design system for

midas Gen Integrated

Building and General structures

PUSHOVER ANALYSIS

User’s Guide

midas Gen Ver.7.4.1

1

Contents

00

E h

Enhancements

t in

i P

Pushover

h

A

Analysis

l i

1

Pushover Global Control

2

Pushover Load Cases

3

Define Pushover Hinge Properties

4

Assign Pushover Hinge Properties

5

Pushover Hinge Properties Table

6

Pushover Analysis Result

7

Important Notice to Existing Users

2

0-1

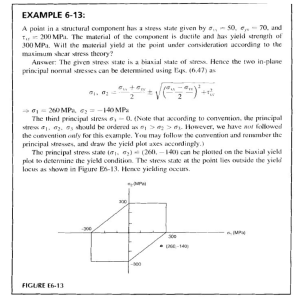

Gen V741 Pushover Enhancement :ANALYSIS

ANALYSIS #1

NONLINEAR ELEMENT

0-4

~ 0-7

Moment-Rotation (M-θ) type hinge can be used in Load control pushover analysis. (Beam, Wall Element) : Eurocode8:2004, FEMA,

Bilinear Tri

Bilinear,

Tri-linear

linear type

Out-of-plane nonlinearity for wall elements of the plate type is reflected.

Distributed hinge is added. (Moment-curvature relation): Plasticity of the entire element considered. Enter integration points (1~20).

(* Only plasticity at both ends was considered for the present Multi-linear type element.)

Defining

g hinge

g properties

p p

for nonlinear g

general link completely

p

y revised.

Moment-Rotation (M-θ) type hinge and Moment-Curvature (M-φ) type hinge can be used in combination.

PUSHOVER HINGE PROPERTIES

Eurocode8: 2004 hinge properties is newly added.

added

Masonry material type is newly added. It is applicable only for beam element.

PMM TYPE (Change in axial forces considered)

– RC Tri-linear : Crack surface(1st yield surface) can be defined.

- Steel Tri-linear : 1st, 2nd yyield surface can be separately

p

y defined.

0-8

0-9

~ 0-10

- Maximum yield moment about ±My, ± Mz can be individually defined.

Skeleton curve considering slip is newly added for truss element and general link.

The user can directly define the initial stiffness of nonlinear hinges.

The user can directly define yield deformations.

3

0-2

Gen V741 Pushover Enhancement :ANALYSIS

ANALYSIS #2

3

NONLINEAR ANALYSIS

Improvement on load control method: 100% of applied load is accurately reflected in analysis.

Addition of Load Incremental Method

- Auto-stepping control: The first step is loaded up to 90% of the elastic limit of the structure. Further steps are automatically divided into

n −1

the ratio of

{(n + 1) − i} / ∑ i .

i =1

- Equal step (1/nstep): Equally divided steps.

- User defined Increment-control function

Auto-terminating condition is added.

- Current Stiffness Ratio: If the analysis results do not converge, analysis will be terminated.

Auto-terminating

terminating condition by story drift ratio is added (Displacement Control).

- Auto

Analysis Speed

0-11

Analysis speed is improved by adopting INCORE Solver. Analysis time is reduced to 40-50% compared to the old version.

[Comparing analysis time]

old

version

Ver.7.4.1

Ver.7.4.1 /

old version

Skyline S

olver

47.570

[sec]

20.790

[sec]

43.70 [%]

MultiFrontal S

olver

46.780

[sec]

20.490 [se

c]

43.80 [%]

¾ Number of Nodes: 135

¾ Number of elements:beam (234), wall (12)

¾ Nonlinear hinges are assigned to all the elements.

¾ Incremental method: Displacement Control (50

steps)

4

0-3

Gen V741 Pushover Enhancement : PRE & POST

Pre-processing

p

g

1

PUSHOVER GLOBAL CONTROL : Total control of pushover analysis is available with one dialog.

Initial load

Default value of stiffness reduction ratio (bi-linear/tri-linear hinge curve)

Nonlinear Analysis Option (Maximum Iteration, Convergence Criteria)

Scale Factor for Ultimate Rotation and Secondary Seismic Elements as per Eurocode8-3

PUSHOVER HINGE PROPERTIES

3

Addition of Eurocode8:2004 pushover hinge properties, Masonry material type

Define hinge properties by elements (six components can be defined in a single dialog.)

Hinge properties about y-axis and z-axis are separately defined.

Show yield strength in real value as well as the ratio of the yield surface.

Assign hinge properties by Drag & Drop

PUSHOVER HINGE PROPERTIES TABLE

5

Check hinge properties using Pushover Hinge Properties table

Post-processing

Pushover graph

Target displacement as per EN 1998-1:2004, Force-Deformation graph, displacement graph by steps, etc.

Pushover Hinge result table

Safety verification, Hinge status, Plastic deformation, etc.

6

5

0-4

Gen V741 Pushover E Enhancement :ANALYSIS

Moment-Rotation (M-θ) type hinge can be used in Load control pushover analysis.

analysis

(Eurocode8:2004, FEMA, Bilinear type and Trilinear type)

Both Load-control and Displacement-control

increment method are available regardless

g

of

the element type.

Bilinear and Trilinear is available for the Moment

MomentRotational angle interaction element

6

0-5

Gen V741 Pushover Enhancement :ANALYSIS

Out-of-plane

Out

of plane nonlinearity for wall elements of

the Plate Type is reflected.

Nonlinearity can be defined for 6 components.

For wall elements of the Membrane Type,

Type only inin

plane nonlinearity can be reflected.

Nonlinearity can be defined for in-plane

component

p

only.

y

7

0-6

Gen V741 Pushover Enhancement :ANALYSIS

Distributed hinge is added. (Moment-curvature relation): Plasticity of the entire element considered.

Select Moment-Curvature(Distributed)

Æ Enter integration points (1~20) .

applicable for beam elements

(Not applicable for wall elements)

Enter integration point

8

0-7

Gen V741 Pushover Enhancement :ANALYSIS

Defining hinge properties for nonlinear general link completely revised.

Old version

i

Nonlinear general link was defined in the

inelastic hinge properties dialog.

G V741(NEW)

Gen

Nonlinear general link is defined in the PUSHOVER hinge properties dialog.

Note that general link hinge properties assigned in the old version are not automatically

converted in V741.

9

0-8

Gen V741 Pushover Enhancement :ANALYSIS

added

Eurocode8 :2004 type is added.

added

Masonry material type is added.

Select Moment – Rotation (M-θ).

Pier type / Spandrel type

Applicable for Beam/Column, Wall and Truss type.

applicable for beam element type.

10

0-9

Gen V741 Pushover Enhancement :ANALYSIS

PMM TYPE(Change in axial force considered):RC Tri-linear type

RC Tri-linear : Crack surface (1st yield surface) can be defined.

Maximum yield moment about ± My, ± Mz can be individually defined.

11

0-10

Gen V741 Pushover Enhancement :ANALYSIS

PMM TYPE(Change in axial forces considered):Steel Trilinear type

Steel Tri-linear : 1st and 2nd yield surfaces can be separately defined.

12

0-11

Gen V741 Pushover Enhancement :ANALYSIS

Analysis speed

Analysis speed is improved by adopting INCORE Solver. Analysis time is reduced to 40-50% compared to the old version.

ANALYSIS MODEL

Pushover curve in the old version

Pushover curve in V741

[C

[Comparing

i analysis

l i ti

time]]

¾ Number of Nodes: 135

old version

Ver.7.4.1

Ver.7.4.1 / old version

Skyline Solver

47.570 [sec]

20.790 [sec]

43.70 [%]

Mult-Frontal Solver

46.780 [sec]

20.490 [sec]

43.80 [%]

¾ Number of elements:beam (234), wall (12)

¾ Nonlinear hinges are assigned to all the elements.

¾ Incremental method: Displacement Control (50 steps)

13

0-12 Gen V741 Pushover analysis flow chart

Pushover Analysis

y Procedure

Define Initial load, convergence criteria, stiffness reduction ratio, etc.

Pushover Global Control

Pushover Load cases

Define incremental step, load pattern, incremental method (load control/

displacement control), auto-termination condition, etc.

Define whether to consider initial load and P-Delta effect

Incremental Control Function : set a user-defined incremental function (for Load

Control)

Define Pushover Hinge Properties

Assign Hinge Properties

Specify element type and material type

Hinge properties by force components (Fx, Fy Fz, Mz, My, Mz): yield strength,

skeleton curve type, P-M interaction, etc.

Assign hinge properties to elements

Perform Pushover Analysis

Yield strength is automatically calculated for each element.

Pushover analysis results: Pushover curve, Hinge Status Results, etc.

Pushover Results

Various pushover graphs

Various pushover hinge result tables

14

0-13

Gen V741 New context menu

PUSHOVER ANALYSIS / PUSHOVER HINGE PROPERTIES

Pushover Global Control : Enter the necessary analysis conditions to be applied to Pushover analysis.

-Initial load, Convergence criteria, Stiffness reduction ratio, Reference location for distributed hinges

-Pushover Global Control can be defined in a single dialog.

P h

Pushover

L d cases : Enter

Load

E t lload

d cases and

d analysis

l i conditions

diti

ffor pushover

h

analysis.

l i

-Increment steps, Increment Method (Load control / Displacement control), Analysis stopping

condition etc.

Define Pushover Hinge Properties(TYPE) : Define the plastic hinge data to be used in Pushover analysis.

-Nonlinear element type,

yp , Pushover hinge

g components,

p

, Hinge

g location,, Skeleton curve type,

yp , Hinge

g

properties etc.

-When auto-calculation is selected, the corresponding yield strength is automatically calculated based

on the design code. .

Assign Pushover Hinge Properties : Assign the hinge properties to the elements.

P h

I

tF

ti

E t th

t l ffunction

ti tto apply

l tto th

i C

t l

Pushover

Increment

Functions

: Enter

the iincrementt control

the St

Stepping

Control

Option

PUSHOVER HINGE PROPERTIES TABLE

Pushover Hinge Table : Check the hinge property type assigned to the elements

Pushover Hinge Properties Table : Check the hinge properties assigned to the elements. (Yield strength,

Yield deformation, Initial Stiffness etc.)

Perform Pushover Analysis

PUSHOVER RESULT

15

1-1 Pushover global control #1

Integrated menu for the user’s convenience

Old version

Gen V741(NEW)

Pushover analysis control

#1 : Initial Load

#2 : Convergence Criteria

* In the old version,

Increment Step

was not able to

define by load

cases.

Initial Load

#4 : Stiffness reduction ratio new

Define default value of stiffness

reduction ratio.

#3 Auto-Calculation new

Specify the reference location (i-end, jend, center) for calculating yield strength

of beam element

Specify scale factors for ultimate rotation

and identify secondary seismic elements.

16

1-2 Pushover global control #2

Define Initial Load

In order to assign the initial load, ‘Use Initial Load’ option

needs to be checked on in the Pushover Load Case dialog.

When P-M interaction is considered, the user needs to apply

the initial load.

Default value of Stiffness Reduction Ratio

Define the default stiffness reduction ratio of the skeleton

curve

curve.

Control Convergence Criteria

Specify the maximum number of sub-iterations and a tolerance

limit for convergence criterion. It is applied to all the pushover

load cases.

Data for Auto-Calculation of Capacity

Specify the reference location (i-end, j-end, center) for

calculating yield strength of beam element

Specify scale factors for ultimate rotation and identify

secondary seismic elements.

17

2-1 Pushover load cases (common)

Enter Increment Step

Enter number of steps to reach the estimated collapse

load or the prescribed displacement.

The incremental steps must be entered as a positive

integer value (nstep≥1), and minimum 20 steps are

recommended. (Default = 20)

Initial Load

Check on to assign the load defined prior to Pushover a

nalysis as the initial load for Pushover analysis.

When P

M interaction is considered, the user needs to

P-M

apply the initial load.

P-Delta Analysis

Select Incremental method

Load control, Displacement control

Define Pushover load case

18

2-2 Pushover load cases(load control)

INCREMENT CONTROL

Auto-Stepping Control

The applied load (Qud) is divided by the automatically

calculated load parameters.

parameters

The first step is loaded up to 90% of the elastic limit of the

structure. Further steps are automatically divided by the

n −1

ratio of {(n + 1) − i} / ∑ i .

i =1

Equal Step

The applied load (Qud) is equally divided by the number of

nstep.

Incremental Control Function

The applied load (Qud) is divided by the user-defined

function.

AUTO STOPPING CONDITION

Current Stiffness Ratio : If the Current Stiffness Ratio (Cs) is

entered and the ratio of the stiffness at the current an

incremental step to the initial stiffness reaches the specified

value, the analysis is terminated.

If the Limit Inter-Story Deformation Angle is entered and the

maximum Inter-Story Deformation Angle reaches the

specified value, the analysis is terminated

19

2-3 Pushover load cases : Load control #1

Improvement in Auto-Stepping Control

Old Version

Gen V741(NEW)

Exact load of entered data was not clear.

STEP 2 ~ STEP n : 100% of applied load is

accurately reflected in analysis.

100% of applied load was not accurately reflected.

5

Load

2

Incremental load

by equal step

Estimated

Collapse Load

Qud*X

Ultimate Load

by analysis

(Collapse Load)

Qu

Forcce

4

3

2

1 STEP : 90% of the elastic limit

1

1

Elastic

limit

Displacement

0

0

0.01

0.02

0.03

0.04

0.05

Displ.

20

2-3 Pushover load cases : Load control #2

Improvement of auto stepping control

Old Version

Gen V741(NEW)

1STEP : 90% of the elastic limit

* Elastic Limit: The load when

initial yield occurs

100% of applied load was not

reflected even though pushover

analysis was completed.

S F:1.0

S.F:

0 : 100% of applied load

is reflected.

Æ S.F:0.7 : 70% of applied load

was reflected.

21

2-3 Pushover load cases : Load control #3

Auto stepping control

Last step

1ST step

1) Estimate the elastic limit load by applying the lateral load defined by the

user. Here, elastic Limit means the estimated 1st yielding force.

2) 90% of elastic limit is defined as the load parameter of the

3) Define the incremental load at the

1st

1st

Pn = λn × P ; λn

= 1.0

step.

P1 = λ1 × P

Where,

step: λ1

Incremental load at the last step

λ1 : load parameter at the 1st step

Ex.

P1 : Incremental load at the 1st step

P

: total load

2nd step ~ (the last step-1) step

1) Load parameter at the current step ( i )

λi = λi −1 +

{(n + 1)) − i} ×

n −1

∑i

(1 − λ1 )

i =1

Where,

λi : load parameter at the current step

λi −1 : load parameter at the preceding step

n

i

λ1

: the number of total steps

: current step

: load parameter at the 1st step

2) Incremental load at the current step

Pi = λi × P

Where,

λi

Pi

P

: load parameter at the current step

: Incremental Load at the current step

: Total lateral load

22

2-3 Pushover load cases : Load control #4

Gen V741(NEW)

Equal Step is newly added.

Equal-step increment (1/n step)

The applied load (Qud) is equally divided by

the number of nstep.

Auto-Stepping Control

1step : 90% of the elastic limit

step 2 ~ final step : Auto-stepping

23

2-4 Incremental control function #1

Enter the

E

h iincrement controll ffunction

i to apply

l to the

h SStepping

i

Control Option in the Pushover Load Cases.

For example, if the user enters the Increment Control Function as

below and Increment Step (nstep) is specified as 10,

or

applied the Increment Control Function is as the table below.

below

Incremental Control Function

24

2-4 Incremental control function #2

Procedure for Pushover Increment Function

① Generate the Increment Control

Function.

② Define the generated function in

the Pushover Load Case dialog.

③ After performing analysis, pushover

curve will be produced identical to

the pattern of Load-Displacement

curve.

④ Check text file which contains

analysis results of the load

parameter and Increment Function.

25

2-5 Auto stopping control #1

Current Stiffness Ratio

Gen V741(NEW)

Current Stiffness Ratio

Elastic(Linear)

(

) : Cs = 1.0

Stable range

: 0.0 < Cs < 1.0

Unstable range : Cs<0.0

CS

CS

0.0 < Cs ≤ 1.0

Analysis

A l i is

i terminated

i

d if

the maximum number

of increments is

reached, or negative

values are encountered

in the stiffness matrix.

The user can obtain the

solution.

CS

Analysis is automatically

terminated when Cs reaches

the specified value.

26

2-5 Auto stopping control #2

Current Stiffness Ratio

Analysis Model

In case of displacement control

: The user can obtain the solution.

In case of load control

:The user cannot obtain the solution since stiffness is 0.

変位増分

Gen V741(NEW)

Analysis is automatically terminated

when

hen ccurrent

rrent stiffness ratio reaches 0

0.

1 Column

Stiffness reduction ratio:0.0

(Perfect Plasticity)

27

2-6 Pushover load cases : Displacement control

Displacement control option

Global

- Specify the target displacement with respect to the node where

the maximum translational displacement occurs.

Master Node

- Specify the master node, translational direction and maximum

displacement.

Auto-stopping condition

If the Limit Inter-Story Deformation Angle is entered and the

maximum Inter-Story Deformation Angle reaches the specified

value, the analysis is terminated. new

28

3-0 Define pushover hinge properties

1

Define Pushover Hinge

g Properties

p

Define the plastic hinge data to be used in Pushover analysis.

The hinge properties which are not assigned to the elements

are displayed in blue.

2

Assign

g Pushover Hinge

g Properties

p

Assign the hinge properties in Define Hinge Properties to all the

elements.

When the hinge properties are assigned to the elements, it is

displayed in Black.

B: Element type

( B: Beam, T: Truss, W: Wall, SPR: GL

GL-LINK

LINK )

3: Element number

Beam : Defined hinge name

The assigned hinge data can be modified and

updated data are automatically applied to all the

assigned element.

When the user modifies the assigned hinge

data, new hinge properties are

automatically generated.

29

3-1 Define pushover hinge properties

“M-θ” and “M-Φ” type hinge properties (Eurocode 8: 2004, Masonry, FEMA, Bilinear, & Tri-linear type)

Old Version

Gen V741(NEW)

1

Element type

2

Material type

3

Load-deformation relationship of the

flexural member

- M-θ type

- M-Φ distributed type (beam elements in

dynamic nonlinear analysis)

- M-Φ lumped type (existing Multi-linear

type)

4

1

2

Type of wall element

- Membrane: Only in-plane plasticity is

considered

4

- Plate: Both in-plane and out-of-plane

plasticity are considered

3

5

Reflection of coupled axial force-biaxial m

oment behavior

6

- Component: the degree of freedom to be

assigned to the plastic hinge type

5

- Hinge Location

1) M-θ/M-Φ lumped type beam or wall

elements: Center, I-end & J-end

2) M-Φ Distributed type beam elements:

Number of integral points

3) Truss, General link:Center

-Skeleton Curve: Eurocode8:2004, FEMA,

Bilinear & Tri-linear type

6

7

7

Relevant hinge properties

- Yield strength, stiffness reduction

ratio

- Initial stiffness

- Yield strain

Multi-linear type and FEMA type can not be

simultaneously used.

30

3-2 Define pushover hinge properties

When Definition is Moment-Rotation (M-θ) :

Component

Definition of hinge properties

Initial stiffness

Location of hinge

Fx (Axial)

Axial force - Strain (Relative Displ.)

EA/L

Middle

Fy, Fz (Shear)

Shear force- Shear strain

GAs/L

Middle

Mx (Torsion)

(

)

Torsional moment - Rotation

GJ/L

I-end, J-end

My, Fz (Flexure)

Flexural moment - Rotation

6EI/L, 3EI/L, 2EI/L

I-end, J-end

When Definition is Moment-Curvature (M-φ Lumped, Distributed)

Component

p

Definition of hinge

g properties

p p

Initial stiffness

Location of hinge

g

Fx (Axial)

Axial force - Strain

EA

Integration point

Fy, Fz (Shear)

Shear force- Shear strain

GAs

Integration point

Mx (Torsion)

Torsional moment - Curvature

GJ

Integration point

My, Fz (Flexure)

Flexural moment - Curvature

EI

Integration point

When Element Type is Truss (Fx component):

Component

Definition of hinge properties

Initial stiffness

Location of hinge

Fx (Axial)

Axial force - Strain

EA

Integration point

When Element Type is General Link

Component

Definition of hinge properties

Initial stiffness

Location of hinge

Fx (Axial)

Axial force - Strain (Relative Displ.)

User-defined (EA/L)

Middle

Fy,

Fy Fz (Shear)

Shear forceforce Strain (Relative Displ.)

Displ )

User-defined

User defined (GAs/L)

Middle

Mx (Torsion)

Torsional moment - Rotation

User-defined (GJ/L)

Middle

My, Fz (Flexure)

Flexural moment - Rotation

User-defined (EI/L)

Middle

31

3-3 Define pushover hinge properties: Eurocode8:2004 #1new

2

1

3

4

8

5

1

Input method of yield strength

2

Rebar arrangement between i-end and

j-end (symmetric/Asymmetric)

3

When ‘Asymmetric’ is selected.

4

Hinge properties in the positive

and negative

g

directions ((Symmetric

y

or Asymmetric)

5

Define primary curve (M/My, D/Dy)

6

Yield strength

7

Yield strain

8

Class of cross section

9

Compliance Criteria

10

Initial stiffness

9

6

7

10

32

3-4 Define pushover hinge properties: Eurocode8:2004 #2

1

Input

p method of yyield strength

g

Auto-Calculation : The corresponding yield strength is automatically

calculated based on the design code.

* Following definitions are required for Auto-Calculation.

1. Design Code

2. Material and section properties defined from the standards

3. Rebar data for RC members

1

2

4

User Input : All the input data are user-defined parameters.

2

Value Type of I-End & J-End

Symmetric : Select if rebar arrangement between i-end and j-end are

symmetrical.

Asymmetric : Select if rebar arrangement between i-end and j-end are

asymmetrical.

* Value Type of I-End & J-End option is activated when User Input option is

selected.

* The asymmetrical yield strengths between I-end and J-end are automatically

reflected when input method is set to Auto-Calculation.

4

Type

Symmetric : Select if the hinge properties are symmetric in the positive and

negative directions.

Asymmetric : Select if the hinge properties are asymmetric in the positive

and negative directions.

33

3-5 Define pushover hinge properties: Eurocode8:2004 #3

6-1

Yield strength

g

The values are automatically calculated using the section information if

Input Method is set to Auto-Calculation. Or the user may enter the values of

Yield Moment manually if Input Method is set to User-Input. The coordinate

system follows the Element local Coordinate System.

RC structures

t

t

M={As2*fsc*(d-d2)}+M’

Flexural

Hinge

Where, As2= area of compression steel

M’=K’bd2fck

fsc=700(xu-d2)/xu ≤ fyd

d2=effective depth to compression steel

xu=(δ-0.4)d

fyd=design yield strength of reinforcement

Shear strength of reinforcement, VRd,S is the smaller value of:

6

Eurocode2:2004, Equation(6.8) and (6.9)

Shear

Hinge

Shear strength of concrete, VRd,C

Rd C is given by:

Eurocode2:2004, Equation(6.2a) and (6.2b)

Therefore, Shear strength,

Therefore

strength VRd is

FY = max (VRd,s ; VRd,c)

Where, αcw=1.0

αcc =1.0

fcd=αcc fck/γC

γC=1.0

34

3-6 Define pushover hinge properties: Eurocode8:2004 #4

6-2 Yield strength

g

Steel structures

Flexural

Hinge

Eurocode3:2005, Equation (6.13)

Shear

Hinge

Eurocode3:2005, equation (6.18)

After assigning hinge properties to the element, calculated yield

strength and yield strain can be checked in the detail report.

6

35

3-7 Define pushover hinge properties: Eurocode8:2004 #5

7

Yield rotation

Auto-Calculation

The values are automatically calculated using the section information if this

option is checked off. Or the user may enter the values of Yield Rotation

manually. The coordinate system follows the Element local Coordinate

System.

RC structures (Eurocode8-3:2004, Annex A.3.1)

DY

Eurocode8-3:2004, Equation(A.10b)

Flexural

Hinge

DU

Eurocode8-3:2004, Equation(A.1)

7

Steel structures

Flexural

Hinge

θy= MyL/6EI

DY

Where, My: Yield moment, L: Length of a member,

E: Elasticity of Modulus, I: moment of inertia

36

3-8 Define pushover hinge properties: Eurocode8:2004 #6

8

Class of cross section

Rotation capacity at the end of steel beams or columns depends on the class of

cross section. In order for the program to automatically determine the class of

cross section for the pushover analysis, select ‘Auto’. For the automatic

classification Steel Code Checking should be performed first.

Plastic Rotation Capacity

p

y

9

Compliance Criteria

Enter the target performance indices for the structure in terms of deformation.

The values outlined in Eurocode 8-3 are used as the basic values. Only positive

values are entered if symmetrical.

y

10

8

9

Define the initial stiffness

By default, initial stiffness of moment hinge is taken equal to the Yield

Strength divided by Yield Rotation, and the Yield Strength and Yield Rotation

are automatically

t

ti ll calculated

l l t db

based

d on Eurocode

E

d 8 partt 1 & 3

3. A

Any safety

f t

factors including partial factors are not reflected in the calculation of strength

and deformation.

6EI/L, 3EI/L, 2EI/L: It is activated when Definition is defined as Moment Rotation (M-θ).

User: The initial stiffness that has been automatically calculated is displayed

here. If the value is modified, the modified value will be applied as the

initial stiffness.

Elastic Stiffness: Elastic stiffness is used for the initial stiffness.

10

37

3-9 Define pushover hinge properties: Masonry #1

new

2

1

Spandrel type

3

4

yp

Pier type

5

1

Masonry Properties

2

Input method of yield strength

3

Hinge properties in the positive

and negative directions (Symmetric

or Asymmetric)

A

ti )

4

Define primary curve (M/My, D/Dy)

5

Yield strength

6

Yield strain

7

Initial stiffness

7

6

Calculated resistance can be checked in Design > Pushover

Analysis > Pushover Hinge Result Table > Beam Summary table.

Yield

Yield

strength deformation

38

3-10 Define pushover hinge properties: Masonry #2

1

Masonry

y properties

p p

Spandrel type

In the structural model, masonry spandrels may be taken into account as

coupling beams between two wall elements. This assumption implies that

they should regularly bonded to the adjoining walls and connected both to

the floor tie beam and to the lintel below. If the structural model takes into

account the coupling beams, a frame analysis may be used for the

determination of the action effects on the vertical and horizontal structural

elements.

Spandrel type

Pier type

Pier type

Building Type: Flexural capacity and shear resistance of masonry pier

depends on the type of building as shown in the table below.

Element Local axis of masonry wall pier

In-plane horizontal direction and transverse direction of the wall pier should coincide with the local z-axis and local

y-axis of the element, respectively as shown in the figure below, which directly affects the resistance of the wall

pier. Also, the program calculates hinge properties (My component) on the assumption above.

39

3-11 Define pushover hinge properties: Masonry #3

5, 6

Yield strength & Yield strain

Pier type

Axial resistance

Compression; N R = f m ⋅ D ⋅ t , Tension; N R = 0

Where, D : In-plane horizontal dimension of the wall pier (depth)

t : Out-of-plane horizontal dimension of the wall pier (thickness)

Shear resistance

1.5 ⋅ t0

σ

New Building; VR = D ' ⋅ t ⋅ t0 , Existing Building; VR = D ⋅ t ⋅

t0

1+

β

1.5

'

Where, D : Depth of the compressed area of the masonry pier

β = 1.5 (1.5 ≤ H / D)

= H / D (1.0 ≤ H / D < 1.5)

= 1.0 ( H / D < 1.0)

H : In-plane vertical dimension of the wall pier (height)

σ = N (D ⋅ t)

N : Axial force

Flexural resistance

MR =

5

N ⋅D⎛

σ ⎞

⎜1 −

⎟

2 ⎝ k ⋅ fm ⎠

Spandrel type

Axial resistance:

Compression; N R = f hd ⋅ h ⋅ t, Tension;

Where,

Height

Wh

i h off the

h masonry spandrel

d l

h: H

t : Width of the masonry spandrel

Shear resistance:

6

NR = 0

VR = h ⋅ t ⋅ f vk 0

Flexural resistance

MR =

Hp ⋅h ⎛

Hp

⎞

⎜1 −

⎟

2 ⎝ 0.85 ⋅ f hd ⋅ h ⋅ t ⎠

Where, H p is taken as the minimum value between 0.4 f hd ⋅ h ⋅ t and

user-defined value.

40

3-12 Define pushover hinge properties: FEMA

Old version

i

G V741(NEW)

Gen

1

2

3

4

5

1

Input method of yield strength

2

Rebar arrangement between i-end and

j-end (symmetric/Asymmetric)

3

When ‘Asymmetric’ is selected.

4

Hinge properties in the positive and

negative directions (Symmetric or

Asymmetric)

5

Define primary curve (M/My, D/Dy)

6

Yield strength

7

Yield strain

8

Acceptance Criteria

9

Initial stiffness

8

6

7

9

41

3-13 Define pushover hinge properties: multilinear#1

Multi-linear Type of M-θ element

RC Tri-linear : Define 2nd slope by αy

Old version

Gen V741(NEW)

1

2

3

4

5

1

Input method of yield strength

2

Input type of Skeleton Curve

3

Rebar arrangement between i-end and

j-end (symmetric/Asymmetric)

4

Hinge properties in the positive and

negative directions (Symmetric or

Asymmetric)

5

Yield strength

6

Stiffness reduction ratio

7

Initial stiffness

8

Initial gap in tension and compression

6

7

8

42

3-14 Define pushover hinge properties: multilinear#2

Enter y

yield strength

g

1

Auto-Calculation : The corresponding yield strength is automatically

calculated based on the design code.

* Following definitions are required for Auto-Calculation.

1. Design Code

2. Material and section properties defined from the standards

3. Rebar data for RC members

User Input : All the input data are user-defined parameters.

1

2

3

Define Skeleton Curve

2

Strength - Stiffness Reduction

: Define the Skeleton Curve using the yield strength and the stiffness

reduction ratio.

Strength – Yield Deformation

: Define the Skeleton Curve using the yield strength and the yield

deformation defined by the user.

* Strength - Yield Deformation option is activated when the Input Method is

set to User Input.

* Yield Deformation is changed depending on the component. (Fx : yield

deformation, Fy & Fz : yield strain, Mx & My & Mz : yield rotation angle)

3

Value Type of I-End & J-End

Select if rebar arrangement between i-end and j-end are asymmetrical

I End & J-End

J End option is activated when the hinge type is

* Value Type of I-End

defined as Moment-Rotation (M-Θ) or Moment-Curvature (M-φ Lumped) and

User Input option is selected.

43

3-15 Define pushover hinge properties: multilinear#3

4

In case of Asymmetric

between I-end and J-end

y

Enter nonlinear properties when asymmetric is selected for ‘Value Type of IEnd & J-End’ in M-θ interaction element

6

Enter yield strength

Auto-Calculation

:The values are automatically calculated using the section information if

Input Method is set to Auto-Calculation.

4

* Following

g definitions are required

q

for Auto-Calculation.

1. Design Code

2. Material and section properties defined from the standards

3. Rebar data for RC members

6

User Input : All the input data are user-defined parameters. (P1<=P2)

- P1 : 1st yield strength

- P2 : 2nd yield strength

Yield strength of bilinear (auto-calculation)

P1

RC /SRC (Encased)

STEEL/ SRC(Filled)

(Ultimate,Mu)

(Ultimate,Mu)

Yield strength of Tri-linear (auto-calculation)

RC /SRC (Encased)

STEEL/ SRC(Filled)

P1

(Crack,Mc)

(Yield,My)

P2

(Ultimate,Mu)

(Ultimate,Mu)

44

3-16 Define pushover hinge properties: multilinear#4

7

Stiffness reduction ratio

Stiffness reduction ratio : Define the slope after yielding

α1 : Stiffness reduction ratio after 1st yielding (α1≤1.0)

α2 : Stiffness reduction ratio after 2nd yielding (α2≤α1≤1.0)

Use Value of Global Control Data

: Stiffness reduction ratio defined in Pushover Global Control dialog is used.

User Defined

Use ay by AIJ Code : Use αy calculated as per AIJ code

⎛

⎝

α y = ⎜ 0.043 + 1.64npt + 0.043

a

⎞⎛ d ⎞

+ 0.33η0 ⎟⎜ ⎟

D

⎠⎝ D ⎠

2

*Define when RC Tri-linear, M-θ element and AIJ Code is selected.

*When coupled axial force-biaxial moment behavior is not considered, αy is

calculated based on the axial force in the initial load.

* When coupled axial force-biaxial moment behavior is considered, αy is

calculated based on the moment-rotation relationship for a member’s

section.

*The user can define the shear span to depth ratio for αy. (Default is

“Auto”.)

8

7

8

Define the initial stiffness

6EI/L, 3EI/L, 2EI/L : It is activated when Definition is defined as Moment

- Rotation (M-θ).

User : Defined by the user

Elastic Stiffness : Elastic stiffness is used for the initial stiffness.

45

3-17 Pushover Global Control : Stiffness Reduction Factor

1

Define the default stiffness reduction factor of the skeleton

curve.

2

If “Use Value of Global Control Data” option is selected, in the

Directional Properties of Pushover Hinge dialog, the default

values will be considered.

3

4

In order to change the stiffness reduction factor after

assigning

g g hinge

g p

properties

p

to the elements,, the user needs to

change the default value in Pushover Global Control dialog.

Corrected stiffness reduction factor ( 3 ) is automatically

updated in the Directional Properties of Pushover Hinge

dialog.

46

3-18 Input method of PMM type

1

2

1

2

3

4

By selecting P-M-M in status deformation option, coupled axial force-biaxial moment behavior can be

reflected.

- P-M-M

P M M in

i status

t t d

deformation

f

ti iis applicable

li bl only

l ffor beam

b

and

d wall

ll elements.

l

t

- For Wall element of Membrane Type, only My component is applicable.

Skeleton Curve

- Specified skeleton curve in ‘My’

component must be identical to that in

p

‘Mz’ component.

3

Yield Surface Properties

4

Input method

(Auto-calculated / User-defined)

5

Primary curve

6

Define the yield strength : For auto-calculation,

yield strength is automatically calculated based on

the design code. When P-M-M in status deformation

option

ti is

i selected,

l t d the

th yield

i ld strength

t

th is

i updated

d t d for

f

each step considering coupled axial force and

biaxial moment behavior.

7

Yield surface: Yield surface about strong and weak

axes can be checked by table or graph.

5

6

7

In case of P-M-M in status

deformation,, yyield strength

g

is

automatically calculated using

the section information

even

though ‘User Defined’ option is

checked on.

47

3-19 Define yield surface #1

Old version

Gen V741(NEW)

Crack surface of RC Type (1st yielding

surface) was not able to be defined.

MY,max

Yield surface about strong and weak axes

48

3-20 Define yield surface #2

Define RC yield surface

1

2

3

4

5

6

7

8

9

11

10

12

1

Input method of yield strength

2

Rebar arrangement

g

between i-end and jj-end (

symmetric/Asymmetric)

3

Hinge properties in Y-axis and Z-axis

(symmetric/Asymmetric)

4

Define the skeleton curve and initial stiffness,

etc for the rotation about yy-axis and z-axis.

5

In case ‘Asymmetric’ is selected in Value Type

of I-end & J-end

6

Hinge properties in the positive and negative

directions (Symmetric or Asymmetric)

7

Yield strength about y-axis and z-axis

8

PM interaction curve

9

Yield surface about strong and weak axes

• Tension (-), Compression (+)

• Crack surface is defined by PC0, MC0

10

Show Value : Click to display the applied

forces and moments in analysis.

11

MU0 (Ultimate axial force without axial force)

12

Yield surface can be checked by graph.

49

3-21 Define yield surface #3 : RC Eurocode8, FEMA & Bilinear

1

Define the yield strength

Define Yield/Ultimate surface

Pmax(c) : Yield axial force in compression

MY0

: Ultimate moment without axial force

→ the user cannot enter MY0 directly.

directly

MY,max : Maximum ultimate moment

1

2

Define the yield surface

2

Yield/Ultimate Surface : Tension(-), Compression(+)

Since membrane type of wall does not have out-of-plane

stiffness, moment about only Y-axis is defined.

50

3-22 Define yield surface #4 : RC Tri-linear

1

Define the yield strength

1st Yield (Crack) strength

1

PC0(t) : Yield axial force in tension

MC0 – Crack moment without axial force

2nd Yield (Ultimate) strength

Pmax(c) – Yield axial force in compression

MY0 – Ultimate moment without axial force

(The user cannot enter MY0 directly.)

MY,max – Maximum ultimate moment

2

2

Define the yield surface

1st Yield (Crack) surface

The program automatically compute the crack surface

using PC0(t) and MC0.

2nd yield (Ultimate) surface

Tension(-), Compression (+)

* Since membrane type of wall does not have out-of-plane

stiffness,

moment about

only

Y-axis

defined.

iff

b

l Y

i iis d

fi d

51

3-23 Define yield surface #6 : Steel Eurocode8, FEMA, Bilinear

1

Define the yield strength

2nd Yield (Ultimate) strength

Pmax(c) – Yield axial force in compression

MY y, z, max – Maximum ultimate moment

1

2

Define the yield surface

1st and 2nd yield (Ultimate) surface

2

Tension(-), Compression (+)

52

3-23 Define yield surface #5 : Steel Tri-linear

1

Define the yield strength

1st Yield (Crack) strength

PC(t) : Yield axial force in tension

1

MC y, z – Maximum crack moment

2nd Yield (Ultimate) strength

Pmax(c) – Yield axial force in compression MY y, z, max –

Maximum ultimate moment

2

2

Define the yield surface

1st and 2nd yield (Ultimate) surface

Tension(-), Compression (+)

53

4-1 Assign pushover hinge properties #1

Assigned the hinge properties in Assign Pushover Hinge Properties menu

1

Define Pushover Hinge Properties

The hinge properties which is not assigned to elements is

displayed in blue.

2

3

Select the ‘Assign Pushover Hinge

Properties’ menu.

4

Select the hinge type to assign to the selected elements and then click

OK button.

b tt

→ Assigned

A ig d hinge

hi g symbols

b l are di

displayed

l

d iin contours.

t

Select the elements to which hinge properties are assigned.

5

Nonlinear hinges assigned to the elements are generated in the Work Tree.

54

44 2 Assign pushover hinge properties #2

Assign the hinge properties to the corresponding element by Drag & Drop of a mouse

1

Define Pushover Hinge Properties

The hinge properties which is not assigned to elements is

displayed in blue.

2

Select the elements to which hinge

g properties

p p

are assigned.

g

.

3

Select a desire hinge property in the work tree and drag &

drop in the model view.

4

Pushover hinge symbols are displayed to the assigned elements.

Nonlinear hinges assigned to the elements are generated in the

Work Tree.

Note

If the specified hinge data and the selected elements do not

match the hinge properties are not assigned.

match,

assigned

General link type hinge properties cannot be assigned by

Drag & Drop of a mouse.

55

4-3 Assign pushover hinge properties #3

Changes in ‘Display’ option regarding Pushover Analysis: “Misc” Æ “Design”

Old version

Gen V741(NEW)

56

5-1 Pushover hinge properties table #1

Nonlinear hinge properties table

Display the assigned hinge properties per component in the table . Display method of assigned element is changed.

From the Main Menu, Design > Pushover Analysis

> Select the

t e Pushover

us ove Hinge

ge Properties

ope t es Table

able

From the Tree Menu, Select the Assign Pushover Hinge Properties,

Right-Click

g

and select Pushover Hinge

g Properties

p

Table…

Show Hinges on Selected Elements

Display the Pushover Hinge Properties Table

for the selected elements only.

Show All Hinges

Display the Pushover Hinge Properties Table

for all the elements to which hinge properties

are assigned.

57

5-2 Pushover hinge properties table #2

Pushover hinge properties table

The color of the table

All the assigned hinge properties are displayed in the table.

Marked in blue

: Values which cannot be changed.

Hinge properties cannot be deleted in the table.

Marked in green

: Values which can be changed.

Marked in gray

: Values which is not used.

• Pushover Hinge properties dialog can be opened

by double-clicking

double clicking the element number.

number

• Pushover Hinge properties dialog can be opened

by clicking the components.

components

58

5-3 Change the assigned hinge properties #1

Change the hinge properties by defined hinge properties type (Recommend)

Assigned hinge properties to the numerous elements can be modified at once.

1

1

Modify hinge properties in the Define

Pushover Hinge Properties dialog.

2

All the assigned hinge properties are

automatically updated according to

the modified hinge properties.

2

59

5-4 Change the assigned hinge properties #2

Change hinge properties by assigned members

After assigning hinge properties, hinge properties by members can be changed.

2

1

3

1

Right-click on the assigned hinge properties to

be revised.

2

Select ‘Properties’ to open the Pushover Hing

e Properties dialog.

3

Click ‘Enable to Modify’ option.

4

Change the properties and click ‘OK’ button.

5

New hinge properties is automatically generat

ed.

6

Name of assigned hinge properties is updated.

4

5

6

60

5-5 Change the assigned hinge properties #3

Change hinge properties using Pushover hinge properties Table

1,

2

5

3

4

1

Right-click on the assigned hinge properties to

be revised.

2

Click ‘Pushover Hinge Properties Table’.

3

Modify the values in the table.

4

If the values are updated

p

in the table,,

message is displayed.

5

New hinge property is generated and the assig

ned hinge name is updated.

61

6-1 Pushover analysis result

Old version

Gen V741(New)

Plot graphs for pushover analysis results

- Force versus Deformation for Beam, Truss, Wall and General Link

- Incremental nodal displacement

- Pushover hinge results for the load increment

Check the pushover analysis results in a spreadsheet format table.

- Member forces, Strain, Ductility, Yield strength and Yield strain

- Initial

I iti l Stiffness

Stiff

* For PMM type, yield moment for each step due to P-M interaction

can be checked in the table.

Check the hinge status (Ductility, Deformation, Force, Status of

yielding) resulting from the Pushover analysis in Contours.

62

6-2 Pushover analysis result– Pushover Analysis Result

Result of Pushover Analysis

1

2

3

4

5

6

7

1

Check Reactions, Deformations, Forces and Stresses for each Pushover

Step.

2

Check the hinge status (Ductility,

(Ductility Deformation

Deformation, Force,

Force Status of yielding)

in Contours.

3

Capacity curve and capacity spectrum of a structure

4

Plot graphs for pushover analysis results.

5

Plot graphs for pushover analysis results related to the story data.

6

Check the pushover analysis results in a spread sheet format table.

7

Produce text files for pushover analysis results.

63

6-3 Pushover analysis result– Hinge Status Result #1

Display the hinge formation result for each step

Display the load parameter

used in pushover analysis.

64

6-4 Pushover analysis result– Hinge Status Result #2

Pushover Hinge Status

Ductility Factor (D/D1) : Ratio of the displacement to the 1st yielding

displacement at the corresponding step

65

6-5 Pushover analysis result– Hinge Status Result #3

Pushover Hinge Status Result

Ductility Factor (D/D2) : Ratio of the displacement to the 2nd yielding

displacement at the corresponding step

66

6-6 Pushover analysis result– Hinge Status Result #4

Pushover Hinge Status Result

Total deformation

67

6-7 Pushover analysis result– Hinge Status Result #5

Pushover Hinge Status Result

Plastic Deformation: Plastic deformation (total deformation – yielding deformation)

68

6-8 Pushover analysis result– Hinge Status Result #6

Pushover Hinge Status Result

Force

69

6-9 Pushover analysis result– Hinge Status Result #7

Pushover Hinge Status Result

Status of Yielding: Hinge status for Bilinear/Trilinear type hinge.

70

6-10 Pushover analysis result– Hinge Status Result #8

Pushover Hinge Status Result

Status of Yielding (FEMA)

71

6-11 Pushover analysis result– Hinge Status Result #9

Pushover Hinge Status Result

Status of Yielding (Eurocode8)

72

6-12 Pushover analysis result – Pushover Curve #1

Display the capacity curve of a structure

73

6-13 Pushover analysis result – Pushover Curve #2

Target Displacement (Eurocode8: 2004)

The target displacement of a structure is determined through the

transformation to an equivalent single degree of freedom system.

For the detailed formula, refer to ANNEX B DETERMINATION OF THE

TARGET DISPLACEMENT FOR NONLINEAR STATIC (PUSHOVER)

ANALYSIS, EN 1998-1:2004. The target displacement, which is

obtained from the above,

above corresponds to the seismic demand of the

Limit State of Significant Damage (SD).

Target displacement of the Limit State of Near Collapse (NC) is

taken equal to that of SD multiplied by 1.5. Target displacement of

the Limit State of Damage Limitation (DL) is taken equal to that of

SD divided by 2.5.

Demand

Roof displacement corresponding to the target displacement for

the seismic action is considered.

Capacity

Gl b l capacity

i

h masonry structure in

i terms off rooff

Global

off the

displacement (Master node). Only applicable to Masonry material

models.

Step

The nearest increment step to the target displacement

Remark

Assessment of the result in terms of the global response for the

masonry structure. Only applicable to Masonry material models.

74

6-14 Pushover analysis result – Pushover Curve #3

Global assessment (Masonry pushover)

Capacity

Global capacity of the masonry structure in terms of roof displacement (Master

node). Only applicable to Masonry material models.

Global capacity of the Limit State of Significant Damage (SD) is taken equal to the

roof displacement at which total lateral resistance (base shear) has dropped below

80% of the peak resistance of the structure, due to progressive damage and failure

off lateral

l

l resisting

i i elements.

l

Global capacity of the Limit State of Damage Limitation (DL) is taken as the

minimum value between a) displacement corresponding to the maximum base

shear in the pushover curve and b) displacement corresponding to the story drift of

3/1000.

Remark

Assessment of the result in terms of the global response for the masonry structure.

Only applicable to Masonry material models.

Limit State of SD: The assessment is OK if the g

global capacity

p

y of the Limit

State of SD is greater than the target displacement of the Limit State of SD and

q* is less than 3. q* is the ratio between the acceleration in the structure with

unlimited elastic behavior Se(T*) and in the structure with limited strength F*y / M*.

q* = Se(T*)M*/F*y.

Wh

Where,

Se(T*):

) represents

t the

th elastic

l ti acceleration

l ti

response spectrum

t

att the

th

period T* of the idealized equivalent SDOF system.

F*y: The yield force of the idealized system

M*:The mass of an equivalent SODF system

Limit State of DL: The assessment is OK if the global capacity of the Limit

State of DL is greater than the target displacement of the Limit State of DL (i.e.=

(i e =

Target Displacement of the Limit State of SD divided by 2.5.

75

6-15 Pushover analysis result – Pushover Graph

Pushover Graph

Draw graph of analysis results for specific node or element for specific interest

2

6

3

5

1

7

8

4

76

6-16 Pushover analysis result– Pushover Story Graph #1

Pushover Story Graph

Draw Story

y Shear Graph

p

for Selected Story

77

6-17 Pushover analysis result– Pushover Story Graph #2

Pushover Story Graph

Draw Member Shear Graph

p

for Selected Element

78

6-18 Pushover analysis result– Pushover Story Graph #3

Pushover Story Graph

Draw Story Shear/Drift/Drift Ratio

Graph for Selected Pushover Steps

79

6-19 Pushover analysis result– Hinge Table #1

Pushover Hinge Result Table

Show Story Hinge Status for Selected Load Case and Selected Pushover Step

Show Number of Hinge Status according to

FEMA or Multi-Linear Type Definition

80

6-20 Pushover analysis result– Hinge Table #2

Pushover Hinge Result Table

Show Yield Step of Element for Selected Load Case and Selected DOF

Ex) Beam Element No. 63 yields at 18th Pushover Step in Dx DOF

81

6-21 Pushover analysis result– Hinge Table #3

Pushover Hinge Result Table

Show analysis summary of beam element for selected load case

Ex) Hinge status of beam element at 30th pushover step in Dx DOF

82

6-22 Pushover analysis result– Hinge Table #4

Pushover Hinge Result Table

Show member force for selected load case and selected DOF

Ex) Member force of beam element at 30th pushover step in all DOF

83

6-22 Pushover analysis result– Hinge Table #5

Pushover Hinge Result Table

Show total deformation of member for selected load case and selected DOF

Ex) Total deformation of beam element at 30th pushover step in all DOF

84

6-23 Pushover analysis result– Hinge Table #6

Pushover Hinge Result Table

Show plastic deformation of member for selected load case and selected DOF

Ex) Plastic deformation of beam element at 30th pushover step in all DOF

85

6-24 Pushover analysis result– Hinge Table #7

Pushover Hinge Result Table

Show ductility factor (D/D1) of member for selected load case and selected DOF

D/D1 = Total Deformation / 1st Yield Deformation

Ex) Ductility factor (D/D1) of beam element at 30th pushover step in all DOF

86

6-25 Pushover analysis result– Hinge Table #8

Pushover Hinge Result Table

Show ductility factor (D/D2) of member for selected load case and selected DOF

D/D2 = Total Deformation / 2nd Yield Deformation

Ex) Ductility factor (D/D2) of beam element at 30th pushover step in all DOF

87

6-26 Pushover analysis result– Hinge Table #9-1

Pushover Hinge Result Table

Check safety verification results for the no-collapse requirement (ultimate limit

state)

t t ) under

d the

th seismic

i i design

d i situation

it ti

- Ductile member: safety verification in terms of member deformations (chord rotations) with

appropriate material partial factors and confidence factor applied on member deformation

capacities.

- Brittle member: safety verification is checked in terms of member forces (shear forces) with

appropriate material partial factors and confidence factor applied on member force capacities.

88

6-27 Pushover analysis result– Hinge Table #9-2

Capacity for assessment in the Safety Verification Table

(1) Reinforced Concrete Structures (Beam & Column) (Eurocode8-3:2004, Annex A.3.1)

*For ductile elements, mean values of properties divided by CF are used. For brittle members,

mean values of properties divided by CF and by partial factor.

89

6-28 Pushover analysis result– Hinge Table #9-3

Capacity for assessment in the Safety Verification Table

(2) Steel Structures (Beam & Column) (Eurocode8-3:2004, Annex B.5.2)

• For ductile elements, mean values of properties divided by CF are used. For brittle members, mean values of properties divided

by CF and by partial factor.

* θy= MyL/6EI

Where, My: Yield moment, L: Length of a member, E: Elasticity of Modulus, I: moment of inertia

90

6-29 Pushover analysis result– Pushover Text #1

Pushover Text

Text output:

Displacements

p

p

91

6-30 pushover analysis result– Pushover text #2

Pushover Text

Text output:

member forces / stresses of beam,, truss or wall elements

p

92

6-31 Pushover analysis result– Pushover Text #3

Pushover Text

Text output:

Deformation and Forces of general

link

p

g

93

6-32 Pushover analysis result : Reactions

Gen V741 (New)

Search Reaction Forces/Moment

Reactions

Search Reaction Forces/Moments

Reaction Forces/Moments

Reaction Force/Moments

94

6-33 Pushover analysis result : Deformations

Gen V741 (New)

Search Displacement

Deformations

Search Displacement

Deformed Shape

Displacement Contour

95

6-34 Pushover analysis result : Deformations

Gen V741 (New)

Deformed Shape

Deformations

Search Displacement

Deformed Shape

Displacement Contour

96

6-35 Pushover analysis result : Deformations

Gen V741 (New)

Displacement Contour

Deformations

Search Displacement

Deformed Shape

Displacement Contour

97

6-36 Pushover analysis result : Forces

Gen V741 (New)

Beam Forces/Moments

Forces

Truss Forces

Beam Forces/Moments

g

Beam Diagrams

Wall Forces/Moments

Wall Diagrams

Plate Forces/Moments

Plate Cutting Line Diagram

M b Diagrams

Member

Di

98

6-37 Pushover analysis result : Forces

Gen V741 (New)

Beam Diagrams

Forces

Truss Forces

Beam Forces/Moments

g

Beam Diagrams

Wall Forces/Moments

Wall Diagrams

Plate Forces/Moments

Plate Cutting Line Diagram

M b Diagrams

Member

Di

99

6-38 Pushover analysis result : Stresses

Gen V741 (New)

Beam Stresses

Stresses

Truss Stresses

Beam Stresses

g

Beam Stresses Diagram

Plane Stress/Plate Stresses

Plane Strain/Stresses

Axisymmetric Stresses

Solid Stresses

100

6-39 Pushover analysis result : Stresses

Gen V741 (New)

Beam Stresses Diagram

Stresses

Truss Stresses

Beam Stresses

g

Beam Stresses Diagram

Plane Stress/Plate Stresses

Plane Strain/Stresses

Axisymmetric Stresses

Solid Stresses

101

7-1 Important Notice to Existing Users #1

Data conversion – Analysis Control Data

Th model

d l fil

t d in

i the

th old

ld version

i can b

d iin th

i and

d are automatically

t

ti ll converted

t d iinto

t th

f

t

The

files created

be opened

the new version

the new iinputt format.

Old Version

Gen V741(NEW)

Convergence Criteria

→ Moved to the Pushover Global Control dialog.

dialog

Initial Load → Moved to the Pushover Global Control dialog.

102

7-2 Important Notice to Existing Users #2

Data conversion – Pushover Load Cases

Old Version

Gen V741(NEW)

Number of Incremental Steps

→ Moved to the Pushover Load Case dialog. (Number of

Increment Steps can be set by load cases separately.)

Auto-stepping Control

→ Control method is totally revised.

103

7-3 Important Notice to Existing Users #3

Data conversion – Hinge Properties Assignment

Old Version

Define hinge properties by components

1

Hinge properties by component

Gen V741(NEW)

Define hinge properties by elements

Hinge properties by element

1

* 3 components of hinge properties have been defined.

2

Hinge properties by component are assigned to the

elements.

* 9 hinge properties have been defined.

Hinge properties by element are assigned to the

elements.

2

* 36 hinge properties have been assigned.

1

* 9 hinge properties have been assigned.

1

2

2

Nonlinear hinge properties were defined by force components in the old version, however in the new version, they are defined by elements.

For example, in order to assign axial and flexural hinge properties to one element in the old version, the user defined two different hinge

properties However,

properties.

However in the new version,

version only one hinge property defining the axial and flexural properties is needed.

needed

In the new version, when the user opens a model file created in the old version, the component hinge properties will be individually assigned

to the corresponding elements (one component hinge property per element). So, the converted file size of the model may become larger than

that of the old version. This is not the general way to define hinge properties in the new version, but it is intended to avoid errors in converting

files. Refer to Assign Hinge Properties to learn how to assign hinge properties in the new version.

104

7-4 Important Notice to Existing Users #4

Data conversion –Hinge Properties Type

Old Version

Gen V741(NEW)

Old Version: Multi-linear

Old Version: FEMA

→ New Version: Moment-Curvature (Lumped)

→ New Version: Moment-Rotation

105