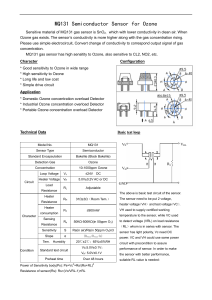

MicRopRrocessor

The microprocessor contains program logic necessary to drive outputs.

Input / output (I/o) board

The I/O BOARD accepts a 20,2081220 VAC supply voltage from the building power

source. There is a voltage selector switch on the board. This switch will always be shipped

in the 220 volt position. Please adjust to match the input voltage. It includes connection

points for the temperature / relative humidity / pressure sensors, two wire ventilation

communications cable, HatchNet communications cable, and an alarm relay output. The

microprocessor, which contains the control logic for the ventilation system, plugs

into a socket located on the VO Board.

TEMPERATURE, RELATIVE HUmiDITY, AND NIFfEReNTIAL

PREssURE SENSORS,

These sensors provide input data to the Microprocessor. The Titan is typically connected to

one temperature and one humidity sensor, but additional sensors may be parallel-series

wired to provide an average reading in large room areas. The Titan can accoÍrmodate up to

three differential pressure sensors for controlling room pressure, and two separate plenum

areas.

RIBBON CABLES / WIRE ASSHMBLIES and SOCKET / PLUG

ASSEMBLIES

These connect all the various components together so that in the unlikely event that a

component fails, it can be replaced in a matter of minutes with an off-the-shelf spare. (See

Recommended Spare Parts List Section)

The Titan Series control can be used to operate a variety of ventilation equipment and

components including air conditioners, combination air conditioning heating units with

either gas or electric heat, single or multi-speed exhaust and supply fans, humidifiers,

dehumidifiers, floating point and analog signal damper actuators, modulating chilled or hot

water valves, evaporative coolers, make-up air furnaces, unit heaters, and variable speed

fans. However, In order to interface with these many different types of ventilation

equipment, the Titan Series control must be connected to one of the following remote

communication boards via two wire communication cable. These boards are typically

remotely located at the point of control, that is, at the equipment that is being controlled.

coMMUNICATION INTERFACE BOARD {CIB 100}

The Communication Interface Board (CIB100) has 12 dry contact digital relay outputs, three

0-1OVDC analog outputs for cooling-humidity-heating, one 2-10VDC analog output for

damper control and two freezestat connections. The CIB100 is commonly installed as a

control interface in air conditioning and heating units, but may also be included as a

component in three phase single or multi-speed motor control centers supplied by HPC.

Further, it may be utilized as a general control system interface when upgrading or

retrofitting an older "hard-wired" ventilation control system for use with the Titan Series

control.

COMM IN terminals accept the incoming communicptions cable from the main Titan

control, and COMM OUT terminals pass the communications on to the next Remote

Communication Board in the ventilation systern..The CIB100 is powered by a24YAC signal

on terminals ACI (Transformer Common) and AC2 (Control Line). This 24VAC control

voltage may originate in the ventilation unit where it may already be readily available, or it

may be supplied by an auxiliary control transformer if required.

Terminals 1 through 12 are AC2 control line outputs switched through the corresponding 12

dry contact digital relays. Terminals C, ANl, AN2, and AN3 provide three outputs of 01OVDC for cooling-humidityheating, and terminals C and AN4 provide one analog output

of 2-10VDC for damper control. The freezestat connections are "SW-I" and "S'W-2". A

short across "S'W-l" will cause the heating valve to drive to 25oA mirnmum. A short across

"S'W-2" will cause the heating and cooling valve to drive to 25oA minimum and limit the

damper position to 30Yo open maximum.

An on-board liquid crystal display with contrast potentiometer provides output status

information. The toggle button allows the user to switch between the output statuses of the

12 normally open (N.O.) relays (0 indicates an open circuit, and 1 indicates a closed circuit),

or the states of the four analog outputs (indicated as a percentage of scaled DC voltage). Light

emitting diodes (L.E.D.'s) indicate active communication.

MOTOR STARTER INTERFACE BOARD

The Motor Starter Interface Board (MSIB) is used to start single phase, I2OVAC or 220

VAC, fan and blower motors and small water pumps. The MSIB is typically installed on

fractional horsepower supply and exhaust fans, single phase evaporative coolers, and fan

driven centrifugal humidifiers. It can opérate single or two speed motors. Be sure to verifr

the correct supply voltage before connecting this board to high voltage as it is configured

from the factory to accept either 120 or 220 volts AC.

HPC-4OO OuTPUT INTERFACE BOARD

The IIPC400 Output Interface Board is used only when connecting the Titan control to a

variable speed fan (i.e. Multifan) such as is common in hatcher exhaust plenums.

HPC.5OO INTERFACE COMMUNICATION CARD

The IIPC500 Interface Communication Card is used for special pu{pose applications.

This board was developed for the case when one or two outputs are needed and a CIB is not

necessary. There are currently two different programs for the HPC500. In the picture

below you will see the marking "RH" on the program chip.

The two program options are as follows: The "RH" program provides two 0-10 VDC

outputs. The first will control a room variable speed fan using a VFD. The second will

control steam humidity. This can be for a live steam valve or an input signal to a gas fired

unit. The relay will also provide a dry contact for control of humidity in a standard

on/off system.The"2PL" program will deliver a 0-10 VDC output to a variable frequency

drive for plenum pressure control. This can control both plenum A and plenum B. See

the wiring detail below for terminal designations.

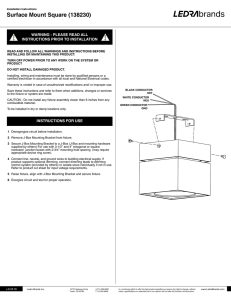

MouNTING The TITAn encloure

The Titan Series should be located on a wall at a minimum height of 7' above finished

floor to prevent damage from buggy traffic. If possible, choose a location that allows the

display to be easily seen from a distance and is not subjected to frequent wash-down. The

location should also be well away from swinging doors. Once a location has been

carefully chosen, the unit can be mounted. The controller is provided with four mounting

feet with which to secure the unit to the wall (see figure).

MOUNTinG TEMPERATURe ANd HUMIDITY sensors

ln order to mount the ternperature lhumidity sensor, you will first need to determine the

best location for the sensor(s) in the room you are trying to control. If the sensors are not

properly located in the room, the controller may not react properly to environmental

changes. (Consult Hatchery Planning Company if you have any questions or refer to the

project design documents for suggested locations).

If you are installing the controller in an incubator or hatcher room you will want to locate

the sensor somewhere near the machine intake.

If you are installing the controller in any other room without incubating or hatching

machines, install the sensor on an interior wall or suspend from the ceiling in a central

location.

In all cases, avoid placing the sensors directly in front of ventilation discharge duct

openings, direct sources of heat or cooling where they could be adversely affected by

oscillating temperatures, or near atomized or vaponzed humidity discharge points.

The temperature and humidity sensor (if equipped) are supplied from the factory premounted together on a2"x4" mounting plate (see photo above). This plate fits any

standard 2"x 4" junction or "handy''box.

Route conduit from the Titan control to the desired sensor location, and terminate with a

handybox. Pull the required cable through the conduit from control to the sensor location,

connect the sensors to the cable as shown in the wiring diagrams, and then secure the

mounting plate to the handybox.

MOUNTING OPTIONAL PRESSURE AND PRESSURE LINE

TERMINATION BOXES

Depending on the specific model, the Titan Series may also be equipped to measure and

control differential pressure. That is, it measures the difference in pressure between two

areas. These areas are called the 'control' and 'reference' areas. The area in which

pressure is to be controlled is referred to as

the 'control' area. The other area is called the 'reference'. The controlled area will be

maintained 'positive', 'even', or 'negative' in relation to the reference area. The reference

area depends upon the application. There are two silicon tubes connected to each pressure

sensor within the Titan controller.

These tubes are connected to brass fittings mounted on the bottom of the unit.

The left fitting is reserved for the 'reference' line.

The right fittings (up to three) are used for the 'control' lines.

Referring to the three photos above, the fitting to the far right (optional) would be for

pressure control of a single plenum (or plenum A) installation. The fitting to the left

(optional) would be for pressure control in a room installation. The next fitting to the left

(optional, located right of the reference line) would be for pressure control of a second

plenum (or plenum B) installation.

Although the actual pressure sensors are located on the VO board of the Titan control, you

will need to route sections of 1/4" O.D. polyethylene tubing (not supplied) from the Titan

to the applicable 'control' ,areas, and one tube from the Titan to the 'reference' area. The

end of each tubing line should be connected to a pressure line termination box (supplied by

Hapco), to prevent water, debris, and outside weather conditions from affecting

performance or causing damage.

Connect these tubes to the appropriate brass fittings. Be sure to insert the brass tube

supports (provided) inside each end of the plastic tube to prevent it from collapsing when

the compression nut is tightened. It is important during this installation that you do not

kink, cut, or damage the lines in any way in order to prevent inaccurate pressure readings.

MOUNTING OPTIONAL HPC-4OO VARIABLE SPEED FAN

CONTROLLERS

The HPC-400 should be located on a wall within 10 feet of the variable speed fan it is to

control. If the HPC-400 is controlling two fans try to locate the HPC-400 an equal distance

between the fans. If possible, choose a location that allows the display to be easily seen

from a distance and is not subjected to frequent washdown. If the HPC-400 is going to

control a variable speed fan in a plenum then locate the control outside the plenum as close

to the fan as possible. The HPC-400 should be mounted a mínimum of 7' above finished

floor to prevent damage from buggy traffic. The location should also be well away from

swinging doors. Once a location has been carefully chosen, the unit can be mounted.

The controller was provided with four mounting feet in which to secure to wall (see

figure).

Position the enclosure on the wall in the chosen the four corners of the mounting feet and

Scribe location and hold steady" Insert a pencil into each hole in the locations for the

mounting screws.

Depending upon the wall material (ie. insulated panel, concrete block, etc.) you will need

to use an appropriate fastener. Remove enclosure and drill the appropriate mounting

holes in the wall. Secure the enclosure to the wall using the anchors/fasteners. At this

point, it is suggested that all power connections be made to the output board.

MSUNTING OF CIB100

In packaged heating / air conditioning units, air handlers, climate changers, etc., the

CIB100 is usually mounted (with the provided hardware) directly inside the control section

of the ventilation unit. In cases where space is limited, it may be supplied in a fiberglass

enclosure for mounting to the exterior of the unit, to the supply or return ductwork, or any

other convenient location near the ventilating unit. Refer to the design documents supplied

with the Titan control system for detailed drawings.

MOUNTING OF MSIB

The Motor Starter Interface Board is usually supplied pre-mounted in a fiberglass electrical

enclosure for attachment to a wall or to the exterior of the ventilation unit. Refer to the

design documents supplied with the Titan control system for detailed drawings.

WIRING OF TITAN AND HPC-400

Wiring of Titan Controller

If you are connecting to an existing control system and do not know how to connect to the

existing control system you have, make sure to contact Hatchery Planning at l-800-2481617, for further assistance.

Failure to heed the above waming will VOID THE WARRANTY. Rernember that conduit

is a pathway, not only for wire, but for any other substance including air,wafer, dust, and

debris. By far, the single most coÍlmon contributing factor in circuit failure is moisture.

Therefore, care should be taken to provide a dry and clean connection to all Titan controls

and components. Penetrations must be made in the BOTTOM of the enclosure to prevent

water from entering the control. Carefully mark and drill a hole in the BOTTOM of the

Titan for the conduit entrance, avoiding damage to the VO board. The wire specifications

are as follows: use 14 AWG stranded wire for the l20l240VAC power connection and

ground. Use 14 AWG for all connections to remote coil(s) or solenoid(s). Route the

incoming power supply through a disconnect switch (not supplied) that is mounted near

the Titan. Make all connections as shown in the appropriate diagrams following:

Wiring Optional HPC-400 Variable Speed Fan Controllers

Shown is atypícaI HPC-400 output board. Be darnage to the board. See detail previous

page controller.

sure to verifu supply voltage before connecting to prevent for wiring connections to the

output board of the HPC-400