Received: 3 July 2020

Revised: 9 October 2020

Accepted: 17 October 2020

DOI: 10.1002/mrc.5110

RESEARCH ARTICLE

NMR relaxometry analysis of molecular degradation in

internal combustion engine lubricants

Eustaquio M. Erro |

Leandro J. Gerbino

Laboratorio de Relaxometría y Técnicas

Especiales (LaRTE), Facultad de

Matemática, Astronomía, Física y

Computación, Universidad Nacional de

Córdoba and IFEG-CONICET, Ciudad

Universitaria, Córdoba, Argentina

Correspondence

Eustaquio M. Erro and Esteban Anoardo,

Laboratorio de Relaxometría y Técnicas

Especiales (LaRTE), Facultad de

Matemática, Astronomía, Física y

Computación, Universidad Nacional de

Córdoba and IFEG-CONICET. Ciudad

Universitaria, 5000 Córdoba, Argentina.

Email: anoardo@famaf.unc.edu.ar;

emerro@famaf.unc.edu.ar

Funding information

Fondo para la Investigación Científica y

Tecnológica, Grant/Award Number:

PICT-2017-2195

| Carla C. Fraenza

| Esteban Anoardo

Abstract

A set of experimental techniques headed by proton fast field-cycling nuclear

magnetic resonance (1HFFC-NMR) were used to analyze the effects of

degradation of lubricant oil used in an internal combustion engine (ICE). Its

relaxometric, spectroscopic, and rheological properties were evaluated and

interpreted in terms of changes in the chemical structure and the involved

molecular dynamics. In order to better understand the relaxometric behavior,

chemical changes induced by heat were investigated for selected n-alkanes, as

model-systems due to their structural simplicity. Fourier transform infrared

(FTIR) spectroscopy, viscosity measurements, and foaming were used to

contrast NMR relaxometry experiments. Main observed changes associated

with oil degradation can be attributed to molecular oxidation, fragmentation,

and ramification. As an outstanding feature of this work, we show that the

relaxometric analysis can be done without any special treatment of the sample,

allowing results in less than 10 min.

KEYWORDS

degradation, lubricant, NMR, relaxometry

1 | INTRODUCTION

Internal combustion engine (ICE) lubricants are a complex mixture of hydrocarbons constituted by base oil and

specific additives.[1,2] Their main function is not only

reducing wear and friction but also providing protection

against corrosion and removing combustion residues

from the engine. A new/fresh ICE lubricant degradation

starts immediately after engine operation is set on, progressing with time according to the use and conditions of

the engine. Lubricant degradation sets in due to intrinsic

and external factors directly affecting its performance

and consequently, compromising the engine efficiency

and its useful life. This is essentially the main reason of

why condition monitoring technology for ICE lubricants

turned to be a topic of increasing interest at both

academic and industrial sectors.[3–5]

Magn Reson Chem. 2020;1–7.

Most important and commonly used methods to

sense quality and degradation of lubricant oils include

Fourier transform infrared (FTIR) spectroscopy,[6–8]

high-pressure differential scanning calorimetry,[9] bulk

oil oxidation stability,[10] cinematic viscosity,[11] total

basic and acid number, and metals by atomic absorption

spectroscopy and gas chromatography.[12] Also, nuclear

magnetic resonance (NMR) spectroscopy is often used to

analyze lubricants.[13,14]

Fast field-cycling NMR relaxometry (FFC-NMR)[15,16]

was shown to be very useful for the characterization of

lubricant oils through the involved molecular dynamics.[17] In this technique, the spin–lattice relaxation time

(T1) is measured as a function of the magnetic field

strength (B0), that is, the 1H Larmor frequency (ν0 = γ

B0/2π, where γ is the proton gyromagnetic ratio). NMR

relaxometry allows characterizing the underlying

wileyonlinelibrary.com/journal/mrc

© 2020 John Wiley & Sons, Ltd.

1

2

molecular dynamics, such as molecular rotations and

diffusion. This information is obtained through the theoretical model that is used to describe the relaxation profile.[15,16] Our physical model uses frequency domain

data from lubricant oils relaxation rate dispersions.[18]

In this work, FFC-NMR relaxometry was used to evaluate nuclear magnetic relaxation rate (R1 = 1/T1)

changes in lubricant oil samples used in a car engine.

Results are analyzed using a theoretical model that

provides us with information about rotational and translational diffusion. FTIR spectroscopy, cinematic viscosity,

and foaming test were used to explain the relationship

between molecular transformation in the lubricant oil

and relaxation rate changes. In order to better understand the FTIR and the relaxometric behavior of

hydrocarbonated molecular systems under thermal stress,

we extended the experiments to simple pure molecules

like N-octacosane, n-1-octadecene and cis-9-octadecenoic

acid. We assume that the observed thermal effects in

these molecules can be extrapolated to the molecular

blend composing the lubricant. This procedure also

serves as a further validation of the theoretical model

in use.

2 | MATERIALS AND METHODS

The commercial lubricant oil used in our experiments

was Castrol Magnatec10W-40 (semisynthetic). The aged

lubricant oil samples come from an automobile gasoline

engine. N-octacosane 99% and n-1-octadecene were

purchased from Aldrich, oleic acid was from Sintorgan,

and n-octadecane was from Shell. N-octacosane thermal

degradation was carried out by heating a sample at 250 C

for 2 h in a homemade electric-resistance thermostatic

sand bath.

Relaxometry experiments where implemented with a

Spinmaster FFC-2000 CDC Relaxometer (Stelar; Mede,

Italy) using samples of 1.5 ml. R1 was determined

using standard prepolarized (PP) and nonpolarized

(NP) sequences.[15] In all the experiments reported here,

both the polarization and acquisition magnetic fields

were set to 0.375 T (equivalent to 15 MHz for 1H Larmor

frequency). Relaxation dispersion curves for lubricant

oil samples were determined by measuring 20 points

distributed within a Larmor frequency window ranging

from 30 kHz to 15 MHz. For the rest of the samples, at

least 10 points were measured within a Larmor frequency

range from 10 kHz to 15 MHz instead. Each point was

determined through an exponential fitting of 16 acquired

single acquisitions (without phase-cycling averaging) for

different relaxation delays. The typical total time per each

relaxation dispersion curve was between 2 and 3 min. R1

ERRO ET AL.

showed to be insensitive to the time window over which

the NMR signal was acquired (after a 90 pulse). The spin

relaxation process was mono-exponential, within errors,

at all frequencies. Measurements were carried out at

30 C for lubricant oil samples and 70 C for n-octacosane

and the other studied molecules. The sample temperature

was controlled using a Stelar Variable Temperature Controller (VTC) within ±1 C. The temperature measurement was calibrated using a Cu–Al thermocouple glued

into a 10-mm NMR tube connected to a CHY 503 electronic thermometer (CHY Firemate, Tainan, Taiwan).

A Bruker IFS66VFTIR instrument, equipped with a

photoconductive MCT detector and OPUS software was

used to obtain the condensed-phase FTIR spectra. All

spectra were recorded at 3,500–400 cm−1 interval with a

resolution of 2 cm−1 from 32 coadded interferograms. A

rheometer (Physica MCR 301—Anton Paar, Germany)

was used for viscosity determinations. The cut speed

interval was 1 × 10−3 to 1 × 103 Hz, with a conic geometry (1.006 )—50 mm plate diameter, and temperature

control at 40 C with a Peltier system. For foaming

characteristics measurement, the procedure described in

ASTM D892-03 was followed. Samples maintained at a

temperature of 24 C were blown with air at a constant

rate for 5 min and then allowed to settle for 10 min. The

volumes of foam were measured at the end of both

periods.

2.1 | Theory

We analyze the relaxation data by considering translational diffusion and molecular rotations, assuming that

both contributions are statistically independent (and

dominant in different timescales)[17,18]:

Rot

R1 ðωÞ = RTr

1 ðωÞ + R1 ðωÞ,

ð1Þ

where Tr stands for the translational diffusion term and

Rot for the rotational.

For the account of translational diffusion, we consider

the force-free-hard-sphere (FFHS) model[19–21]:

RTr

1 ðω Þ =

AD

fJ ½zðωÞ + 4J ½zð2ωÞg,

Dd

ð2Þ

where

AD =

and

8 4 2 μ0 2

πγ h

n,

4π

45

ð3Þ

ERRO ET AL.

3

2

J ðz Þ =

1 + 58 z + z8

2

3

5

6

z

z

1 + z + z2 + z6 + 81

+ 648

:

ð4Þ

qffiffiffiffiffiffiffiffi

2

In these equations, ω = 2πν0, and zðωÞ 2ωd

D . D represents the relative diffusion coefficient (defined as

D ≡ D1 + D2 where the Dj are the self-diffusion coefficients of the involved molecules; d is the closest distance

between two nuclei located in different molecules, n is

the proton density, ћ is the Plank's constant divided by

2π, μ0 the vacuum magnetic permeability constant, and γ

the proton gyromagnetic ratio.

The molecular rotations contribution to the spin–

lattice relaxation rate can be expressed by a Lorentzian

form[19]:

RRot

1 ðωÞ = AR

τR

4τR

,

+

1 + ω2 τR 2 1 + 4ω2 τR 2

ð5Þ

where

AR =

3 42 μ0 2 1

γ

:

4π r 6

10

ð6Þ

With r the effective interproton distance between two

nuclei embedded in the same molecule and τR is the

rotational correlation time.

3 | R ES U L T S A N D D I S C U S S I O N

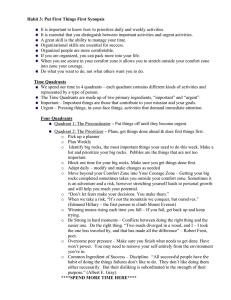

Relaxation rates dispersions and FTIR spectra obtained

for the fresh (0 km), used (10,000 km), and overused

(20,000 km) Castrol Magnatec samples are shown in

Figure 1a,b, respectively.

In Figure 1a, relaxometric profiles obtained for a

Castrol Magnatec lubricant oil with different levels of

degradation caused by an internal combustion engine are

presented as a function of the Larmor frequency. It is

clearly evidenced that the relaxation rate increases with

ageing, as observed in the whole measured frequency

range.

As can be observed in Figure 1b, six FTIR absorption

peaks (I–VI) were selected from the spectra for the evaluation of chemical changes. I (2,910 cm−1) corresponds to

C–H stretching from methyl (–CH3) and methylidene

bridge (–CH2–) groups; II (1,714 cm−1) corresponds to –

CO– stretching from carboxylic acid and aliphatic ketone

carbonyl groups; III (1,626 cm−1) corresponds to N–H

bending from amine; and IV, V, and VI (1,450, 1,368, and

723 cm−1) corresponds to C–H bending from alkane. In

concordance with relaxometric results, the FTIR spectra

show a progressive transformation of lubricant oil

F I G U R E 1 (a) R1 dispersion curves (symbols) and their

corresponding fittings (solid lines) using the model given by

Equations 1–6. Circles represent the fresh lubricant oil (0 km),

squares and triangles represent the used (10,000 km) and overused

(20,000 km) lubricant oil samples, respectively. Experiments were

realized at 30 C. (b) Fourier transform infrared (FTIR) spectra for

the fresh lubricant oil (black line), the used lubricant oil (green

line), and the overused lubricant oil (red line)

hydrocarbons molecules. The signal increase at II and III

indicates oxygen and nitrogen incorporation. A slight

increase in the peak areas ratio for I, IV, V, and VI

evidence molecular fragmentation and ramification.

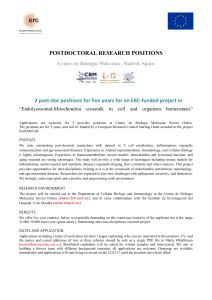

Lubricant oils gradually accumulate residues from

various sources including both internal and external to

the engine. Most common are metallic particles, soot,

dust, fuel, and water, among others. In order to test the

influence of such residues in the relaxation dispersion

profile, a considerable fraction of the solid residues was

separated by centrifugation using an Allegra 21 centrifuge

(Beckman-Coulter; Brea, United States). Centrifugation

was done at 9,000 rpm during 20 min. The supernatant of

4

the centrifuged specimen was further analyzed using

the NMR relaxometry technique. Then, a comparative

analysis was carried out between the R1 dispersion curves

obtained for the centrifuged and noncentrifuged oil

(Figure 2).

As can be observed in Figure 2, both relaxation dispersion curves are indistinguishable within experimental

errors. This result means that the presence of residues

does not affect the relaxometric analysis in an appreciable way, at least for the given conditions: accumulated

residues after 20,000 km of use and centrifugation at

9,000 rpm (20 min). The fact that processes governing the

spin–lattice relaxation are hardly influenced by the

presence of solid residues represents the advantage that

used ICE lubricants can be analyzed directly, without

any special sample treatment, allowing getting results in

a few minutes.

The model given by Equation 1 was used to analyze

the data shown in Figures 1a and 2. Some of the

involved physical parameters in this model, namely, d,

D, AR (Equation 6), and τR, were calculated from data

fitting, with initial values settled within their most probable intervals (according to previous results in different

oils). The proton density n was calculated as described

in Erro et al.[18] The obtained fitting curves using Equation 1 are shown in Figures 1a and 2, where a good

agreement with data can be observed within the experimental errors. The corresponding fitting parameters are

presented in Table 1, and their numerical values are in

agreement with similar studies already reported in the

literature.[14,18,22]

F I G U R E 2 R1 dispersion curves (symbols) and their

corresponding model fittings (solid lines) using the model given by

Equations 1–6. Circles represent the overused centrifuged lubricant

oil; triangles represent the noncentrifuged overused lubricant oil,

respectively. Experiments were performed at 30 C

ERRO ET AL.

From Table 1, we learn that the relative diffusion

coefficient D shows a tendency to decrease with the

increase of use of the lubricant. This behavior can be

associated to an increase in the viscosity due to changes

in the chemical structure and oxidation of the

hydrocarbonated chains (Table 2). The values of the

closest distance between two nuclei, d, and the rotational

amplitude (AR) did not show any tendency. An increase

in the rotational correlation times τR for the fresh, used,

and overused samples was observed. This result is also

consistent with an increase in the viscosity and consequently, a slower molecular mobility (Table 2). Last

column of Table 1 shows the parameters corresponding

to the centrifuged oil R1 dispersion (Figure 2). A significant similarity with the parameters of the noncentrifuged

specimen can be observed.

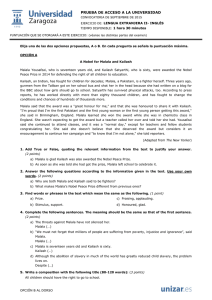

In an attempt to better understand the relaxometric

changes observed in these samples, a model molecule

was chosen for its study. N-octacosane (C28H58) is a very

simple molecule and a good model to study potential

chemical modifications (ramification, fragmentation, and

oxidation). To identify molecular changes induced by

heat, a thermal degradation was carried out by heating

an n-octacosane sample at 250 C for 2 h. Figure 3a shows

spin–lattice relaxation dispersion rates obtained for

n-octacosane in its pristine state (■) and thermally

treated n-octacosane (□) at a temperature of 70 C. Figure

3b shows FTIR spectra for a nontreated n-octacosane

(black line) and thermally treated n-octacosane (red line).

Figure 3a shows that the relaxation rate values

measured for thermally treated n-octacosane (□) are

larger than those obtained for the nontreated sample

(■). In addition, it can also be observed that the

treated sample shows up a higher R1 dispersion (clearly

observable in the MHz regime). This result suggests that

the chemical modifications promoted by thermal stress

are the responsible for a more efficient spin–lattice

relaxation process.

Four FTIR regions of the spectra (I–IV) were selected

from Figure 3b for the evaluation of chemical changes in

n-octacosane molecules. I, III, and IV corresponds to

methyl (–CH3) and methylene (–CH2–) groups. The

change observed in III and IV indicates a decrease of

methylene groups, which is consistent with a fragmentation process mediated by heat. Besides, the change in the

areas ratio between I to III and I to IV, suggest that the

methyl groups population increased throughout the

thermal treatment. II corresponds to carbonyl groups

(–C O–) and only appears in the thermally treated

sample. This confirms that heat causes the oxidation of

n-octacosane. The evidence suggests that the linear

n-octacosane is oxidized, fragmented, and ramified when

is exposed to a thermal treatment of 250 C for 2 h.[23]

ERRO ET AL.

5

TABLE 1

Parameters obtained using the model given in Equation 1

Parameter

d [m] × 10

−10

Fresh 0 km

Used 10,000 km

Overused 20,000 km

Centrifuged overused 20,000 km

3.0 ± 0.1

2.9 ± 0.1

2.5 ± 0.1

2.6 ± 0.1

D [m /s] × 10−11

2.7 ± 0.6

2.1 ± 0.6

1.6 ± 0.4

1.5 ± 0.4

AR [1/s ] × 10

6.0 ± 0.4

6.0 ± 0.4

3.3 ± 0.2

3.3 ± 0.2

3.0 ± 0.2

3.9 ± 0.2

4.8 ± 0.4

4.8 ± 0.4

2

2

−9

τR [s] × 10

TABLE 2

8

Measured cinematic viscosity values

Castrol Magnatec 10W-40, T: 40 C

Use (km)

Cinematic viscosity [cSt]

(95 ± 1)a

0

10,000

(106 ± 1)

20,000

(122 ± 3)

a

Value reported by the manufacturer: 96 cSt.

F I G U R E 3 (a) R1 dispersion curves for n-octacosane in its

pristine state (■) and thermally treated state (□). Measurements

performed at 70 C. (b) FTIR spectra of fresh nondegraded

n-octacosane (black line) and thermally treated n-octacosane

(red line)

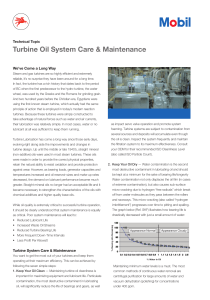

In view of our FTIR results, we can say that Castrol

Magnatec and n-octacosane exhibit the same type of

chemical alterations, which, as a whole, impact on the

relaxometric results increasing the R1 values in both

cases. Thus, R1 dispersion curves for several molecules

having different size and containing two different

functional groups were used in attempts to assess a more

precise causative significance of the observed changes in

the relaxation rates. In Figure 4, R1 dispersion curves for

three n-alkanes, n-heptane (■, C7H16), n-octadecane (□,

C18H38), and n-octacosane (C28H58) with (▲) and

without (▲) thermal treatment are presented. Oleic acid

(, cis-9-octadecenoic acid, C18H34O2) and n-1-octadecene

(♦, C18H36) R1 dispersion curves were added to Figure 4

in order to show the effect that carboxylic acid groups

and double carbon to carbon bonds have on the relaxation rate values.

The R1 dispersion curves for the n-alkanes, n-heptane

(■), n-octadecane (□), and n-octacosane (▲), presented

in Figure 4, show a regular increasing of relaxation rate

values as a function of molecular size. This can be

FIGURE 4

R1 dispersion curves for n-heptane (■), noctadecane (□), n-1-octadecene (♦), n-octacosane (▲), oleic acid

(), and thermally treated n-octacosane (▲). Experiments were

performed at 70 C

6

ERRO ET AL.

explained in terms of the molecular weight: the bigger

the molecules are, the higher the restriction in the movements they have. Such restriction plays in favor for a

more efficient relaxation process. No significant differences were observed between n-octadecane (□) and

n-1-octadecene (♦) curves, indicating that a double

carbon to carbon bond at one end of the molecule does

not affect the proton relaxation in a significant way.

Finally, the relaxation rate dispersion obtained for oleic

acid () shows that carboxylic acid groups generate a

considerable increment in relaxation rate values respect

of the obtained for n-octadecane (□). The oxygens from

carboxylic acid groups form hydrogen bond interactions

with neighboring molecules, which restricts movements

and give some “structure” to the liquid phase, doing, as

was previously mentioned, a more efficient relaxation

dynamics. Thermally treated n-octacosane (▲) shows

the higher relaxation rate values, which, based on

the evidence gathered, is caused by the chemical

restructuration produced by molecular oxidation, ramifications, and chain-rupture.

The standard test method for foaming characteristics

of lubricating oils (ASTM D892) gives us information

about how long takes certain amount of foam to disappear. Table 3 shows foam volume and permanence time

for the Castrol Magnatec samples.

The foam volume and permanence time values

depend directly from the strength and number of molecular interactions,[24] the longer time (>600 s) obtained for

the overused lubricant oil sample indicates a greater

ability to form and retain bubbles due to a mayor number

of oxidized molecules forming hydrogen bond intermolecular interactions. The oxidized molecules (which

have polar oxygenated functional groups) act as surfactants, thus reducing the surface tension and facilitating

foaming. Shorter times evidence that a smaller number of

molecules have incorporated oxygen. As a consequence,

strong intermolecular interactions like hydrogen bonding

are much less probable, thus having a minor impact

in the dynamical behavior of the lubricant molecular

blend.

TABLE 3

Foam volume and permanence time for the fresh,

used, and overused Castrol Magnatec samples

Castrol Magnatec 10W-40, T: 24 C

Use (km)

Foam volume (ml)

Permanence time (s)

0

(10 ± 1)

(150 ± 7)

10,000

(30 ± 2)

(300 ± 15)

20,000

(250 ± 20)

>600

4 | CONCLUSIONS

Results obtained in this work suggest that the progressive

increment of the relaxation rate values observed in

the fresh, used, and overused lubricant samples are

directly related to chemical transformation and structural

alterations of the molecules.

Based on our study about chemical modification in

molecules of lubricant oil and n-octacosane mediated by

heat, we are able to affirm that molecular oxidation,

ramification, and chain rupture are the main factors

affecting nuclear magnetic relaxation of protons. The

strong similitude between the overused centrifuged and

noncentrifuged lubricant oil R1 dispersions suggest that

the presence of solid combustion residuals, soot, and

metallic particles (among others), dispersed in the engine

oil, are not affecting the relaxometric behavior in an

observable way. This is a clear advantage of nuclear

magnetic relaxometry, because it allows the analysis of

lubricant oils without prior treatment of the sample.

However, this point calls for a deeper analysis because

over a threshold concentration, these components may

affect the relaxation rate dispersion. In fact, in the

present case, from Table 1, we learn that even the diffusion constant remains unaffected after removing the solid

residuals, that is, the molecular transport is not being

affected by the solid residuals accumulated in the

lubricant after 20,000 km of use.

A C KN O WL ED G EME N T S

The authors acknowledge financial and general support

from FONCYT, CONICET, and Universidad Nacional de

Córdoba. CCF acknowledges a postdoctoral fellowship

from CONICET.

DATA AVAILABILITY STATEMENT

The data that support the results here discussed are

available under request.

ORCID

Esteban Anoardo

4305

https://orcid.org/0000-0001-6667-

RE FER EN CES

[1] Z. Pawlak, in Tribochemistry of lubricating oils, (Ed: B. J.

Briscoe) Tribology and Interface Engineering Series Vol. 45,

Elsevier, Amsterdam 2003.

[2] C. A. Passut, in Engine Lubricants, (Eds: Q. J. Wang, Y. W.

Chung) Encyclopedia of Tribology, Springer, Boston, MA

2013.

[3] E. S. Mohamed, Appl. Therm. Eng. 2018, 132, 824.

[4] J. Wang, Z. Wang, F. Gu, X. Ma, J. Fei, Y. Cao, An investigation into the sensor placement of a marine engine lubrication

ERRO ET AL.

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

system for condition monitoring, in Advances in Asset Management and Condition Monitoring. Smart Innovation, Systems

and Technologies, (Eds: A. Ball, L. Gelman, B. Rao) Vol. 166,

Springer, Cham 2020.

L. Wei, H. Duan, D. Jia, et al., Friction 2020, 8, 95.

H. E. Henderson, M. Fefer, A. Legzdins, Am. Chem. Soc. Div.

Pet. Chem. Prepr. 1999, 44, 284.

R. Balabin, R. Safieva, Fuel 2008, 87, 2745.

M. Bassbasi, A. Hafid, S. Platikanov, R. Tauler, A. Oussama,

Fuel 2013, 104, 798.

B. K. Sharma, A. J. Stipanovic, Thermochim. Acta 2003, 402, 1.

T. Colclough, Ind. Eng. Chem. Res. 1987, 26, 1888.

A. A. Bhosale, K. Joshi, T. Karadkar, K. Mangidkarand, P.

Mundhe, Appl. Mech. Mater. 2014, 446, 558.

M. F. Fox, D. J. Picken, M. C. R. Symons, A. L. Thomson,

Tribol. Int. 1997, 30, 417.

S. L. Silva, A. M. S. Silva, J. C. Ribeiro, F. G. Martins, F. A. Da

Silva, C. M. Silva, Anal. Chim. Acta 2011, 707, 18.

E. Förster, H. Nirschl, G. Guthausen, Appl. Magn. Reson. 2017,

48, 51.

E. Anoardo, G. Galli, G. Ferrante, Appl. Magn. Reson. 2001,

20, 365.

R. Kimmich, E. Anoardo, Prog. Nucl. Magn. Reson. Spectrosc.

2004, 44, 257.

7

[17] M. Ballari, F. Bonetto, E. Anoardo, J. Phys. D Appl. Phys. 2005,

38, 3746.

[18] E. M. Erro, C. C. Fraenza, L. Gerbino, E. Anoardo, Mol. Phys.

2019, 117, 983.

[19] A. Abragam, Principles of Nuclear Magnetism, Clarendon

Press, Oxford 1961.

[20] L. Hwang, J. Freed, J. Chem. Phys. 1975, 63, 4017.

[21] J. Freed, J. Chem. Phys. 1978, 68, 4034.

[22] M. Hermansson, E. Johansson, M. Jansson, J. Synth. Lubr.

1996, 13, 279.

[23] D. Rush, A. Jaeschke, J. A. J. Geenevasen, E. Tegelaar, J.

Pureveen, M. D. Lewan, S. Schouten, J. S. Sinninghe Damsté,

Org. Geochem. 2014, 76, 136.

[24] P. W. Atkins, J. De Paula, Atkins' Physical Chemistry, Oxford

University Press, Oxford 2006.

How to cite this article: Erro EM, Gerbino LJ,

Fraenza CC, Anoardo E. NMR relaxometry

analysis of molecular degradation in internal

combustion engine lubricants. Magn Reson Chem.

2020;1–7. https://doi.org/10.1002/mrc.5110

![[23915447 - Open Geosciences] Dispersion modeling of air pollutants in the atmosphere a review (1)](http://s2.studylib.es/store/data/009245647_1-e01e6d572fb5c9e569adf677cc203c10-300x300.png)