waveforms in Acceleration/Deceleration

Sample waveforms in the following order:

- Sampled at each rotation speed.

(1)Speed - Phase current waveform

- When the motor has coil switch specifications, sample both

L coil and H coil waveforms at maximum rotation speed.

- U and V phases are available. D/A output is as well.

(2)Speed - Current feedback waveform

- Sampled at each rotation speed.

- When the motor has coil switch specifications, sample both

L coil and H coil waveforms at maximum rotation speed.

(3)Speed - q axis integral term current

* q axis integral term current: Controls the current applied

to the motor stator’s coil

- Sampled at maximum rotation speed only.

- When the motor has coil switch specifications, sample both

L coil and H coil waveforms at maximum rotation speed.

(4)Speed - d axis integral term current

* d axis integral term current: Controls the current applied

to the motor rotor’s coil (waveforms are unnecessary for

IPM spindle, whose rotor is not coil but magnet)

Key point

Acceleration time is determined by (a) motor’s power characteristics, (b) power of spindle amplifier, and

(c) machine’s inertia (including mechanical loss due to friction). In tuning, setting a longer acceleration

time is allowed for protecting the machine, while shortening the time is not allowed. For shorter

acceleration time, it is necessary to improve the factors (a) to (c) above.

44

Servo/Spindle Tuning Guide

3.4 Measuring Waveforms

Settings of D/A output No. and output magnification

Set the following parameters when using D/A output.

Setting

No.

Parameter name

#13125

SP125

D/A output channel 1

data No.

#13126

SP126

D/A output channel 2

data No.

#13127

SP127

D/A output channel 1

output scale

#13128

SP128

D/A output channel 2

output scale

(1)Speed Phase current

waveform

(2)Speed Current feedback waveform

(3)Speed q axis integral

term current

(4)Speed d axis integral

term current

31778

31782

1

31764

3

Differs according to the machine's maximum rotation speed.

(Ex.) "20" when maximum speed is 10000r/min, "40" when 5000r/min

2

100

2

2

3.4.2 Waveform in Orientation

Sample the following waveform:

- Sampled at each rotation speed.

Current command Orientation completion signal

- The same waveform should be sampled in the orientation

from stop.

Settings of D/A output No. and output magnification

Set the following parameters when using D/A output.

No.

Parameter name

Setting

#13125

SP125

D/A output channel 1 data No.

2

#13126

SP126

D/A output channel 2 data No.

16492

#13127

SP127

D/A output channel 1 output scale

100

#13128

SP128

D/A output channel 2 output scale

100

3.4.3 Others

For synchronous tap, spindle synchronization and spindle/C-axis control, the followings are required: speed

waveform, droop waveform and current feedback waveform.

45

MITSUBISHI CNC

3 Spindle Tuning Procedure

3.5 Waveform Examples and Tuning Methods

3.5.1 Waveforms in Acceleration/Deceleration

The following shows the examples of each type waveform before and after tuning.

Speed - Current feedback waveform

(Before tuning)

(After tuning)

Point 1: Acceleration end --> constant speed:

Make sure that the waveform is as stable as

possible (less than half in the range of 50%/

DIV, with two or less fluctuations).

Factors of unstableness: (a) speed loop gain is

too low or (b) position loop gain is too high

Tuning method

Set the higher speed loop gain (SP005) or lower

position loop gain (SP001).

46

Servo/Spindle Tuning Guide

3.5 Waveform Examples and Tuning Methods

Point 2: During constant speed:

Make sure that the waveform is as stable as

possible (with less current fluctuation).

Factors of unstableness:

(a) speed loop gain is too low or (b) oscillation

Tuning method

(1) Set the higher speed loop gain (SP005).

(2) If the fluctuation still exists, lower the speed loop

gain.

Current value will change depending on the load

current during rotation. Large current value is

acceptable as long as it stays below 70% of the

value at acceleration. If the current value is 70%

or above, the machine may have problems such

as a lack of motor’s capacity or an excessive

inertia.

Point 3: Constant speed --> deceleration start:

Make sure there is no "jump" in the current

waveform.

"Jump" means the instantaneous fluctuation

within 10ms or less time. "Overvoltage" or

"Overcurrent" alarm is likely to occur at the

current's jump.

Tuning method

Lower the "#13071 SP071" and "#13072 SP072"

values.

No.

Parameter name

#13071

SP071

#13072

SP072

Setting

Variable current limit during decel- Set this parameter to adjust the deceleraeration, lower limit value

tion time by changing the current limit value

Variable current limit during decel- during deceleration according to the motor

speed.

eration, break point speed

47

MITSUBISHI CNC

3 Spindle Tuning Procedure

Speed - Phase current waveform

(Before tuning)

(After tuning)

48

Servo/Spindle Tuning Guide

3.5 Waveform Examples and Tuning Methods

Point 4: During constant speed:

Make sure the waveform is as stable as

possible (with less current fluctuation).

Factors of unstableness:

(a) speed loop gain is too low or (b) oscillation

Tuning method

(1) Set the higher speed loop gain (SP005).

(2) If the fluctuation still exists, lower the speed loop

gain.

Current value will change depending on the load

current during rotation. Large current value is

acceptable as long as it stays below 70% of the

value at acceleration. If the current value is 70%

or above, the machine may have problems such

as a lack of motor’s capacity or an excessive

inertia.

Point 5: Constant speed --> deceleration start:

Make sure there is no "jump" in the current

waveform.

Phase current waveform may have more

obvious "jump". "Overvoltage" or "Overcurrent"

alarm is likely to occur at the current's jump.

Tuning method

Lower the "#13071 SP071" and "#13072 SP072"

values.

49

MITSUBISHI CNC

3 Spindle Tuning Procedure

Speed - q axis integral term current

(Before tuning)

(After tuning)

Point 6: After acceleration (during constant speed

rotation and deceleration):

Make sure that the fluctuation is within ±1V,

and the current is stable (with no fluctuation

including cyclic current fluctuation) during

constant speed. (Ignore the waveform in

acceleration.)

Factors of unstableness: (a) speed loop gain is

too low or (b) oscillation

Tuning method

(1) Set the higher speed loop gain (SP005).

(2) If the fluctuation still exists, lower the speed loop

gain.

50

Servo/Spindle Tuning Guide

3.5 Waveform Examples and Tuning Methods

Speed - d axis integral term current

(Before tuning)

(After tuning)

Point 7: After acceleration (during constant speed

rotation and deceleration):

Make sure that the fluctuation is within ±1V,

and the current is stable (with no fluctuation

including cyclic current fluctuation) during

constant speed. (Ignore the waveform in

acceleration.)

Factors of unstableness: (a) speed loop gain is

too low or (b) oscillation

Tuning method

(1) Set the higher speed loop gain (SP005).

(2) If the fluctuation still exists, lower the speed loop

gain.

51

MITSUBISHI CNC

3 Spindle Tuning Procedure

3.5.2 Waveform in Orientation

Acceleration/deceleration --> Orientation (Current command - Orientation completion signal)

Deceleration Orientation

Current

command

Orientation

completion

signal

Point 1: Make sure that the current peak value in

orientation is smaller than the value in

deceleration.

Tuning method

If the current value is over the range:

Lower the "#13016 SP016" value until the current

value is within the range.

If the current value is within the range:

"#13016 SP016" can be set higher for shortening

the orientation time (Point 2).

No.

#13016

Parameter name

SP016 (DDT)

Phase alignment deceleration rate

52

Setting

Set the single-rotation position alignment

deceleration rate for orientation stopping

Servo/Spindle Tuning Guide

3.5 Waveform Examples and Tuning Methods

Stop (at 180 degrees position) --> Orientation (Current command - Orientation completion signal)

Current

command

Orientation

completion

signal

Point 3: Make sure that the current peak value in

orientation is less than 100%.

Tuning method

If the current value is over the range:

Lower the "#3107 ori_spd" value until the current

value is within the range.

If the current value is within the range:

"#3107 ori_spd" can be set higher for shortening the

orientation time (Point 4).

No.

#3107

Parameter name

ori_spd

Orientation command speed

53

Setting

Set the spindle speed during orientation

command

Revision History

Date of revision

Jun. 2008

Manual No.

BNP-C8027-023A(ENG) First edition created.

Revision details