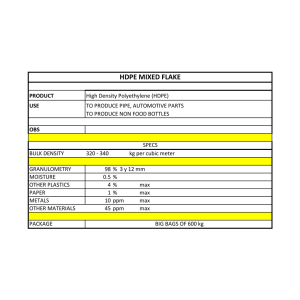

Water Treatment and Industrial Applications innovation > technology > future Tekna evo SOLENOID DOSING PUMPS 603 800 803 Intelligent Display, once a function is selected the pump will only display the parameters to set, which are linked to the selected function PVDF pump head and ceramic ball valve are standard Automatic Switching Power Supply 100÷240 Vac 50/60 Hz INNOVATIVE l l l LONG LIFE DIAPHRAGM TESTED TO GIVE "FIVE YEARS" WORKING LIFE 2 versions: analog and digital 3 models that cover 1.1 to 29 gph with an output pressure up to 170 psi l One style configuration allows for easy planning and preparation for installations l l l The advanced design and manufacturing process allows the diaphragm to have a unique life expectancy Made of pure solid PTFe, the diaphragm is compatible with most chemicals The diaphragm has been tested over a period of 5 years giving superior results routine diaphragm replacement is no longer a requirement TeChNICal FeaTUreS Model 603 800 803 02 seko Flow rate [gph] Pressure [psi] Stroke capacity [cc/stroke] 1.1 1.3 1.5 2.1 1.8 3.6 3.9 4.8 8 10 14.5 29 170 145 0,42 0,52 0,63 0,83 0,38 0,55 0,83 1,00 1,11 1,39 2,22 3,00 110 30 230 145 70 10 70 60 30 0 > water & industry > products overview Ø Connections IN / OUT [inches] Fequency max [stroke/min] Consumption [W] 0.17” x 1/4” 160 12,2 0.17” x 1/4” 300 23,9 5/16” x 7/16” 300 22,2 TEKNA EVO FEATURES level control input NeMa 4X rated Manual priming valve Complete standard installation kit includes: – PVDF foot filter and injection valve – PVC suction tube – Pe delivery tube electrical connections are configured with "quick-connectors", capped when not in use PTFe diaphragm. Standard pump head in PVDF Standard power supply Case made in PP reinforced with fiber glass. Automatic Switching 100-240 Vac 50-60 hz MATERIALS USED IN THE PUMP HEAD PERFORMANCE CURVE BODY PVDF Ball ValVeS PVDF BallS CeraMIC DIaPhraGM PTFe l 270 240 210 PVDF is suitable for almost all chemicals used in the Industrial, Waste Water Treatment and potable Water applications. Ceramic balls are used to ensure chemical compatibility and pump reliability. The parts that make contact with the injected chemicals have been chosen to provide for precise compatibility with most chemicals used in the industry. Pressure in psi l 300 180 800 150 120 90 60 603 803 30 0 2 5 8 11 14 17 Flow rate gallons / hour DIMENSION [inches] Model 603 800 803 a (height) 9.09” B (Width) 4.68” C (Depth) D (Max height) innovation 5.70” 5.86” 10.11” > technology > future 03 TEKNA EVO PRODUCT LINE ANALOG VERSION AKL [Constant dosage] with FPM level control input Select from two frequency ranges (0÷20% or 0÷100%). The constant flow rate is easily adjusted with the analog control dial, located on the front panel. The Power-On led and level control indicators are also on this panel. APG [Proportional dosage] with FPM level control input analog dosing pump with constant flow rate manually adjustable, proportional flow rate according to an external analog (4÷20 ma) or digital pulse signal (e.g. from water meter). l l Control dial (percentage and "n" value in multiplication mode) 6 position adjustable switch: - 3 in division mode (1, 4, 10 = n) - 1 in multiplication mode (n=1) - 1 for proportional 4÷20 ma signal l 04 seko > water & industry > products overview - 1 for constant functionality “pacing” function adjustable by dip switch TEKNA EVO PRODUCT LINE DIGITAL VERSION TPG [Proportional dosage] with FPM level control input TPR [Proportional dosage] with FPM level control input TCK [Timed dosage] with FPM level control input Digital dosing pump with constant flow rate manually adjustable, proportional flow rate according to an external analog (4÷20 ma) or digital pulse signal (e.g. from water meter). Digital dosing pump with ph/redox control meter built in. Digital dosing pump with a manually adjustable flow rate or timer control. l Timer function, Batch dosing, ppm dosing, Statistics, Password and On/Off input (remote switch) l l l l l Digital interface for constant or proportional dosing, depending on the measured ph or rx value l Programmable timed relay PT100 probe input for thermal compensation repetition alarm relay Input On-Off for remote control 4÷20 ma output innovation > technology > future 05 Kontrol 100 SINGLE-PARAMETER CONTROL INSTRUMENT Graphic display 128 by 128 pixel resolution monochrome display with graphic icons to show digital output status, washing cycle, alarms menu. Enclosure box wall mounting ABS plastic material IP65 (144x144) and panel mounting IP54 (96x96) Universal Power Supply 100…240 Vac 50/60 Hz The Kontrol 100-series are advanced controllers designed for simpler high-end applications. The units feature an independent proportional control output, probe quality checking and a variety of outputs . The user has full programming authority. FEATURES APPLICATIONS l Waste Water l Drinking Water l Pure Water l Cooling Towers l Boiler l reverse Osmosis l Crate Wash l Galvanic Process l CIP l Irrigation l Swimming Pool l Sea water l Dairy CONFIGUraTION OUTPUTS all outputs relay, SSr and Output ma are configurable with primary and secondary measure. CUrreNT OUTPUTS 4÷20ma Galvanic isolation . Two independent programmable Output Measures with Proportional routine regulation. relaY OUTPUTS Two independent relays, two set points, alarm remote and back washing probe setting by software. On/OFF, Timed routine function setting. SOlID STaTe relaY (SSr) Two Frequency output signal, two set points with Proportional routine regulation. Multi-Color Backlight Function Four different Backlight colors to underline functions. 06 seko > water & industry > products overview MEASURE RANGE pH ORP Conductivity Flow Rate Dissolved Oxygen Chlorine and Chlo. Dioxide Hydrogen Peroxide Ozone (03) Peracetic Acid Turbidity Temperature 0 ÷ 14,00 ph ± 2500 mV 0,054 ÷ 20 /200 /2.000 /20.000 /200.000 μS 0 ÷ 99.999 liters/Sec. 0 ÷ 20,0 ppm or mg/l - 0 ÷ 200% SaT 0 ÷ 0,50/1,00 /2,00 /5,00 /10,0 /20,0 /200,0 ppm 0 ÷ 500 /1000 /2000 /10.000 /100.000 ppm 0 ÷ 0,5 /2,00 /5,00 /10,00 ppm 0 ÷ 500 /2000 /10.000 /20.000 ppm 0,00 ÷ 1,00 /10,0 /100 NTU/FTU with PT100/PT1000 32 ÷ 212 °F (0 ÷ 100°C) Kontrol 500/502 SINGLE AND TWIN-PARAMETER CONTROL INSTUMENTS Graphic display 128 by 64 pixel resolution monochrome display with graphic icons to show: digital outputs’ status, data storage, washing cycle, alarms. Enclosure box wall mounting ABS plastic material IP65 (144x144) and panel mounting IP54 (96x96) Universal Power Supply 100…240 Vac 50/60 Hz The Kontrol 500-series are advanced controllers designed for high-end applications. The units feature independent proportional PID-enabled control outputs, rS 485 serial port with MODBUS protocol, USB port on request, probe quality checking, a variety of outputs and full data logging capability. The user has full programming authority. FEATURES DaTa lOGGING Internal Flash Memory with records interval from 1 to 99 min. (near to 16000 records). Visualization key for stored data in tabular and graphic form. Type: Circular (F.I.F.O.) or Filling. rS485 SerIal POrT For set-up and real-time data acquisition from remote or for stored data download on PC or laptop (Communication Software Master Controller NeT required). MODBUS rTU communication protocol. USB POrT Download measuring data on removable memory Usb Pen Drive (upon request). MeaSUre INPUT l l l high measuring resolution with probe quality control. a modular measuring system Chlorine measure in sea water application. CUrreNT OUTPUTS 4÷20ma Galvanic isolation Two independent programmable. Output Measures with PID routine regulation. APPLICATIONS l Waste Water l Drinking Water l Cooling Towers l Boiler l legionella disinfection l reverse Osmosis l Sludge l Crate Wash l Galvanic Process l Dioxide Station l CIP l Irrigation l Swimming Pool l Fish Farming l Sea water l Dairy MEASURE RANGE pH ORP Conductivity Inductive Conduct. Dissolved Oxygen Chlorine and Chlo. Dioxide Hydrogen Peroxide Ozone (03) Peracetic Acid Turbidity Suspended Solids Turbidity Temperature 0 ÷ 14,00 ph ± 1500 mV 0 ÷ 20 /200 /2.000 /20.000 /200.000 μS 0 ÷ 10.000 /10.000 /100.000 /999.999 μS 0 ÷ 20,0 ppm or mg/l - 0 ÷ 200% SaT 0 ÷ 0,50/1,00 /2,00 /5,00 /10,0 /20,0 /200,0 ppm 0 ÷ 500 /1000 /2000 /10.000 /100.000 ppm 0 ÷ 0,5 /2,00 /5,00 /10,00 ppm 0 ÷ 500 /2000 /10.000 /20.000 ppm 0,00 ÷ 1,00 /10,0 /100 NTU/FTU 0,0 ÷ 4,00 /40,0 /400/4.000 NTU/FTU 0÷30 gr/l with PT100/PT1000 32 ÷ 212 °F (0 ÷ 100°C) relaY OUTPUTS Four independent relays, two set points, one alarm remote output, one backwashing probe output. On/OFF, Timed routine function setting. innovation > technology > future 07 A Worldwide Group at your service BrAzil n Seko do Brasil Commercio de Sistemas de Dosagem limitada 03170-050 São Paulo (SP) sekobrasil@sekobrasil.com.br www.sekobrasil.com.br BenelUx n Seko Benelux B.V. 7532 SK enschede (The Netherlands) info@sekobenelux.com ChinA n Seko China ltd 072750 hebei china@seko.com www.sekochina.com DenmArk n Seko Denmark 4600 Køge info@seko.com FrAnCe n Seko lefranc-Bosi S.A. 77435 - Marne la Vallee Cedex 2 lefrancbosi@lefrancbosi.com service.commercial@seko.fr www.lefrancbosi.com GermAny n Seko Deutschland Gmbh 55252 Mainz - Kastel info@seko-messtechnik.de www.seko-germany.com Subject to change without notice. itAly n Seko Spa 02010 S.rufina - rieti sales@seko.com itAly n Seko Spa [Process & Sytems] 20068 Peschiera Borromeo Milano info.psd@seko.com info@seko.com mexiCO n Sistemas de dosificacion de mexico Seko C.P. 11560, México D.F. info@seko.com rOmAniA n Seko Sieta S.r.l. 400393 Cluj-Napoca info.dpro@seko.com rUSSiA n OOO Seko 129347 - Moscow sekorussia@seko.com www.sekorussia.ru SinGAPOre n Seko Dosing Systems Asia Pacific Pte ltd 608838 Singapore asiapacific@seko.com SOUth AFriCA n Seko Southern Africa (Pty) ltd Kyasand - Johannesburg Gauteng sales@sekosa.co.za SPAin n Seko ibérica Sistemas de Dosificación S.A. 08960 Sant Just Desvern Barcelona sekoiberica@sekoiberica.com SweDen n Seko Sweden 26123 landskrona info@seko.com tUrkey n Seko endüstriyel Pompalar ve Proses Sistemleri San. ve tic. ltd. Şti. Kartal Istanbul info@seko.com.tr www.seko.com.tr UniteD ArAB emirAteS n Seko middle east Fze P.O. Box 42090 – hamriyah Free Zone, Sharjah info@seko.ae sales@seko.ae UniteD kinGDOm n Seko Uk Chemical Controls ltd harlow, essex - CM19 5Jh seko.uk@seko.com www.sekouk.com USA n Seko Dosing Systems Corporation Tullytown - Pa 19007 Phone: +1 215 945 01 25 Fax: +1 215 945 09 37 sales@sekousa.com www.sekousa.com > © Seko Dosing Systems Corp. > 0000850001.BROW&I15A.US