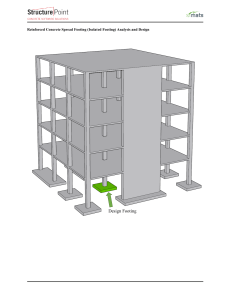

Compression Members CE 422 Steel Design I 1 Columns: Columns are compression members which are subjected to concentric axial compressive forces. These are to be found in trusses and as a lateral bracing members in frame building. Short columns are sometimes referred to as to as “struts” or “stanchions”. Beam-Columns: P Beam-columns are members subjected to combined axial compressive and bending stresses; These are found in single storey of multi-storey framed structures. P Columns Theory: Stocky columns (short) fail by yielding of the material at the cross section, but most columns fail by “buckling” at loads for less then yielding forces. P (a) 2 P (b) Note that the ideal state is never realized in practice and some eccentricity of load will be always present 3 For “slender” columns, Euler (1759) predicted the critical buckling load (Pcr) – also known as Euler Buckling Load as: Pcr where: 2 EI 2 L (C 1) E = Young Modulus of Elasticity. I = Minor moment of Inertia. L = Unbraced length of column. 4 Pcr Pcr 2 EI L2 2 E Ar 2 L2 2 EA L / r 2 Fcr Note: 2E L 2 ---- Euler Buckling Critical Load where: r = minor radius of gyration Crippling Stress r The critical buckling load is a function of the section properties (A, L, r) and the modulus of elasticity for material, and is not a function of the strength or grade of the material. 5 Example C-1 Find the critical buckling load for W 12 x 50, supported in a pinned-pinned condition, and has an over-all length of 20 feet? Solution: Fcr 2E L 2 r rmin = ry = 1.96 inch (properties of section). Fcr 2 29000 2012 2 1.96 19 ksi Pcr = σcr A = 19.1 x 14.7 = 280.8 kips Note: The steel grade is not a factor affecting buckling, also note Fcr << Fy. 6 7 For short (stocky) columns; Equation gives high values for (σcr), sometimes greater than proportional limit, Engessor (1889) proposed to use (Et) instead of (E) in Euler formula: Tangent modulus of elasticity is Et I Pcr 2 (C 3) L 2 The instantaneous rate of change of stress as a function of strain. It is the slope at any point on a stress-strain diagram. where: Et = Tangent Modulus of Elasticity Et < E When (Fcr) exceeds (Fpl), this is called “Inelastic Buckling”, constantly variable (Et) need to be used to predict (Fcr) in the inelastic zone. Shanley (1947), resolved this inconsistency. 8 Depending on (L/r) value the column buckling strength was presented as shown by Shanley. Residual Stresses:Due to uneven cooling of hot-rolled sections, residual stresses develop as seen here. The presence of “residual stresses” in almost all hotrolled sections further complicates the issue of elastic buckling and leads towards inelastic buckling. 9 The Euler buckling formula (C-1) is based on: 1 – Perfectly straight column. (no crookedness). 2 – Load is concentric (no eccentricity). 3 – Column is pinned on both ends. The Previous conditions are very difficult to achieve in a realistic building condition, especially the free rotation of pinned ends. Thus an “effective slenderness factor” is introduced to account for various end conditions: Thus: Fcr 10 π 2E KL 2 r , or Fcr π 2Et Kl 2 r C 4 where: K = Effective length factor. (Kl) = Effective length. (Kl/r) = Effective slenderness ratio. 11 AISC (Chapter E) of LRFD code stipulates: Pu (factored load) c Pn where: Pu = Sum of factored loads on column. c = Resistance factor for compression = 0.90 Pn = Nominal compressive strength = Fcr Ag Fcr = Critical buckling Stress. (E3 of LFRD) a) for Kl 4.71 r E Fy or F e 0.44Fy Fy F Fcr 0.658 e Fy b) for Kl 4.71 r E Fy or F e Fcr 0.877Fe where: 12 Fe π 2E KL 2 r E - 3.2 0.44Fy E - 3.3 E - 3.4 The above two equations of the LRFD code can be illustrated as below: where: Kl λc rπ Fy E The code further stipulates that an upper value for column should not exceed (200). For higher slenderness ratio, Equation (E-3.3) controls and (Fy) has no effect on (Fcr). 13 14 Example C-2 Determine the design compressive strength (cPn) of W 14x74 with an untraced length of (20 ft), both ends are pinned, (A-36) steel is used? Solution: Kl =1 x 20 x 12 = 240 in rmin = ry = 2.48 240 Kl 96.77 200 (0k) r 2.48 max. π 2 x2900 Fe 30.56 ksi 2 2 (96.77) Kl r Fy Fe Fcr 0.658 Fy (0.658) 1.178 x 36 0.611 36 21.99 ksi c Pn = 0.9 x Fcr x Ag = 0.9 x (21.99) x 21.8 = 433.44 kips (Answer) π 2E 0.44 Fy = 0.44 x 36 =15.84 ksi Fe ≥ 0.44 Fy Equ. E-3.2 (controls) Also from (table 4-22) LFRD Page 4-320 c Fcr = 19.75 ksi (by interpolation) c Pn = c Fcr Ag = 430.55 kips (much faster) 15 16 17 For most profiles used as column, the buckling of thin elements in the section may proceed the ever-all bucking of the member as a whole, this is called local bucking. To prevent local bucking from occurring prior to total buckling. AISC provides upper limits on width to thickness ratios (known as b/t ratio) as shown here. See AISC (B4) (Page 16.1-14) See also: Part 1 on properties of various sections. 18 Upper limits on width to thickness ratios Based on Table B4.1 19 Depending on their ( b/t ) ratios (referred to as ) , sections are classified as: a) Compact sections are those with flanges fully welded (connected) to their web and their: p (AISC B4) b) Non compact Sections: p r (B4) c) Slender Section: > r (B4) Certain strength reduction factors (Q) are introduced for slender members. (AISC E7). This part is not required as most section selected are compact. 20 Example C-3 Determine the design compressive strength (c Pn) for W 12 x 65 column shown below, (Fy = 50 ksi)? K x L x 1 x 24 x 12 54.55 rx 5.28 (controls) K yLy ry 1 x 8 x 12 31.79 3.02 π 2E Solution: A) By direct LRFD From properties: Ag =19.1 in2 rx = 5.28 in ry = 3.02 in 21 π 2 x29000 Fe 96.2 ksi 2 2 (54.55) Kl r Fe 0.44 Fy ( 22 ksi) Equ. (E 3.2) 50 96.2 Fcr 0.658 Fy 0.8045 x 50 40.225 ksi c Pn = 0.9 x Fcr Ag = 0.9 x 40.225 x 19.1 = 691.5 kips B) From Table (4.22) LRFD Evaluate = Kl r max = 54.55 Enter table 4.22 (page 4 – 318 LRFD) cFc = 36.235 ksi (by interpolation) Pn = Fc x Ag = 692.0 kips C) From (Table 4.1 LRFD) K xL x 1x24 (KL) y 13.7 ft rx 1.75 ry Enter table (4.1 ) page 4.17 LFRD with (KL)y = 13.7 Pn = 691.3 kips (by interpolation). 22 23 24 Example C-4 P Find the maximum load capacity (Pn) of the W 14 x 53 (A-36) C B 25 ft. 15 ft. Solution: y-axis C 10 ft. column shown in figure ? x-axis P A Lx = 25 ft, kx = 0.8, rx = 5.89 in. A x x x x Section (AB) Ly = 15 ft, ky = 0.8, ry = 1.92 in. Section (BC) Ly = 10 ft., ky = 1.0, ry = 1.92 in. 0.8 25 12 Kl 41 5.98 r x max Kl r y Enter table (4-22) , Fc = 24.1 ksi Column capacity Pn = Fcr Ag = 24.1 x 15.6 = 376 kips 0.8 15 12 75 1.92 (controls) 25 26 Design with Columns Load Table (4) LFRD:A) Design with Column Load Table (4) LFRD: The selection of an economical rolled shape to resist a given compressive load is simple with the aid of the column load tables. Enter the table with the effective length and move horizontally until you find the desired design strength (or something slightly larger). In some cases, Usually the category of shape (W, WT, etc.) will have been decided upon in advance. Often the overall nominal dimensions will also be known because of architectural or other requirements. As pointed out earlier, all tabulated values correspond to a slenderness ratio of 200 or less. The tabulated unsymmetrical shapes – the structural tees and the single and double-angles – require special consideration and are covered later. 27 EXAMPLE C - 5 A compression member is subjected to service loads of 165 kips dead load and 535 kips live load. The member is 26 feet long and pinned in each end. Use (A572 – Gr 50) steel and select a W14 shape. SOLUTION Calculate the factored load: Pu = 1.2D + 1.6L = 1.2(165) + 1.6(535) = 1054 kips Required design strength cPn = 1054 kips From the column load table for KL = 26 ft, a W14 145 has design strength of 1230 kips. ANSWER Use a W14 145, But practically W14 132 is OK. 28 29 EXAMPLE C - 6 Select the lightest W-shape that can resists a factored compressive load Pu of 190 kips. The effective length is 24 feet. Use ASTM A572 Grade 50 steel. SOLUTION The appropriate strategy here is to find the lightest shape for each nominal size and then choose the lightest overall. The choices are as follows. W4, W5 and W6: None of the tabulated shape will work. W8: W 8 58, cPn = 205 kips W10: W10 49, cPn = 254 kips W12: W12 53, cPn = 261 kips W14: W14 61, cPn = 293 kips Note that the load capacity is not proportional to the weight (or cross-sectional area). Although the W8 58 has the smallest design strength of the four choices, it is the second heaviest. ANSWER Use a W10 49. 30 Example C-7 Select the lightest W – 10 section made of A 572-Gr50 steel to resist a factored load of (600 kips) ? Solution: Assume weak axis (y-y) controls buckling: Enter design tables of AISC (Section 4) with KyLy = 9 ft. Select W 10 x 54 (capacity = 625 k > 600 k OK) Check strong axis buckling strength: Enter table for W10 x 54 with (KL)eq. = 10.53 ft. Capacity = 595.8 kips (by interpolation) N.G. Select W10 x 60 capacity = 698 kips for KyLy = 9 ft. capacity = 666 kips for (KL)eq. = 10.5 ft. 31 B) Design for sections not from Column Load Tables: For shapes not in the column load tables, a trial-and-error approach must be used. The general procedure is to assume a shape and then compute its design strength. If the strength is too small (unsafe) or too large (uneconomical), another trial must be made. A systematic approach to making the trial selection is as follows. 1) Assume a value for the critical buckling stress Fcr. Examination of AISC Equations E3-2 and E3-3 shows that the theoretically maximum value of Fcr is the yield stress Fy. 2) From the requirement that cPn Pu, let cAgFcr Pu and A g φPFu c cr 3) Select a shape that satisfies this area requirement. 4) Compute Fcr and cPn for the trial shape. 5) Revise if necessary. If the design strength is very close to the required value, the next tabulated size can be tried. Otherwise, repeat the entire procedure, using the value of Fcr found for the current trial shape as a value for Step 1 6) Check local stability (check width-thickness ratios). Revise if necessary. 32 33 34 Example C-8 Select a W18 shape of A36 steel that can resist a factored load of 1054 kips. The effective length KL is 26 feet. Solution: Try Fcr = 24 ksi (two-thirds of Fy): Required Ag Pu 1054 48.8 in 2 c Fcr 0.9( 24) Try W18 x 192: Ag = 56.4 in2 > 48.8in2 KL 26(12) 111.8 200 rmin 2.79 Fe 35 π 2E π 2 x29000 (OK) 22.9 ksi 111.8 Kl r Fe 0.44 Fy (15.84) LRFD Equ. E . 3.2 2 2 36 Fy 36 22.9 Fcr 0.658 Fe Fy 0.658 x36 0.532 x 36 18.64 ksi φ cPn 0.9 A gFcr 0.9 x 56.4 x 18.64 943 kips 1054 k (N.G.) Try Fcr 18.64 ksi (the value just computed for the W18 x 192) : Required A g Pu 1054 62.83 in 2 φ cFcr 0.9(18.64) Try W18 x 234 : A g 68.8 in 2 . 62.83 in 2 KL 26(12) 109.5 200 rmin 2.85 (OK) 37 Fe π 2E Klr 2 π 2 29000 23.87ksi 2 109.5 Fe 0.44Fy Use LFRD (Equ.E - 3.2) Fy 36 23.87 Fcr 0.658 Fe Fy 0.658 x 36 0.532 x 36 19.15 ksi φ cPn 0.9 A gFcr 0.9 x 68.8 x 19.15 1185 kips 1054 k (OK) This shape is not in the column load tables, so the width - thickness ratios must be cheacked : bf 95 2.8 15.8 2t f 36 h 253 13.8 42.2 tw 36 Answer Use a W18 x 234 (OK) (OK) 38 The effective length factor (K) was introduced in page (C-7) for six ideal conditions, these are not encountered in practical field conditions. LRFD commentary provides both real conditions and standard ideal conditions (C-C2.2) (page 16.1-239 to 242) Braced Frames: Unbraced Frames: No lateral movement is allowed (0.5 < K < 1.0) (sideway prevented) Lateral movement possible (1.0 < K < 20.0) (sideway allowed) a) Diagonal bracing b) Shear Walls (masonry, reinforcement concrete or steel plate) 39 GA Ic /L c Ig /L g where A is top of column GB Ic /L c Ig /L g where B is bottom of column * For fixed footing G = 1.0 * For pinned support G = 10.0 40 Example C – 9:In the rigid frame shown below, Determine Kx for columns (AB) & (BC). Knowing that all columns webs are in the plane. W12 x 96 Solution: Column (AB): (A): W24 x 55 A 12' W24 x 68 B W12 x 120 Ic /L c GA Ig /L g 833/12 1070/12 1586 1350/20 1830/18 169.2 0.94 W24 x 68 W24 x 55 W12 x 120 Joint 12' 15' C 20' 20' 18' 41 42 For joint B,:G ΣIc /L c 1070/12 1070/15 160.5 0.95 ΣIg /L g 169.2 169.2 From the alignment chart for sideways uninhibited, with G A = 0.94 and GB = 0.95, Kx = 1.3 for column AB. Column (BC): For joint B, as before, G = 0.95 For joint C, at a pin connection the situation is analogous to that of a very stiff column attached to infinitely flexible girders – that is, girders of zero stiffness. The ratio of column stiffness to girder stiffness would therefore be infinite for a perfectly frictionless hinge. This end condition is only be approximated in practice, so the discussion accompanying the alignment chart recommends that G be taken as 10.0. From the alignment chart with GA = 0.95 and GB = 10.0, Kx = 1.85 for column BC. 43 When an axially loaded compression member becomes unstable overall (that is, not locally unstable), it can buckle in one of three ways, as shown in figure. 1. Flexural buckling. We have considered this type of buckling up to now. It is a deflection caused by bending, or flexure, about this axis corresponding to the largest slenderness ratio (Figure a). This is usually the minor principal axis – the one with the smallest radius of gyration. Compression members with any type of cross-sectional configuration can fail in this way. 44 2. Torsional buckling This type of failure is caused by twisting about the longitudinal axis of the member. It can occur only with doubly symmetrical cross sections with very slender cross-sectional elements (Figure b). Standard hot-rolled shapes are not susceptible to torsional buckling, but members built up from thin plate elements may be and should be investigated. The cruciform shape shown is particularly vulnerable to this type of buckling. This shape can be fabricated from plates as shown in the figure, or built up from four angles placed back to back. 45 3. Flexural-torsional buckling. This type of failure is caused by a combination of flexural buckling and torsional buckling. The member bends and twists simultaneously (Figure c). This type of failure can occur only with unsymmetrical cross sections, both those with one axis of symmetry – such as channels, structural tees, double-angle shapes and equal-leg single angles – and those with no axis of symmetry, such as unequal-leg single angles. The AISC Specification requires an analysis of torsional or flexural-torsional buckling when appropriate. Section E3 of the Specification covers double-angle and tee-shaped members, and Appendix E3 provides a more general approach that can be used for any unsymmetrical shape. 46 When length exceeds requirements for a single section, built-up compression section are used as shown below: The code provides details for built-up section under LRFD EG. 47 Example C – 10 :- Calculate the capacity of the built-up column shown below. Lx = Ly = 25 ft, Kx = 1.6, Ky = 1.0 Fy = 42 ksi ? Solution:- From table 4.22 page 4.321 cFcr = 18.3 ksi Design Nominal Strength = cFcr Ag =18.3 x 22.70 = 415.4 kips. 48 49