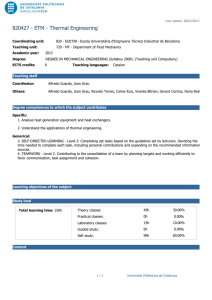

Computers and Chemical Engineering 76 (2015) 27–41 Contents lists available at ScienceDirect Computers and Chemical Engineering journal homepage: www.elsevier.com/locate/compchemeng Review Review and classification of recent observers applied in chemical process systems Jarinah Mohd Ali a , N. Ha Hoang b,∗∗ , M.A. Hussain a,∗ , Denis Dochain c a b c Department of Chemical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia Faculty of Chemical Engineering, University of Technology, VNU-HCM, 268 Ly Thuong Kiet Str., Dist. 10, HCM City, Viet Nam CESAME, Université Catholique de Louvain, 4-6 Avenue G. Lemaître, B-1348 Louvain-la-Neuve, Belgium a r t i c l e i n f o Article history: Received 16 July 2013 Received in revised form 12 January 2015 Accepted 21 January 2015 Available online 11 February 2015 Keywords: Review Observer State estimation Chemical process a b s t r a c t Observers are computational algorithms designed to estimate unmeasured state variables due to the lack of appropriate estimating devices or to replace high-priced sensors in a plant. It is always important to estimate those states prior to developing state feedback laws for control and to prevent process disruptions, process shutdowns and even process failures. The diversity of state estimation techniques resulting from intrinsic differences in chemical process systems makes it difficult to select the proper technique from a theoretical or practical point of view for design and implementation in specific applications. Hence, in this paper, we review the applications of recent observers to chemical process systems and classify them into six classes, which differentiate them with respect to their features and assists in the design of observers. Furthermore, we provide guidelines in designing and choosing the observers for particular applications, and we discuss the future directions for these observers. © 2015 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). Contents 1. 2. 3. 4. 5. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Classifications and applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Methodology for observer design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1. Observability conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2. Estimated variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3. Kinetics information of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4. Observer formulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4.1. Model of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4.2. Observer equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4.3. Observer gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4.4. Error dynamic equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5. Evaluating the observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Current and future trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Appendix A. Observability matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Appendix B. Observability Gramians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 29 30 34 34 34 34 35 35 35 35 35 35 36 36 36 37 38 ∗ Corresponding author. Tel.: +60 3 79675206; fax: +60 3 79675319. ∗∗ Corresponding author. Tel.: +84 8 38650484; fax: +84 8 38637504. E-mail addresses: jarinah@siswa.um.edu.my (J. Mohd Ali), ha.hoang@hcmut.edu.vn (N. Ha Hoang), mohd azlan@um.edu.my (M.A. Hussain), denis.dochain@uclouvain.be (D. Dochain). http://dx.doi.org/10.1016/j.compchemeng.2015.01.019 0098-1354/© 2015 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). 28 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Nomenclature A, B, C, E, F, G state space matrices sign component wise for vector argument of z = col(z1 ,. . .,zn ) x1 measured component concentration x̂ estimated state vector ẋ, ż dynamic of state vector Z process vector measurement noise covariance vector RV u1 , u2 vector partition correspond to auxiliary variables d discrete L, K observer gain . estimated state vector with linear innovative term of discontinuous function external transfer vector U1 , U2 O observability matrix Pk−1 covariance at time k − 1 Fk−1 nonlinear state transition function auxiliary variable D(s) estimated disturbance A1 , A2 unique solution of process vector D1 (s), D2 (s) lumped disturbances in loop including external disturbances x̂ 1. Introduction The implementation of state feedback laws in a controlled plant is often based on the assumptions that all states are available for online measurement; however, in practice, some of them may not be measurable due to a lack of appropriate estimating devices or the high price of sensors (Dochain et al., 2009; Jana, 2010; Soroush, 1997; Wang et al., 1997). As a consequence, measuring the missing states or variables is expensive and time consuming due to the significant technical standard requirements and the high cost of installation of these devices (Gonzalez et al., 2001; Hulhoven et al., 2006). For these reasons, devices called observers have been developed to reconstruct the state vector in order to estimate the missing variables and, at the same time, to reduce the usage of high-priced sensors (Dochain et al., 2009). Luenberger (Luenberger, 1964, 1966, 1967, 1971) and Kalman (Welch and Bishop, 1995) introduced the basic concepts of state observers and Kalman Filter (KF)-based observers in the 1960s. However, over the years, research in the design of observers has become popular but challenging due to the requirements of high accuracy, low cost and good prediction performances. In fact, many observers today are simply modifications and extended versions of the classical Luenberger observer and Kalman filter. In recent years, various types of observers have been developed to accurately estimate state variables in linear and nonlinear chemical processes (Aguirre and Pereira, 1998; Bastin and Dochain, 1990; del-Muro-Cuellar et al., 2007; Gonzalez et al., 1998; Huang et al., 2010; Lombardi et al., 1999; Pedret et al., 2009). They have been widely used both theoretically and practically through simulations and real plant testing (Bejarano and Fridman, 2010; Busawon and Kabore, 2001; Farza et al., 2011; Lee, 2011; Lin et al., 2003; Oya and Hagino, 2002). Researchers have also developed observers for systems to tackle problems such as disturbances, mismatches and faults. For this purpose, different types of observers were developed with closely similar formulations designed to overcome the drawbacks of each other. For example, to estimate disturbances, the disturbance observer (DOB) was introduced (Chen et al., 2009; Kim et al., 2011), and later, the modified disturbance observer (MDOB) was developed to target large disturbances and mismatches (Yang et al., 2011). After that, the fractional-order disturbance observer (FODOB) and Bode-ideal-cut-off observer (BICO-DOB) (Olivier et al., 2012) were developed to include methodology for tuning and optimizing the estimation performance. Another example is the asymptotic observer, which was first developed based on available measurements of the temperature of a mixture and a subset of the concentrations (Dochain et al., 1992) and later extended on the basis of the energy balance almost similar to the thermodynamic properties of the mixtures (Dochain et al., 2009; Hoang et al., 2012, 2013). Due to the variety of methodologies in observer design for chemical process systems, combining and classifying them into several different groups would be highly useful to serve as guidelines to select and then design the appropriate observers for a specific chemical application. Previous surveys have only included the study of one or two types of observers. For example, the reviews by Spurgeon (2008) and Hidayat et al. (2011) focused respectively on single observer types such as the sliding mode observers and observers for linear distributed parameter systems. Another survey from Radke and Zhiqiang reviewed the design advantages of a particular type of disturbance observers for practitioners (Radke and Zhiqiang, 2006), whereas Ruhm solely explained the concepts of open and closed loop observers (Ruhm, 2008). Dochain has presented the available results of state and parameter estimation approaches for chemical and biochemical processes, specifically the extended Luenberger (ELO), Kalman (EKO), asymptotic and interval observers (Dochain, 2003). Kravaris and coworkers provided an overview of recent developments regarding the design of nonlinear Luenberger observers, with special emphasis on the exact error linearization techniques, and discussed general issues including observer discretization, sampled data observers and the use of delayed measurements (Kravaris et al., 2012). In addition, Prakash and coworkers reviewed recently developed Bayesian estimators (Prakash et al., 2011), and Daum focused only on the extended nonlinear filters on the basis of the classical KF (Daum, 2005). Chen has also reviewed Bayesian filtering from KF to particle filter, emphasizing the stochastic filtering theory based on Bayesian perspectives (Chen, 2003). However, all of these reviews are specific in nature and do not consider the whole spectrum of the different classes of observers available. Therefore, this review paper intends to provide a comprehensive survey considering the unique features of different types of recent observers in chemical process systems (Dochain, 2003; Kravaris et al., 2012) by categorizing them into different classes, a level of organization not currently available in the literature. Six classes are proposed, namely, Luenberger-based observers, finitedimensional system observers, Bayesian estimators, disturbance and fault detection observers, artificial intelligence (AI)-based observers and hybrid observers. In brief, the main contribution of this review is to provide the list of recent observers that have been applied in chemical process systems and to classify them into six classes with emphasis on their positive highlights based on their estimation performances in specific chemical process systems. Recent observers refer to the observers developed since the year 2000, as most observers before that would be referred to as the classical types (Elicabe et al., 1995; Gonzalez et al., 1998; Lee and Ricker, 1994; Oliveira et al., 1996; Soroush, 1997; Wang et al., 1997). All of these observers can be either linear or nonlinear and have served as specific estimators to several unit operations. However, this review does not include some methodologies such as the recursive error method (Lee et al., 2000) and the partial least square method (Roffel et al., 2003), which have also been considered as estimators. J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 This paper is organized as follows. The introduction is in Section 1, followed by the classification of observers and their applications in chemical process systems in Section 2. Section 3 discusses the observer design methodology. Section 4 focuses on the current and future trends of observers, while Section 5 concludes the review. 2. Classifications and applications The formulations of observer design methodologies in research publications have normally been written and explained with merely theoretical emphasis, which makes it difficult for practitioners and researchers, especially newcomers to this area, to choose (potentially) appropriate observers for their systems. In addition, selecting the most suitable observer for any specific system is an important but difficult task for installed systems due to the diversity of the many available methods, observer types, application range and nature of chemical process systems. So far, this research area has been very active and attracts attention from many researchers (Aguilar-Garnica et al., 2011; López-Negrete and Biegler, 2012; Mesbah et al., 2011; Nagy Kiss et al., 2011; Olivier et al., 2012). Based on our extensive review of the recent observers applied to chemical process systems, we can clearly differentiate them into six major classes. These classes are the Luenbergerbased observers, finite-dimensional system observers, Bayesian estimators, disturbances and fault detection observers, artificial intelligence-based observers and hybrid observers. The attributes, advantages, limitations and guidelines for practitioners according to each class are given in Table 1, while Table 2 sorts these recent observers into their respective classes. In addition, the selection of the recent observers according to those classes is depicted in Fig. 1 to guide and help researchers in their selection. The category of Luenberger-based observers is the first class that groups together all of the observers designed based on the Luenberger observer methodology, or, in other words, it involves the extended versions of the classical Luenberger observer itself (Alonso et al., 2004; Dochain, 2003; Fissore et al., 2007; Tronci et al., 2005; Vries et al., 2010). The extended Luenberger observer (ELO), sliding mode observer (SMO), adaptive state observer (ASO), generic and backstepping observers are examples of observers falling into this class. This type of observer is suitable for less complex linear systems with relatively simpler computational methods (Bejarano et al., 2007b). The second category is the finite-dimensional system observers, which include, among others, the reduced-order, low-order, high-gain, asymptotic and exponential observers. These finitedimensional system observers are designed for chemical process systems whose dynamics are described by ordinary differential equations (ODEs) (Bitzer and Zeitz, 2002) and are quite straightforward to implement. They suit systems with less kinetic information, but the accuracy of the convergence rate is uncertain. For example, for the case of asymptotic and exponential observers, the convergence rate can only be shown if the process operating conditions are such that the dilution rate is bounded (Dochain et al., 1992; Dochain, 2000; Hadj-Sadok and Gouze, 2001; Hoang et al., 2013). It is worth noting that asymptotic/exponential and interval observers can also be extended to infinite dimensional systems (i.e., distributed parameter systems) such as for tubular reactors and plug flow reactors (Dochain, 2000; Aguilar-Garnica et al., 2011). Bayesian estimators, in the third category, provide an approach based on the probability distribution estimation of state variables by utilizing the available data of the system (Chen et al., 2004). It assumes that all variables are stochastic in nature, and thus, the distribution of state variables is achievable based on the measured variables. Examples of the Bayesian type of estimators are the 29 extended Kalman filter (EKF), particle filter (PF) and moving horizon estimator (MHE). These are based on probability distribution and are therefore consistent and versatile estimators, which are highly appropriate for fast estimation (Abdel-Jabbar et al., 2005; Fan and Alpay, 2004; Patwardhan and Shah, 2005). However, the computational complexity involved in using this approach makes them infeasible for high-dimensional systems. The fourth class is the disturbance and fault detection observers. Although they can be of different classes, both are included in one category because they are mostly applied to estimate irregularities in the system, either through disturbances or faults (Olivier et al., 2012). Fault detection observers can also be applied to estimate parameters for fault diagnosis of chemical process systems. Examples of disturbance and fault detection observers are the disturbance observer (DOB), the modified disturbance observer (MDOB), the unknown input observer (UIO) and the nonlinear unknown input observer (NUIO). These are highly specific types of observers and focus only on disturbances or fault detection related variables during the estimation process (Chen et al., 2009; RochaCózatl and Wouwer, 2011; Sotomayor and Odloak, 2005; Yang et al., 2011). They are mostly suitable for estimating disturbances and faults, which provide early warning to operators prior to causing disruption to the process units (Sotomayor and Odloak, 2005; Zarei and Poshtan, 2010). The fifth class is the artificial intelligence (AI)-based observers. AI is the science of making the program perform intelligencebased tasks, which include methods such as fuzzy logic, artificial neural networks (ANN), expert systems and genetic algorithms. These types of observers have been widely utilized as estimators in recent times. For example, the work by Hussain and coworkers utilized a hybrid neural network (HNN) to predict porosity in a food drying process (Hussain et al., 2002), and the research by Aziz and coworkers applied ANN to estimate the heat released from a polymerization reactor (Aziz et al., 2000). Other applications of AI-based observers can also be found in many papers (Barton and Himmelblau, 1997; Islamoglu, 2003; Khazraee and Jahanmiri, 2010; Kordon et al., 1996; Kuroda and Kim, 2002; Liu, 2007; Ng and Hussain, 2004; Turkdogan-Aydınol and Yetilmezsoy, 2010; Wang et al., 2006, Wei et al., 2007). However, this review paper covers only recent types of AI-based observers coupled with conventional (model-based) types, as purely AI observers are not recent in nature. Examples of these recent types are the fuzzy Kalman filter (FKF) and the EKF-neural network observers (Porru et al., 2000; Prakash and Senthil, 2008). These AI-based observers overcome the limitations of single-based observers and are suitable for systems with incomplete model structure and information. The formulation of AI-based observer may be difficult and time consuming compared to the other hybrid observers in some systems (Senthil et al., 2006). In addition, the AI elements must first be adapted for online implementation (Himmelblau, 2008; Lashkarbolooki et al., 2012; Rivera et al., 2010). The sixth class is the hybrid observers, which are combinations of more than one observer to obtain improved estimation in certain systems. An example of this is the extended Luenberger observer (ELO) combined with the asymptotic observer (AO) (Hulhoven et al., 2006). ELO provides good convergence factors, while AO estimates parameters without any kinetics data. Therefore, the combination results in an improved hybrid observer that contains both features. Hybrid observers are good at overcoming the limitations of the single observer, but choosing the appropriate combination may be tedious and time consuming (Aguilar-Lopez and Maya-Yescas, 2005; Bogaerts and Wouwer, 2004; Goffaux et al., 2009). Normally this class of observer is suitable for conditions where the singlebased observer is not accurate enough for the process systems, for instance, to compensate for offsets in estimation resulting from the use of the single observer (Hulhoven et al., 2006). 30 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Table 1 Observers’ overall evaluation according to classes. No. Class of observers 1 Luenbergerbased observers 2 3 Finitedimensional system observers Bayesian estimators Example of observer equation Attributes Advantages Limitations Guidelines for practicing engineers For sliding mode observer: Extension of classical Luenberger observer Simple computational methods Design is always based on the perfect knowledge of system parameters For exponential observer: d = F + Gx1 − LU1 + U2 dt Knowledge of process system kinetics is not necessary Easy implementation and simple formulation Convergence factor depends strongly on the operating condition For less complex linear systems, this type of observer is sufficient for crucial parameter estimation Suitable for systems with less kinetics information For extended Kalman filter: T + Rv Pk|k−1 = Fk−1 Pk−1|k−1 Fk−1 Based on probability distribution and mathematical inference of the system Fast estimation based on prediction-correction method and versatile estimators Good at estimating disturbances and predicting faults before they can affect the unit operations of the plant Overcome limitations of single observer and suitable for systems with incomplete model structure The complexity of their computational method is sometimes infeasible for high dimensional systems May ignore other uncertainties during the estimation process . x̂ = Ax̂ + Bu + Lsign(y − C x̂) 4 Disturbance and fault detection observers For disturbance estimation: D(s) = D̃1 (s) + D̃2 (s) + · · · + D̃n (s) Focus on estimating disturbances and detecting faults within the system 5 AI-based observers According to AI-elements, example using fuzzy logic where the IF-THEN rule is: IF e is negative small AND e is zero THEN x̂estimated = xactual Combination of observers with AI elements 6 Hybrid observers For combination of extended Luenberger and asymptotic observer: dZ(t) = D(t)Z(t) + A1 u1 (t) + A2 u2 (t) dt Combination of two or more observers The detailed applications of the various observers under these six classes are listed in Table 3. The table does not need any further elucidation because it is comprehensive and self-explanatory in nature, covering the objectives, the positive highlights, applications in various unit operations and the relevant references involved for each of the observer types. 3. Methodology for observer design Observers were first designed based on linear formulation; these original observers were known as linear observers and used to estimate states and unknown variables in a linear process in the eventual presence of disturbances or noise (Bara et al., 2001; Overcome the limitations of a single observer May be difficult and time consuming For online implementation, the AI elements must first be adapted to the system Choosing appropriate combination may be tedious For fast estimation results based on probability theory, Bayesian estimators may be applied If the objective is to estimate disturbances and parameters to predict faults, then these type of observers are the most appropriate For highly nonlinear systems with an incomplete or unknown model This is suitable for systems where a single type of observer is not accurate enough Bejarano and Fridman, 2010; Bejarano et al., 2007a,b; Bodizs et al., 2011; Busawon and Kabore, 2001; El Assoudi et al., 2002; Fissore, 2008; Jafarov, 2011; Lee, 2011; Oya and Hagino, 2002; Vries et al., 2010). Later, because most processes exhibit highly nonlinear behavior, researchers formulated nonlinear observers (Besancon, 2007; Bitzer and Zeitz, 2002; Boulkroune et al., 2009; Busawon and Leon-Morales, 2000; de Assis and Filho, 2000; Di Ciccio et al., 2011; Dong and Yang, 2011; Farza et al., 1997, 2011; Floquet et al., 2004; Hashimoto et al., 2000; Kalsi et al., 2009; Kazantzis and Kravaris, 2001; Kazantzis et al., 2000; Ko and Wang, 2007; Kravaris et al., 2007; Maria et al., 2000; Schaum et al., 2008). Most researchers developed observers based on the mathematical model of the systems and used the first principles model prior to developing the observer’s equation (Dochain et al., 2009). Table 2 Recent observers categorized under different classes. Class Luenberger-based observers Specific observer 1. Extended Luenberger observer (ELO) 2. Sliding mode observer (SMO) 3. Adaptive state observer (ASO) 4. High-gain observer 5. Zeitz nonlinear observer 6. Discrete-time nonlinear recursive observer (DNRO) 7. Geometric observer 8. Backstepping observer Finite-dimensional system observers Bayesian estimators Disturbance and fault detection observers Artificial intelligence-based observers Hybrid observers 1. Reduced-order observer 2. Low-order observer 3. High gain observer 4. Asymptotic observer (AO) 5. Exponential observer 6. Integral observer 7. Interval observer 1. Particle filter (PF) 2. Extended Kalman filter (EKF) 3. Unscented Kalman filter (UKF) 4. Ensemble Kalman filter (EnKF) 5. Steady state Kalman filter (SSKF) 6. Adaptive fading Kalman filtering (AFKF) 7. Moving horizon estimator (MHE) 8. Generic observer 9. Specific observer 1. Disturbance observer (DOB) 2. Modified disturbance observer (MDOB) 3. Fractional- order disturbance observer 4. Bode-ideal cut-off observer 5. Unknown input observer (UIO) 6. Nonlinear unknown input observer 7. Extended unknown input observer 8. Modified proportional observer 1. Fuzzy Kalman filter 2. Augmented fuzzy Kalman filter 3. Differential neural network observer 4. EKF with neural network model 1. Extended Luenberger-asymptotic observer 2. Proportional-integral observer 3. Proportional-SMO 4. Continuous-discrete observer 5. Continuous-discreteinterval observer 6. Continuous-discreteEKF 7. High-gaincontinuous-discrete J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 31 Fig. 1. General guideline for selecting recent observers according to their classification. Therefore, most observer designs are model-based approaches (Damour et al., 2010a, 2010b; Dochain et al., 2009; Salehi and Shahrokhi, 2008) with the exception of the AI-based observers (Bahar and Ozgen, 2010; Lahiri and Ghanta, 2008; Mohebbi et al., 2011; Rezende et al., 2008; Wei et al., 2010). The gain of the observer and its estimation error dynamics are also significant in designing the model-based observers, as shown in several references (Aguilar-Lopez and Martinez-Guerra, 2007; De Battista et al., 2011; Hulhoven et al., 2008; Porru et al., 2000). However, the success of observer designs is evaluated based on their capabilities in estimating the difficult-to-measure states with satisfactory convergence rates (Bitzer and Zeitz, 2002; Ciccio et al., 2011; Hashimoto et al., 2000; Kravaris et al., 2007; Lafont et al., 2011; Morel et al., 2006) and with approximately zero estimation errors (Benaskeur and Desbiens, 2002; Bogaerts and Wouwer, 2004; Kazantzis et al., 2000; Liu, 2011). The first important step before designing the observer is to consider the detectability or observability condition of the system because observers have to be designed for a detectable or observable system. Observability is the condition in which all initial states are observable and a system is said to be observable if, for any initial condition vectors, its internals states can be inferred by knowledge of its (external) outputs (Evangelisti, 2011; Moreno and Dochain, 2008; Soroush, 1997). Detectability is a weaker condition than observability, where the non-observable states can still decay to zero asymptotically (Evangelisti, 2011; Moreno and Dochain, 2008). Both concepts will influence the feasibility conditions of the observers (Dochain et al., 1992; Hoang et al., 2013; Moreno and Dochain, 2008). The concept of observability is central in reconstructing unmeasurable state variables. This explains the need of observers to estimate unknown states prior to developing control laws and the fact that not all states are available directly through on-line measurements (Ogata, 1995). Extensive discussions on observability and detectability can be found in various references (Astolfi and Praly, 2006; Evangelisti, 2011; Hermann and Krener, 1977; Moreno and Dochain, 2008; Soroush, 1997; Zuazua, 2007). Once the system dynamics fulfill the observability or detectability conditions, observers can then be designed to estimate the state variables. In this respect, the choice of a suitable observer according to the six classes provided in Section 2 is therefore of great importance. Prior to that, the desired estimated states (i.e. the exact values of the observed states) and initial conditions must be defined clearly (Farza et al., 2011). After that, tests are run to compare the estimates with the actual values to determine the performance of the proposed observer (Aamo et al., 2005; De Battista et al., 2011; Hajatipour and Farrokhi, 2010; Jana et al., 2006; Nagy Kiss et al., 2011; Salehi and Shahrokhi, 2008). The test not only is important for the design of the single observer but also determines whether a hybrid observer is further needed to estimate the parameter (Goffaux et al., 2009; Hulhoven et al., 2006; Sheibat-Othman et al., 2008). If there are huge discrepancies between the actual and estimated values, a hybrid observer should be developed to improve the estimates. Furthermore, if systems are complex and models are difficult to obtain from the first principles, hybrid AIbased observers would possibly be a suitable choice (Chairez et al., 2007; Porru et al., 2000; Prakash and Senthil, 2008). The design guideline for these observers based on the six classes is depicted in Fig. 2 with detailed explanation in the following subsections. 32 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Table 3 Application of recent observers in chemical process systems under different classes. Observer System Positive highlight(s) Ref. Class 1: Luenberger-based observers Crystal mass ELO Crystallization unit Damour et al. (2010a,b) ELO ELO Solutes concentration Process kinetics, influent concentrations Substrate concentration, specific growth rate Specific growth rate Substrate concentration Biomass and substrate concentration Reactor parameters Growth rate, kinetic coefficient Liquid, vapor flow rate, reboiler coefficient Radical concentration Fed-batch crystallizer Fixed bed reactor Good estimation without perfect initial condition Robust against model deviation Easy to implement, simple structures Fermentation process Smooth estimates Fed-batch bioreactor Bioreactor Bioreactor Accurate and error free estimation Proven stability factor Proven stability factor CSTR Bioreactor Debutanizer Distribution coefficients Compositions, partially known parameters Concentrate and tailing grade Distillation column Batch distillation column Stable estimator Guaranteed convergence factor Precise estimates under mismatch condition Estimates without information of initiator Guaranteed convergence factor Good convergence factor Sheibat-Othman et al. (2008) Jana et al. (2006) Murlidhar and Jana (2007) Nitrogen oxide (NOx ) inlet concentration, outlet reactant conversion Product compositions Loop reactor Guaranteed convergence, zero estimation error Fast, reliable estimates Benaskeur and Desbiens (2002) Fissore et al. (2007) Tronci et al. (2005) Compositions, solid mass fraction, production rate Copolymerization reactor Overcomes ill-conditioning of the observability matrix Accurate estimation Class 2: Finite-dimensional system observers Reduced-order Down hole pressure Reduced-order Reactor concentration Gas-lift well CSTR Stable estimates Good concentration estimates Reduced-order Low-order High-gain High-gain Bioreactor 30-tray distillation column CSTR CSTR Robust estimation Robust against noise Robust against noise and disturbances Precise estimates Exponential Substrate concentration Steady state profiles Reaction heat Reactor concentration and temperature Reactor concentration Tubular reactora Exponential Exponential AO Top tray compositions Microorganisms concentration Concentrations, enthalpy Batch distillation column Bioreactor CSTR AO Reactor concentration Tubular reactora AO Growth rate Activated sludge process Interval Activated sludge process Interval Interval Organic concentration, growth rates Reactant concentration Residual parameters Good estimation without process kinetics Good convergence properties Guaranteed convergence Good estimation, not sensitive to noise Good estimation without process kinetics Precise estimation without process kinetics Converge toward bounded interval Aamo et al. (2005) Salehi and Shahrokhi (2008) Kazantzis et al. (2005) Singh and Hahn (2005c) Aguilar et al. (2002) Biagiola and Figueroa (2004b) Dochain (2000) Integral Heat of reaction SMO SMO SMO SMO DNRO ASO ASO ASO ASO ASO Backstepping Zeitz nonlinear observer Geometric Geometric Objective/estimate(s) Polymerization process Solid-solid separation unit Distillation column Mesbah et al. (2011) Mendez-Acosta et al. (2008) Pico et al. (2009) De Battista et al., 2011 Gonzalez et al. (2001) Hajatipour and Farrokhi (2010) Huang et al. (2010) Zhang and Guay (2002) Jana et al. (2009) López and Alvarez (2004) Jana (2010) El Assoudi et al. (2002) Dochain et al. (2009) Dochain (2000) Plug flow reactora Separator (grinding process) CSTR Robust estimation Good convergence factor Hadj-Sadok and Gouze (2001) Hadj-Sadok and Gouze (2001) Aguilar-Garnica et al., 2011 Meseguer et al. (2010) Robust estimation Aguilar-Lopez (2003) Class 3: Bayesian estimators SSKF Time-delay Stirred tank heater Consistent estimates even with noise SSKF Product compositions Batch distillation column Stable estimation EKF Interface temperature Freeze-drying process EKF Component’s concentration Batch distillation column EKF Product compositions Batch distillation column Good estimation without perfect initial condition Simple observer design yet accurate estimation Precise estimate even with noise Patwardhan and Shah (2005) Venkateswarlu and Avantika (2001) Velardi et al. (2009) EKF EKF Outlet reactor concentration Liquid compositions Accurate concentration estimation Robust against modeling error EKF Top tray compositions and flow rates Solutes concentration Solutes concentration Particle size distribution CSTR Reactive distillation column Distillation column Fed-batch crystallizer Fed-batch crystallizer Semi-batch reactor Robust against model deviation Robust against model deviation Good estimation without accurate model EKF UKF UKF Guaranteed convergence factor Yildiz et al. (2005) Venkateswarlu and Avantika (2001) Himmelblau (2008) Olanrewaju and Al-Arfaj (2006) Jana et al. (2006) Mesbah et al. (2011) Mesbah et al. (2011) Mangold et al. (2009) J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 33 Table 3 (Continued) Observer Objective/estimate(s) System Positive highlight(s) Ref. UKF Biomass concentration Fermentor Wang et al. (2010) UKF EnKF EnKF AFKF Uncertain parameters Solute concentrations Unmeasured disturbances Product compositions Hybrid tank system Fed-batch crystallizer Hybrid tank system Batch distillation column AFKF Temperature Heat exchanger PF Yield parameter Fermentor PF Conditional density CSTR PF Conditional density Batch Reactor MHE MHE Solutes concentration Molecular weight distribution Fed-batch crystallizer Polymerization reactor Effective estimation despite using the simplified mechanistic model Effective control and good estimation Robust against model deviation Effective control and good estimation Precise estimate despite noisy conditions Good estimation without coefficient adjustment Good estimation based on maximization algorithm theory Few assumptions required for estimation Few assumptions required for estimation Robust against model deviation Smooth estimates MHE Tray efficiencies Binary distillation column MHE Generic observer Biomass concentration Carbon and nitrogen concentrations Carbon and nitrogen concentrations Prakash et al. (2010) Mesbah et al. (2011) Prakash et al. (2010) Venkateswarlu and Avantika (2001) Bagui et al. (2004) Chitralekha et al. (2010) López-Negrete et al. (2011) López-Negrete et al. (2011) Animal cell cultures Sequential batch reactor Able to handle constraint during estimation Accurate estimates Robust against modeling error Mesbah et al. (2011) López-Negrete and Biegler (2012) López-Negrete and Biegler (2012) Raïssi et al. (2005) Boaventura et al. (2001) Sequential batch reactor Robust against modeling error Boaventura et al. (2001) Class 4: Disturbances and fault detection observers Disturbances related to time DOB delay FO-DOB Disturbances due to mismatch Conveyor (grinding process) Cyclone (grinding process) Chen et al. (2009) BICO-DOB Disturbances due to mismatch Cyclone (grinding process) MDOB Jacketed stirred tank heater CSTR Robust against uncertainties Aguilar-Lopez and Martinez-Guerra (2005) UIO Closed-loop system disturbances Uncertainties in reactive concentration, reactor and jacket temperature Fault in actuator and sensor Overcome the effect of internal disturbances Optimize the estimation even with huge disturbances Optimize the estimation even with huge disturbances Smooth disturbances estimate Polymerization reactor Accurate estimation UIO Fault in input sensor CSTR QUIO Faults in concentration, flow rates, light intensity Fault in residuals Fault in residuals Bioreactor Accurately estimating fault even in the presence of disturbances Satisfactory estimates Sotomayor and Odloak (2005) Zarei and Poshtan (2010) CSTR CSTR Acting as alternative fault alarm Acting as alternative fault alarm Rocha-Cózatl and Wouwer (2011) Zarei and Poshtan (2010) Zarei and Poshtan (2010) CSTR Unbiased estimation Prakash and Senthil (2008) CSTR Satisfactory unbiased estimates Prakash and Senthil (2008) Specific observer Modified proportional NUIO EUIO Class 5: AI-based observers FKF Olivier et al. (2012) Olivier et al. (2012) Yang et al. (2011) Microreactor Good agreement with the actual value Poznyak et al. (2007) Wastewater treatment plant Heterogeneous reactor Guaranteed small estimation error Chairez et al. (2007) EKF-NN Reactor temperature and concentration Reactor temperature and concentration Anthracene dynamics decomposition and contaminant concentration Formic acid, fumaric acid, maleic acid, oxalic acid Outlet reactor concentration Further reduction in estimation error compared to EKF Porru et al. (2000) Class 6: Hybrid observers ELO-AO Continuous-discrete Biomass concentration Biomass concentration Bioreactor Batch reactor Stable rate of convergence Robust against modeling error Process kinetics Bioreactor Biomass, substrate concentration Polymer molecular weight, monomer concentration, reactor temperature Unknown inputs Bioreactor Avoids growth of interval sizes during estimation Accurate estimates, reduced error Hulhoven et al. (2006) Aguilar-Lopez and Martinez-Guerra (2005) Goffaux et al. (2009) ASFKF DNNO DNNO Continuous-discreteinterval Continuous-discreteEKF Proportional-SMO Proportional-integral High-gain-continuousdiscrete a Rate coefficient Polymerization reactor Robust against noise and uncertain parameters Bogaerts and Wouwer (2004) Aguilar-Lopez and Maya-Yescas (2005) Wastewater treatment plant Polymerization process Stable estimation rate Nagy Kiss et al. (2011) Estimates without information of initiator Sheibat-Othman et al. (2008) Finite-dimensional system observers may be extended to the infinite-dimensional systems such as for tubular and plug flow reactor. 34 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Fig. 2. General methodology for observer design. 3.1. Observability conditions Two types of observability conditions typically applied for observer designs are the observability matrix and the observability Gramian. The observability matrix appears with the alteration of the state space models such as conversion to canonical forms, while the observability Gramian arises when considering the operator properties including system reduction and optimal linear quadratic regulators (Curtain and Zwart, 1995; Singh and Hahn, 2005a). Both the observability matrix and the observability Gramian provide sufficient conditions for the observability of a system; however, the observability matrix is related to the differential properties, while the observability Gramian is based on the integral conditions (Tsakalis, 2013). Furthermore, the type of observability used to detect the observable condition will depend on the formulation of the systems. Brief formulations of both observability conditions are given in Appendices A and B, respectively. 3.2. Estimated variables The estimated variables are the difficult-to-measure parameters intended to be estimated using observers. They are systemdependent and not specific to one parameter for a particular process unit (Liu, 1999) such as reactor concentration in a CSTR (Salehi and Shahrokhi, 2008), production rate and solid mass fraction in a polymerization reactor (López and Alvarez, 2004) or specific growth rate in a bioreactor (De Battista et al., 2011). The estimated parameters are normally the crucial parameters that may potentially lead to uncertainty in the process and can affect product quality (Alanis et al., 2010; Fan and Alpay, 2004; Mesbah et al., 2011; Olivier et al., 2012). The parameters should also be updatable for online implementation and to eliminate bias between simulation and the online estimation implementation (Sandink et al., 2001). Examples of estimated parameters in various chemical process systems are given in Section 2 (we refer the readers to the ‘Objective/Estimate(s)’ column in Table 3). 3.3. Kinetics information of the system The kinetics information of the system determines the system’s nonlinearities based on the mathematical model that represents it (Biagiola and Figueroa, 2004b). This information is required to aid in the selection of the appropriate observers. For a system where this information is complete and system parameters are well known, the Luenberger-based observer is appropriate, while the Bayesian estimator is used for systems in which only certain system parameters are known (Dochain, 2000, 2003). When less kinetic information is available, researchers can apply exponential or asymptotic observers (Dochain, 2000; El Assoudi et al., 2002; Hadj-Sadok and Gouze, 2001; Hoang et al., 2013; Hulhoven et al., 2008). AI-based observers may be suitable for systems with incomplete model information. 3.4. Observer formulation Since most observers are model-based (Boaventura et al., 2001; Chen et al., 2009; de Canete et al., 2012; Prakash et al., 2011; Vicente et al., 2000; Yang et al., 2011), the design steps include modeling of the systems prior to developing the observer equation, computing J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 the gain of the observer and deriving the estimation error model or the error dynamic equation (D’Attellis et al., 1997; Di Ruscio, 2009; Dochain, 2003; Gajic, 2003; Soroush, 1997). Classification of recent observers into six classes as in Section 2 can be helpful in designing the observers, as we can now apply either method 1 or 2 in the design (we refer the readers to Fig. 2). For example, modeling can be simplified if the observers are from the finite dimensional and AI-based classes because those two classes can be designed for systems with incomplete models or less kinetic information (Dochain et al., 1992, 2009; Senthil et al., 2006). If the systems require specific parameter estimation such as disturbances, the focus can be narrowed down to the disturbances and fault detection observer types. Thus, we can directly apply the disturbances and faults detection observers and obtain the best estimation performance. Furthermore, if our systems are simple linear systems with easyto-formulate models, we can apply the Luenberger-based observers instead of choosing from all other types of observers available (Damour et al., 2010a, 2010b; Mesbah et al., 2011). In addition, we can apply the hybrid observer to overcome the limitations of single observers and to improve the estimation performance (Goffaux et al., 2009; Hulhoven and Bogaerts, 2002; Hulhoven et al., 2006). 3.4.1. Model of the system The system for observer design is normally based on a mathematical model (Ahn et al., 1999; Bagui et al., 2004; Mohseni et al., 2009), which is typically incorporated into the mass and energy balance of the systems (Bernard and Gouze, 2004; Dochain et al., 2009; James et al., 2002; Salehi and Shahrokhi, 2008) and consequently it may range from the finite-dimensional to the infinite-dimensional case. It can also include several appropriate assumptions, for example, assuming perfect mixing and constant physical parameters to simplify the modeling steps (Biagiola and Figueroa, 2004a). 3.4.2. Observer equation The observer equation is developed to determine the observer structure for a given system based on dynamic knowledge and incorporated with the observer gain and the error dynamic equation (Bitzer and Zeitz, 2002; Cacace et al., 2010). For a linear model-based observer, the state space representation is normally used to describe the observer equation, and the measurement equation is also involved in the formulation (Fuhrmann, 2008; Patwardhan et al., 2006; Patwardhan and Shah, 2005; Senthil et al., 2006). The number of measured variables will also affect the sensitivity of the estimation (Venkateswarlu and Avantika, 2001). 3.4.3. Observer gain The design of the observer structure will require an appropriate gain (Dochain, 2003), and it is chosen based on the stability of the error dynamics of the system (Busawon and Kabore, 2001; Yang et al., 2012). The observer gain can be solved using the Butterworth polynomial and the Ackermann formula (Di Ruscio, 2009). Additionally, the Riccati equation is also applied to determine the gain value by observing the error dynamic output (Farza et al., 2011). 3.4.4. Error dynamic equation The error dynamic equation is needed to ensure the observer structure is bounded to the modeling error (Wang et al., 1997) to increase the robustness of the observer (Jung et al., 2008). It can be represented in terms of the linear time-varying system (Mishkov, 2005; Röbenack and Lynch, 2004) and must be designed in such a way that it is asymptotically or exponentially stable (Biagiola and Figueroa, 2002; Härdin and van Schuppen, 2007; Iyer and Farell, 1996; Röbenack and Lynch, 2004; Zambare et al., 2003). In certain systems, where the dynamic information is limited and it is difficult to develop the error bounds due to large uncertainties (Dochain, 2000), the error dynamic equation can be ignored in the observer 35 design. This can be seen in the development of the asymptotic observer (Dochain et al., 1992, 2009). 3.5. Evaluating the observer The performance of an observer is usually tested in simulation followed by online implementation (BenAmor et al., 2004; Bogaerts and Wouwer, 2004; Escobar et al., 2011). The test will begin with a nominal or simulator model that is different from the observer model and includes both the process and possibly measurement noise (Di Ruscio, 2009). Normally, some reasonable model errors are introduced to the simulator model to test its performance under plant model mismatches (Aguilar-Lopez and Martinez-Guerra, 2005; Aguilar-Lopez and Maya-Yescas, 2005; Jana et al., 2006; Lin et al., 2003). Poor noise assumptions can lead to bias estimation and divergence and require more assumptions for the design (Biagiola and Figueroa, 2004a). 4. Current and future trends In previous years, single-based observers (i.e., Luenberger-based and finite-dimensional observers) have commonly been used to estimate the difficult-to-measure parameters in a chemical process system prior to generating the control design and to replace highpriced sensors in the plant. These observers, however, started to face challenges in handling uncertainties in both model and measurements (Dochain, 2003). In addition, many of these observers require accurate knowledge of the process dynamics for the design, which are difficult to obtain, especially in nonlinear chemical processes. AI-based observers have become popular for nonlinear systems due to their reduced dependency on accurate models but also are limited in terms of robustness. Thus, in order to overcome these limitations and challenges, hybrid observers have been introduced (Hulhoven and Bogaerts, 2002; Hulhoven et al., 2006; Poznyak et al., 2007). These hybrid observers also have the advantage of being easy to formulate and implement with the availability of powerful modern computing resources. Therefore, in general, the trend in the use of observers for chemical process has changed from single-based observer design (Bara et al., 2001; Benaskeur and Desbiens, 2002; Hadj-Sadok and Gouze, 2001; Kazantzis et al., 2000) to hybrid observers design (Goffaux et al., 2009; Hulhoven et al., 2006; Prakash and Senthil, 2008), including AI-based designs, as seen in the trend pattern for the usage of recent observers in chemical process systems shown in Fig. 3. The statistics given in the figure show that although all other classes of observers have always been in use, the trends have been inconsistent and very much dependent on the particular system to be resolved. However, the hybrid observer, which did not exist before 2000, has been consistently increasing in its usage since then. This could be due to many factors but one main reason is the availability of many types of observers (as seen in Section 2) that could be easily combined in the modern software available at present (de Assis and Filho, 2000; de Canete et al., 2012; Escobar et al., 2011; Rivera et al., 2010). Hybrid observers has also becoming popular due to their ability to obtain better estimation performances, handle offsets efficiently and increase the rate of convergence (Aguilar-Lopez and Martinez-Guerra, 2007; Hulhoven and Bogaerts, 2002). The sliding mode observer hybrid with an asymptotic/exponential observer is an example where a sliding mode observer provides good convergence rate with guaranteed robustness and stability (Hajatipour and Farrokhi, 2010) while the asymptotic/exponential observer supports a process system with minimal kinetic data (Jana et al., 2006), which is beneficial in situations where there is a lack of information or data regarding 36 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Fig. 3. Current and future trend of recent observers in chemical process systems. the process system. Another example involves the combination of a reduced-order observer with both the sliding mode and asymptotic/exponential observers where only certain parameter estimations are required (Zhu, 2012). The sliding mode has also been merged with a low-order observer to cater for high-dimensional processes and to overcome the uncertainties in chemical process applications such as the distillation column (Singh and Hahn, 2005c). At the same time, many researchers have also shown their interest in applying pure AI techniques, such as the artificial neural network (ANN), fuzzy logic and expert systems for predicting the parameters in difficult-to-model systems (Bahar and Ozgen, 2010; Beigzadeh and Rahimi, 2012; Brudzewski et al., 2006; de Canete et al., 2012; Delrot et al., 2012; Hussain et al., 2002; Patnaik, 1997; Porter Ii and Passino, 1995; Singh et al., 2005, 2007). AI algorithms have also been merged with each other for estimation purposes with different types of formulations (Arauzo-Bravo et al., 2004; Chitanov et al., 2004; Chuk et al., 2005; Li et al., 2002; Ng and Hussain, 2004; Sivan et al., 2007; Wei et al., 2007, 2010; Wilson and Zorzetto, 1997; Yang and Yan, 2011; Yetilmezsoy et al., 2011). However, the problems with AI-based observers, especially in online estimations, are issues related to robustness and stability, which may be difficult to resolve if the data collected for the AI design do not cover the whole range of the operating region for the observer (Himmelblau, 2008; Wang et al., 2011; Wei et al., 2010). Furthermore some of the formulations of AI-based designs are black box in nature and are difficult to envision with respect to real plant parameters. Hence, we foresee that the future direction of observer design is toward the use of hybrid-based types including the AI-based observers, although single-based observers (e.g., the Bayesian Estimators, the asymptotic and exponential observers) will still be applicable in many applications involving chemical process systems. 5. Conclusions For a chemical process plant, it is always vital to capture process states for monitoring purposes, to develop state feedback laws for control, and to prevent process disruptions, plant shutdowns and even failures. Unfortunately, not all of the important states are measurable due to the lack of appropriate devices or the costs and feasibility of installing sensors in the plant. For that purpose, observers, which are computational algorithms designed to estimate unmeasured state variables, have been developed. However, estimation techniques are available in various types and categories, making it difficult to select one for any particular application. Thus, we classified the observers into six classes with the aim to differentiate them with respect to their features and to assist in the design of observers, emphasizing their positive highlights, advantages and limitations based on their performance in chemical process systems. The classifications can also be used to assist researchers and practitioners in selecting the appropriate observers for implementation or designing them for a specific application. In addition to this, it was recognized that the trend of observer design would be toward the use of hybrid observers due to the rapid development in software that allows easy combination of observer algorithms. Acknowledgments The authors are grateful to the University of Malaya and the Ministry of Higher Education in Malaysia for supporting this collaborative work under the high impact research grant UM.C/HIR/MOHE/ENG/25. The Viet Nam National Foundation for Science and Technology Development (NAFOSTED) is acknowledged for financial support through project code 104.99-2014.74. Appendix A. Observability matrix. The main interest of the observability of a dynamic system is that it allows a priori to come up with an observer which rebuilds the system states with certain rate of convergence. Consider a discrete-time system in the form of steady state: x(k + 1) = Ad x(k) (A.1) With output measurement given by: y(k) = Cd x(k) (A.2) If x(0) is known then the state variables at every instant of the discrete-time system can also be determined. This is proven for k = 0, 1,. . .,n − 1 as follows based on the substitution of k value into Eqs. (A.1) and (A.2). At k = 0: x(1) = Ad x(0) (A.3) y(0) = Cd x(0) (A.4) At k = 1: x(2) = Ad x(1) (A.5) y(1) = Cd x(1) (A.6) Substituting Eq. (A.3) into Eq. (A.6): y(1) = Cd x(1) = Cd Ad x(0) (A.7) J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 At k = 2: x(3) = Ad x(2) (A.8) y(2) = Cd x(2) (A.9) By taking the derivative in the continuous-time measurements, for first derivative: ẏ(t0 ) = C ẋ(t0 ) (A.10) As a summary, from k = 0: until n − 1:, assuming the ndimensional vector n(0) has n unknown components we obtain: y(0) = Cd x(0) (A.22) Substituting Eq. (A.20) into Eq. (A.22): Substituting Eqs. (A.3) and (A.5) into Eq. (A.9): y(2) = Cd x(2) = Cd A2d x(0) 37 ẏ(t0 ) = C ẋ(t0 ) = CAx(t0 ) For second derivative: ÿ(t0 ) = C ẍ(t0 ) = CA2 x(t0 ) (A.12) y(2) = Cd x(2) = Cd A2d x(0) (A.13) (A.24) For (n − 1)th derivative, similarly we have: (A.11) y(1) = Cd x(1) = Cd Ad x(0) (A.23) y n−1 (t0 ) = Cxn−1 (t0 ) = CAn−1 x(t0 ) (A.25) As a summary, we obtain y(0) = Cx(t0 ) .. . (A.26) ẏ(t0 ) = C ẋ(t0 ) = CAx(t0 ) (A.27) 2 y(n − 1) = Cd x(n − 1) = Cd An−1 x(0) d (A.14) each with dimenThe matrix blocks Cd , Cd Ad , Cd A2d , . . ., Cd An−1 d sion p × n will stack on top of each other with overall dimension of the matrix is np × n. ⎡ ⎤(np)×1 y(0) ⎢ y(1) ⎥ ⎢ ⎥ ⎢ y(2) ⎥ ⎢ ⎥ ⎢ ⎥ .. ⎣ ⎦ . y(n − 1) ⎡ Cd ⎤(np)×n ⎢ C A ⎥ ⎢ d d ⎥ ⎢ ⎥ 2 ⎥ ⎢ = ⎢ Cd Ad ⎥ ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ (A.15) Cd An−1 d (A.16) ⎡ C (A.29) ⎤(np)×n ⎢ CA ⎥ ⎢ ⎥ ⎢ CA2 ⎥ ⎥ =⎢ ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ × x(t0 ) (A.30) CAn−1 It will have unique solution provided the system matrix has rank n(order of the system). ⎤ C ⎢ CA ⎥ ⎢ ⎥ ⎢ CA2 ⎥ ⎥=n rank ⎢ ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ (A.31) CAn−1 Cd An−1 d Therefore, the observability matrix, denoted by O, must equal to rank n (i.e. rank O = n) to determine the initial condition, x(0). Cd y(t0 ) ⎤(np)×1 ⎢ ẏ(t ) ⎥ ⎢ ⎥ 0 ⎢ ⎥ ⎢ ÿ(t0 ) ⎥ Thus ⎢ ⎥ ⎢ ⎥ ⎢ ⎥ .. ⎣ ⎦ . ⎡ ⎢ C A ⎥ ⎢ d d ⎥ ⎢ ⎥ 2 ⎥ ⎢ rank ⎢ Cd Ad ⎥ = n ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ ⎡ yn−1 (t0 ) = Cxn−1 (t0 ) = CAn−1 x(t0 ) yn−1 (t0 ) ⎤ Cd (A.28) .. . ⎡ It will have unique solution provided the system matrix has rank n(order of the system). ⎡ ÿ(t0 ) = C ẍ(t0 ) = CA x(t0 ) ⎤(np)×n ⎢ C A ⎥ ⎢ d d ⎥ ⎢ ⎥ 2 ⎥ ⎢ O(Ad , Cd ) = ⎢ Cd Ad ⎥ ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ has rank n (A.17) Therefore, the observability matrix, denoted by O, must equal to rank n (i.e. rank O = n) to determine the initial condition, x(t0 ). ⎡ ⎤(np)×n C ⎢ CA ⎥ ⎢ ⎥ ⎢ CA2 ⎥ ⎢ ⎥ O(A, C) = ⎢ ⎥ ⎢ .. ⎥ ⎣ . ⎦ has rank n (A.32) CAn−1 Cd An−1 d Appendix B. Observability Gramians. Now consider the linear continuous-time system: ẋ(t) = Ax(t) (A.18) With output measurement given by: y(t) = Cx(t) (A.19) The knowledge of x(t0 ) is sufficient to determine x(t) at any time instant. At t = t0 : ẋ(t0 ) = Ax(t0 ) (A.20) y(t0 ) = Cx(t0 ) (A.21) Besides that, another observability condition known as observability Gramians has also been discussed by several researchers (Bru et al., 2004; Singh and Hahn, 2005b; Vaidya, 2007; Yasuda and Skelton, 1991). Observability Gramians is based on the Gramians matrices and must satisfy the Lyapunov equation. For a discrete-time system, the k-step observability Gramian can be defined as: Qk = OTk Ok = k−1 i=0 T (Ai ) C T CAi (B.1) 38 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 The system is observable if and only if rank (Qk ) = n, thus the observability Gramians is as follows: Qk = limk→∞ Qk = ∞ i=1 T (Ai ) C T CAi (B.2) Where Q (in Eq. (B.2)) satisfies a Lyapunov equation AT QA − Q = − CT C. Next, for a linear continuous-time system define as: t T (eA ) C T CeA d Qt = (B.3) 0 The system is observable if and only if rank (Qk ) = n, thus the observability Gramians is as follows: ∞ T (eA ) C T CeA d Q = limt→∞ Qt = (B.4) 0 where similarly, Q (in Eq. (B.4)) satisfies a Lyapunov equation AT QA − Q = − CT C. References Aamo OM, Eikrem GO, Siahaan HB, Foss BA. Observer design for multiphase flow in vertical pipes with gas-lift – theory and experiments. J Process Control 2005;15:247–57. Abdel-Jabbar NM, Jumah RY, Al-Haj Ali MQ. State estimation and state feedback control for continuous fluidized bed dryers. J Food Eng 2005;70:197–203. Aguilar-Garnica E, Garcia-Sandoval JP, Gonzalez-Figueredo C. A robust monitoring tool for distributed parameter plug flow reactors. Comp Chem Eng 2011;35:510–8. Aguilar-Lopez R. Integral observers for uncertainty estimation in continuous chemical reactors: algebraic-differential approach. Chem Eng J 2003;93:113–20. Aguilar-Lopez R, Martinez-Guerra R. State estimation for nonlinear systems under model unobservable uncertainties: application to continuous reactor. Chem Eng J 2005;108:139–44. Aguilar-Lopez R, Martinez-Guerra R. Robust state estimation for repetitive operating mode process: application to sequencing batch reactors. Chem Eng J 2007;126:155–61. Aguilar-Lopez R, Maya-Yescas R. State estimation for nonlinear systems under model uncertainties: a class of sliding-mode observers. J Process Control 2005;15:363–70. Aguilar R, Martinez-Guerra R, Poznyak A. Reaction heat estimation in continuous chemical reactors using high gain observers. Chem Eng J 2002;87:351–6. Aguirre LA, Pereira MFS. A modified observer scheme for fault detection and isolation applied to a poorly observed process with integration. J Process Control 1998;8:47–56. Ahn SM, Park MJ, Rhee H-K. Extended Kalman filter-based nonlinear model predictive control for a continuous MMA polymerization reactor. Ind Eng Chem Res 1999;38:3942–9. Alanis AY, Sanchez EN, Ricalde LJ. Discrete-time reduced order neural observers for uncertain nonlinear systems. Int J Neural Syst 2010;20:29–38. Alonso AA, Kevrekidis IG, Banga JR, Frouzakis CE. Optimal sensor location and reduced order observer design for distributed process systems. Comp Chem Eng 2004;28:27–35. Arauzo-Bravo MJ, Cano-Izquierdo JM, Gómez-Sánchez E, López-Nieto MJ, Dimitriadis YA, Lopez-Coronado J. Automatization of a penicillin production process with soft sensors and an adaptive controller based on neuro fuzzy systems. Control Eng Practice 2004;12:1073–90. Astolfi A, Praly L. Global complete observability and output-to-state stability imply the existence of a globally convergent observer. Math Control Signals Syst 2006;18:32–65. Aziz N, Hussain MA, Mujtaba IM. Performance of different types of controllers in tracking optimal temperature profiles in batch reactors. Comp Chem Eng 2000;24:1069–75. Bagui F, Abdelghani-Idrissi MA, Chafouk H. Heat exchanger Kalman filtering with process dynamic acknowledgement. Comp Chem Eng 2004;28:1465–73. Bahar A, Ozgen C. State estimation and inferential control for a reactive batch distillation column. Eng Appl Artif Intell 2010;23:262–70. Bara GI, Daafouz J, Kratz F, Ragot J. Parameter-dependent state observer design for affine LPV systems. Int J Control 2001;74:1601–11. Barton RS, Himmelblau DM. Online prediction of polymer product quality in an industrial reactor using recurrent neural networks. In: International Conference on Neural Networks, vol. 1; 1997. p. 111–4. Bastin G, Dochain D. On-line estimation and adaptive control of bioreactors. Amsterdam: Elsevier; 1990. Beigzadeh R, Rahimi M. Prediction of thermal and fluid flow characteristics in helically coiled tubes using ANFIS and GA based correlations. Int Commun Heat Mass Transfer 2012;39:1647–53. Bejarano FJ, Fridman L. High order sliding mode observer for linear systems with unbounded unknown inputs. Int J Control 2010;83:1920–9. Bejarano FJ, Fridman L, Poznyak A. Hierarchical second-order sliding-mode observer for linear time invariant systems with unknown inputs. Int J Syst Sci 2007;38:793–802. Bejarano FJ, Fridman L, Poznyak A. Output integral sliding mode control based on algebraic hierarchical observer. Int J Control 2007b;80:443–53. BenAmor S, Doyle Iii FJ, McFarlane R. Polymer grade transition control using advanced real-time optimization software. J Process Control 2004;14:349–64. Benaskeur AR, Desbiens A. Modified error decentralized control with observer backstepping. Int J Control 2002;75:923–31. Bernard O, Gouze J-L. Closed loop observers bundle for uncertain biotechnological models. J Process Control 2004;14:765–74. Besancon G. Nonlinear observers and applications. London: Springer; 2007. Biagiola SI, Figueroa JL. State estimation in nonlinear processes. application to pH process control. Ind Eng Chem Res 2002;41:4777–85. Biagiola SI, Figueroa JL. Application of state estimation based NMPC to an unstable nonlinear process. Chem Eng Sci 2004a;59:4601–12. Biagiola SI, Figueroa JL. A high gain nonlinear observer: application to the control of an unstable nonlinear process. Comp Chem Eng 2004b;28:1881–98. Bitzer M, Zeitz M. Design of a nonlinear distributed parameter observer for a pressure swing adsorption plant. J Process Control 2002;12:533–43. Boaventura KM, Roqueiro N, Coelho MAZ, Araújo OQF. State observers for a biological wastewater nitrogen removal process in a sequential batch reactor. Bioresour Technol 2001;79:1–14. Bodizs L, Srinivasan B, Bonvin D. On the design of integral observers for unbiased output estimation in the presence of uncertainty. J Process Control 2011;21:379–90. Bogaerts P, Wouwer AV. Parameter identification for state estimation – application to bioprocess software sensors. Chem Eng Sci 2004;59:2465–76. Boulkroune B, Darouach M, Zasadzinski M, Gillé S, Fiorelli D. A nonlinear observer design for an activated sludge wastewater treatment process. J Process Control 2009;19:1558–65. Bru R, Coll C, Thome N. Gramian matrices and balanced model of generalized systems. Appl Math Comput 2004;148:341–50. Brudzewski K, Kesik A, Kołodziejczyk K, Zborowska U, Ulaczyk J. Gasoline quality prediction using gas chromatography and FTIR spectroscopy: an artificial intelligence approach. Fuel 2006;85:553–8. Busawon KK, Kabore P. Disturbance attenuation using proportional integral observers. Int J Control 2001;74:618–27. Busawon KK, Leon-Morales JD. An observer design for uniformly observable nonlinear systems. Int J Control 2000;73:1375–81. Cacace F, Germani A, Manes C. Observability through delayed measurements: a new approach to state observers design. Int J Control 2010;83:2395–410. Chairez I, Poznyak A, Poznyak T. Reconstruction of dynamics of aqueous phenols and their products formation in ozonation using differential neural network observers. Ind Eng Chem Res 2007;46:5855–66. Chen WS, Bakshi BR, Goel PK, Ungarala S. Bayesian estimation via sequential monte carlo sampling: unconstrained nonlinear dynamic systems. Ind Eng Chem Res 2004;43:4012–25. Chen XS, Yang J, Li SH, Li Q. Disturbance observer based multi-variable control of ball mill grinding circuits. J Process Control 2009;19:1205–13. Chen Z. Bayesian filtering: from Kalman filters to particle filters, and beyond. Statistics 2003;182:1–69. Chitanov V, Kiparissides C, Petrov M. Neural-fuzzy modelling of polymer quality in batch polymerization reactors. In: 2nd international IEEE conference on intelligent systems, vol. 3; 2004. p. 67–72. Chitralekha SB, Prakash J, Raghavan H, Gopaluni RB, Shah SL. A comparison of simultaneous state and parameter estimation schemes for a continuous fermentor reactor. J Process Control 2010;20:934–43. Chuk OD, Ciribeni V, Gutierrez LV. Froth collapse in column flotation: a prevention method using froth density estimation and fuzzy expert systems. Miner Eng 2005;18:495–504. Curtain R, Zwart H. An introduction to infinite-dimensional linear systems theory. New York: Springer-Verlag; 1995. D’Attellis CE, Garcia RA, Mancilla Aguilar JL. Nonlinear observers. Nonlinear analysis: theory. Methods Appl 1997;30:3891–6. Damour C, Benne M, Boillereaux L, Grondin-Perez B, Chabriat J-P. NMPC of an industrial crystallization process using model-based observers. J Ind Eng Chem 2010a;16:708–16. Damour C, Benne M, Grondin-Perez B, Chabriat J-P. Nonlinear predictive control based on artificial neural network model for industrial crystallization. J Food Eng 2010b;99:225–31. Daum F. Nonlinear filters: beyond the Kalman filter. Aerospace and electronic systems magazine. IEEE 2005;20:57–69. de Assis AJ, Filho RM. Soft sensors development for on-line bioreactor state estimation. Comp Chem Eng 2000;24:1099–103. De Battista H, Picó J, Garelli F, Vignoni A. Specific growth rate estimation in fed-batch bioreactors using second-order sliding observers. J Process Control 2011;21:1049–55. de Canete JF, del Saz-Orozco P, Gonzalez S, Garcia-Moral I. Dual composition control and soft estimation for a pilot distillation column using a neurogenetic design. Comp Chem Eng 2012;40:157–70. del-Muro-Cuellar B, Velasco-Villa M, Jiménez-Ramírez O, Fernández-Anaya G, Álvarez-Ramírez J. Observer-based smith prediction scheme for unstable plus time delay processes. Ind Eng Chem Res 2007;46:4906–13. Delrot S, Guerra TM, Dambrine M, Delmotte F. Fouling detection in a heat exchanger by observer of Takagi–Sugeno type for systems with unknown polynomial inputs. Eng Appl Artif Intell 2012;25:1558–66. J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Di Ciccio MP, Bottini M, Pepe P, Foscolo PU. Observer-based nonlinear control law for a continuous stirred tank reactor with recycle. Chem Eng Sci 2011;66:4780–97. Di Ruscio D. Linear polynomial estimator: the state observer.; 2009 http://home.hit. no/∼hansha/documents/control/theory/state observer.pdf Dochain D. State observers for tubular reactors with unknown kinetics. J Process Control 2000;10:259–68. Dochain D. State and parameter estimation in chemical and biochemical processes: a tutorial. J Process Control 2003;13:801–18. Dochain D, Couenne F, Jallut C. Enthalpy based modelling and design of asymptotic observers for chemical reactors. Int J Control 2009;82:1389–403. Dochain D, Perrier M, Ydstie B. Asymptotic observers for stirred tank reactors. Chem Eng Sci 1992;47:4167–77. Dong Y, Yang Y. Observer design for a class of multi-input multi-output nonlinear systems. Int J Syst Sci 2011;42:695–703. El Assoudi A, El Yaagoubi EH, Hammouri H. Non-linear observer based on the Euler discretization. Int J Control 2002;75:784–91. Elicabe GE, Ozdeger E, Georgakis C, Cordeiro C. Online estimation of reaction rates in semicontinuous reactors. Ind Eng Chem Res 1995;34:1219–27. Escobar RF, Astorga-Zaragoza CM, Tellez-Anguiano AC, Juarez-Romero D, Hernandez JA, Guerrero-Ramirez GV. Sensor fault detection and isolation via high-gain observers: application to a double-pipe heat exchanger. ISA Trans 2011;50:480–6. Evangelisti E. Controllability and observability. Berlin Helderlberg: Springer-Verlag; 2011. Fan S, Alpay E. Calorimetric estimation for a batch-loop emulsion polymerisation reactor. Chem Eng Sci 2004;59:2811–5. Farza M, Hammouri H, Othman S, Busawon K. Nonlinear observers for parameter estimation in bioprocesses. Chem Eng Sci 1997;52:4251–67. Farza M, Oueder M, Abdennour RB, M Saad M. High gain observer with updated gain for a class of MIMO nonlinear systems. Int J Control 2011;84:270–80. Fissore D. Robust control in presence of parametric uncertainties: observer-based feedback controller design. Chem Eng Sci 2008;63:1890–900. Fissore D, Pisano R, Barresi AA. Observer design for the selective catalytic reduction of NOx in a loop reactor. Chem Eng J 2007;128:181–9. Floquet T, Barbot JP, Perruquetti W, Djemai M. On the robust fault detection via a sliding mode disturbance observer. Int J Control 2004;77:622–9. Fuhrmann PA. Observer theory. Linear Algebra Appl 2008;428:44–136. Gajic Z. Introduction to linear and nonlinear observers; 2003 http://www.ece. rutgers.edu/∼gajic/psfiles/observers.pdf Goffaux G, Vande Wouwer A, Bernard O. Improving continuous–discrete interval observers with application to microalgae-based bioprocesses. J Process Control 2009;19:1182–90. Gonzalez J, Aguilar R, Alvarez-Ramirez J, Barren MA. Nonlinear regulation for a continuous bioreactor via a numerical uncertainty observer. Chem Eng J 1998;69:105–10. Gonzalez J, Fernandez G, Aguilar R, Barron M, Alvarez-Ramirez J. Sliding mode observer-based control for a class of bioreactors. Chem Eng J 2001;83:25–32. Hadj-Sadok MZ, Gouze JL. Estimation of uncertain models of activated sludge processes with interval observers. J Process Control 2001;11:299–310. Hajatipour M, Farrokhi M. Chattering free with noise reduction in sliding-mode observers using frequency domain analysis. J Process Control 2010;20:912–21. Härdin HM, van Schuppen JH. Observers for linear positive systems. Linear Algebra Appl 2007;425:571–607. Hashimoto Y, Matsumoto K, Matsuo T, Hamaguchi T, Yoneya A, Togari Y. Antisaturation discrete-time nonlinear controllers and observers. Comp Chem Eng 2000;24:815–21. Hermann R, Krener AJ. Nonlinear controllability and observability. IEEE Trans Autom Control 1977;22:728–40. Hidayat Z, Babuska R, De Schutter B, Nunez A. Observers for linear distributedparameter systems: a survey. In: IEEE international symposium on robotic and sensors environments (ROSE); 2011. p. 166–71. Himmelblau DM. Accounts of experiences in the application of artificial neural networks in chemical engineering. Ind Eng Chem Res 2008;47:5782–96. Hoang H, Couenne F, Le Gorrec Y, Chen C-L, Ydstie BE. Passivity based controller and observer of exothermic chemical reactors. Adv Control Chem Process 2012;8:377–84. Hoang H, Couenne F, Le Gorrec Y, Chen C-L, Ydstie BE. Passivity-based nonlinear control of CSTR via asymptotic observers. Annu Rev Control 2013;37(2):278–88. Huang R, Patwardhan SC, Biegler LT. Stability of a class of discrete-time nonlinear recursive observers. J Process Control 2010;20:1150–60. Hulhoven X, Bogaerts P. Hybrid full horizon-asymptotic observer for bioprocesses. In: Proceedings of the 15th IFAC world congress; 2002. p. 1–6. Hulhoven X, Wouwer AV, Bogaerts P. State observer scheme for joint kinetic parameter and state estimation. Chem Eng Sci 2008;63:4810–9. Hulhoven X, Wouwer AV, Bogaerts P. Hybrid extended Luenberger-asymptotic observer for bioprocess state estimation. Chem Eng Sci 2006;61:7151–60. Hussain MA, Shafiur Rahman M, Ng CW. Prediction of pores formation (porosity) in foods during drying: generic models by the use of hybrid neural network. J Food Eng 2002;51:239–48. Islamoglu Y. A new approach for the prediction of the heat transfer rate of the wireon-tube type heat exchanger – use of an artificial neural network model. Appl Therm Eng 2003;23:243–9. Iyer NM, Farell AE. Design of a stable adaptive nonlinear observer for an exothermic stirred tank reactor. Comp Chem Eng 1996;20:1141–7. Jafarov EM. Robust reduced-order sliding mode observer design. Int J Syst Sci 2011;42:567–77. 39 James S, Legge R, Budman H. Comparative study of black-box and hybrid estimation methods in fed-batch fermentation. J Process Control 2002;12:113–21. Jana AK. A nonlinear exponential observer for a batch distillation. In: 11th international conference on control automation robotics & vision (ICARCV); 2010. p. 1393–6. Jana AK, Nath Samanta A, Ganguly S. Observer-based control algorithms for a distillation column. Chem Eng Sci 2006;61:4071–85. Jana AK, Samanta AN, Ganguly S. Nonlinear state estimation and control of a refinery debutanizer column. Comp Chem Eng 2009;33:1484–90. Jung J, Huh K, Hee Lee T. Observer design methodology for stochastic and deterministic robustness. Int J Control 2008;81:1172–82. Kalsi K, Lian J, . Zak SH. Reduced-order observer-based decentralised control of nonlinear interconnected systems. Int J Control 2009;82:1157–66. Kazantzis N, Huynh N, Wright RA. Nonlinear observer design for the slow states of a singularly perturbed system. Comp Chem Eng 2005;29:797–806. Kazantzis N, Kravaris C. Discrete-time nonlinear observer design using functional equations. Syst Control Lett 2001;42:81–94. Kazantzis N, Kravaris C, Wright RA. Nonlinear observer design for process monitoring. Ind Eng Chem Res 2000;39:408–19. Khazraee SM, Jahanmiri AH. Composition estimation of reactive batch distillation by using adaptive neuro-fuzzy inference system. Chin J Chem Eng 2010;18:703–10. Kim M, Moon S, Na C, Lee D, Kueon Y, Lee JS. Control of mold level in continuous casting based on a disturbance observer. J Process Control 2011;21:1022–9. Ko C-L, Wang F-S. On-line estimation of biomass and intracellular protein for recombinant Escherichia coli cultivated in batch and fed-batch modes. J Chin Inst Chem Eng 2007;38:197–203. Kordon AK, Dhurjati PS, Bockrath BJ. On-line expert system for odor complaints in a refinery. Comp Chem Eng 1996;20(Suppl. 2):S1449–54. Kravaris C, Hahn J, Chu Y. Advances and selected recent developments in state and parameter estimation. Comp Chem Eng 2012;51:111–23. Kravaris C, Sotiropoulos V, Georgiou C, Kazantzis N, Xiao M, Krener AJ. Nonlinear observer design for state and disturbance estimation. Syst Control Lett 2007;56:730–5. Kuroda C, Kim J. Neural network modeling of temperature behavior in an exothermic polymerization process. Neurocomputing 2002;43:77–89. Lafont F, Busvelle E, Gauthier J-P. An adaptive high-gain observer for wastewater treatment systems. J Process Control 2011;21:893–900. Lahiri SK, Ghanta KC. Development of an artificial neural network correlation for prediction of hold-up of slurry transport in pipelines. Chem Eng Sci 2008;63:1497–509. Lashkarbolooki M, Vaferi B, Mowla D. Using artificial neural network to predict the pressure drop in a rotating packed bed. Sep Sci Technol 2012;47:2450–9. Lee JH, Ricker NL. Extended Kalman filter based nonlinear model predictive control. Ind Eng Chem Res 1994;33:1530–41. Lee S. Observer for discrete-time Lipschitz non-linear systems with delayed output. IET Control Theory Appl 2011;5:54–62. Lee TC, Lee KS, Yoon T-W, Yang DR. A composition estimator for multicomponent flash drum using recursive equation error method. Comp Chem Eng 2000;24:1281–6. Li E, Jia L, Yu J. A genetic neural fuzzy system-based quality prediction model for injection process. Comp Chem Eng 2002;26:1253–63. Lin H, Zhai G, Antsaklis PJ. Set-valued observer design for a class of uncertain linear systems with persistent disturbance and measurement noise. Int J Control 2003;76:1644–53. Liu J. On-line soft sensor for polyethylene process with multiple production grades. Control Eng Pract 2007;15:769–78. Liu W-J. Design of decentralised variable structure observer for mismatched nonlinear uncertain large-scale systems. Int J Syst Sci 2011;42:349–57. Liu W. An extended Kalman filter and neural network cascade fault diagnosis strategy for the glutamic acid fermentation process. Artif Intell Eng 1999;13: 131–40. Lombardi M, Fiaty K, Laurent P. Implementation of observer for on-line estimation of concentration in continuous-stirred membrane bioreactor: application to the fermentation of lactose. Chem Eng Sci 1999;54:2689–96. López-Negrete R, Biegler LT. A moving horizon estimator for processes with multirate measurements: a nonlinear programming sensitivity approach. J Process Control 2012;22:677–88. López-Negrete R, Patwardhan SC, Biegler LT. Constrained particle filter approach to approximate the arrival cost in moving horizon estimation. J Process Control 2011;21:909–19. López T, Alvarez J. On the effect of the estimation structure in the functioning of a nonlinear copolymer reactor estimator. J Process Control 2004;14:99–109. Luenberger D. Observers for multivariable systems. IEEE Trans Autom Control 1966;11:190–7. Luenberger D. Canonical forms for linear multivariable systems. IEEE Trans Autom Control 1967;12:290–3. Luenberger D. An introduction to observers. IEEE Trans Autom Control 1971;16:596–602. Luenberger DG. Observing the state of a linear system. IEEE Trans Military Electron 1964;8:74–80. Mangold M, Buck A, Schenkendorf R, Steyer C, Voigt A, Sundmacher K. Two state estimators for the barium sulfate precipitation in a semi-batch reactor. Chem Eng Sci 2009;64:646–60. Maria G, Maria C, Salcedo R, de Azevedo SF. Databank transfer-of-information, shortcut and exact estimators used in the wastewater biological treatment process identification. Comp Chem Eng 2000;24:1713–8. 40 J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Mendez-Acosta HO, Palacios-Ruiz B, Alcaraz-Gonzalez Vc, Steyer J-P, GonzalezAlvarez Vc, Latrille E. Robust control of volatile fatty acids in anaerobic digestion processes. Ind Eng Chem Res 2008;47:7715–20. Mesbah A, Huesman AEM, Kramer HJM, Van den Hof PMJ. A comparison of nonlinear observers for output feedback model-based control of seeded batch crystallization processes. J Process Control 2011;21:652–66. Meseguer J, Puig V, Escobet T, Saludes J. Observer gain effect in linear interval observer-based fault detection. J Process Control 2010;20:944–56. Mishkov RL. Non-linear observer design by reduced generalized observer canonical form. Int J Control 2005;78:172–85. Mohebbi M, Shahidi F, Fathi M, Ehtiati A, Noshad M. Prediction of moisture content in pre-osmosed and ultrasounded dried banana using genetic algorithm and neural network. Food Bioprod Process 2011;89:362–6. Mohseni SS, Babaeipour V, Vali AR. Design of sliding mode controller for the optimal control of fed-batch cultivation of recombinant E. coli. Chem Eng Sci 2009;64:4433–41. Morel E, Tartakovsky B, Guiot SR, Perrier M. Design of a multi-model observer-based estimator for anaerobic reactor monitoring. Comp Chem Eng 2006;31:78–85. Moreno JA, Dochain D. Global observability and detectability analysis of uncertain reaction systems and observer design. Int J Control 2008;81:1062–70. Murlidhar GM, Jana AK. Nonlinear adaptive control algorithm for a multicomponent batch distillation column. Chem Eng Sci 2007;62:1111–24. Nagy Kiss AM, Marx B, Mourot G, Schutz G, Ragot J. Observers design for uncertain Takagi–Sugeno systems with unmeasurable premise variables and unknown inputs. Application to a wastewater treatment plant. J Process Control 2011;21:1105–14. Ng CW, Hussain MA. Hybrid neural network – prior knowledge model in temperature control of a semi-batch polymerization process. Chem Eng Process: Process Intens 2004;43:559–70. Ogata K. Discrete-time control systems. 2nd ed Prentice-Hall International, Inc.; 1995. Olanrewaju MJ, Al-Arfaj MA. Estimator-based control of reactive distillation system: application of an extended Kalman filtering. Chem Eng Sci 2006;61:3386–99. Oliveira R, Ferreira EC, Oliveira F, Feyo de Azevedo S. A study on the convergence of observer-based kinetics estimators in stirred tank bioreactors. J Process Control 1996;6:367–71. Olivier LE, Craig IK, Chen YQ. Fractional order and BICO disturbance observers for a run-of-mine ore milling circuit. J Process Control 2012;22:3–10. Oya UH, Hagino K. Observer-based robust control giving consideration to transient behaviour for linear systems with. Int J Control 2002;75:1231–40. Patnaik PR. Application of fuzzy logic for state estimation of a microbial fermentation with dual inhibition and variable product kinetics. Food Bioprod Process 1997;75:239–46. Patwardhan SC, Manuja S, Narasimhan S, Shah SL. From data to diagnosis and control using generalized orthonormal basis filters. Part II: Model predictive and fault tolerant control. J Process Control 2006;16:157–75. Patwardhan SC, Shah SL. From data to diagnosis and control using generalized orthonormal basis filters. Part I: Development of state observers. J Process Control 2005;15:819–35. Pedret C, Alantara S, Vilanova R, Ibeas A. Observer-controller design for a class of stable/unstable inverse response processes. Ind Eng Chem Res 2009;48:10986–93. Pico J, De Battista H, Garelli F. Smooth sliding-mode observers for specific growth rate and substrate from biomass measurement. J Process Control 2009;19:1314–23. Porru G, Aragonese C, Baratti R, Alberto S. Monitoring of a CO oxidation reactor through a grey model-based EKF observer. Chem Eng Sci 2000;55:331–8. Porter Ii LML, Passino KM. Genetic adaptive observers. Eng Appl Artif Intell 1995;8:261–9. Poznyak T, García A, Chairez I, Gómez M, Poznyak A. Application of the differential neural network observer to the kinetic parameters identification of the anthracene degradation in contaminated model soil. J Hazard Mater 2007;146:661–7. Prakash J, Gopaluni RB, Patwardhan SC, Narasimhan S, Shah SL. Nonlinear Bayesian state estimation: review and recent trends. In: 2011 international symposium on advanced control of industrial processes (ADCONIP); 2011. p. 450–5. Prakash J, Patwardhan SC, Shah SL. State estimation and nonlinear predictive control of autonomous hybrid system using derivative free state estimators. J Process Control 2010;20:787–99. Prakash J, Senthil R. Design of observer based nonlinear model predictive controller for a continuous stirred tank reactor. J Process Control 2008;18:504–14. Radke A, Zhiqiang G. A survey of state and disturbance observers for practitioners. In: American control conference; 2006. p. 6. Raïssi T, Ramdani N, Candau Y. Bounded error moving horizon state estimator for non-linear continuous-time systems: application to a bioprocess system. J Process Control 2005;15:537–45. Rezende MCAF, Costa CBB, Costa AC, Maciel MRW, Filho RM. Optimization of a large scale industrial reactor by genetic algorithms. Chem Eng Sci 2008;63: 330–41. Rivera EC, Atala DIP, Filho FM, Carvalho da Costa A, Filho RM. Development of real-time state estimators for reaction–separation processes: A continuous flash fermentation as a study case. Chem Eng Process: Process Intens 2010;49: 402–9. Röbenack K, Lynch AF. An efficient method for observer design with approximately linear error dynamics. Int J Control 2004;77:607–12. Rocha-Cózatl E, Wouwer AV. State and input estimation in phytoplanktonic cultures using quasi-unknown input observers. Chem Eng J 2011;175:39–48. Roffel B, Betlem BHL, de Blouw RM. A comparison of the performance of profile position and composition estimators for quality control in binary distillation. Comp Chem Eng 2003;27:199–210. Ruhm KH. Observer process – survey; 2008 http://www.mmm.ethz.ch/dok01/ d0000862.pdf Salehi S, Shahrokhi M. Two observer-based nonlinear control approaches for temperature control of a class of continuous stirred tank reactors. Chem Eng Sci 2008;63:395–403. Sandink CA, McAuley KB, McLellan PJ. Selection of parameters for updating in on-line models. Ind Eng Chem Res 2001;40:3936–50. Schaum A, Moreno JA, Díaz-Salgado J, Alvarez J. Dissipativity-based observer and feedback control design for a class of chemical reactors. J Process Control 2008;18:896–905. Senthil R, Janarthanan K, Prakash J. Nonlinear state estimation using fuzzy Kalman filter. Ind Eng Chem Res 2006;45:8678–88. Sheibat-Othman N, Peycelon D, Othman S, Suau JM, Fevotte G. Nonlinear observers for parameter estimation in a solution polymerization process using infrared spectroscopy. Chem Eng J 2008;140:529–38. Singh AK, Hahn J. Determining optimal sensor locations for state and parameter estimation for stable nonlinear systems. Ind Eng Chem Res 2005a;44: 5645–59. Singh AK, Hahn J. On the use of empirical gramians for controllability and observability analysis. In: Proceedings of the American control conference, vol. 1; 2005b. p. 140. Singh AK, Hahn J. State estimation for high-dimensional chemical processes. Comp Chem Eng 2005c;29:2326–34. Singh V, Gupta I, Gupta HO. ANN based estimator for distillation – inferential control. Chem Eng Process: Process Intens 2005;44:785–95. Singh V, Gupta I, Gupta HO. ANN-based estimator for distillation using Levenberg–Marquardt approach. Eng Appl Artif Intell 2007;20:249–59. Sivan S, Filo O, Siegelmann H. Application of expert networks for predicting proteins secondary structure. Biomol Eng 2007;24:237–43. Soroush M. Nonlinear state-observer design with application to reactors. Chem Eng Sci 1997;52:387–404. Sotomayor OAZ, Odloak D. Observer-based fault diagnosis in chemical plants. Chem Eng J 2005;112:93–108. Spurgeon SK. Sliding mode observers: a survey. Int J Syst Sci 2008;39:751–64. Tronci S, Bezzo F, Barolo M, Baratti R. Geometric observer for a distillation column: development and experimental testing. Ind Eng Chem Res 2005;44:9884–93. Tsakalis K. Stability, controllability and observability; 2013, http://tsakalis.faculty. asu.edu/notes/sco.pdf Turkdogan-Aydınol FI, Yetilmezsoy K. A fuzzy-logic-based model to predict biogas and methane production rates in a pilot-scale mesophilic UASB reactor treating molasses wastewater. J Hazard Mater 2010;182:460–71. Vaidya U. Observability gramian for nonlinear systems. In: 46th IEEE conference on decision and control; 2007. p. 3357–62. Velardi SA, Hammouri H, Barresi AA. In-line monitoring of the primary drying phase of the freeze-drying process in vial by means of a Kalman filter based observer. Chem Eng Res Des 2009;87:1409–19. Venkateswarlu C, Avantika S. Optimal state estimation of multicomponent batch distillation. Chem Eng Sci 2001;56:5771–86. Vicente M, BenAmor S, Gugliotta LM, Leiza JR, Asua JM. Control of molecular weight distribution in emulsion polymerization using on-line reaction calorimetry. Ind Eng Chem Res 2000;40:218–27. Vries D, Keesman KJ, Zwart H. Luenberger boundary observer synthesis for Sturm–Liouville systems. Int J Control 2010;83:1504–14. Wang G-B, Peng S-S, Huang H-P. A sliding observer for nonlinear process control. Chem Eng Sci 1997;52:787–805. Wang J, Cao LL, Wu HY, Li XG, Jin QB. Dynamic modeling and optimal control of batch reactors, based on structure approaching hybrid neural networks. Ind Eng Chem Res 2011;50:6174–86. Wang J, Zhao L, Yu T. On-line estimation in fed-batch fermentation process using state space model and unscented Kalman filter. Chin J Chem Eng 2010;18:258–64. Wang L, Shao C, Wang H, Wu H. Radial basis function neural networks-based modeling of the membrane separation process: hydrogen recovery from refinery gases. J Nat Gas Chem 2006;15:230–4. Wei H, Su GH, Qiu SZ, Ni W, Yang X. Applications of genetic neural network for prediction of critical heat flux. Int J Therm Sci 2010;49:143–52. Wei NC, Hussain MA, Wahab AKA. Control of a batch polymerization system using hybrid neural network – first principle model. Can J Chem Eng 2007;85:936–45. Welch G, Bishop G. An introduction to the Kalman filter; 1995 http://www.cs. unc.edu/∼tracker/media/pdf/SIGGRAPH2001 CoursePack 08.pdf Wilson JA, Zorzetto LFM. A generalised approach to process state estimation using hybrid artificial neural network/mechanistic models. Comp Chem Eng 1997;21:951–63. Yang C, Yan X. A fuzzy-based adaptive genetic algorithm and its case study in chemical engineering. Chin J Chem Eng 2011;19:299–307. Yang J, Li S, Chen W-H. Nonlinear disturbance observer-based control for multi-input multi-output nonlinear systems subject to mismatching condition. Int J Control 2012:1–12. Yang J, Li S, Chen X, Li Q. Disturbance rejection of dead-time processes using disturbance observer and model predictive control. Chem Eng Res Des 2011;89:125–35. Yasuda K, Skelton RE. Assigning controllability and observability Gramians in feedback control. J Guid Control Dyn 1991;14:878–85. J. Mohd Ali et al. / Computers and Chemical Engineering 76 (2015) 27–41 Yetilmezsoy K, Fingas M, Fieldhouse B. An adaptive neuro-fuzzy approach for modeling of water-in-oil emulsion formation. Colloids Surf A: Physicochem Eng Aspects 2011;389:50–62. Yildiz U, Gurkan UA, Özgen C, Leblebicioğlu K. State estimator design for multicomponent batch distillation columns. Chem Eng Res Des 2005;83:433–44. Zambare N, Soroush M, Ogunnaike BA. A method of robust multi-rate state estimation. J Process Control 2003;13:337–55. Zarei J, Poshtan J. Design of nonlinear unknown input observer for process fault detection. Ind Eng Chem Res 2010;49:11443–52. 41 Zhang T, Guay M. Adaptive nonlinear observers of microbial growth processes. J Process Control 2002;12:633–43. Zhu F. State estimation and unknown input reconstruction via both reducedorder and high-order sliding mode observers. J Process Control 2012;22: 296–302. Zuazua E. Controllability and observability of partial differential equations: some results and open problems. Handbook of differential equations: evolutionary equations, vol. 3; 2007. p. 527–621.