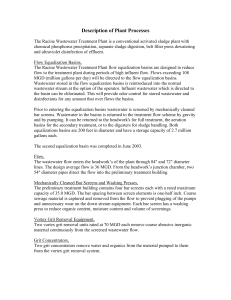

Experimental Methods in

Wastewater Treatment

Experimental Methods in

Wastewater Treatment

Mark C. M. van Loosdrecht

Per H. Nielsen

Carlos M. Lopez-Vazquez

Damir Brdjanovic

Published by:

IWA Publishing

Alliance House

12 Caxton Street

London SW1H 0QS, UK

T: +44 (0) 20 7654 5500

F: +44 (0) 20 7654 5555

E: publications@iwap.co.uk

I: www.iwapublishing.com

First published 2016

© 2016 IWA Publishing

Apart from any fair dealing for the purposes of research or private study, or criticism or review, as permitted under the UK Copyright, Designs and Patents

Act (1998), no part of this publication may be reproduced, stored or transmitted in any form or by any means, without the prior permission in writing of

the publisher, or, in the case of photographic reproduction, in accordance with the terms of licences issued by the Copyright Licensing Agency in the UK,

or in accordance with the terms of licenses issued by the appropriate reproduction rights organization outside the UK. Enquiries concerning reproduction

outside the terms stated here should be sent to IWA Publishing at the address printed above.

The publisher makes no representation, express or implied, with regard to the accuracy of the information contained in this book and cannot accept any

legal responsibility or liability for errors or omissions that may be made.

Disclaimer

The information provided and the opinions given in this publication are not necessarily those of IWA and IWA Publishing and should not be acted upon

without independent consideration and professional advice. IWA and IWA Publishing will not accept responsibility for any loss or damage suffered by any

person acting or refraining from acting upon any material contained in this publication.

British Library Cataloguing in Publication Data

A CIP catalogue record for this book is available from the British Library

Library of Congress Cataloguing in Publication Data

A catalogue record for this book is available from the Library of Congress

Cover design:

Graphic design:

Peter Stroo

Hans Emeis

ISBN: 9781780404745 (Hardback)

ISBN: 9781780404752 (eBook)

Preface

Wastewater treatment is a core technology for water

resources protection and reuse, as is clearly demonstrated

by the great success of its consequent implementation in

many countries worldwide. During the last decennia

scientific research has made vast progress in understanding

the complex and interdisciplinary aspects of the biological,

biochemical, chemical and mechanical processes involved.

It can be concluded that the global application of existing

knowledge and experience in wastewater treatment

technology will represent a cornerstone in future water

management, as expressed in the Strategic Development

Goals accepted by the UN in September 2015.

Only about one fifth of the wastewater produced

globally is currently being adequately treated. To achieve

the goal for sustainable water management by 2030 would

require extra wastewater treatment facilities for about

600,000 people each day. I am convinced that this book

will make its own significant contribution to meeting this

ambitious goal.

In the near future, most of the global population will

live in cities and in low and middle-income countries,

where most wastewater is not adequately treated. Probably

the most limiting factor in achieving the goals for

sustainable water management is the lack of qualified,

well-trained professionals, able to comprehend the

scientific research results and transfer them into practice. It

is therefore of prime importance to make currently

available scientific advances and proven experiences in

wastewater treatment technology applications easily

accessible worldwide. This was one of the drivers for the

development of this book, which represents an innovative

contribution to help overcome such a capacity development

challenge. The book is most definitely expected to

contribute to bridging the gaps between the science and

technology, and their practical applications.

The great collection of authors and reviewers

represents an interdisciplinary team of globally

acknowledged experts. The book will therefore make a

major contribution to establishing a common professional

language, enhancing global communication between

wastewater professionals. In addition, the authors have

linked the description of the scientific basis for wastewater

treatment processes with a video-based online course for

the training of students, researchers, engineers, laboratory

technicians and treatment plant operators, demonstrating

commonly accepted experimentation procedures and their

application for lab-, pilot-, and full-scale treatment plant

operation.

From the perspective of the IWA this book also has the

great potential to enhance the development of a new

generation of researchers and enable them to communicate

on a global scale and beyond their specific field of

expertise. Both aspects are urgently needed to develop

adapted solutions for specific local conditions and to make

them globally available for implementation.

There has been a trend for some time that scientific

research and practice have been growing apart from each

other. Part of the reason for this is the global

implementation of an academic assessment method that

primarily focuses on the impact of publications on the

progress in scientific research. Applied research results

with an impact on practice in water quality management

are not yet being sufficiently rewarded as their impact is

not always reflected by citations in scientific journals. This

book attempts to overcome this problem as it aims to

enhance the dialogue and co-operation between scientists

and practitioners. Scientists are encouraged to deal with the

practical problems with scientific methods, while the

practitioners are encouraged to understand the scientific

background of all the processes relevant for treatment plant

optimization.

While conventional wastewater treatment plant

operation was driven by effluent quality and cost

minimization, this book fully incorporates the paradigm

shift towards material and energy recovery from

wastewater. In this respect the book is also very relevant

for developed countries, as the new paradigm will heavily

influence the future development of wastewater

management worldwide.

As IWA president I want to congratulate the authors of

this book on their great achievement and also thank the Bill

& Melinda Gates Foundation and the Dutch government

for their financial support.

Prof. Dr. Helmut Kroiss

President International Water Association

Contributors

Carlos M. Lopez-Vazquez

Damir Brdjanovic

Eldon R. Rene

Elena Ficara

Elena Torfs

Eveline I.P. Volcke

George A. Ekama

Glen T. Daigger

Gürkan Sin

Henri Spanjers

Holger Daims

Ilse Y. Smets

Imre Takács

Ingmar Nopens

Jeppe L. Nielsen

Jiři Wanner

Juan A. Baeza

Kartik Chandran

Krist V. Gernaey

Laurens Welles

Mads Albertsen

Mari K.H. Winkler

Mark C.M. van Loosdrecht

Mathieu Spérandio

Morten S. Dueholm

Nancy G. Love

Per H. Nielsen

Peter A. Vanrolleghem

Piet N.L. Lens

Rasmus H. Kirkegaard

Robert J. Seviour

Sebastiaan C.F. Meijer

Sophie Balemans

Søren M. Karst

Sylvie Gillot

Tessa P.H. van den Brand

Tommaso Lotti

Yves Comeau

UNESCO-IHE Institute for Water Education, The Netherlands

UNESCO-IHE Institute for Water Education, The Netherlands

UNESCO-IHE Institute for Water Education, The Netherlands

Milan University of Technology, Italy

Université Laval, Canada

Ghent University, Belgium

University of Cape Town, South Africa

University of Michigan, United States of America

Technical University of Denmark, Denmark

Delft University of Technology, The Netherlands

University of Vienna, Austria

Catholic University of Leuven, Belgium

Dynamita, France

Ghent University, Belgium

Aalborg University, Denmark

University of Chemistry and Technology Prague, Czech Republic

Universitat Autònoma de Barcelona, Spain

Columbia University, United States of America

Technical University of Denmark, Denmark

UNESCO-IHE Institute for Water Education, The Netherlands

Aalborg University, Denmark

University of Washington, United States of America

Delft University of Technology, The Netherlands

Institut National des Sciences Appliquées de Toulouse, France

Aalborg University, Denmark

University of Michigan, United States of America

Aalborg University, Denmark

Université Laval, Canada

UNESCO-IHE Institute for Water Education, The Netherlands

Aalborg University, Denmark

La Trobe University, Australia

Yuniko BV, The Netherlands

Ghent University, Belgium

Aalborg University, Denmark

IRSTEA, France

KWR Watercycle Research Institute, The Netherlands

Milan University of Technology, Italy

École Polytechnique de Montréal, Canada

1. 2.

1. 2.

2.

2.

6.

4.

3.

6.

5.

3.

8.

6.

6.

6.

7.

7.

5.

4.

5.

2.

8.

6.

1. 2. 4.

3.

8.

2.

1. 7. 8.

3. 4. 6.

2.

8.

7.

5.

6.

8.

4.

2.

2.

2.

Chapter author

Chapter reviewer

About the editors

Prof. Dr. Mark C.M. van Loosdrecht

Mark C.M. van Loosdrecht is a well-renown scientist recognised

for his significant contributions to the study of reducing energy

consumption and the footprint of wastewater treatment plants

through his patented and award-winning technologies Sharon®,

Anammox® and Nereda®. His main work focuses on the use of

microbial cultures within the environmental process-engineering

field, with a special emphasis on nutrient removal, biofilm and

biofouling. Currently he is a full professor and Group Leader of

Environmental Biotechnology at TU Delft. A fellow of the Royal

Dutch Academy of Arts and Sciences (KNAW), the Netherlands

Academy of Technology and Innovation (AcTI) and the

International Water Association (IWA), Professor van Loosdrecht

has won numerous prestigious awards. His research interests

include granular sludge systems, microbial storage polymers,

wastewater treatment, gas treatment, soil treatment, microbial

conversion of inorganic compounds, production of chemicals from

waste, and modelling. Apart from his other achievements, he has

published over 500 papers, supervised 65 PhD students so far and

is an honorary professor at the University of Queensland. He is

also currently the Editor-in-Chief for Water Research and Advisor

to IWA Publishing.

Prof. Dr. Per Halkjær Nielsen

Per H. Nielsen is a full professor at the Department of Chemistry

and Bioscience at Aalborg University, Denmark where he heads

the multidisciplinary Centre for Microbial Communities. He is also

a visiting scientist at the Singapore Centre on Environmental Life

Sciences

Engineering,

Nanyang

Technological

University, Singapore. Prof. Nielsen’s research group has been

active in environmental biotechnology for over 25 years, focusing

on the microbial ecology of biological wastewater treatment,

bioenergy production, bioremediation, biofilms, infection of

implants and the development of system microbiology approaches

based on new sequencing technologies. He chaired the IWA

specialist group Microbial Ecology and Water Engineering for

eight years (2005-2013) and is Chair of the IWA BioCluster. He is

a Fellow of the Danish Academy of Technical Sciences (ATV) and

the International Water Association (IWA) and has received

several prestigious awards. He has published more than 230 peerreviewed publications and supervised 25 PhD students. His main

research interest is microbial ecology in water engineering,

particularly related to wastewater treatment where he has

developed and applied several novel methods to study uncultured

microorganisms, e.g. by using next-generation sequencing

technologies. He is the initiator and responsible for the MiDAS

field guide open resource for wastewater microbiology.

Dr. Carlos M. Lopez-Vazquez

Carlos M. Lopez-Vazquez is Associate Professor in Wastewater

Treatment Technology at UNESCO-IHE Institute for Water

Education. In 2009 he received his doctoral degree on

Environmental Biotechnology (cum laude) from Delft University

of Technology and UNESCO-IHE Institute for Water Education.

During his professional career, he has taken part in different

advisory and consultancy projects for both public and private

sectors concerning municipal and industrial wastewater treatment

systems. After working for a couple of years in the Water R&D

Department of Nalco Europe on industrial water and wastewater

treatment applications, he re-joined UNESCO-IHE’s Sanitary

Engineering Chair Group in 2009. Since then, he has been

involved in education, capacity building and research projects

guiding dozens of MSc and several PhD students. By applying

mathematical modelling as an essential tool, he has a special focus

on the development and transfer of innovative and cost-effective

wastewater treatment technologies to developing countries,

countries in transition and industrial applications.

Prof. Dr. Damir Brdjanovic

Damir Brdjanovic is Professor of Sanitary Engineering at

UNESCO-IHE and Endowed Professor at Delft University of

Technology in the Environmental Biotechnology Group. Areas of

his expertise include pro-poor and emergency sanitation, faecal

sludge management, urban drainage, and wastewater treatment. He

is a pioneer in the practical application of models in wastewater

treatment practice in developing countries. He invented the Shit

Killer® device for excreta management in emergencies, the awardwinning eSOS® Smart Toilet and associated software eSOS

View®, with funding by the Bill & Melinda Gates Foundation

(BMGF). He has initiated the development and implementation of

innovative didactic approaches and novel educational products

(including e-learning) at UNESCO-IHE. In 2015, together with the

BMGF, he founded the Global Faecal Sludge Management elearning Alliance. Currently his chair group consists of ten staff

members, three post-doctoral fellows and 22 PhD students. In

addition, in excess of 100 MSc students have graduated under his

supervision so far. Prof. Brdjanovic has a sound publication

record, is co-initiator of the IWA Journal of Water, Sanitation and

Hygiene for Development, and is the initiator, author and editor of

five books in the wastewater treatment and sanitation field. In

2015 he became an International Water Association Fellow.

About the book and online course

Over the past twenty years, the knowledge and

understanding of wastewater treatment has advanced

extensively and moved away from empirically-based

approaches to a fundamentally-based first-principles

approach embracing chemistry, microbiology, and physical

and bioprocess engineering, often involving experimental

laboratory work and techniques. Many of these

experimental methods and techniques have matured to the

degree that they have been accepted as reliable tools in

wastewater treatment research and practice. For sector

professionals, especially the new generation of young

scientists and engineers entering the wastewater treatment

profession, the quantity, complexity and diversity of these

new developments can be overwhelming, particularly in

developing countries where access to advanced level

laboratory courses in wastewater treatment is not readily

available. In addition, information on innovative

experimental methods is scattered across scientific

literature and only partially available in the form of

textbooks or guidelines. This book seeks to address these

deficiencies. It assembles and integrates the innovative

experimental methods developed by research groups and

practitioners around the world and broadly applied in

wastewater treatment research and practice.

Experimental Methods in Wastewater Treatment book

forms part of the internet-based curriculum in sanitary

engineering at UNESCO-IHE and, as such, may also be

used together with video recordings of methods and

approaches performed and narrated by the authors,

including guidelines on best experimental practices. The

book is written for undergraduate and postgraduate

students, researchers, laboratory staff, plant operators,

consultants, and other sector professionals.

The idea of making this book and the online learning

course was conceived in 2009 when UNESCO-IHE agreed

to utilize some of the programmatic funds provided by the

Dutch Ministry of Foreign Affairs to develop innovative

learning methods and products. However it took until 2011

to acquire the additional funds from the Bill & Melinda

Gates Foundation (BMGF) that enabled the original idea to

be fully executed. The conceptual framework for the book,

and the online course that it is part of, was agreed upon in

Montreal during the IWA World Water Congress and

Exhibition in September 2010 and further detailed during

the IWA event in Essen, Activated Sludge – 100 Years and

Counting. The latter was the occasion when the concept

was introduced of also having established reviewers in the

field to provide critical feedback on the manuscripts and

improve the quality of the final product, in addition to the

esteemed groups of experts writing the chapters of the

book. Besides providing chapters in the book, authors were

requested to prepare presentation slides, tutorial exercises

and to deliver scenarios and narration for video-recorded

lectures and execution of experimental procedures at

UNESCO-IHE and partner laboratories. These materials

have been compiled into a digital package available to

those registered for the online course. IWA Publishing has

agreed to publish the book and market both the book and

online learning course. It has also been agreed that the

book and online course digital materials are available free

of charge. The online course is delivered once or twice a

year depending on the demand (please consult the

UNESCO-IHE website for further information on how to

embark on the course or download the course materials).

The book is also used for teaching as part of a lecture series

in the Sanitary Engineering specialization of the UNESCOIHE’s Master’s Program in Urban Water and Sanitation. It

is conceptualized in such a way that it can be used as a selfcontained textbook or as an integral part of the online

learning course.

A number of individuals deserve to be singled out as

their support was crucial in this development and is highly

appreciated: Dr. Roshan Shrestha, Dr. Doulaye Koné, Dr.

Frank Rijsberman and Dr. Brian Arbogast (BMGF), and

Dr. Wim Duven and Jetze Heun (UNESCO-IHE). The

book was edited by Peter Stroo, Hans Emeis, Claire Taylor,

Michelle Jones, and Maggie Smith. The credit for the

content goes to all the authors, reviewers and enthusiastic

group of editors. Further, I acknowledge the contributors

who allowed their data, images and photographs to be used

in this book and the course.

Finally, I hope that this book and the training

materials will be useful in your research or practical work,

be it at a laboratory-, pilot- or full-scale wastewater

treatment plant.

Prof. Dr. Damir Brdjanovic

Professor of Sanitary Engineering

Table of contents

1. INTRODUCTION

1

Mark C.M. van Loosdrecht, Per H. Nielsen, Carlos M. Lopez-Vazquez

and Damir Brdjanovic (aut.)

2. ACTIVATED SLUDGE ACTIVITY TESTS

7

Carlos M. Lopez-Vazquez, Laurens Welles, Tommaso Lotti, Elena Ficara,

Eldon R. Rene, Tessa P.H. van den Brand, Damir Brdjanovic

and Mark C.M. van Loosdrecht (aut.)

Yves Comeau, Piet N.L. Lens and Nancy G. Love (rev.)

2.1 INTRODUCTION

2.2 ENHANCED BIOLOGICAL PHOSPHORUS REMOVAL

2.2.1 Process description

2.2.2 Experimental set-up

2.2.2.1 Reactors

2.2.2.2 Activated sludge sample collection

2.2.2.3 Activated sludge sample preparation

2.2.2.4 Substrate

2.2.2.5 Analytical procedures

2.2.2.6 Parameters of interest

2.2.3 EBPR batch activity tests: Preparation

2.2.3.1 Apparatus

2.2.3.2 Materials

2.2.3.3 Media preparation

2.2.3.4 Material preparation

2.2.3.5 Activated sludge preparation

2.2.4 Batch activity tests: Execution

2.2.4.1 Anaerobic EBPR batch activity tests

2.2.4.2 Anoxic EBPR batch tests

2.2.4.3 Aerobic EBPR batch tests

2.2.5 Data analysis

2.2.5.1 Estimation of stoichiometric parameters

2.2.5.2 Estimation of kinetic parameters

2.2.6 Data discussion and interpretation

2.2.6.1 Anaerobic batch activity tests

2.2.6.2 Aerobic batch activity tests

2.2.6.3 Anoxic batch activity tests

2.2.7 Example

2.2.7.1 Description

2.2.7.2 Data analysis

2.2.8 Additional considerations

2.2.8.1 GAO occurrence in EBPR systems

2.2.8.2 The effect of carbon source

2.2.8.3 The effect of temperature

2.2.8.4 The effect of pH

2.2.8.5 Denitrification by EBPR cultures

2.2.8.6 Excess and shortage of intracellular compounds

2.2.8.7 Excessive aeration

2.2.8.8 Shortage of essential ions

2.2.8.9 Toxicity/inhibition

2.3 BIOLOGICAL SULPHATE REDUCTION

2.3.1 Process description

2.3.2 Sulphide speciation

2.3.3 Effects of environmental and operating conditions on SRB

2.3.3.1 Carbon source

2.3.3.2 COD to SO42- ratio

2.3.3.3 Temperature

2.3.3.4 pH

7

9

9

11

11

16

16

17

19

22

22

22

24

24

25

28

29

30

33

34

36

36

41

42

42

45

46

47

47

47

51

51

51

51

52

52

52

53

53

53

54

54

56

57

57

58

58

59

2.3.3.5 Oxygen

2.3.4 Experimental set-up

2.3.4.1 Estimation of volumetric and specific rates

2.3.4.2 The reactor

2.3.4.3 Mixing

2.3.4.4 pH control

2.3.4.5 Temperature control

2.3.4.6 Sampling and dosing ports

2.3.4.7 Sample collection

2.3.4.8 Media

2.3.5 Analytical procedures

2.3.5.1 CODorganics and CODtotal

2.3.5.2 Sulphate

2.3.5.3 Sulphide

2.3.6 SRB batch activity tests: preparation

2.3.6.1 Apparatus

2.3.6.2 Materials

2.3.6.3 Media

2.3.6.4 Material preparation

2.3.6.5 Mixed liquor preparation

2.3.6.6 Sample collection and treatment

2.3.7 Batch activity tests: execution

2.3.8 Data analysis

2.3.8.1 Mass balances and calculations

2.3.8.2 Data discussion and interpretation

2.3.9 Example

2.3.10 Practical recommendations

2.4 BIOLOGICAL NITROGEN REMOVAL

2.4.1 Process description

2.4.1.1 Nitrification

2.4.1.2 Denitrification

2.4.1.3 Anaerobic ammonium oxidation (Anammox)

2.4.2 Process-tracking alternatives

2.4.2.1 Chemical tracking

2.4.2.2 Titrimetric tracking

2.4.2.3 Manometric tracking

2.4.3 Experimental set-up

2.4.3.1 Reactors

2.4.3.2 Instrumentation for titrimetric tests

2.4.3.3 Instrumentation for manometric tests

2.4.3.4. Activated sludge sample collection

2.4.3.5 Activated sludge sample preparation

2.4.3.6 Substrate

2.4.3.7 Analytical procedures

2.4.3.8 Parameters of interest

2.4.3.9 Type of batch tests

2.4.4 Nitrification batch activity tests: Preparation

2.4.4.1 Apparatus

2.4.4.2 Materials

2.4.4.3 Media preparation

2.4.5 Nitrification batch activity tests: Execution

2.4.6 Denitrification batch activity tests: Preparation

2.4.6.1 Apparatus

2.4.6.2 Materials

2.4.6.3 Working solutions

2.4.6.4 Materials preparation

2.4.7 Denitrification batch activity tests: Execution

2.4.8 Anammox batch activity tests: Preparation

59

60

60

60

61

61

61

62

62

62

63

63

64

64

65

65

65

65

66

67

68

68

69

69

70

70

72

73

73

74

75

76

76

77

77

78

79

79

79

80

81

82

82

83

83

86

86

86

86

86

87

92

92

93

93

93

93

99

2.4.8.1 Apparatus

2.4.8.2 Materials

2.4.8.3 Working solutions

2.4.8.4 Materials preparation

2.4.9 Anammox batch activity tests: Execution

2.4.10 Examples

2.4.10.1 Nitrification batch activity test

2.4.10.2 Denitrification batch activity test

2.4.10.3 Anammox batch activity test

2.4.11 Additional considerations

2.4.11.1 Presence of other organisms

2.4.11.2 Shortage of essential micro- and macro-nutrients

2.4.11.3 Toxicity or inhibition effects

2.4.11.4 Effects of carbon source on denitrification

2.5 AEROBIC ORGANIC MATTER REMOVAL

2.5.1 Process description

2.5.2 Experimental set-up

2.5.2.1 Reactors

2.5.2.2 Activated sludge sample collection

2.5.2.3 Activated sludge sample preparation

2.5.2.4 Media

2.5.2.5 Analytical tests

2.5.2.6 Parameters of interest

2.5.3 Aerobic organic matter batch activity tests: Preparation

2.5.3.1 Apparatus

2.5.3.2 Materials

2.5.3.3 Working solutions

2.5.3.4 Material preparation

2.5.3.5 Activated sludge preparation

2.5.4 Aerobic organic matter batch activity tests: Execution

2.5.5 Data analysis

2.5.6 Example

2.5.6.1 Description

2.5.6.2 Data analysis

2.5.7 Additional considerations and recommendations

2.5.7.1 Simultaneous storage and microbial growth

2.5.7.2 Lack of nutrients

2.5.7.3 Toxicity or inhibition

99

99

99

100

100

103

103

105

107

109

109

109

110

110

111

111

112

112

112

113

113

114

114

115

115

115

115

116

117

117

118

119

119

119

121

121

121

121

3. RESPIROMETRY

133

Henry Spanjers and Peter A. Vanrolleghem (aut.)

George A. Ekama and M. Spérandio (rev.)

3.1 INTRODUCTION

3.1.1 Basics of respiration

3.1.2 Basics of respirometry

3.2 GENERAL METHODOLOGY OF RESPIROMETRY

3.2.1 Basics of respirometric methodology

3.2.2 Generalized principles: beyond oxygen

3.2.2.1 Principles based on measuring in the liquid phase

3.2.2.2 Principles based on measuring during the gas phase

3.3 EQUIPMENT

3.3.1 Equipment for anaerobic respirometry

3.3.1.1 Biogas composition

3.3.1.2 Measuring the gas flow

3.3.2 Equipment for aerobic and anoxic respirometry

3.3.2.1 Reactor

3.3.2.2 Measuring arrangement

3.3.2.3 Practical implementation

3.4 WASTEWATER CHARACTERIZATION

3.4.1 Biomethane potential (BMP)

3.4.1.1 Purpose

3.4.1.2 General

133

134

135

136

136

136

136

138

141

141

141

142

143

143

143

144

150

150

150

150

3.4.1.4 Data processing

3.4.1.5 Recommendations

3.4.2 Biochemical oxygen demand (BOD)

3.4.2.1 Purpose

3.4.2.2 General

3.4.2.3 Test execution

3.4.3 Short-term biochemical oxygen demand (BODst)

3.4.3.1 Test execution

3.4.3.2 Calculations

3.4.4 Toxicity and inhibition

3.4.4.1 Purpose

3.4.4.2 Test execution

3.4.4.3 Calculations

3.4.4.4 Biodegradable toxicants

3.4.5 Wastewater fractionation

3.4.5.1 Readily biodegradable substrate (SB)

3.4.5.2 Slowly biodegradable substrate (XCB)

3.4.5.3 Heterotrophic biomass (XOHO)

3.4.5.4 Autotrophic (nitrifying) biomass (XANO)

3.4.5.5 Ammonium (SNHx)

3.4.5.6 Organic nitrogen fractions (XCB,N and SB,N)

3.5 BIOMASS CHARACTERIZATION

3.5.1 Volatile suspended solids

3.5.2 Specific methanogenic activity (SMA)

3.5.2.1 Purpose

3.5.2.2 General

3.5.2.3 Test execution

3.5.2.4 Data processing

3.5.3 Specific aerobic and anoxic biomass activity

3.5.3.1 Maximum specific nitrification rate (AUR)

3.5.3.2 Maximum specific aerobic heterotrophic

respiration rate (OUR)

3.5.3.3 Maximum specific denitrification rate (NUR)

151

151

152

152

152

153

157

158

160

160

160

160

161

162

163

166

167

168

168

168

168

169

169

169

169

169

169

170

171

171

4. OFF-GAS EMISSION TESTS

177

173

173

Kartik Chandran, Eveline I.P. Volcke, Mark C.M. van Loosdrecht (aut.)

Peter A. Vanrollegem and Sylvie Guillot (rev.)

4.1 INTRODUCTION

4.2 SELECTING THE SAMPLING STRATEGY

4.2.1 Plant performance

4.2.2 Seasonal variations in emissions

4.2.3 Sampling objective

4.3 PLANT ASSESSMENT AND DATA COLLECTION

4.3.1 Preparation of a sampling campaign

4.3.2 Sample identification and data sheet

4.3.3 Factors that can limit the validity of the results

4.3.4 Practical advice for analytical measurements

4.3.5 General methodology for sampling

4.3.6 Sampling in the framework of the off-gas measurements

4.3.7 Testing and measurements protocol

4.4 EMISSION MEASUREMENTS

4.5 N2O MEASUREMENT IN OPEN TANKS

4.5.1 Protocol for measuring the surface flux of N2O

4.5.1.1 Equipment, materials and supplies

4.5.1.2 Experimental procedure

4.5.1.3 Sampling methods for nitrogen GHG emissions

4.5.1.4 Direct measurement of the liquid-phase N2O content

4.6 MEASUREMENT OF OFF-GAS FLOW IN OPEN TANKS

4.6.1 Protocol for aerated or aerobic zone

4.6.2 Protocol for non-aerated zones

4.7 AQUEOUS N2O and CH4 CONCENTRATION DETERMINATION

177

178

178

178

179

179

179

180

181

181

182

183

185

185

186

188

188

188

189

191

191

192

192

192

4.7.1 Measurement protocol for dissolved N2O measurement

using polarographic electrodes

4.7.1.1 Equipment

4.7.1.2 Experimental procedure

4.7.2 Measurement protocol for dissolved gasses using

gas chromatography

4.7.3 Measurement protocol for dissolved gas measurement

by the salting-out method

4.7.3.1 Equipment

4.7.3.2 Sampling procedure

4.7.3.3 Measurement procedure

4.7.3.4 Calculations

4.7.4 Measurement protocol for dissolved gas measurement

by the stripping method

4.7.4.1 Operational principle

4.7.4.2 Equipment

4.7.4.3 Calibration batch test

4.7.4.4 Measurement accuracy

4.7.4.5 Calculation of the N2O formation rate in the stripping device

4.8 DATA ANALYSIS AND PROCESSING

4.8.1 Determination of fluxes

4.8.2 Determination of aggregated emission fractions

4.8.3 Calculation of the emission factors

5. DATA HANDLING AND PARAMETER ESTIMATION

193

193

193

194

194

195

195

195

196

196

196

197

198

198

198

199

199

199

200

201

Gürkan Sin and Krist V. Gernaey (aut.)

Sebastiaan C.F. Meijer and Juan A. Baeza (rev.)

5.1 INTRODUCTION

5.2 THEORY AND METHODS

5.2.1 Data handling and validation

5.2.1.1 Systematic data analysis for biological processes

5.2.1.2 Degree of reduction analysis

5.2.1.3 Consistency check of experimental data

5.2.2 Parameter estimation

5.2.2.1 Manual trial and error method

5.2.2.2 Formal statistics methods

5.2.3 Uncertainty analysis

5.2.3.1 Linear error propagation

5.2.3.2 The Monte Carlo method

5.2.4 Local sensitivity analysis and identifiability analysis

5.2.4.1 Local sensitivity analysis

5.2.4.2 Identifiability analysis using the collinearity index

5.3 METHODOLOGY AND WORKFLOW

5.3.1 Data consistency check using elemental balance and

a degree of reduction analysis

5.3.2 Parameter estimation workflow for non-linear least

squares method

5.3.3 Parameter estimation workflow for the bootstrap method

5.3.4 Local sensitivity and identifiability analysis workflow

5.3.5 Uncertainty analysis using the Monte Carlo method and

linear error propagation

5.4 ADDITIONAL EXAMPLES

5.5 ADDITIONAL CONSIDERATIONS

201

202

202

202

203

204

205

205

205

209

209

209

210

210

210

211

6. SETTLING TESTS

235

211

212

212

213

213

214

232

Elena Torfs, Ingmar Nopens, Mari K.H. Winkler, Peter A. Vanrolleghem,

Sophie Balemans and Ilse Y. Smets (aut.)

Glenn T. Daigger and Imre Takács (rev.)

6.1 INTRODUCTION

6.2 MEASURING SLUDGE SETTLEABILITY IN SSTs

6.2.1 Sludge settleability parameters

6.2.1.1 Goal and application

6.2.1.2 Equipment

6.2.1.3 The sludge volume index (SVI)

6.2.1.4 The diluted sludge volume index (DSVI)

6.2.1.5 The stirred specific volume index (SSVI3.5)

6.2.2 The batch settling curve and hindered settling velocity

6.2.2.1 Goal and application

6.2.2.2 Equipment

6.2.2.3 Experimental procedure

6.2.2.4 Interpreting a batch settling curve

6.2.2.5 Measuring the hindered settling velocity

6.2.3 vhs-X relation

6.2.3.1 Goal and application

6.2.3.2 Equipment

6.2.3.3 Experimental procedure

6.2.3.4 Determination of the zone settling parameters

6.2.3.5 Calibration by empirical relations based on SSPs

6.2.4 Recommendations for performing batch settling tests

6.2.4.1 Shape and size of the batch reservoir

6.2.4.2 Sample handling and transport

6.2.4.3 Concentration range

6.2.4.4 Measurement frequency

6.2.5 Recent advances in batch settling tests

6.3 MEASURING FLOCCULATION STATE OF ACTIVATED SLUDGE

6.3.1 DSS/FSS test

6.3.1.1 Goal and application

6.3.1.2 Equipment

6.3.1.3 DSS test

6.3.1.4 FSS test

6.3.1.5 Interpretation of a DSS/FSS test

6.3.2 Recommendations

6.3.2.1 Flocculation conditions

6.3.2.2 Temperature influence

6.3.2.3 Supernatant sampling

6.3.3 Advances in the measurement of the flocculation state

6.4 MEASURING THE SETTLING BEHAVIOUR OF GRANULAR SLUDGE

6.4.1 Goal and application

6.4.2 Equipment

6.4.3 Density measurements

6.4.4 Granular biomass size determination

6.4.4.1 Sieving

6.4.4.2 Image analyser

6.4.5 Calculating the settling velocity of granules

6.4.6 Recommendations

6.4.6.1 Validation of results

6.4.6.2 Application for flocculent sludge

6.5 MEASURING SETTLING VELOCITY DISTRIBUTION IN PSTs

6.5.1 Introduction

6.5.2 General principle

6.5.3 Sampling and sample preservation

6.5.4 Equipment

6.5.5 Analytical protocol

6.5.6 Calculations and result presentation

6.5.6.1 Mass balance check

6.5.6.2 Calculation of the settling velocity distribution

6.5.6.3 Recommendations

237

237

237

238

238

238

239

239

240

241

241

241

242

242

243

244

245

245

245

245

245

245

246

246

246

246

246

247

248

249

249

249

249

250

250

250

251

251

252

252

253

253

254

254

255

255

255

255

256

256

257

258

258

258

259

7. MICROSCOPY

263

Jeppe L. Nielsen, Robert J. Seviour and Per H. Nielsen (aut.)

Jiři Wanner (rev.)

235

236

237

237

7.1 INTRODUCTION

7.2 THE LIGHT MICROSCOPE

7.2.1 Standard applications of light microscopy

263

263

265

7.2.2 Low power objective

7.2.3 High power objective

7.2.4 Immersion objective

7.2.5 Important considerations

7.2.6 Bright-field and dark-field illumination

7.2.7 Fluorescence microscopy

7.2.8. Confocal laser scanning microscopy

7.3 MORPHOLOGICAL INVESTIGATIONS

7.3.1 Microscopic ‘identification’ of filamentous microorganisms

7.3.2 ‘Identification’ of protozoa and metazoa

7.4 EXAMINING ACTIVATED SLUDGE SAMPLES MICROSCOPICALLY

7.4.1 Mounting the activated sludge sample

7.4.2 Gram staining

7.4.2.1 Reagents and solutions for Gram staining

7.4.2.2 Procedure

7.4.3 Neisser staining

7.4.3.1 Reagents and solutions for Neisser staining

7.4.3.2 Procedure

7.4.4 DAPI staining

7.4.4.1 Reagents and solutions for DAPI staining

7.4.4.2 Procedure

7.4.5 CTC staining

7.4.5.1 Reagents and solutions for CTC staining

7.4.5.2 Procedure

7.5 FLUORESCENCE in situ HYBRIDIZATION

7.5.1 Reagents and solutions for FISH

7.5.2 Procedure

7.6 COMBINED STAINING TECHNIQUES

7.6.1 FISH-DAPI staining

7.6.1.1 Reagents and solutions for DAPI staining

7.6.1.2 Procedure

7.6.2 FISH-PHA staining

7.6.2.1 Reagents and solutions for PHA staining

7.6.2.2 Procedure

265

265

265

266

266

267

269

269

270

271

272

272

273

273

274

274

274

275

275

275

275

276

276

276

276

277

278

280

281

281

281

282

282

282

8. MOLECULAR METHODS

285

Søren M. Karst, Mads Albertsen, Rasmus H. Kirkegaard, Morten S. Dueholm

and Per H. Nielsen (aut.)

Holger Daims (rev.)

8.1 INTRODUCTION

8.2 EXTRACTION OF DNA

8.2.1 General considerations

8.2.2 Sampling

8.2.3 DNA extraction

8.2.3.1 Cell lysis

8.2.3.2 Nuclease activity inhibition and protein removal

8.2.3.3 Purification

8.2.3.4 Elution and storage

8.2.4 Quantification and integrity

8.2.5 Optimised DNA extraction from wastewater activated sludge

8.2.5.1 Materials

8.2.5.2 DNA extraction

8.3 REAL-TIME QUANTITATIVE PCR (qPCR)

8.3.1 General considerations

8.3.2 Materials

8.3.3 Methods

8.3.4 Data handling

8.3.5 Data output and interpretation

8.3.6 Troubleshooting

8.3.7 Example

8.3.7.1 Samples

8.3.7.2 qPCR reaction setup

285

286

286

286

286

286

287

287

287

287

288

288

288

289

289

291

292

294

294

295

295

295

296

8.3.7.3 Results

8.4 AMPLICON SEQUENCING

8.4.1 General considerations

8.4.2 The 16S rRNA gene as a phylogenetic marker gene

8.4.3 PCR amplification

8.4.3.1 PCR reaction

8.4.3.2 PCR biases

8.4.3.3 Primer choice

8.4.4 DNA sequencing

8.4.4.1 Sequencing platform

8.4.4.2 Sequencing depth

8.4.5 Bioinformatic processing

8.4.5.1 Available software

8.4.5.2 Raw data

8.4.5.3 Quality scores and filtering

8.4.5.4 Merging paired end-reads

8.4.5.5 OTU clustering

8.4.5.6 Chimera detection and removal

8.4.5.7 Taxonomic classification

8.4.5.8 The OTU table

8.4.6 Data analysis

8.4.6.1 Defining the goal of the data analysis

8.4.6.2 Data validation and sanity check

8.4.6.3 Communities or individual species?

8.4.6.4 Identifying core and transient species

8.4.6.5 Explorative analysis using multivariate statistics

8.4.6.6 Correlation analysis

8.4.6.7 Effect of treatments on individual species

8.4.7 General observations

8.4.7.1 A relative analysis

8.4.7.2 Copy number bias

8.4.7.3 Primer bias

8.4.7.4 Standardization

8.4.7.5 Impact of the method

8.4.8 Protocol: Illumina V1-3 16S rRNA amplicon libraries

8.4.8.1 Apparatus

8.4.8.2 Materials

8.4.8.3 Protocol

8.4.9 Interpretation and troubleshooting

8.4.9.1 Sample DNA quality control and dilution

8.4.9.2 Library PCR

8.4.9.3 Library cleanup

8.4.9.4 Library quality control

8.4.9.5 Library pooling

8.4.9.6 Pool quality control and dilution

8.4.9.7 Storage

8.4.10 Protocol: Illumina V1-3 16S amplicon sequencing

8.4.10.1 Apparatus

8.4.10.2 Reagents

8.4.10.3 Protocol

8.4.10.4 Interpretation and troubleshooting

8.4.11 Design of Illumina 16S amplicon sequencing adaptors

8.5 OTHER METHODS

LIST OF SYMBOLS AND ABBREVIATIONS

296

297

297

297

299

299

300

300

301

301

301

301

301

302

303

303

303

304

304

304

304

304

305

305

306

306

307

307

307

307

307

307

308

308

308

308

308

309

311

311

312

312

313

314

314

314

314

314

314

314

315

317

319

1

INTRODUCTION

Authors:

Mark C.M. van Loosdrecht

Per H. Nielsen

Carlos M. Lopez-Vazquez

Damir Brdjanovic

Wastewater treatment forms a crucial link in the services

that the sanitation sector delivers to society. For

centuries, sanitation largely consisted of transporting

fresh, clean water to the cities, and using this water to

transport the waste out of the city and discharge it into

the natural environment. However, with the increase in

human populations in cities as a result of the industrial

revolution in the 19th century, this could no longer be

maintained. The occurrence of epidemic diseases

facilitated the development of wastewater treatment

facilities and their implementation since the early 20th

century. This development has been largely an empirical

activity with theoretical approaches following

experimental observations (Figure 1.1).

Figure 1.1 Noyes Laboratory on the campus of the University of Illinois in

Urbana was arguably the most important in promoting research in

wastewater in the early 20th century (photo: University of Illinois, 1902).

The discovery and development of activated sludge

technology (described in detail in Jenkins and Wanner,

2014) was crucial as it triggered the rapid development

and application of various analytical and experimental

methods. Experimental work in the Lawrence

Experimental Station in Massachusetts, USA, which at

that time (1912) was a unique facility aimed at the

experimental verification of different possible

wastewater treatment procedures, inspired Gilbert

Fowler to request Edward Ardern and William Lockett to

repeat the experiments with wastewater aeration in the

UK that he had seen in the USA. In 1913 and 1914

Lockett and Ardern carried out lab-scale experiments at

the Manchester - Davyhulme wastewater treatment plant

(Figure 1.2). Glass bottles were used to represent labscale aeration basins ‘fed’ by sewage from different

districts of Manchester. Contrary to the experiments that

Fowler saw in Massachusetts, in the Manchester aeration

tests the sediment that remained after decantation was left

in the bottle and a new dose of sewage was added to the

sediment for the next batch. Lockett and Ardern soon

found that the amount of the sediment increased with the

increasing number of batches. At the same time the

aeration time necessary for ‘full oxidation’ of sewage

(full oxidation was a term used to describe the removal

of degradable organics and for complete nitrification)

was reduced. By using this technique of repeated batch

aeration with the sediment remaining in the bottle,

Lockett and Ardern were able to shorten the required

aeration time for ‘full oxidation’ from a few weeks to less

than one day, which made the process technically

© 2016 Mark C.M. van Loosdrecht et al. Experimental Methods In Wastewater Treatment. Edited by M.C.M. van Loosdrecht, P.H. Nielsen. C.M. Lopez-Vazquez and D. Brdjanovic. ISBN:

9781780404745 (Hardback), ISBN: 9781780404752 (eBook). Published by IWA Publishing, London, UK.

2

feasible. The sediment formed during the aeration of

sewage was called activated sludge due to its appearance

and activity. Lockett and Ardern published their results

in a famous series of three papers (Ardern and Lockett

1914a, 1914b, 1915). This was the ‘birth’ of activated

sludge, which is today the workhorse of wastewater

treatment and the most widely applied sewage treatment

technology in the world.

EXPERIMENTAL METHODS IN WASTEWATER TREATMENT

Examples are the commonly used chemical or biological

oxygen demand tests. The iconic ‘Standard Methods for

the Examination of Water and Wastewater’ (APHA et al.,

2012, Figure 1.3) has for generations of sanitary

engineers been the resource for analysing their

experimental systems and full-scale operations. These

methods focus heavily on the chemical characterization

and measurement of specific microorganisms.

Figure 1.2 The Davyhulme Sewage Works Laboratory, where the activated

sludge process was developed in the early 20th century (photo: United

Utilities).

Wastewater engineering is a profession that is

extremely experiment-based, and therefore it has always

had the need to develop and standardise methods. This

seemingly simple activity is strongly hampered by two

factors, namely: (i) wastewater engineering is a typical

interdisciplinary activity where chemical engineers, civil

engineers, microbiologists and chemists interact to

develop and understand the processes; the challenge here

is to integrate methods and approaches from these

disciplines, and, (ii) in addition, wastewater and its

treatment processes are by their nature difficult to define

with exactitude. It is for instance virtually impossible to

measure all the individual compounds in the wastewater

itself. Identifying all the relevant microorganisms in the

processes has long been impossible and is still a

complicated challenge. Defining all the potentially

occurring chemical conversions is, due to the myriad of

chemicals present, again an almost impossible task.

Due to the undefined nature of the experimental

system, research has tended to progress slowly and it

heavily depends on standardised methods that may not be

exact but, when used in a standardised way, are very

helpful and useful to compare experimental results.

Figure 1.3 The Standard Methods for the Examination of Water and

Wastewater. The first edition appeared in 1905 (image: APHA et al., 2012).

Societal demands on the efficiency of wastewater

treatment plants have advanced, moving from public

health protection to water resources and environmental

protection and nowadays to integrated resource and

energy recovery. Therefore the need to accurately

characterize the microbial processes in the wastewater

treatment processes has increased over recent decades.

Certainly, it is a challenge to develop standardized

methods for experimental work that can be easily

repeated in different laboratories. In many cases, the

exact handling is important, but it is not easy to be written

down in a practical protocol.

INTRODUCTION

Therefore, to avoid these problems, it was decided to

develop not only a book describing all the experimental

methods but also a video catalogue with the methods

described in this book actually being demonstrated in the

laboratory. This book and its associated video-based

material are designed to support the research and

development field with a manual for characterizing the

biological processes in wastewater treatment. The editors

have decided in this first edition of the ‘Experimental

methods in wastewater treatment’ book to focus on the

activated sludge process since this is worldwide by far

the most applied technology. Nevertheless, most of the

methods presented in this book can also be applicable to

biofilm-based technologies or anaerobic digestion

processes.

The decision to focus on experimental methods

related to the activated sludge process has resulted in

seven chapters describing the key experimental methods.

The content and focus of these chapters are summarised

in Table 1.1. Activated sludge consists of a myriad of

microorganisms, converting a range of important

compounds (organic matter, oxygen, nitrogen and

phosphate compounds). The first three chapters focus on

characterizing the conversion capacities of the microbial

communities for the major microbial processes. A

distinction has been made between full liquid-phasebased methods and methods where the conversion are

characterized by measuring the respiration of the

organisms, usually gas-phase measurements. Since there

is an increasing focus on and interest in assessing the

environmental impact of wastewater treatment plants, a

separate chapter has been added for measuring

greenhouse gas emissions from wastewater treatment

plants. These chapters are followed by a chapter

describing data handling techniques. Measurements

often, certainly from full-scale or pilot plants, have

relatively large uncertainties. With adequate data

handling techniques the measurements can be used to

derive associated (difficult to directly measure) process

data or to minimise their uncertainty.

Activated sludge processes mainly depend on settling

of the flocculent sludge to separate the biomass from the

cleaned wastewater. This is often the Achilles heel of the

treatment process and a key factor in the process design.

One chapter is therefore devoted to characterization of

the sludge settling properties.

As said earlier, microorganisms are the workhorses in

the activated sludge process. Therefore the microscope is

unavoidably the main technique to observe them directly,

not only for individual organisms but also for the floc

3

morphology related to settling characteristics. For a long

time the microscope has been the main method of choice

when observing which bacteria are present in activated

sludge. However, although very helpful, it cannot show

the full complexity of the microbial community. The last

decade’s advance in molecular DNA-based techniques

has revolutionized the way one can observe

microorganisms. These generic novel methods are

described in the final chapter of this book.

Within the chapters the authors have tried to describe

especially those methods that are experimentally

complex and not standard analytical procedures.

Therefore, standard analytical methods for e.g. organic

matter, ammonium, phosphate etc. are not described in

detail. On the other hand, it was also decided to include

some analytical techniques recently developed and/or

improved that are becoming frequently used but are

scattered across scientific literature (e.g. glycogen and

poly-hydroxy-alkanoates determination). In addition,

methods that could be of academic interest but currently

have limited practical application have not been included

in detail in the text.

In terms of symbols and notation, an attempt has been

made to standardize them as much as possible. While this

was achieved at the chapter level, full standardization

was not possible across all the chapters due to their

diverse nature and heterogeneity of items as well as lack

of global agreement on the use of symbols and notations,

although the most common guidelines were quite closely

followed (e.g. Corominas et al., 2010).

The book is conceptualized so as to satisfy users with

high demands who are able to handle complex analytical

and experimental equipment. However, the content is

equally suited to the requirements of less advanced

laboratories and less experienced experimenters; in

particular, the complementary, freely available video

materials address the execution of experiments in more

challenging environments, such as those usually

prevailing in most less developed countries.

"To measure is to know."

Lord Kelvin

4

EXPERIMENTAL METHODS IN WASTEWATER TREATMENT

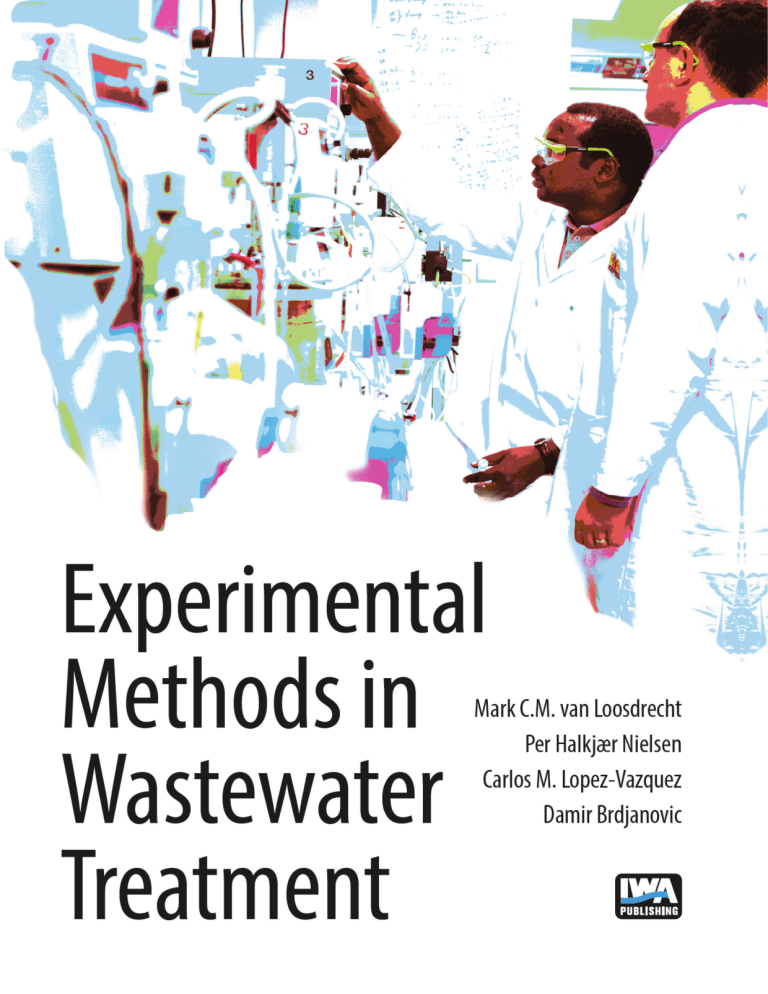

Table 1.1 A simplified overview of the experimental methods presented in the book per process of interest.

Process

Introduction

Organic matter

removal

Activated sludge

activity tests

Kinetics

AOO and NOO

activity

Kinetics

Stoichiometry

Nitrification

Overview and

rationale to

experimental

methods

Denitrification

Anammox

EBPR

Anaerobic

treatment

Respirometry

Biochemical

oxygen demand

(BOD)

Short-term

biochemical

oxygen demand

Wastewater

characterization

and fractionation

Biomass

characterization

Toxicity and

inhibition

Wastewater

characterization

and fractionation

Biomass

characterization

AOO and NOO

activity

Toxicity and

inhibition

Kinetics

Stoichiometry

Denitrification

over NO2 and NO3

Denitrification

on RBCOD and

SBCOD

Stoichiometry

Kinetics

AMX activity

Kinetics

Stoichiometry

Denitrification

over NO2 and NO3

Toxicity and

inhibition

Stoichiometry

Kinetics

PAO, GAO, and

Aerobic kinetics

DPAO activity

Kinetics

Stoichiometry

SRB activity

Kinetics

Stoichiometry

Chapter

Off-gas emission Data handling and Settling tests

tests

parameter

estimation

Sampling

methods for

nitrogen GHG

emissions

Methods for

off-gas

measurements

Aqueous N2O and

CH4 concentration

determination

methods

Gas

measurement

methods in open

tanks

Microscopy

Light

microscopy

distributions in

Confocal

primary settling microscopy

tanks

Morphological

investigations

Sludge

settleability in

Staining

secondary settling techniques

tanks

Fluorescence in

situ

Flocculation

Hybridization

properties

(FISH)

Settling

behaviour of

Combined

granular sludge staining

techniques

Molecular

methods

Settling velocity

Data handling

and validation

Parameter

estimation

Uncertainty

analysis

Local sensitivity

analysis and

identifiability

analysis

DNA extraction

Real-time

quantitative PCR

Amplicon

sequencing

and

stoichiometry

Toxicity and

inhibition

Specific

methanogenic

activity

Biomethane

potential

Toxicity and

inhibition

Kinetics

Stoichiometry

Settling

AMX Anammox organisms

AOO Ammonium oxidizing organisms

CH4 Methane

DNA Deoxyribonucleic acid

DPAO Denitrifying poly-phosphate accumulating organisms

EBPR Enhanced biological phosphorus removal

FISH Fluorescence in situ hybridization

GAO Glycogen accumulating organisms

GHG Greenhouse gas emissions

N2O Nitrous oxide

NO2 Nitrite

NO3 Nitrate

NOO Nitrite oxidizing organisms

PAO Poly-phosphate accumulating organisms

PCR Polymerase chain reaction

RBCOD Readily biodegradable COD also known as readily biodegradable organics

SBCOD Slowly biodegradable COD also known as slowly biodegradable organics

SRB Sulphate reducing bacteria or SRO Sulphate reducing organism

INTRODUCTION

5

Figure 1.4 The mission of UNESCO-IHE is to contribute to the education and training of professionals, to expand the knowledge base through research and

to build the capacity of sector organizations, knowledge centres and other institutions active in the fields of water, the environment and infrastructure in

developing countries and countries in transition. The photos depict the illustrative example of the Institute's latest project in Cuba where the laboratory of the

Instituto de Investigaciones para la Industria Alimenticia (IIIA) in Havana has been equipped with new state-of-the-art technology and where the local staff

has been trained on how to operate the equipment and prepare and carry out experimental work (photo: Brdjanovic, 2015).

References

American Public Health Association (APHA), American Water

Works Association (AWWA), and Water Environment

Federation (WEF) (2012). Standard Methods for the

Examination of Water and Wastewater, 22nd Edition. New

York. ISBN 9780875530130.

Ardern, E., Lockett, W.T. (1914a) Experiments on the Oxidation of

Sewage without the Aid of Filters. J. Soc. Chem. Ind., 33: 523.

Ardern, E., Lockett, W.T. (1914b) Experiments on the Oxidation of

Sewage without the Aid of Filters, Part II. J. Soc. Chem. Ind.,

33: 1122.

Ardern, E., Lockett, W.T. (1915) Experiments on the Oxidation of

Sewage without the Aid of Filters, Part III. J. Soc. Chem. Ind.,

34: 937.

Corominas, L.L., Rieger, L., Takács, I., Ekama, A.G., Hauduc, H.,

Vanrolleghem, P.A., Oehmen, A., Gernaey, K.V., van

Loosdrecht, M.C.M., Comeau Y. (2010). New framework for

standardized notation in wastewater treatment modelling.

Water Sci Technol. 61(4): 841-57.

Jenkins, D. and Wanner, J. Eds. (2014) 100 years of activated sludge

and

counting.

IWA

Publishing,

London,

ISBN

9781780404936, pg. 464.

The section on activated sludge historical development

presented in this chapter is adapted from Jenkins and Wanner

(2014).

6

EXPERIMENTAL METHODS IN WASTEWATER TREATMENT

2

ACTIVATED SLUDGE ACTIVITY TESTS

Authors:

Reviewers:

Carlos M. Lopez-Vazquez

Laurens Welles

Tommaso Lotti

Elena Ficara

Eldon R. Rene

Tessa P.H. van den Brand

Damir Brdjanovic

Mark C.M. van Loosdrecht

Yves Comeau

Piet N.L. Lens

Nancy G. Love

2.1 INTRODUCTION

Different conditions and factors affect the degree and rate

(speed) at which the compounds and contaminants of

concern are removed by microbial populations in

biological wastewater treatment systems. Certainly, the

plant configuration and operational conditions play a

major role in the prevalence of specific microbial

populations and their activities, but factors as diverse and

broad as wastewater characteristics and environmental

and climate conditions have a strong influence as well.

Eventually, in any biological wastewater treatment

system, there will be a need to assess, define and

understand the plant performance with regard to the

removal of certain contaminants and the response of the

sludge to inhibitory or toxic compounds of interest.

Moreover, from a modelling perspective it is also of

interest to assess and determine the stoichiometry and

kinetic rates of the conversion processes performed by

specific microbial populations (e.g. ordinary

heterotrophic organisms: OHOs; denitrifying ordinary

heterotrophic organisms: dOHOs; ammonium-oxidizing

organisms: AOOs; nitrite-oxidizing organisms: NOOs;

phosphate-accumulating organisms: PAOs; sulphatereducing bacteria: SRB, also identified as sulphatereducing organisms, SRO (Corominas et al., 2010); or,

anaerobic ammonium-oxidizing organisms: anammox.

Thereby, the execution of batch activity tests can be

rather useful to: (i) study the biodegradability of a given

wastewater stream (municipal or industrial), (ii)

determine the stoichiometric and kinetic parameters

involved in the conversion of a specific compound, (iii)

study the potential interactions (e.g. symbiosis and

competition) between microbial populations and (iv)

assess the potential inhibitory or toxic effects of certain

wastewaters, compounds or substances.

The nature and type of the batch activity tests can

differ depending upon the compounds of interest and the

metabolism and physiology of the microbial populations

involved in the removal or conversion processes. For

instance, they can range from relatively simple aerobic

tests where organic matter removal by OHOs is measured

to more complex alternating anaerobic-anoxic-aerobic

© 2016 Carlos M. Lopez-Vazquez et al. Experimental Methods In Wastewater Treatment. Edited by M.C.M. van Loosdrecht, P.H. Nielsen. C.M. Lopez-Vazquez and D. Brdjanovic. ISBN:

9781780404745 (Hardback), ISBN: 9781780404752 (eBook). Published by IWA Publishing, London, UK.

8

batch tests

presence of

nitrite and

performing

(EBPR).

EXPERIMENTAL METHODS IN WASTEWATER TREATMENT

to assess the activity of PAOs under the

different electron acceptors (such as nitrate,

oxygen) from activated sludge systems

enhanced biological phosphorus removal

This chapter presents an overview of the most

common batch activity tests and protocols and their

execution with the aim of assessing the conversion

processes involved in: (i) enhanced biological

phosphorus removal by PAOs under alternating

anaerobic-aerobic conditions, (ii) denitrification via

nitrate or nitrite by PAOs, (iii) reduction of sulphate by

SRBs, (iv) removal of organics under aerobic conditions

by OHOs, (v) denitrification by dOHOs using nitrate or

nitrite as final electron acceptor, (vi) oxidation of

ammonia and nitrite by AOOs and NOOs under aerobic

conditions and (vii) nitrogen removal by anammox

bacteria. These experimental protocols aim to serve as a

useful guide that establishes a basis for standardizing

batch activity tests for use on existing, emerging and

innovative treatment processes. It was decided to start the

order of presentation with EBPR systems involving

PAOs as the processes are complex and include all three

biochemical activated sludge environments: anaerobic,

anoxic and aerobic.

Figure 2.1.1 Experimental facilities for activated sludge activity tests at UNESCO-IHE Institute for Water Education in the Netherlands (photo: UNESCO-IHE).

ACTIVATED SLUDGE ACTIVITY TESTS

9

20i306, 2007; Nielsen et al., 2010). In particular, efforts

have focused on developing a better understanding of the

actual EBPR metabolic mechanisms, to unravel the

microbial identity of the organisms involved, and to

optimize the required process configurations, all with the

aim of improving and increasing the EBPR process

efficiency and reliability.

2.2 ENHANCED BIOLOGICAL

PHOSPHORUS REMOVAL

2.2.1 Process description

Enhanced biological phosphorus removal (EBPR) can be

implemented in activated sludge wastewater treatment

systems by introducing an anaerobic stage at the start of

the wastewater treatment lines. High P-removal

efficiency, lower operational costs, lower sludge

production and the potential recovery of phosphorus have

contributed to its application and popularity (Mino et al.,

1998; Henze et al., 2008; Oehmen et al., 2007). EBPR is

performed by phosphorus (polyphosphate)-accumulating

organisms (PAOs) (Comeau et al., 1987; Mino et al.,

1998) that, by intracellular accumulation of

polyphosphate (poly-P), can remove higher quantities of

phosphorus (0.35-0.38 g P g VSS-1 of PAOs) than OHOs

(0.03 g P g VSS-1 of OHOs) (Wentzel et al., 2008). The

scientific,

microbiological

and

engineering

characteristics of the EBPR process have been the main

focus of research carried out during the last few decades

by different research groups (Wentzel et al., 1986, 1987;

Comeau et al., 1986, 1987; Smolders et al., 1994a,b;

Mino et al., 1987, 1998; Oehmen et al., 2005a, 2005c,

Anaerobic

PAOs are heterotrophic organisms. However, unlike

OHOs, PAOs have the unique capability of using

intracellularly stored poly-P to produce the required

energy (adenosine tri-phosphate, ATP) under anaerobic

conditions to store readily biodegradable organic matter

(RBCOD), such as volatile fatty acids (VFA) like acetate

(Ac) and propionate (Pr), as intracellular poly-βhydroxy-alkanoates (PHAs). Stored PHAs are later

utilized under anoxic or aerobic conditions for enhanced

phosphorus uptake, glycogen synthesis, biomass growth

and maintenance. This feature gives PAOs a competitive

advantage over other microbial populations of relevance.

Thus, PAOs can be enriched to achieve EBPR by

recycling activated sludge through alternating the

anaerobic and anoxic or aerobic stages, while directing

the influent which is usually rich in VFA to the anaerobic

stage. A schematic representation of the PAOs’

metabolism is shown in Figure 2.2.1.

Aerobic (Anoxic)

Settling

CO2

PO4

VFA

Influent

Gly

(PO4, VFA)

PP

PHA

Effluent

PO4

Gly

PHA

PP

O2 (NOx)

RAS

WAS

Liquid phase

Anaerobic

Aerobic

Settling

PO4

PO4

VFA

PO4

PAO biomass

PP

PHA

PP

GLY

GLY

PHA

PHA

PP

GLY

Figure 2.2.1 Conceptual scheme of an activated sludge wastewater treatment plant performing EBPR, illustrating the activity of PAOs (Lopez-Vazquez, 2009;

adapted from Meijer, 2004).

10

EXPERIMENTAL METHODS IN WASTEWATER TREATMENT

Mino et al., 1998). Thus, the anaerobic uptake of VFA by

PAOs results in the storage of PHAs and simultaneous

hydrolysis of poly-P and glycogen. The most common

PHA polymers stored by PAOs are poly-βhydroxybutyrate (PHB), poly- -hydroxyvalerate (PHV)

and poly-β-hydroxy-2-methylvalerate (PH2MV). Their

presence and amount depends on the VFA composition

(Ac or Pr). When Ac is the most abundant VFA in the

media, PAOs store mostly PHB (up to 90 % of the stored

PHAs) (Smolders et al., 1994a), but when Pr is the

dominant VFA, then PHAs exist mostly as PHV and

PH2MV (Oehmen et al., 2007).

In the anaerobic stage, PAOs store intracellularly the

readily biodegradable organics present in the raw influent

or settled sewage (mostly VFA) as PHAs using two other

intracellularly stored polymers that take part in the

aforementioned metabolism: poly-P and glycogen (a

polymer of glucose). Poly-P is hydrolysed and utilized by

PAOs to provide the required energy (as ATP) for the

transport and storage of VFA as PHAs (Wentzel et al.,

1986), while glycogen is used to supply the required

reducing power for the conversion of VFA into PHAs as

well as to provide the additional required energy (as

ATP) (Comeau et al., 1986, 1987; Smolders et al., 1994a;

Anaerobic

Aerobic

Settling

CO2

Effluent

VFA

Influent

Gly

Gly

(VFA)

PHA

PHA

O2

RAS

WAS

GAO biomass

Liquid phase

Anaerobic

Aerobic

Settling

VFA

PO4

PHA

PO4

PO4

GLY

GLY

PHA

PHA

GLY

Figure 2.2.2 Conceptual scheme of the microbial activity of GAOs (adapted from Lopez-Vazquez, 2009).

In addition to VFA uptake, the anaerobic hydrolysis

of poly-P and glycogen also provides the energy required

by PAOs to cover their anaerobic maintenance

requirements without carbon uptake. Consequently, the

hydrolysis of poly-P leads to the release of

orthophosphate (PO4) into the bulk liquid, which is

reflected in an increase in orthophosphate concentration

in the liquid phase during the anaerobic stage (Figure

2.2.1). In addition to the uptake of VFA present in the

influent of the activated sludge system, PAOs can also

store VFA generated by fermentative organisms in the

anaerobic stage from fermentable organics present in the

influent. Once PAOs reach the aerobic stage, they utilize

the PHAs stored in the anaerobic phase as a carbon and

energy source using oxygen as the electron acceptor; the

energy from this reaction is used to take up and store a

higher amount of PO4 than the amount previously

released in the anaerobic stage (Figure 2.2.1). This results

in the aerobic uptake and removal of phosphorus from the

liquid phase. In the aerobic stage, PHAs are also used to:

(i) replenish the intracellular glycogen pool, (ii) support

biomass growth, and (iii) cover the aerobic maintenance

energy needs of PAOs (Smolders et al., 1994b). Net Premoval from wastewater is achieved through the

ACTIVATED SLUDGE ACTIVITY TESTS

wastage of activated sludge (WAS) at the end of the

aerobic phase, when the sludge contains a high poly-P

content (Figure 2.2.1). Alternatively, denitrifying

phosphorus-accumulating organisms (DPAOs) exist

which can also take up PO4 under anoxic conditions using

nitrate or nitrite as electron acceptors (Vlekke et al.,

1988; Kuba et al., 1993; Hu et al., 2002; Kerr-Jespersen

et al., 1993; Guisasola et al., 2009). Also, PAOs, being

heterotrophic organisms, are able to take up carbon

sources

under

aerobic

conditions,

releasing

orthophosphate while the carbon source is available and

removing PO4 afterwards (Guisasola et al., 2004; Ahn et

al., 2007). However, eventually PAO can lose the

competition against OHOs due to their metabolic

adaptation to permanent aerobic conditions (Pijuan et al.,

2006). For a deeper understanding of the metabolism and

factors affecting the EBPR process, the reader is referred

to materials published elsewhere (Comeau et al., 1986;

Mino et al., 1998; Oehmen et al., 2007).

The proliferation of glycogen-accumulating

organisms (GAOs) has been observed in EBPR systems

under certain conditions (e.g. when acetate or propionate

are present as the sole carbon source, when temperatures

exceed 20 °C, at pHs below 7.0, and/or at dissolved

oxygen (DO) concentrations higher than 2 mg L-1)

(Oehmen et al., 2007; Lopez-Vazquez et al., 2009a,b;

Carvalheira et al., 2014). GAOs have an apparently

similar metabolism to that of PAOs, but they rely solely

on their intracellularly-stored glycogen pools as the

source of energy and reducing equivalents that drive the

anaerobic storage of VFA as PHAs without any

contribution from poly-P (Figure 2.2.2). Their presence

is often associated with suboptimal EBPR performance

because they do not contribute to phosphorus removal,

but compete with PAOs for substrate under anaerobic

conditions leading to the deterioration of EBPR systems

(Saunders et al., 2003; Thomas et al., 2003). Therefore,

GAOs are assumed to be an undesirable population in

EBPR systems.

11

produce DO concentrations higher than 2 mg L-1 under

aerobic conditions, (iii) provide complete mixing

conditions, (iv) allow temperature control; (v) allow pH

control, and (vi) have ports for sample collection and the

addition of influent, solutions, gases and any other liquid

media or substrate used in the test (Figures 2.2.4 and

2.2.5).

Figure 2.2.3 Vintage EBPR experimental setup with the characteristic

yellowish colour of highly enriched biomass with PAOs used at Delft

University of Technology in the early 1990s for the development of the

TUDelft bio-P metabolic model (Smolders et al., 1994a, 1994b; Murnleitner

et al., 1997) and pioneering research on the impact of temperature on EBPR

(Brdjanovic et al., 1998a) (photo: Brdjanovic, 1994).

2.2.2 Experimental setup

2.2.2.1 Reactors

To assess the EBPR process performance, batch activity

tests can be carried out under anaerobic, aerobic and

anoxic conditions depending upon the parameters of

interest and nature of the study. In any case, the

bioreactor(s) used for the execution of tests must: (i)

avoid oxygen intrusion under anaerobic and anoxic

conditions, (ii) provide enough aeration capacity to

Figure 2.2.4 Temporary experimental setup used to carry out batch tests

with activated sludge at the WWTP Haarlem Waarderpolder in the

Netherlands. This was the first study (Brdjanovic et al., 2000) in which a

separate validation of the TUDelft bio-P metabolic model was carried out

using various batch tests with mixed culture biomass from a full-scale plant

(photo: Brdjanovic, 1997).

12

Anaerobic conditions

The experimental setup used for EBPR batch activity

tests must be able to create and maintain strict anaerobic

conditions. This means that no electron acceptors

(namely oxygen, nitrate or nitrite) should be available to

the biomass during the anaerobic phase.

A redox probe can be used to monitor the creation of

anaerobic conditions when the redox values are lower

than -300 mV. The lab setup should be airtight and

equipped with an off-gas exit connected to the lid of the

bioreactor. Usually, there are three undesirable sources

of oxygen: (i) the oxygen dissolved in the influent, (ii)

the residual oxygen present in the activated sludge itself,

and (iii) oxygen intrusion from the head space. To

remove the first two listed sources, N2 gas should be

sparged under mixing conditions from the bottom of the

bioreactor for 5 to 10 min prior to the beginning of the

test and during influent addition. Sparging time will

depend on the mass transfer properties of the gas-liquid

interface, which depends on a number of factors

including: the dimensions of the bioreactor, the presence

and location of baffles, dimensions and stirring speed of

mixing blades, gas diffuser configuration and flow rate,

and medium composition. To avoid oxygen intrusion, the

headspace can be flushed either by the N2 gas already