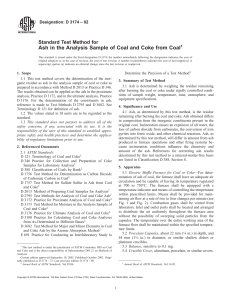

ANÁLISIS PROXIMO DE UNA MUESTRA DECARBON OBTENIDO DE UNA MINA DE CUCUNUBA Yuri Astrid Espinosa 20101150018. Jhoan Andres Samaca 20091150065. Cristian David Villada 20101150074. __________________________________________________________________ ABSTRACT. In the present work the next analysis of a sample of coal from a mine in Cundinamarca was performed located in a province Ubaté, the percentage of moisture, ash and volatile material was determined, with the following values respectively: 11.7% moisture, 19.16% ash, 21.44% volatile material. Keywords: Percentage of moisture, ash, volatile material, coal. __________________________________________________________________ INTRODUCTION. Coal is a dark solid, layered and fuel, resulting from the accumulation and burial of plant material of the first geological eras. These carbon deposits develop through changes initial and subsequent biological effects of mechanical pressure and temperature within the sediments. The coal is characterized as the fossil fuel that there is a greater amount of resources, reaching 75% of total reserves estimated. So worth mentioning its wide geographical distribution, knowing exploitable deposits in almost all countries. (P 1984). Almost all coal is used in combustion processes and coke. Thus, on the basis of data from primary energy consumption in Spain in 1998, 80% coal is burned to generate electricity or steam for industrial and domestic use, while, although in much smaller numbers, use in the field of iron and steel, cement and coke is equally significant, the rest is used in other relatively minor activities such as the manufacture of pigments and fillers and water filtration. THE CARBOGENESIS Carbogenesis the process of transformation that is caused by carbon from plant substances, higher plants (mainly wood) and to a lesser extent, lower organisms such as algae, spores or pollen is called. This process consists of two main stages, the biochemical state that determines the type of coal and geochemical or metamorphic phase that determines the rank of coal. (Zapata, 2006). BIOCHEMICAL PHASE For a coal is formed, vegetable substances from which should have been preserved oxidation and total microbial destruction. By this fact that is postulated that the genesis of coal should occur in wetlands where water deposits covered or Saturus vegetables, limiting access of oxygen and by inhibiting the action of microorganisms that cause rot. This water had to be estancanda otherwise will be plenty of oxygen and must also be shallow to allow growth of a significant amount of vegetable matter. The decomposition process (limited) of these plant substances depends on the environment in which it takes place mainly in relation to three factors: content of nutrients for bacteria and fungi, oxygen and pH. Theories exist widely accepted that explained according to these parameters the formation of macerals (organic aggregates physically and distinct chemical properties, in which the organic fraction of the coal is distributed) and thus, different types of existing coal . Macerals would therefore coal constituents (in the organic fraction). Macerals have sizes from 2 microns to several centimeters, and are not well defined and characterized by chemical composition uniformity in the degree of crystallization. Are generally considered three coal macerals groups according to their origin: Vitrinite produced from "wood", being derived from the main chemical constituents of this (cellulose and lignin). EI decomposition of Ia "wood" is produced by the action of aerobic bacteria near the surface of the tank and anaerobic bacteria to a greater depth, leading to what is known as peat. Is the majority maceral in existing coal (> 80%), accounting for Ias properties coked. The inertinite, compounds ligno-cellulosic original had previously dehydrogenation processes have been motivated by fire (coking) or the biochemical action. EI subsequent decomposition process had to be primarily aerobic by the action of various fungi and bacteria. This material is commonly found very finely divided and mixed with vitrinite. The exinita or stems lipnitita Ias more resistant plant substances to degradation, such as Ias resins, cuticles, spores, pollen and algal (with high hydrogen contents). In this case the forming process is essentially anaerobic, denominating putrefaction. GEOCHEMICAL PHASE The biochemical phase might end when deposits were found at depths greater than 10 meters. In this relatively short period, a million years at most, have happened in the course of 250 to 300 million years separating us from the Carboniferous period, a slow transformation of organic matter at varying depths, subject, therefore, to changing conditions of temperature and pressure. Is geochemical stadium, which determines the range or metamorphic evolution of coal. The temperature increases with the depth of 3-5 ° C per 100 m. It is possible that these temperatures have been sufficient for extremely slow chemical reactions profoundly transform Ia fossil material. It has been found (Hilt rule) that in certain fields, coal rank increases regularly with the depth of the layer. This transformation process affects the properties of coal, the following effects can be observed when the increase coal rank: Ias aromatic structures increased. Increased calorific value (with a small decrease for very high rank coals). Decreased volatile content. Decreased oxygen content. These facts are used to characterize the range of coal. Composition and structure of coal Coal is a sedimentary rock composed mainly of an organic fraction (maceral) and to a lesser extent, minerals, also containing water and gases in the submicroscopic pores. These main organic compounds are the result of the formation and condensation of polynuclear rings carbocicliclos, where carbon, hydrogen and oxygen are the basic elements and sulfur and nitrogen are complementary. obstructing every step of the combustion gases, thus producing industries CocaCola wanted by the behavior of coal in heating than other parameters, because the coke quality produced depends on that feature. Furthermore, all coal industries porcesan, holes are significantly more affected Asphalts and byproduct gases obtained. This explains why the content of volatile materials is one of the most important classification parameters in this type of activity. It then analyzes the coal properties specified for use in power stations, performing also an assessment of their importance in the functioning of these. Testing standards. There are many tests that support the different systems characterization of coals; so in recent years there has been a transition from elemental chemical composition, as a classification criterion, using directly related technological criteria for the use for which it is intended carbon (fuel or feedstock for the manufacture gas or coke). Thus the degree of a carbon, or economic value is defined by the relationship between its main characteristics or properties and possible applications. In this regard, the following considerations must be: 1. It is clear that in the field of coal combustion is the most important parameter determined heating power in a bomb calorimeter. 2. In the case of heat treatment, achieves important behavior against heating. Some species gather, others swell thereby 3. next Analysis: Includes measurement of moisture, volatile, ash and carbon; It is the simplest and most widespread form of characterization of a coal as it can take basic laboratory equipment. Humidity is generally determined by the percentage weight loss of a sample by heating in an oven at 105 ° C. Above this temperature losses appear, unimportant for most coals chemisorbed water, but significant to the lignite and generally much lower the higher the fuel range. As the heating temperature rises, the bound water in the occasion of the beginning of pyrolysis reactions come off. Fuel moisture: varies greatly, depending on conditions DEM extraction and mechanical preparation, the time that has been exposed to weather and atmospheric conditions at the time of sampling. Allowing carbon balance specific to certain atmosphere of humidity, temperature is obtained equilibrium moisture or humidity, fuel property, which varies depending on the range it contains, according to the ASTM, are measured at 30 ° C in air (Zapata, 2006) (P 1984) (1992 C.) (G 1987) and 97% relative humidity. The moisture content coal purposes in different fields: • Carbones low end, with higher moisture content have higher transport costs. • High levels of humidity define the coal mining as an inert, reducing the flame temperature, the enthalpy change of state with smoke evacuation and increased consumption of auxiliaries (fans). • A low moisture content promotes and inhibits potential milling crowds. Volatile content: During starting of the combustion process is clear from the coal volatile matter consisting of different amounts of hydrogen, carbon oxides, methane and other low molecular weight hydrocarbons. The volatile content of coal is an important property of this, providing an indication of the reactivity and ease of ignition. In practice, measuring the amount of volatiles is a function of the characteristics of the coal sample and the selected combustion process. Here, the test proposed by ISO determination fixed temperature (900 ° C), the length (7 min), and the container that has to be deposited out of contact with air; weight loss of the sample under these conditions is defined as the coal volatile content. An excessively high in volatile (over 30%) can cause security problems in milling due to the appearance of spontaneous ignitions. ash: Is the solid residue which remains after complete combustion of any organic matter and the oxidation of the mineral matter in the coal. It is never equal to the contents of the content of mineral fuel before combustion of substances because they changed their ways of combination. Among the many chemical reactions involved are dehydration of kaolin and gypsum, dissociation of carbonates and pyrite oxidation. Furthermore, certain components such as chlorides totally or partially volatilize. The most important chemical transformations are represented, at least theoretically, by the reactions: Al2O3·2 SIO2·2 H2O →Al2O3·2 SIO2 +2 H2O CaCO3 → CaO+ CO2 2 FeS2 ++5.5 O2 → 4SO2+ Fe2O3 These reactions cause a weight loss product with respect to the reactants, so that, except in very rare cases, the content of ash obtained by calcination in air is always a measure the effect of mineral content in the coal. This forces to normalize the temperature and duration of the test. Consequently, the ash quality defined coal combustion in determining the current contents incombustible matter. A higher ash content, calorific value lower present the raw coal and the higher the additional cost of handling and treatment as well as the potential erosion problems in the transportation equipment and combustion. CLASSIFICATION OF COALS One of the most accepted classifications for coal corresponds to the American Society for Testing and Materials (ASTM D388-777), shown in Table 1, which is RULES OF COAL Although there is no standard with standards for the quality of coal and wood (with the exception of Resolution 123 of 1998, which standardizes the sulfur content by region)the rules under which they perform laboratory procedures are presented. RULES OF COAL divided into four classes according to the properties referred the composition of the plants and the conditions of pressure and temperature (degree of metamorphism) who underwent during its formation. (B.S.Pawlowsky, 1971). Although there is no standard with standards for the quality of coal and wood (with the exception of Resolution 123 of 1998, which standardizes the sulfur content by region) the rules laboratory under which they perform procedures are presented. (General rules on sampling analysis of coals, 1995) and Applicable documents: a. ASTM Standards (General Standards on Sampling and analysis of coals, 1995) • D-86 test for the distillation of petroleum products at atmospheric pressure. • D268 Guide to analyze volatile and intermediate chemicals solvents for use in paints and coatings and related materials. • D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method). • D525: Test method for oxidation stability of gasoline (Induction period method). • D 923: Standard Test Method for checking the electrical insulation fluid. • D 4177: Practice for Sampling automatically petroleum and petroleum products. • D 5854 practice for mixing and handling of fuel volatility measurements. Documentos aplicables: a. Normas ASTM: (Normas Generales Sobre Muestreo y analisis de carbones, 1995) • D-86 de prueba para la destilación de productos de petróleo a presión atmosférica • D268: Guía para analizar sustancias químicas volátiles e intermedios de disolventes para su uso en pinturas y revestimientos y materiales relacionados • D323: Método de ensayo para la presión de vapor de los productos de petróleo (método Reid) • D525: Método de ensayo para la estabilidad a la oxidación de la gasolina (período de inducción método) • D 923: Método de prueba para comprobar el aislamiento eléctrico del líquido • D 4177: Práctica para el muestreo automáticamente petróleo y sus derivados • D 5854 para la práctica de mezcla y manipulación de combustibles medidas de volatilidad b. AMERICAN NATIONAL STANDARDS: • B93.19 standard method for extracting fluid samples from lines of a trading system with hydraulic fluid force (for analysis of particle contamination) • B93.44 method for extracting fluid samples warehouse operations with the force of hydraulic fluid. (General rules on sampling and analysis of coals, 1995). DISCUSSION AND ANALYSIS OF RESULTS: %𝐶𝑒𝑛𝑖𝑧𝑎𝑠 = (19.827 − 18,894) 𝑥100 %𝐶𝑒𝑛𝑖𝑧𝑎𝑠 = 93.3% Análisis de humedad residual (ASTM D3173) Table 5. Determination of volatile material Table 3. Results obtained by the analysis of moisture. MATERIAL Pi Pf - Crucible+ coal ( initial) WEIGHT (g) Crucible coal + 21.420 Pf crucible+ coal (final) 20.805 --- Difference 0.615 0.3733 Calculation of % humedity: %humedad = (𝑝𝑖 − 𝑝𝑓) 𝑥100 %humedad = (22.5071 − 22.1338) 𝑥100 %𝐻𝑢𝑚𝑒𝑑𝑎𝑑 = 37.33% Table 4. Determination of cinder. MATERIAL WEIGHT (g) Pi 22.5071 Crucible + 22.1338 coal (final) 110°C difference MATERIAL Calculation of % MV: Weight loss was first established. 𝑝𝑖 − 𝑝𝑓 %𝑃𝑃 = 𝑥100 𝑝𝑚 %𝑃𝑃 = 21.420 − 20.805 𝑥100 1,0000 %𝑃𝑃 =61.5 % WEIGHT (g) Pi CRUCIBLE + 19.827 COAL Pf CRUCIBLE + 18.894 CINDER -- Difference 0.933 Calculation of % cinder %𝐶𝑖𝑛𝑑𝑒𝑟 = (𝑝𝑖 − 𝑝𝑓)𝑥100 Materia volátil: %𝑀𝑉 = %𝑃𝑃 − %𝐻𝑢𝑚𝑒𝑑𝑖𝑡𝑦 %𝑀𝑉 = 61.6 − 37.3 %𝑀𝑉 = 24.1 Table of results: Tabla 7. Results of next analisis to coal DESCRIPCION RESULTADO % Humedity 37.33 % cinder 93.3 % volatile matter 24.1 According to the results (Table 7). The analysis is carried out on a sample of coal assigned by the teacher. It appears that this has a moisture content of 37.33% indicates that the sample corresponding to a coal of low rank, with low heat capacity because much of the energy is dissipated in the enthalpy change of state of water present in the sample. Given this moisture content and based on ASTM (Peña Urueña, 2011) standards is expected to peat. Table 7 shows that the sample contains an ash content of 93.3% which is indicative of the vast amount of non-combustible material present in the sample. By the time the sample was heated to 900 ° C was almost immediate ignition, which is explained by the high content of volatile matter in the sample found in 24.1% calculated. The analyzed sample corresponds to a low rank coal as it has features that allow us to classify it as lignite or peat (Peña Urueña, 2011), this based on their high moisture, ash, volatile material. CONCLUSIONS According to the analysis results for the next coal sample obtained is a possible match to the type of coal lignite or peat. However, it is necessary to obtain greater accuracy with the type of carbon, the final analysis, where data are considered in addition to proximal analysis. Bibliography 1. Normas generales sobre muestreo y analisis de carbones. (1995). Santafe de bogota: ECOCARBON. 2. B.S.Pawlowsky. (1971). Determinacion of total ash content of activated carbon. Electronic via CCC. 3. C., R. (1992). Introduccion a la caracterizacion de carbones. Medellin Facultad Nacional de Minas: Universidad Naciona de Colombia. 4. G., P. (1987). Caracterizacion de Carbones colombianos Zona Checua-Lenguazaque . Bogota: Ingeominas. 5. http://webs.uvigo.es/josanna/p df/Tecnologia_Energetica/Carb on/TEN-T03_AnexoCarbon.pdf. (s.f.). 6. http://www.factoria3.com/docu mentos/CARBON.pdf. (s.f.). 7. http://www.upme.gov.co/Docs/ Cadena_carbon.pdf. (s.f.). 8. P, R. (1984). Carbones: Muestreo, preparacion macro y micropetrografia. Medellin: Universidad Nacional de Colombia. 9. Zapata, C. E. (2006). Guia metodologica para la caracterizacion y evaluacion de la calidad de combustibles solidos, liquidos, y gaseosos. Medellin: Universidad Nacional de Colombia.