See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/312115094

Automatic generation control and monitoring the mechanism of micro hydro

power plant with impulse turbine and synchronous generator

Conference Paper · November 2016

DOI: 10.1109/ICRAI.2016.7791249

CITATIONS

READS

7

1,522

1 author:

Nazib Sobhan

World University of Bangladesh

2 PUBLICATIONS 7 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Electro-Mechanical Design View project

All content following this page was uploaded by Nazib Sobhan on 03 January 2018.

The user has requested enhancement of the downloaded file.

Automatic Generation Control and

Monitoring the mechanism of Micro Hydro

Power Plant with Impulse Turbine and

Synchronous Generator

Nazib Sobhan, arnob.ottoman@gmail.com, +88 01764367591

The classification of hydropower scheme is given below

[9]:

Abstract: This paper presents automatic generation

control and monitoring operation of Micro Hydro

power plant (MHPP), based on Impulse Turbine,

synchronous motor with permanent magnet and a servo

control spear valve. The key objective of this system is

to show the benefits of automatic generation control and

Human Machine Interface (HMI) for MHPP. Mainly,

turbine governing system covers the automatic

generation part. A deflector and a servo valve are used

for turbine governing system and PID controller is used

to adjust with the generator output. The PID controller

is used for the deflector and servo valve. The PLC is

used to control the whole mechanism and SCADA is

combined with PLC for monitoring and supervising the

system. The proposed scheme is verified with severe

MATLAB simulation result and finally a small project

confirmed the feasibility of this model. The output

results of both simulation and real model proves that

this model can work properly in real system.

Generation

Large

Small

Mini

Micro

Pico

1.

2.

3.

4.

5.

INTRODUCTION

Can be used for rural area electrification which area

are far from national grid

The construction of Dam or weir is not costly as large

dam

The low environmental impact

The plant installation can be done in a short time and

also not complicated

The equipment cost is not high compare to other

hydro project.

Now a days, PLC is used for computer based automatic

control and supervising the micro hydro power plant. The

concept is taken from Mae-Ngat hydro power plant under

responsibility of the Electricity Generating Authority of

Thailand (EGAT) [8]. The basic difference of existing

model and proposed model is the type of turbine. In Mae

Ngat the Kaplan turbine but in proposed model Pelton

wheel type Impulse Turbine is used. This turbine is much

easier to control than Kaplan Turbine. The PLC and

SCADA is applied on an existing model built by both AIT

Water Engineering Management (WEM) and Energy

Department. The several experimental results from the

existing model data indicate that the proposed turbine

control system can work properly.

Hydro power technology is the most widely

technology among others renewable energy. More

than 19% of the world’s electricity is coming from this

sector. However, a large potential of hydropower

scheme remains unexploited. This is because,

implementation of mini hydro schemes with

conventional hydraulic, electrical equipment and

controllers are very expensive and uneconomical. To

solve this problem alternative options and new designs

have been developed by the engineers and researchers.

The application of this modified new design would

reduce the cost of mini hydro schemes.[1,2,3,4,12] As

a result, many developing countries like Thailand,

Laos and Bangladesh can use this scheme for rural

electrification where interconnection of transmission

line from electrical grid is uneconomical. For this, it

would be now possible to use more renewable energy

sources than before.

978-1-5090-4059-9/16/$31.00 ©2016 IEEE

Transmission

National Grid

National Grid

Micro Power Grid

Micro Power Grid

Only for Domestic

Use

Among them Micro Hydro Scheme is more popular. The

benefits of Micro Hydro Scheme are given below:

Keywords: Impulse Turbine, Servo Valve, PLC, HMI

and PID

I.

Capacity

1000 MW <

Up to 25 MW

Below 1MW

6kW -100KW

5 KW>

II.

175

Plant Model Description:

Like every power plant this model includes

impulse turbine, synchronous generator and servo

valve as controlling equipment. Moreover, there

is other equipment that is not described in this

paper. The proposed schematic model is given

below:

The Impulse Turbine model is given below:

Fig.2 Mathematical model of Turbine

The mathematical formulation of Impulse Turbine is given

below in details:

The Input Power Coefficient is,

Fig.1 The proposed Plant Model

Cin =

2'PQ

{ρ(v +U 2 )blrb N rb v}

2

Efficiency,

At first the water is flowing to the turbine from the source

(River, Fall) through the Dam or Weir. Then water energy

is converted to water energy to mechanical energy. The

formula of this conversion is given below:

η=

Tω

ΔPQ

I=

v

U

Flow coefficient,

Pw= (1/2)

ρAV3

Where,

Here,

T=Torque, ρ=Density, v=Inlet velocity, U=

Circumferal velocity, P=Pressure, Q=Flow rate, ∆P=Total

Pressure Drop, r=Radius of the turbine, l=total length,

N=Number of blades=blade height, k=Torque Constant.

ρ =Water Density (1000 kgm-3),V= Water Speed (ms-1),A=

water turbine rotor swept area (m2)

and

Cp=

Tt u Z

0.5 u A uV 3

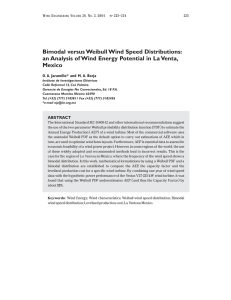

The initial output curve of the turbine is given below:

Cp= Power Coefficient of performance

The water turbine torque is given by,

P

T =

S W

s

Input

Power

Fig.3 The Output curve of Turbine Model (Impulse

Mode)

Ts=Torque of water turbine

Generator Model:

Most of the small or micro hydro sites, synchronous

generator is most preferable, because it has stable, good

characteristics during normal operation and they do not

need an additional DC supply for the excitation.

P= Power of water turbine

Ws=rotor speed of water turbine

1.

Turbine Model:

The generation capacity of hydropower plant

depends on the turbine efficiency. Hence, choose

of turbine in hydro power site is very important

[8]. Recently, a new design of Impulse turbine

model is invented that gives more flexibility and

reliability.

978-1-5090-4059-9/16/$31.00 ©2016 IEEE

Model of Servo Valve:

Servo valve is main control element in micro hydro plant.

Mainly, this valve is used to control the water flow through

dam to turbine. As a result the output power of the prime

mover can be controlled [11].

176

The mathematical model of servo motor control valve is

given below:

The resultant monitoring panel is given below:

1. Home Screen Panel

Fig.4 Mathematical Model of Servo

Motor Control Valve mechanism

Where, Kv=Valve Gain, Tv=Time rate of valve

Results and Discussion:

The results and output are given in some matlab simulation

curves and the SCADA models. The respective parameters

of the plant is given below:

Turbine Flow rate,Q=0-0.11m3/s

Generator Speed range=0-1200 rpm

Output Power=0-4.8 KW Rated Speed (t) =1500 rpm

Input Torque,Tm=37.2 Nm

Damping factor, Kd=0.026

Rated Power,Pe=5.5 KW

Efficiency at rated speed, ƞ=0.9

Rated voltage, V=400V

Rated Current, I=7.9A

Fig.6 The main Home-Screen Panel of MHPP

2.The AGC panel is given below:

The final resultant curve is given below:

Over Voltage

Voltage

Gain

Normal

Operation

Under Voltage

Time

Fig.5 Load changing affect and frequency deviation of

the system

From , the swing equation it is shown that the change of

rotor speed is depend on the difference of input mechanical

power and output electrical power. The main variable is

turbine input power which is depend on water flow.hence,

in this model the governor is used to control the flow and

thus controlling flow is the prime mechanism of automatic

generation control (AGC).

978-1-5090-4059-9/16/$31.00 ©2016 IEEE

177

Fig.7 The various parameters of MHPP

3. The PID monitoring panel is given below:

RESULTS&DISCUSSION:

In this section, some of output graphs of the proposed

micro hydro model is given which describe the system

operation and analysis of the total system. Some of the

graphs are given below:

In this curve the change of input and output power analysis

in accordance to the flow rate is discussed. The power

analysis curve is given below:

Fig.8 The monitoring model of PID application

The proposed experimental set up is given below:

Figure The change of head water level

In this curve the change of input and output power analysis

in accordance to the flow rate is discussed. The power

analysis curve is given below:

Figure 9 The proposed experimental set up

This is the schematic diagram of the whole control system.

The following flow chart describes the whole control

mechanism:

The Input is coming

from Voltage &

Current from the

manual Circuit

The Valve

is finally

rotate by

stepper

motor and

makes

perfect

position

PLC OUTPUT is

connect with

ARDUNIO

Driver circuits

run the motor

with pulse

signal and

direction

coming from

the driver

circuit

978-1-5090-4059-9/16/$31.00 ©2016 IEEE

Figure Rate of change of power with input water flow

PLC

OUTPUT is

connect

with

ARDUNIO

ARDUNIO step

signal is used for

making proper

Pulse for the

Driver Circuit

The turbine and generator are connected with common

rotor. The output speed and frequency is significant for the

model. The speed analysis curve is given below

Speed and frequency changing Curve

178

6.

Duangsoithing T., Kongnam C. Renovation of

Turbine Control System Using PLC-Based for

Small Hydroelectric Power Generation. Brief

Report on Mae-Ngat Hydro power plant by

Electricity Generating Authority of Thailand

(EGAT).

7. Operational description of Pump as a turbine

from AIT-EHMF Collaborative Project on Micro

Hydro system at Asian Institute Of technology,

Thailand.

8. Turbine and hydropower modeling project by

SINTEF Energy Research in 2005.

9. Hydraulic Turbine and turbine Control Model for

system dynamic studies under IEEE system

dynamic performance. Established in 1977.

10. A. Williams (1996), “Pumps as turbines for low

cost micro hydro power”, Renewable Energy

Journal, Volume 9, Issues 1-4, pp.1227-1234.

11. Dolla and Vatti (2006), “ Automatic generation

control of an isolated small-hydro power plant”

Electrical power system research 76(2006) 889896.

12. Handmandlu and Goyal (2008), “Proposing a

new advanced control technique for micro hydro

power plants.” Electrical Power and Energy

Systems 30 (2008) 272-282.

CONCLUSION:

This paper is focused on the control technique of MHPS.

The automatic generation control which is formed by

computerized control technique recovers the faults and

crisis very quickly and effectively. This paper focus on

PLC as computerized tool for system control. For

validation, a small project is built as a real model.

However this model cannot be done in real hydro site due

to lack of budget. The simulation data is taken from the

output result of the experiment in a joint venture project of

Water Engineering Management (WEM) and Energy

Department in AIT. Finally, there are recommendations

like transformer connection and grid fault can be

considered in future work. Moreover, highly

communication devices like Ethernet and Optical fiber can

be used for Stand-alone MHPS.

REFERENCES

1.

2.

3.

4.

5.

Kishor N., Singh N, Raghuvanshi A. (2006).

Adaptive Intelligent hydro turbine speed

identification with water and random load

disturbances. Engineering Applications of

Artificial Intelligence,.

Laghari J., Mokhils H., Bakar A., Mahammad H.

(2012).A comprehensive overview of new

designs in the hydraulic, electrical equipments

and controllers of mini hydro power plants

making it cost effective technology. Renewable

and sustainable Energy reviews,.

Li L., Ma R. (2012).Design and Analysis of

Comprehensive Control System for Hydro

turbines. AASRI Procedia,.

Marquez J, Molina M, Pacas J (2010).Dynamic

modeling, simulation and control design of an

advanced micro-hydro power plant for distributed

generation application. .

Singh R., Chelliah T., Agarwal P. (2014). Power

electronics in hydro electric energy systems-A

reviews.

978-1-5090-4059-9/16/$31.00 ©2016 IEEE

View publication stats

179