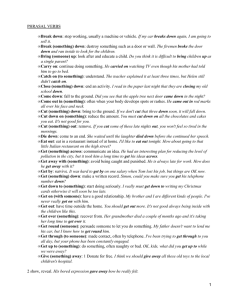

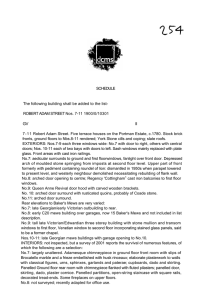

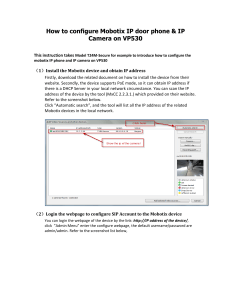

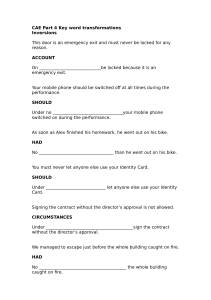

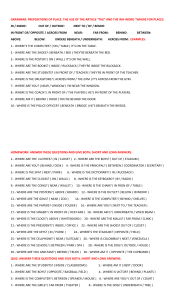

i-COMM™ ii / i-COMM™ CONTROLLER INSTRUCTIONS Pub. No. i-COMM_A FEBRUARY 2016 1 i-COMM™ CONTROLLER i-COMM ii DIGITAL CONTROLLER SPECIFICATIONS ! DANGER When working with electrical or electronic controls, make sure that the power source has been locked out and tagged according to OSHA regulations and approved local electrical codes. ! WA R N I N G Make sure to barricade the door opening on both sides to prevent unauthorized use until the door has been completely installed. NOTICE DO NOT configure devices such as Motion Sensors, Photoeyes or Floor Loops to Toggle Mode. Setting these devices to Toggle may cause the door to close unexpectedly. NOTICE The power MUST be OFF and the door on the close limit switch when plugging in the Downloader Chip. NOTICE When connecting i-COMM to other control systems, isolation relays (Dry Contacts) should be used. NOTICE TO USER Our mission is to “Improve Industrial Safety, Security and Productivity Worldwide Through Quality and Innovation.” 1. If any procedures for the installation or operation have been left out or are not complete, contact RITE-HITE DOORS, INC. Technical Support at 1-563-589-2722. 2. The use of a handheld device is no longer required, an SD card can be used to down load programs. 3. This i-COMM II controller is used on the following door models: FasTrax, FasTraxFR, FasTrax FR LD, FasTraxCL, Fastrax XL, FasTrax LD, LiteSpeed, SplitSecond, Defender, Barrier Glider. 4. Terminals will accept wire sizes from 12 - 22 AWG. 5. 8 Digital Inputs. (24VDC; 10 mA) 6. 3 Relay Outputs. (24VAC/DC; 1 AMP) 7. 6 DC Outputs. (24VDC; 0.5 AMP MAX) REMOVAL AND INSTALLATION 1. Change controller with door in the close position. 2. Make sure you have all the parts before beginning. 3. Unplug the J4 supply harness. 4. Remove wires from the input and output terminals. 5. Remove the board by squeezing the white plastic supports, and remove supports from bracket. 6. Install new board, by snapping onto supports. 7. Plug in the J4 connector. 8. Insert wires into terminals, based on markings, labels on the wires as well as the electrical wiring diagram included with the door. 2 ! DANGER A qualified electrician should install the wiring in accordance with local and national electrical codes. Use lockout and tagout procedures to avoid injury. NOTICE Do not drill holes on top of control box to run conduit, as dust particles and moisture may cause damage to electrical components. The safest location is at the bottom. Failure to do so will void warranty. NOTICE Damage or debris may fall into electrical components causing failure or severe equipment damage, when drilling holes in the box. DO NOT turn control box upside down or go too deeply into the box. FCC COMPLIANCE NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. NOTE: Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesirable operation. LOCKOUT/TAGOUT PROCEDURES The Occupational Safety and Health Administration requires that, in addition to posting safety warnings and barricading the work area, the power supply has been locked in the OFF position or disconnected. It is mandatory that an approved lockout device is utilized. An example of a lockout device is illustrated. The proper lockout procedure requires that the person responsible for the repairs is the only person who has the ability to remove the lockout device. In addition to the lockout device, it is also a requirement to tag the power control in a manner that will clearly note that repairs are under way and state who is responsible for the lockout condition. Tagout devices have to be constructed and printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or become unreadable. RITE-HITE Corporation does not recommend any particular lockout device, but recommends the utilization of an OSHA approved device (refer to OSHA regulation 1910.147). RITEHITE Corporation also recommends the review and implementation of an entire safety program for the Control of Hazardous Energy (Lockout/Tagout). These regulations are available through OSHA publication 3120. Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM CONTROLLER (=> 6/20/12) THE FOLLOWING PAGES ARE FOR i-COMM ii: ALL 7100, FASTRAX, FASTRAXCL, FASTRAXFR, FASTRAX LD, FASTRAX FRLD, FASTRAX XL, LITESPEED, SPLITSECOND AFTER 6/20/12. Pub. No. i-COMM_A FEBRUARY 2016 3 4 I H G F E D C B A N O M P L N O P Q R A B C D E F G H I J K L M J K Q R Component key: Power LED Contrast Button Up Button Enter Button Back Button Down Button LED Input’s X0 - X15 Encoder Terminals Input Terminals DC Terminals OV Terminals J4 Connector Output LED’s K0-K2 & Y0-Y5 Display Battery (CR2032 3V) SD Card Solid State Outputs Relay Outputs i-COMM™ CONTROLLER i-COMM ii LAYOUT Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER RITE-HITE DOORS NOTES PAGE This page intentional left blank. Pub. No. i-COMM_A FEBRUARY 2016 5 i-COMM™ CONTROLLER i-COMM ii SETUP INSTRUCTIONS MUST complete before operating door. Operation of the door is not possible when using the menu system. To adjust CLOSE position: 3. Using up button, scroll to “Close Pos. Adjust”. 4. Press enter button to view parameter value. This parameter will show a coded value on the left and relative change in inches on the right. When entering this parameter the value will always start at 0.0”. ENCODER SETUP INSTRUCTIONS 1. Verify wiring to encoder is properly terminated. 2. Place curtain in the closed (or open) position. If open, curtain should be 1’-2’ below the lintel. 3. Power up the door and press enter button on the icomm, should state “MAIN MENU - ENCODER FOLDER”. 4. Press enter should state “Open Distance”. 5. Press enter to view parameter value (measured in feet), should be O.D.H. - (two) 2’. Change the value using the up or down buttons, round down if required, press enter. 6. Press up button, should state “Motor Drive Side”, press enter and select “Right Drive” or “Left Drive”, press enter. 7. Press up button, should state “Set Close Pos.” (use if curtain is closed) or go to “Set Open Pos.” (use if curtain is open) and press enter button, should state “Set Close (or Open) Pos.) and toggle between RESET ALL LIMITS and Push Up to Start”, press Up button. 8. Press the green flashing Open/Reset button on the front of the control box. Door should run open, time out and close. Proceed to “Open and Close Position Adjustment”. Change values using the up or down buttons. To bring the curtain closer to the floor, adjust this value so that it is less than zero. (i.e. To close the door 4” more, the value for “Close Pos. Adjust” will be -4.0”) Moving this parameter in the positive direction raises the curtain relative to the floor. Changing this value will not affect the open position. Note: If you leave this parameter and return to it, its value will again be zero. Any changes made before leaving the parameter will still be effective. For example: If you lowered the door 4.0”, leave the parameter and return, the parameter will display 0.0”. Even though the display shows 0.0” the -4.0” change has been recorded. TIP: At any point in the menu mode, press the back button until screen states “Door Faulted - Service Required”. This will cause the controller to automatically accept all the changes made and exit the system. 5. Changes are not saved until the menu mode is exited. Turning power off while in the menu mode will cancel all changes. Open and Close Position Adjustment 6. Test operation of door and continue adjustment. To adjust the OPEN position: 7. Press green Open/Reset button. 1. Using up button, scroll to “Open Pos. Adjust”. 2. Press enter button to view parameter value. This parameter will show a coded value on the left and the opening height in inches on the right. This value will always be less than the door opening height. a. The door should begin to open, be ready to shutdown the door if it begins to move in the wrong direction. If motor phase is changed, start over at step #2. b. If rotation is correct proceed to the instructions for adjusting the “Open and Close positions”. Change the value using the up and down buttons. To bring the open position down (closer to the floor) adjust this value to be less than the current value. To open the door more relative to the floor, adjust this parameter in a positive direction. (i.e. To open the door 4” more, and the current value is 72.0”. Change the value for “Open Pos. Adjust” to be 76.0”). Changing this value will not affect the close position. 6 8. Press the back (left button) to exit system. Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM ii SETUP INSTRUCTIONS OPTION Open Distance Motor Drive Side Set Close Pos Set Open Pos Open Pos Adjust Close Pos Adjust Apr Open Pos Encoder Startup Encoder Read Encoder Velocity Open Time Limit Photoeye Blocked Photoeye Failure DESCRIPTION Use this option to set the overall opening distance of the door (in feet). For example, for an 8’ tall FasTrax. This option should be set to “7” [178]. This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option to select which side the motor is located: “Right Drive” or “Left Drive” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position.NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. For example if this option was set to 100” [2540] the door would open 100” [2540] from the closed position. It is recommended to adjust the closed position of the door first, before adjusting the open position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. For example, if this option was set to -1.0”[-25] the door would close approximately 1.0” [25] more. If this option was set to 2.0” [51] the door would close 2.0” [51] less. Use this option to adjust the approach open position. This option is a measurement in inches from the open position. For example, if this option was set to 24.0” [610] the door would slow down 24.0” [610] from the open position. The controller is waiting for valid data from the encoder. It the controller does not receive a response at startup, this will remain on the screen indefinitely. If this does not clear with 5 seconds, please check all encoder wiring. The controller is unable to read valid data from the encoder. Check all wiring and M12 cable connections. Ensure that the shield on the encoder cable is connected to ground, and that the control box is grounded. The error requires the power to be cycled to reset. The controller has received a signal from the encoder that the door is moving faster than allowed. This can occur if the encoder is not properly attached to the shaft (check set screws on encoder collar and sprockets), bad electrical connection to the i-COMM, or improper grounding. The error requires the power to be cycled to reset. Door tried to run, but did not reach the open or close position within 8 seconds. Non-Drive PE’s must have green light on, drive PE’s must have orange & yellow lights on. Check for alignment & power to each. To perform photoeye test, output YDC2 must go off on every cycle open. If it does not the output may have failed. Move the wire in the YDC2 output terminal to YDC1 or YDC0 and change the value of this output to 17 - Off during run open i-COMM TROUBLESHOOTING ISSUE Dim Display No Power Garbled Text at the Door Travels Past Stop Point RESOLUTION Adjust contrast dial. Verify Power Supply LED is Green, if not unplug J4 connector on i-COMM. If LED remains Red, check DC voltage on V+ & V-, should be 24-26 VDC. If LED turns Green, unhook wires from iCOMM to find which wire is shorting the board. If CUI or LED Count down display or Preannounce is present unplug the J46 and/or J48 connector, if text clears up check CUI or LED wiring. text maybe garbled due to trying to display two faults same time. If your door travels past the open or close position when setting up the encoder, try “setting the opposite position”. This is especially helpful on the SplitSecond model. Pub. No. i-COMM_A FEBRUARY 2016 7 i-COMM™ CONTROLLER i-COMM ii PROGRAMMING FOLDERS Use the Enter, Up, Down, Back buttons on the i-Comm to navigate through the folders. To exit system, use back button until “Door Faulted” appears. ENCODER FOLDER See Folder Layout Chart to change / view settings. * MUST perform encoder setup for door operation. GENERAL FOLDER See General Layout Chart to change / view settings. Use to setup Clock, Maintenance cycles VIEW FOLDER See View Layout Chart to change / view settings. Use to view cycle count, fault history, door information. I/O SETUP FOLDER See I/O Setup Layout Chart to change / view settings. Use to setup Input and Output functions TIMER FOLDER See Timer Layout Chart to change / view settings. Use to change reclose or preannounce timer. LOAD / SAVE FOLDER See Load / Save Layout Chart to change / view settings. See Legal information. Use for programming. INVERTER FOLDER See Inverter Layout Chart to change / view settings. Use to change door speeds, torque settings. i-COMM ii PROCEDURES PROCEDURE FOR ADJUSTING RECLOSE TIMER: 1. Press ENTER button. 2. Use UP button to scroll to TIMER FOLDER, press enter, should display “Set Close Timer”. 3. Press ENTER button. 4. To increase reclose time, press UP button. 5. To decrease reclose time, press DOWN button. 6. Press BACK button when complete. PROCEDURE FOR DOWNLOADING A PROGRAM: PROCEDURE FOR CHECKING FAULT HISTORY: 1. Press ENTER button. 2. Use UP button to scroll to VIEW FOLDER, press enter, should display “Fault History”. 3. Press ENTER button, should display the last fault / flash the date / time it occurred. 4. This displays the last 20 faults. 5. Press BACK when complete. 1. Turn off power to the door and insert SD card into socket. 2. Turn on power and press ENTER button. 3. Use UP button to scroll to “LOAD / SAVE Folder”, press enter, scroll to “Copy from SD” and press ENTER button. 4. Press the UP button when prompted. 5. If “Choose file....” displays, choose the correct file and press ENTER to start update. 6. After the i-COMM reboots, remove SD card and operate door. PROCEDURE FOR SETTING CLOCK: 1. Press ENTER button. 2. Use UP button to scroll to GENERAL FOLDER, press enter, should display “Clock”. 3. Press ENTER button, should display M/D/Y and time. 4. Press UP, set year - press enter, set month - press enter, set day - press enter, set hour - press enter, set minute press enter. 5. Press BACK when complete. PROCEDURE FOR SETTING MAINTENANCE: 1. Press ENTER button. 2. Use UP button to scroll to GENERAL FOLDER, press enter, press UP to scroll to “Maint. Months” or Cycles”. 3. Press ENTER button, should display number of months or number of cycles. 4. Press BACK when complete. Note: When setting Maintenance timer, Open / Reset button will flash slow when set time / cycles have expired and display Maintenance Required. To reset Maintenance light, press ENTER button, scroll to General Folder, press ENTER button, scroll to Reset Maintenance, press ENTER, then UP to start, then green Open Button. This will reset flashing Open / Reset button. 8 Pub. No. i-COMM_A FEBRUARY 2016 Watchdog Timer Normal Power Up Breakaway Open Time Limit Menu Interrupt Limit Failure Emergency Stop Close Time Limit Limit Pulse Time Obstruction System Clk Read Unknown State PRO System Photoeye Failure Encoder Read Encoder Velocity Encoder Connection VFD Trip # xxx VFD Comm. Loss Program Inverter Check Rev. Edge Refeed Curtain Encoder-No Power LZR Test Failed VFD Torque Relay Rev. Edge Count Door Locked Curtain Jam Counterweight Counterweight Low Velocity Low Velocity Curtain Jam Door Overtravel Blank 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 255 i-COMM DISPLAY FAULT ERROR DESCRIPTION 0 1 2 FAULT CODE # Pub. No. i-COMM_A FEBRUARY 2016 Inverter is not programmed for proper door operation i-COMM ii has detected a reversing edge continuity error i-COMM ii has detected a curtain refeed error i-COMM ii has detected no power to encoder error i-COMM ii has detected an LZR test error VFD Relay failed to change state i-COMM has detected reversing edge was activated (CE only) i-COMM has detected that the door CUI is locked Curtain is moving slower than expected while closing i-COMM ii has detected a counterweight closing error i-COMM ii has detected a counterweight opening error i-COMM ii has detected a low velocity close error i-COMM ii has detected a low velocity open error Curtain is moving slower than expected while opening i-COMM ii has detected a door overtravel error No Fault i-COMM ii has detected a bad encoder read i-COMM ii has detected a velocity error i-COMM ii has detected a connection error Inverter is in fault. xxx Indicates the active inverter fault i-COMM ii has lost communication with inverter System clock failed State unknown Pro inverter fault (8000, 8000XL) Indicates problem with reversing photoeye's (FSTX Series, LTSPD or SPLT) Run close time limit exceeded Trakline limit problem. Second close limit pulse not detected. Door has detected obstruction and reversed 3 times Indicates the board watchdog timer has reset Indicates loss of power Door is in breakaway mode: FasTrax - chain hoist; 8000CL/XL - sideframe door; 8000/CL/XL overload relay Run open time limit exceeded i-COMM menu interrupted Limit switch has failed E-Stop button pushed or overload relay tripped (8900) or Inverter relay failure (8600) or chain hoist switch open (FasTrax) FAULT REASON PROPOSED ACTION REQUIRED Service Required Service Required Service Required Push Open/Reset Check Connection Service Required Jog to Close Jog to Close Service Required Jog to Close Service Required Jog to Close Door Locked Service Required Service Required Service Required Service Required Service Required Service Required Service Required None Indicates inverter (VFD) is not properly programmed. Re-program inverter. Check reversing edge wires for continuity or if shorted. LiteSpeed header Slack Sensor photoeye has tripped - curtain has reversed 5 times i-COMM board has detected no power to the encoder. Check wiring connections Check wiring of LZR or perform "Teach In" per BEA User's Guide Check torque setting and check VFD relay Cycle power and reset Press and hold the Red button on CUI for 15 seconds to unlock Check for drive system obstruction or high wind load Check counterweight photoeyes and verify counterweight travels freely in the tube Check counterweight photoeyes and verify counterweight travels freely in the tube Wind or pressure on curtain has caused FSTX XL door to close slower than normal Wind or pressure on curtain has caused FSTX XL door to open slower than normal Check for drive system obstruction or high wind load FSTX XL curtain has traveled past the curtain sensing photoeyes None Rev. 2/12/2016 i-COMM board did not read encoder status. Check wiring connections. i-COMM board detected improper speed or wrong direction. Check wiring connections i-COMM board did not read connection to encoder. Check wiring connections i-COMM board displaying inverter (VFD) fault. Check manual for inverter faults i-COMM board has lost communication with inverter (VFD). Check wiring connections Service Required Door did not reach close limit within 8 seconds Service Required Check limit switch Inspect & Reset Door tried to close 3 times but sensed friction or an obstruction, reversed, stayed open and faulted Service Required Clock has elapsed, check and/or replace battery Service Required Cycle power and reset Check Inverter Check inverter for fault codes Jog to Close Reversing photoeye's did not pass test Service Required i-COMM board requires replacement Push Open/Reset Power to the door was lost, press Open/Reset button to operate door Reset/Jog Door If need be - press Open/Reset to "Jog" door. Reset breakaway mechanism. Press Open/Reset button to operate door. Service Required Door did not reach open limit within 8 seconds Push Open/Reset The i-COMM menu was accessed. Press Open/Reset button to operate door. Service Required Door did not read limit switch or two switches activated simutaneously Push Open/Reset E-Stop button was activated or is defective. Check 8900 overload relay, check chain hoist switch on FasTrax series model doors. Press Open/Reset button to operate door. ACTION REQUIRED i-COMM™ CONTROLLER i-COMM ii FAULT DISPLAY MESSAGES 9 i-COMM™ CONTROLLER i-COMM ii FOLDER LAYOUT *NUMBER IS NOT SHOWN IN i-COMM MENU* FOLDER # 0 1 2 3 4 Encoder 5 Folder 6 7 8 9 10 11 NAME Open Distance Motor Drive Side Set Close Position Set Open Position Close Position Adjust Open Position Adjust Partial Open Pos. Encoder Position Encoder Baud Approach Open Pos. Approach Close Pos. Set Open PB Function 12 Set Loop Function I/O Setup Folder Timer Folder 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 I - Zone System Output Def. YK0 Output Def. YK1 Output Def. YK2 Output Def. YDC0 Output Def. YDC1 Output Def. YDC2 Output Def. YDC3 Output Def. YDC4 Output Def. YDC5 Output Def. YDC6 Output Def. YDC7 Input Define X0 Input Define X1 Input Define X2 Input Define X3 Input Define X4 Input Define X5 Input Define X6 Input Define X7 Open Alarm Time VALID VALUES 3 - 24 Right Drive / Left Drive Press UP to Start Press UP to Start +/- 100.0 0 - 990.00 0 - Open Pos. Height 0-01FFFF 433 kbps 999.0 999.0 Auto Close Mode; Toggle & Auto Close, Reset/Jog only; Toggle Mode Auto Close Mode, Reverse / Hold Open Enabled / Disabled 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 33 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 17 (See Table) 0 - 255 34 Input Define X10 35 Input Define X11 36 I - Zone Cut - Out 0 - 30 0 - 66 0 - 48 37 Set Close Timer 0 - 255 / Toggle Mode 38 Preannounce Close 39 Preannounce Open 40 Autocycle Time 0 - 255 0 - 255 0 - 254 / Disabled DESCRIPTION Used to Set Opening distance for door Used to select motor drive side. Use for initial setup of close position Use for initial setup of open position Use to adjust close position. Use to adjust door open position Use to adjust door partial open position Current encoder position Used to select encoder data rate Used to select Approach Open Position Used to select Approach Close Position Use to select the function of the Open/Reset button. DEFAULT Varies Right 433 KBPS Varies Varies Auto Close Mode Auto Close Mode Disabled Use to Enable / Disable the I-Zone system. 0 User configurable relay 20 User configurable relay 20 User configurable relay 3 User configurable DC output 29 User configurable DC output 29 Internal - not available DC output 20 Internal - not available DC output 20 Internal - not available DC output 2 User configurable DC output 20 Internal - not available DC output 20 Internal - not available DC output 8 User configurable input 7 User configurable input 2 User configurable input 2 User configurable input 4 User configurable input 3 User configurable input 2 User configurable input 2 User configurable input 0 Open Alarm Time in minutes. Requires at least one output to be configured to function 25, menu is hidden if not. 24 Torque 60 Unused 42 I-Zone cut out height Use to select induction loop input function Close Timer in seconds. Set to Toggle Mode to disable automatic closing. Preannounce to close timer in seconds Preannounce to open timer in seconds Autocycle Time in minutes 6 2 Disabled Disabled* * No Auto Re-close on Defender model. 10 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM ii FOLDER LAYOUT *NUMBER IS NOT SHOWN IN i-COMM MENU* FOLDER General Folder View Folder Load / Save Folder # NAME 41 Clock VALID VALUES - DESCRIPTION 42 43 44 45 46 47 48 49 50 51 52 53 English, Espanol, Portuguese Enabled / Disabled Disabled, CE, Canada Opt Enabled / Disabled xx 208/220/230/400/460/575 0 - 999 Enabled/Disabled xx Displays current time and date. To set: press UP, scroll to year - press Enter; scroll to month - press Enter; scroll to day - press Enter; scroll to hour - press Enter; scroll to minute - press Enter 57 Reset to Default - Set LCD display language Use to change access mode. Use to enable reversing edge. Used to enable specification packages. Used to enable remote LCD Consult Engineering. Special Applications only Reverse Delay Consult Engineering. Special Applications only Voltage of door Square footage of door. Width x Height Enables non-powered open for LiteSpeed Number of months before maintenance indicator goes off. Note: Once changed user must initiate “Reset Maintenance” Procedure. Number of cycles before maintenance indicator goes off. Note: Once changed user must initiate “Reset Maintenance” Procedure. Resets Maintenance Counters and Timers. Press Up to initiate the reset Used to adjust the speed threshold for the counterweight sensor Resets all settings back to factory defaults 58 59 60 61 62 63 0 - 99999999 - Displays Displays Displays Displays Displays Displays 64 Copy from SD Press UP to Start Copy 65 Copy to SD Card Press UP to Start Copy 66 Legal info to SD Press UP to Start Copy 67 Bootloader Upgrade Press UP to Start Copy 68 Export Settings Press UP to Start Copy 69 Import Settings Press UP to Start Copy Use to upgrade i-COMM II program. Correct .BIN file must be saved so SD Card. Note Card must be SD - 2GB or SDHC - 4,8,16 or 32 GB. Use to copy i-COMM II program to SD Card in .BIN format. Use to display legal information about program. Legal.txt will be saved to SD card. Used to upgrade bootloader. CAUTION: DO NOT INTERRUPT THIS PROCESS Use to save i-COMM II settings to SD Card in .BIN format. Use to copy i-COMM II settings to SD Card in .BIN format. Language PassCode Rev. Edge Option Spec. Package Compact User Interface Partial Open Reverse Delay AB Inverter Delay Voltage Square Feet Non-Powered Open Maintenance Months 54 Maintenance Cycles 0 - 100000 55 Reset Maintenance - 56 Speed Threshold 0-100% 70 Display Cycle Count Fault History Display Model # Display RHC # Display Serial # Firmware Revision CT SK MODBUS, AB PF40 MODBUS, CT SK NO MODBUS, AP PF NO MODBUS, No Inverter Program Inverter Press UP to Start Copy Open Speed 0 - 70 Hz Close Speed 0 - 70 Hz Approach Speed 0 - 70 Hz Accel Time 0 - 10.0 s Accel Time 2 0 - 10.0 s Decel Time 0 - 10.0 s Torque Reverse Level 0 - 100 % DC Brake Time 0 - 10.0 s DC Brake Level 0 - 100 % current Cycle Count fault log. Use Up and Down to scroll door model number RHC number door serial number current program revisions Used to set inverter type Inverter Type Inverter Folder 71 72 73 74 75 76 77 78 79 80 Use to program inverter. Open Speed Close Speed Approach Open Speed Acceleration Rate Acceleration Rate 2 Deceleration Rate Torque Reversing Level Injection Braking Time DC Injection Braking Level DEFAULT English Disabled Disabled Disabled 0%* 460 0 Disabled 6 100000 CT SK MODBUS Varies Varies Varies Varies Varies Varies Varies Varies Varies Last Rev: 7.20.15 48 - Reverse delay should be set to 40% for 8900 TrakLine doors with counterweight. Pub. No. i-COMM_A FEBRUARY 2016 11 i-COMM™ CONTROLLER i-COMM ii INPUT / OUTPUT VALUES TYPE INPUT OUTPUT NUMBER FUNCTION 0 Interlock In 1 2 3 Stop N.C. Activation Toggle 4 5 Close Sequential Activation 6 7 8 Reverse Stop N.O. Manual Open 9 10 11 Auto / Manual Partial Open Activation Partial Open Toggle 12 Toggle w/ Auto Close 13 14 15 16 17 18 19 20 Hand / Auto Mode Disabled Reverse N.C. Clean E-Stop N.C. Seq. Activation 2 LZR in N.C. Preannounce to Open 21 Interlock Override 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Interlock Interlock N.C. Preannounce Open Open N.C. Fault Ready Activation Run Open Run Close Run At Limits I-Zone Alarm Door Open 30 sec. Door Open 60 sec. Door Open 120 sec. Sequential Activation Run Open N.C. Run Close N.C. Run Close N.C. Disabled Flash 3.1 Hz Flash 1.6 Hz Partial Timer Reverse / Activation Door Open Alarm Interlock Pass-Thru 27 28 29 30 31 32 33 34 35 36 DESCRIPTION Interlock Input - When Input is set to this function door will not open until input is ON. Valid only for inputs X3, X4, and X5. Stops the door when input is OFF Opens the door when input is ON, w/ Auto close. Open and Closes the door when ON. Door will not automatically close when opened by a toggle input. Closes the door when input is ON Activates door and blocks sequential activation output from triggering opposite door. Use only for sequential interlocks. Reverses the door when input is ON. Stops the door when input is ON. Opens the door when input is ON. This input will open from a stop condition, unlike activation. Do not connect motion sensors or other automatic devices to a manual open input When input is ON reclose timer is disabled. Opens the door to the partial open position when ON Toggle open/close door to and from partial open position. See function #3 above Open and Closes the door when ON. Door will automatically close when opened by this type of toggle input. When input is ON reclose timer is disabled and hold-to-run close is enabled. Input disabled Reverses the door when input is OFF. Opens door to "Cleaning" position when on. Places door in fault when OFF. Consult Engineering Reverses the door when off and monitors the input for fault Opens the door after the set amount of time in the Preann. to Open timer. Immediate reversal / activation if the door is not closed. Opens the door and overrides any standard interlock configuration ON when door is closed. OFF when door is closed. ON during preannounce to close, and stays on until the door is closed ON when door is open. OFF when door is open. ON during fault. ON when not in fault. ON during activation. ON during run open. ON during run close. ON during run open or close. ON when door is open or closed. ON during I-Zone alarm ON when door is open for more than 30 seconds. ON when door is open for more than 60 seconds. ON when door is open for more than 120 seconds. ON to activate opposite door. Use for sequential interlock. OFF during run open. OFF during run close. OFF during run open or close. Always OFF Flashes at 3.125 Hz. Flashes at 1.5625 Hz. Consult Engineering ON when any reverse command or activation signal is on. ON when door has been opened for time set in "Open Alrm Time" ON when door is able to be opened (Interlock Input is not preventing door from opening) Interlock Pass-Thru N.C. OFF when door is able to be opened (Interlock Input is not preventing door from opening) Preannounce & Close ON during preannounce to close, and while closing. Note this output will turn on while door is closed from Toggle or Close command or re-close timer. Photoeye Test ON when emitters are on, OFF to test photoeyes Encoder Bit 9 Consult Engineering Encoder Bit 10 Consult Engineering Encoder Bit 11 Consult Engineering Encoder Bit 12 Consult Engineering Preannounce to Open ON during the set preannounce to open time. Preannounce to Close ON only during preannounce to close. OFF during run close. Preannounce & Flash Flashes at 3.1 Hz during preannounce to close. OFF during run close. Last updated: 2.09.16 12 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - FASTRAX/LD/CL/FR/FRLD R FasTrax Encoder i-COMM II Quick Reference OUTPUT TABLE INPUT TABLE Relay Output Function Input Function X0 Open PB YK0 Interlock Out X1 Stop PB YK1 Programmable YK2 Programmable X2,X3,X6,X7 Activation Command X4 Close PB X5 Toggle Command DC Output Function X8*,X9* IZone Sensors (R & L) YDC0 X10* 18" Photoeye Input YDC1 Photoeye Test X11* 54" Photoeye Input *YDC2 Photoeye Test X12 Open/Reset PB *YDC3 X13 Induction Loop Input *YDC4 X14* Fault Input YDC5 X15* Input Power *YDC6 * Not shown in I/O menu and not programmable *YDC7 On when door Open Open/Reset PB Light I-Zone Alarm Preannounce to Close NPO Contactor Disabled Encoder Adjustment Descriptions (Refer to i-COMM and Owners Manuals for additional detail) Open Distance Set Close Position Set Open Position Close Position Adjust Open Position Adjust Motor Drive Side Use this option to set the overall opening distance of the door (in feet). This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. Use this option to change the encoder rotation direction. For a motor mounted on the right side of the drive tube, select "Right Drive". For a motor mounted on the left side of the drive tube, select "Left Drive". Timer Adjustment 1. Press [ENTER], Controller will stop and fault door. 2. Press [UP] or [DOWN] until the timer folder is displayed. 3. Press [ENTER], to enter the timer folder. 4. Using [UP] & [DOWN] keys select desired timer. 5. Press [ENTER] to view the current timer value. 6. Use [UP] or [DOWN] keys set the desired value. 7. Press [ENTER] to save the value and return to the timer folder. 8. Press [BACK] until "Door Faulted" is displayed. 9. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates Autocycle Time is the amount of time between each automatic cycle of the door (disabled by default). 53850610-1 Pub. No. i-COMM_A FEBRUARY 2016 13 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - FASTRAX XL 14 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - LITESPEED TM LiteSpeed Encoder i-COMM II Quick Reference OUTPUT TABLE INPUT TABLE Relay Output Function Input Function X0 Open PB YK0 Interlock Out X1 Stop PB YK1 Programmable YK2 Programmable X2,X3,X6,X7 Activation Command X4 Close PB X5 Toggle Command DC Output Function X8*,X9* IZone Sensors (R & L) YDC0 X10* 18" Photoeye Input YDC1 Photoeye Test X11* Header Photoeye Input *YDC2 Photoeye Test X12 Open/Reset PB *YDC3 X13 Induction Loop Input *YDC4 On when door Open Open/Reset PB Light I-Zone Alarm X14* Fault Input YDC5 X15* Input Power YDC6 Disabled *YDC7 Disabled * Not shown in I/O menu and not programmable Preannounce to Close Encoder Adjustment Descriptions (Refer to i-COMM and Owners Manuals for additional detail) Open Distance Set Close Position Set Open Position Close Position Adjust Open Position Adjust Motor Drive Side Use this option to set the overall opening distance of the door (in feet). This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. Use this option to change the encoder rotation direction. For a motor mounted on the right side of the drive tube, select "Right Drive". For a motor mounted on the left side of the drive tube, select "Left Drive". Timer Adjustment 1. Press [ENTER], Controller will stop and fault door. 2. Press [UP] or [DOWN] until the timer folder is displayed. 3. Press [ENTER], to enter the timer folder. 4. Using [UP] & [DOWN] keys select desired timer. 5. Press [ENTER] to view the current timer value. 6. Use [UP] or [DOWN] keys set the desired value. 7. Press [ENTER] to save the value and return to the timer folder. 8. Press [BACK] until "Door Faulted" is displayed. 9. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates Autocycle Time is the amount of time between each automatic cycle of the door (disabled by default). 53850677-1 Pub. No. i-COMM_A FEBRUARY 2016 15 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - SPLITSECOND TM SplitSecond Series i-COMMII Quick Reference OUTPUT TABLE INPUT TABLE Input Function X0 Open PB X1 Stop PB X2 Relay Output Torque Reverse X3,X6,X7 Function YK0 YK1 Interlock Out Programmable YK2 Programmable Activation Command X4 X5 Close PB Toggle Command Unused X8* 36" Photoeye X9* DC Output YDC0 Photoeye Test *YDC2 Photoeye Test *YDC3 X11* 54" Photoeye Input *YDC4 X12 Open/Reset PB YDC5 X13 Induction Loop Input *YDC6 X14* Fault Input On when door Open YDC1 18" Photoeye Input X10* Function *YDC7 Open/Reset PB Light I-Zone Alarm Preannounce to Close NPO Contactor Disabled X15* Input Power * Not shown in I/O menu and not programmable Encoder Adjustment Descriptions (Refer to i-COMM II and Owners Manuals for additional detail) Close Position Adjust Use this option to set the overall opening distance of the door (in feet). This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. Open Position Adjust Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. Open Distance Set Close Position Set Open Position Motor Drive Side Not used on SPLIT SECOND DOOR. Timer Adjustment 1. Press [ENTER], Controller will stop and fault door. 2. Press [UP] or [DOWN] until the timer folder is displayed. 3. Press [ENTER], to enter the timer folder. 4. Using [UP] & [DOWN] keys select desired timer. 5. Press [ENTER] to view the current timer value. 6. Use [UP] or [DOWN] keys set the desired value. 7. Press [ENTER] to save the value and return to the timer folder. 8. Press [BACK] until "Door Faulted" is displayed. 9. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates Autocycle Time is the amount of time between each automatic cycle of the door (disabled by default). 53850616-1 16 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - BARRIER GLIDER 7100 $#44+'4).+&'4 6/ KÄ%1//++.1)+%6#$.' 0#/' +0276(70%6+10 Func. X0 X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 2 2 4 3 2 2 0#/' Open Limit Switch Close Limit Switch User Input (Activation) (4) User Input (Activation) (4) User Input (Close) (4) User Input (Toggle) (4) User Input (Activation) (4) User Input (Activation) (4) Unused Unused Torque Reverse Unused Open/Reset Switch (1) Induction Loop Activation(1) Fault Input Power Indicator 176276(70%6+10 Func. YK0 YK1 YK2 YDC0 YDC1 YDC2 YDC3 YDC4 YDC5 YDC6 YDC7 0 20 20 3 20 2 User Out (Interlock) (4) User Out (Disabled) (4) User Out (Disabled) (4) User Out (Door open) (4) User Out (Disabled) (4) Unused Dedicated (Fault Ind.) Unused User Out (Preannounce) (1) Unused Dedicated (Spare) 56#6'6#$.' O ø 1 X X X X X X X X X X X X 1 1 C Ro Rc 1 ø X X X X X X X X X X X X 1 1 1 1 X X X X X X X X X X X X 1 1 1 1 X X X X X X X X X X X X 1 1 %1//'065 Off when door opened. Off when door closed. On to open door (4) On to open door (4) On to close door (4) On to toggle open or close (4) On to open door (4) On to open door (4) Unused Unused Off to reverse door. Unused On to reset from fault (1) On to open door (1) On to run door On to run door 56#6'6#$.' O C Ro Rc ø X X 1 X X X X X X X 1 X X ø X X X X ø X X ø X X ø X X X X ø X X ø X X ø X X X X X X X %1//'065 On when door closed (4) User selectable output (4) User selectable output (4) On when door open (4) User selectable output (4) Unused PB light output Unused Preannounce to close (1) Unused Spare output 6KOGT#FLWUVOGPV 1. Press [ENTER], Controller will stop and fault door. 2. Press [UP] or [DOWN] until the timer folder is displayed. 3. Press [ENTER], to enter the timer folder. 4. Using [UP] & [DOWN] keys select desired timer. 5. Press [ENTER] to view the current timer value. 6. Use [UP] or [DOWN] keys set the desired value. 7. Press [ENTER] to save the value and return to the timer folder. 8. Press [BACK] until "Door Faulted" is displayed. 9. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates Autocycle Time is the amount of time between each automatic cycle of the door (disabled by default). -'; 11RGP5VCVG %%NQUGF5VCVG 4Q4WPPKPI1RGP 4E4WPPKPI%NQUG 1(( 10 :/C[DG10QT1(( NOTES: (1) Device operation can be changed through menu. Consult i-COMM manual for additional details. (4) Default setting shown in table & comments. Consult i-COMM manual for additional details. 53850651-1 Pub. No. i-COMM_A FEBRUARY 2016 17 i-COMM™ CONTROLLER i-COMM ii LOGIC CHART - DEFENDER Input Table Input Input Function Comments XO Close Command On to close door X1 Stop Command N.C. Off to stop door X2,X3,X6,X7 Activation Command On to open door X4 Stop Command N.C. Off to stop door X5 Toggle Command On to toggle open or close X8 Not Used Not Used X9,X10,X11 Not Used Not Used X12 Open/Reset Switch X13 Induction Loop Activation On to reset fromfault. On to open door X14 Fault Input Must be on for door to run. Note(s) 1 1 2 2 Encoder Adjustment Descriptions (Refer to i-COMM and SplitSecond Manuals for additional detail) Open Distance Use this option to set the overall opening distance of the door (in feet). For example, for an 8ft tall Defender. This option should be set to “8”. This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Set Open Pos. Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Set Close Pos. Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Open Pos. Adjust Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. For example if this option was set to 100” the door would open 100 inches from the closed position. It is recommended to adjust the closed position of the door first, before adjusting the open position. Close Pos. Adjust Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. For example, if this option was set to -1.0” the door would closed approximately 1.0 inch more. If this option was set to 2.0” the door would close 2.0 inches less. NOTES: (1) Default setting shown in table & comments. Record any changes on space provided. Consult i-COMM manual for additional details. (2) Device operation can be changed through menu. Consult i-COMM manual for additional details. Ä 18 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM TO i-COMMii UPGRADE EMERSON INVERTER Pub. No. i-COMM_A FEBRUARY 2016 19 i-COMM™ CONTROLLER i-COMM TO i-COMMii UPGRADE EMERSON INVERTER 20 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM TO i-COMMii UPGRADE AB INVERTER Pub. No. i-COMM_A FEBRUARY 2016 21 i-COMM™ CONTROLLER i-COMM TO i-COMMii UPGRADE AB INVERTER 22 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM TO i-COMMii UPGRADE WIRE HARNESS Pub. No. i-COMM_A FEBRUARY 2016 23 i-COMM™ CONTROLLER i-COMM CONTROLLER (< 6/20/12) THE FOLLOWING PAGES ARE FOR i-COMM 1: ALL 7100, 8000, 8000CL, 8000XL, 8600, 8910, 8920, 8920PL FASTRAX, FASTRAXCL, FASTRAXFR, SPLITSECOND PRIOR TO 6/20/12. 24 Pub. No. i-COMM_A FEBRUARY 2016 Pub. No. i-COMM_A FEBRUARY 2016 Input Terminals Encoder Terminals Up Key Enter Key Display Contrast Potentiometer (Lighter / Darker) Green Input Terminal LED’s Down Key Battery Jumper Power LED J1 Programming Port Clock Battery LCD Display JP1 Jumper JP2 Jumper Induction Loop JP3 Jumper Output Terminals Red Output Terminal LED's i-COMM™ CONTROLLER ENCODER - i-COMM LAYOUT 25 i-COMM™ CONTROLLER i-COMM SETUP INSTRUCTIONS ENCODER SETUP INSTRUCTIONS 1. Change values using the up or down arrows. Verify wiring to encoder is properly terminated. To bring the curtain closer to the floor, adjust this value so that it is less than zero. (i.e. To close the door 4” more, the value for “Close Pos. Adjust” will be -4.0”) Moving this parameter in the positive direction raises the curtain relative to the floor. Changing this value will not affect the open position. Note: right-hand drive doors require a wire to be terminated in the ‘DC’ terminal, while left-hand drive doors do not. If motor phase is changed during this setup, please restart this procedure. 2. Move curtain to closed position. 3. Power up door and press enter button to enter “MAIN MENU”. 4. Using down arrow, scroll to “Open Distance”. 5. Press enter button to view parameter value (measured in feet), should be O.D.H. - (two) 2’. Change the value using the up or down arrow keys, round down if required, then press enter to return to “MAIN MENU”. 6. Scroll using down arrow to item “Set Close Pos.”. 7. Press enter button to view parameter. The controller will display the following message “RESET ALL LIMITS” … “Press Up to Start”. Pressing the up arrow key will reset all of the limits, and reboot the controller. NOTE: DO NOT use this menu item to make adjustment to the limits; this is only for initial setup. 8. Press green Open/Reset button. Note: If you leave this parameter and return to it, its value will again be zero. Any changes made before leaving the parameter will still be effective. For example: If you lowered the door 4.0”, leave the parameter and return, the parameter will display 0.0”. Even though the display shows 0.0” the -4.0” change has been recorded. 4. When parameter is changed press enter button for three (3) seconds to return to the “MAIN MENU”. 5. Test operation of door and continue adjustment. TIP: To adjust the OPEN position: 1. Power up door and press enter button to enter “MAIN MENU”. 2. Using up arrow key, scroll to “Open Pos. Adjust”. 3. Press enter button to view parameter value. This parameter will show a coded value on the left and the opening height in inches on the right. This value will always be less than the door opening height. a. The door should begin to open, be ready to shutdown the door if it begins to move in the wrong direction. If motor phase is changed, start over at step #2. Change the value using the up and down arrow keys. b. If rotation is correct proceed to the instructions for adjusting the “Open and Close positions”. To bring the open position down (closer to the floor) adjust this value to be less than the current value. To open the door more relative to the floor, adjust this parameter in a positive direction. (i.e. To open the door 4” more, and the current value is 72.0”. Change the value for “Open Pos. Adjust” to be 76.0”). Changing this value will not affect the close position. Open and Close Position Adjustment To adjust CLOSE position: 1. Power up door and press enter button to enter “MAIN MENU”. 2. Scroll using up arrow to the item “Close Pos. Adjust”. 3. Press enter button to view parameter value. This parameter will show a coded value on the left and relative change in inches on the right. When entering this parameter the value will always start at 0.0”. 26 At any point in the menu mode, Pressing and holding the enter button for at least 2 seconds will cause the controller to automatically accept all the changes made and exit the menu system. 4. When parameter is changed press enter button for three (3) seconds to return to the “MAIN MENU”. 5. Test operation of the door, and continue adjustment. Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM SETUP INSTRUCTIONS OPTION Open Distance Set Open Pos Set Close Pos Open Pos Adjust Close Pos Adjust Apr Open Pos Encoder Startup Encoder Read Encoder Velocity DESCRIPTION Use this option to set the overall opening distance of the door (in feet). For example, for an 8’ tall FasTrax. This option should be set to “7” [178]. This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. For example if this option was set to 100” [2540] the door would open 100 inches from the closed position. It is recommended to adjust the closed position of the door first, before adjusting the open position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. For example, if this option was set to -1.0”[-25] the door would close approximately 1.0” [25] more. If this option was set to 2.0” [51] the door would close 2.0” [51] less. Use this option to adjust the approach open position. This option is a measurement in inches from the open position. For example, if this option was set to 24.0” [610] the door would slow down 24.0” [610] from the open position. The controller is waiting for valid data from the encoder. It the controller does not receive a response at startup, this will remain on the screen indefinitely. If this does not clear with 5 seconds, please check all encoder wiring. The controller is unable to read valid data from the encoder. Check all wiring. Ensure that the shield on the encoder cable is connected to ground, and that the control box is grounded. The error requires the power to be cycled to reset. The controller has received a signal from the encoder that the door is moving faster than allowed. This can occur if the encoder is not properly attached to the shaft, bad electrical connection to the iCOMM, or improper grounding. The error requires the power to be cycled to reset. Pub. No. i-COMM_A FEBRUARY 2016 27 28 Input Terminals Up Key Power LED J1 Programming Port Down Key LCD Display Green Input Enter Key Terminal LED’s Display Contrast Potentiometer (Lighter / Darker) JP1 Jumper JP3 Jumper Output Terminals Red Output Terminal LED's JP2 Jumper Induction Loop i-COMM™ CONTROLLER NON-ENCODER i-COMM DIGITAL CONTROLLER DETAIL Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM DISPLAY MESSAGES LCD DISPLAY MESSAGES: TOP DISPLAY BOTTOM DISPLAY REASON / FAULT MESSAGES ACTION REQUIRED Door Faulted Push Open/Reset* Service Required* Service Required* Push Open/Reset* Reset / Jog Door* Reset / Jog Door* Push Open/Reset* Service Required* Push Open/Reset* Service Required* Service Required* Inspect & Reset* Service Required* Service Required* Service Required* Check Inverter* None* None* Jog To Close* Normal Power Up Watchdog Timer Reset From Sleep Low Voltage Breakaway Breakaway Emergency Stop Open Time Limit Menu Interrupt Limit Pulse Fail Limit Failure Obstruction Unknown System Clock read Unknown State Pro System Jog to Open Pos Jog to Close Pos Photoeye Failure Indicates Loss of Power Indicates the boards watchdog timer has reset Indicates the controller was awaken from sleep mode Drop in voltage caused controller to restart Door is in breakaway mode FasTrax - Chainfall; 8000/CL/XL - Sideframe door; 8000/CL/XL Overload Relay E-Stop pushed, Overload Relay (8900), Inverter (8600) Run open time limit exceeded Menu Interrupted Trakline limit problem (8910/20/PL only) Limit switch has failed Door has detected obstruction and reversed 3 times Unknown fault System clock failed State unknown Pro Inverter Fault Displays when jogging open Displays when jogging close Indicates problem with photoeye system (FasTrax only) * Displays on Screen during jog only DOOR IS OPENING Door is Opening Door is Open Stand Clear Closing in xx.xs Activation On Waiting for cmd. Photoeye Blocked I-Zone Detection Stand Clear DOOR IS OPEN When not in preannounce to close When in preannounce to close Displays closing time in seconds Indicates activation on (overrides timer display) Indicates door is waiting for manual close cmd. Photoeye is blocked (overrides timer display) I-Zone active (overrides timer display) DOOR IS CLOSING Door Closing Door Closed Door Closed Cycles: xxxxxx Interlock Active Door Stopped Push Open/Close None DOOR IS CLOSED Displays cycle count Door is interlocked and cannot be opened DOOR IS STOPPED DC Controller Input BASIC INPUT WIRING Relay Coil DC OUTPUT WIRING Pub. No. i-COMM_A FEBRUARY 2016 None Perform Interlocking Open/Close Door X_ (+24VDC) DC None None None Device Holding Open Close Door Remove Obstruction Remove Detection YDC_ Try this if YDC0, YDC1 or YDC2 outputs have failed: 1. Move the YDC2 wire to terminal K3. 2. Place a jumper from K3N to 0V. 3. Change value of output YK3 to function needed. Try this if K0 open output relay has failed: 1. Move the wire from open command to terminal K3. 2. Place a jumper from K3N to AC. 3. Change value of output YK3 to 8 - on during run open. Try this if K1 close output relay has failed: 1. Move the wire from close command to terminal K3. 2. Place a jumper from K3N to AC. 3. Change value of output YK3 to 9 - on during run close. 29 i-COMM™ CONTROLLER i-COMM MENU Operation of the door is not possible when using the menu system. 1. To enter the menu press the ENTER key, the Controller will stop and fault the door. 2. Use the arrow keys (Up and Down) to navigate through the choices 3. When the desired item is selected press enter to view the value or setting. 4. Use the arrow keys to change the value if needed. Once editing is completed press ENTER to return to the main menu. 5. When settings are completed, scroll to the "Exit" option in the main menu and press ENTER. 6. Changes are not saved until the menu mode is exited. Turning power off while in the menu mode will cancel all changes. Display Cycle Count Read-Only Displays current cycle count for the door. [All models] Set Close Timer Read/Write Displays and sets current close timer. This time plus the Preannounce Timer will be the amount of time the door will stay open. Setting the Close Timer to 0 will place the door in toggle mode. In toggle mode the reclose timer will be disabled. (Valid Range: 1-255 seconds, with 0=Toggle Mode) [All models] Set Preannounce Read/Write Displays and sets Preannounce to close timer. This time plus the Close Timer will be the amount of time the door will stay open. (Valid Range: 0-255 seconds) [All models] Encoder Position* Read-Only Displays position of encoder. [FasTrax/FR/CL, SplitSecond] Open Pos Adjust* Read/Write Use to change the open position for encoder. [FasTrax/FR/CL, SplitSecond] Close Pos Adjust* Read/Write Use to change the close position for encoder. [FasTrax/FR/CL, SplitSecond] Display Model # Read-Only Displays door model. [All models] Set Loop Func. Read-Write Valid Choices are: Auto Close Mode - Loop board will open and reverse door. (Note: Door will not close in Toggle Mode is enabled (Close Timer = 0)) Rev./Hold Open - Loop board will only reverse door. Loop will not open door from fully closed position. [All models] Set Open PB Func Read-Write Valid Choices are: Auto Close Mode" - Push button will open and reverse door. (Note: Door will not close is Toggle Mode is enabled (Close Timer = 0)) Toggle Mode - Places the Open/Reset button in Toggle. Push the Open/Reset once to open the door and again to close. Note reclose is disabled when door has been opened via Toggle. Reset/Jog Only - Open/Reset button will only reset and jog the door. If pressed while door is traveling close, door will reverse to open. (If Reset Only is required without opening door please consult applications or Rite-Hite Door Technical Support) [All models] I-Zone System Read-Write Use to Enable/Disable I-Zone System. [Valid for FasTrax, Trakline and Protecdor series doors] Output Definition Read-Write Use to change functions of outputs where allowed. (YK2 Relay K2), YK3 (Relay K3), YDC0, (see chart) (Note: Outputs which are not changeable will display "Not Adjustable") YDC1, YDC2, YDC3 Input Define Read-Write Use to change functions of inputs where allowed. X2, X3, X5, X6, X7 (Note: Inputs which are not changeable will display "Not Adjustable") Language Read-Write Use to change language of the menus. Select Additional Languages (i.e., Portuguese, Spanish) [All models] Fault History Read-Only Displays Last five faults as codes. Use arrows to provide a detailed description of each fault code displayed. See details instructions on Page 7. Partial Config Read-Write Consult Technical Support (=/> Version 2.2.5) Reverse Delay Read-Write Consult Technical Support - FasTrax only (=/> Version 2.2.5) (0) AB Inverter Delay Read-Write Consult Technical Support - FasTrax only (=/> Version 2.2.5) (075) use if does not fully close Set Open Pos Read/Write Use to set the open position for encoder, initial setup only. [FasTrax/FR/CL, SplitSecond] Set Close Pos Read/Write Use to set the close position for encoder, initial setup only. [FasTrax/FR/CL, SplitSecond] Open Distance Read/Write Use to set the door opening distance for encoder, initial setup only. [FasTrax/FR/CL, SplitSecond] Open Alrm Time RW - #25 Use to set time alarm on when door open [All models] Clock Read/Write Displays date and time. [FasTrax/FR/CL, SplitSecond] Passcode* Read/Write Consult Customer Service [All models} CE Option Read/Write Use to shut-off light curtain. [European - FasTrax only] X10 PE Cut-Out* Read/Write Use to shut-off lower PE when door closing. [FasTrax/CL/FR only] X11 PE Cut-Out* Read/Write Use to shut-off upper PE when door closing. [FasTrax/CL/FR only] I-Zone Cut-Out Read/Write Use to shut-off I-Zone when door closing. [FasTrax/CL/FR only] Copy from Loader Write-Only Copies program from loader to i-COMM. Use up arrow to start copy process. See details instructions on Page 7. Copy to Loader Read-Only Copies program in i-COMM to loader. Use up arrow to start copy process. See details instructions on Page 7. Exit [Enter] Read-Only Use to exit menu system and save changes. [All models] * - Not on doors prior to 8/13/2010 30 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER i-COMM PROCEDURE INSTRUCTIONS PROCEDURE FOR USING DOWNLOADER CHIP: PROCEDURE FOR CHANGING OPEN BUTTON OPERATION: 1. Turn power off. 1. Press ENTER key. 2. Plug in downloader chip. 2. Use UP / DOWN keys to scroll to “Set Open PB Func”. 3. Turn power on. 3. Press ENTER key. 4. Press ENTER. 4. Choose between “Auto Close Mode”, “Toggle Mode” or Reset/Jog Only”. 5. Scroll to “Copy From Loader”. 5. Press ENTER when complete. 6. Press ENTER and UP key to start copy process. 6. Scroll to EXIT. 7. When complete, turn power off and remove loader. 7. Press ENTER, operate door. 8. Restore power and operate door. The following describes what the fault codes convert to: PROCEDURE FOR ADJUSTING RECLOSE TIMER: Description 1. Press ENTER key. 2. Use UP key to scroll to “Set Close Timer”. 3. Press ENTER key. 4. To increase reclose time, press UP key. 5. To decrease reclose time, press DOWN key. 6. Press ENTER when complete. 7. Scroll to EXIT. 8. Press ENTER to save changes. PROCEDURE FOR CHECKING FAULT HISTORY: Code #define FaultNone 0 #define FaultPowerUp 1 #define FaultBreakaway 2 #define FaultRunOpenTimer 3 #define FaultMenuInt 4 #define FaultLimitSwitch 5 #define FaultEstop 6 #define FaultRunCloseTimer 7 #define FaultLimitPulseFail 8 1. Press ENTER key. #define FaultObstruction 9 2. Use UP / DOWN keys to scroll to “Fault History”. #define FaultTimerRead 0A 3. Press ENTER key. #define FaultStateOB 0B 4. This displays the last 5 faults in numerical code. #define FaultPROSystem 0C 5. For a detailed view, press the UP key to scroll through the fault codes. #define FaultPhotoeye 0D 6. Press ENTER when complete. 7. Scroll to EXIT. 8. Press ENTER, operate door. #define FaultEncoderRead 0E #define FaultEncoderVelocity 0F #define FaultEncoderNC 10 CONNECTOR CONNECTOR TABLE J3 J4 J5 PIN # 1 2 3 4 1 2 3 4 5 6 7 8 1 2 3 4 5 6 This table shows the function of each of the connectors on the i-COMM controller. The voltages listed for each pin assume that either the input or output is activated. FLASHING LAMP OUT I-ZONE ALARM OUT DC POWER OUT RESET INPUT (X12) UNUSED DC COMMON INPUT DC POWER INPUT 24VAC INPUT 24VAC COMMON (N) OPEN/CLOSE CO CLOSE OUTPUT (K1) OPEN OUTPUT (K0) LOOP INPUT 2 LOOP INPUT 1 DC POWER OUT DC COMMON OUT DC POWER OUT LOOP INPUT (X13) UNUSED OUTPUT I-ZONE ALARM OUT DC POWER OUT RESET INPUT (X12) UNUSED DC COMMON INPUT DC POWER INPUT 24VAC INPUT 24VAC COMMON (N) OPEN/CLOSE COM CLOSE OUTPUT (K1) OPEN OUTPUT (K0) LOOP INPUT 2 LOOP INPUT 1 DC POWER OUT DC COMMON OUT DC POWER OUT LOOP INPUT (X13) Pub. No. i-COMM_A FEBRUARY 2016 FLASHING LAMP OUT UNUSED DC POWER OUT RESET INPUT (X12) UNUSED DC COMMON INPUT DC POWER INPUT 24VAC INPUT 24VAC COMMON (N) OPEN/CLOSE COM INVERTER OUT 2(K1) INVERTER OUT 1 (K0) LOOP INPUT 2 LOOP INPUT 1 DC POWER OUT DC COMMON OUT DC POWER OUT LOOP INPUT (X13) FLASHING LAMP OUT UNUSED DC POWER OUT RESET INPUT (X12) UNUSED DC COMMON INPUT DC POWER INPUT UNUSED UNUSED OPEN/CLOSE COM CLOSE OUTPUT (K1) OPEN OUTPUT (K0) LOOP INPUT 2 LOOP INPUT 1 DC POWER OUT DC COMMON OUT DC POWER OUT LOOP INPUT (X13) FLASHING LAMP OUT UNUSED DC POWER OUT RESET INPUT (X12) UNUSED DC COMMON INPUT DC POWER INPUT 24VAC INPUT 24VAC COMMON (N) OPEN/CLOSE COM CLOSE OUTPUT (K1) OPEN OUTPUT (K0) LOOP INPUT 2 LOOP INPUT 1 DC POWER OUT DC COMMON OUT DC POWER OUT LOOP INPUT (X13) 31 i-COMM™ CONTROLLER NON-ENCODER i-COMM BOARD 1. If any procedures for the installation or operation have been left out or are not complete, contact RITE-HITE DOORS, INC. Technical Support at 1-563-589-2722. 2. The use of a handheld device is no longer required, a downloader will be sent to download the new program. 3. This controller is used on the following door models: FasTrax, FasTraxFR, FasTraxCL, SplitSecond, 7100, 7514, 8000, 8000CL, 8000XL, 8600, 8910, 8920, 8920PL. 4. Terminals will accept wire sizes from 12 - 22 AWG. 5. 15 Digital Inputs. (24VDC; 10 mA) 6. 5 Relay Outputs. (24VAC/DC; 1 AMP) 7. 4 DC Outputs. (24VDC; 0.5 AMP MAX) REMOVAL AND INSTALLATION 1. Change controller with door in the close position. 2. Make sure you have all the parts before beginning. 3. Unplug the J3 push button harness. 4. Unplug the J4 power supply harness. 5. Unplug the J5 induction loop harness if applicable. 6. Remove wires from the input and output terminals. 7. Remove the board by cutting the white plastic supports, and remove supports from bracket. 8. Install new board, by screwing supports into mounting bracket. 9. 10. 32 Plug in the J3, J4 and J5 connectors. Insert wires into terminals, based on markings, labels on the wires as well as the electrical wiring diagram included with the door. Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER INPUT / OUTPUT SETTING FUNCTIONS Default Value for Output (Factory Configuration) YK2 YK3 YDC0 YDC1 YDC2 YDC3 Model: X0 X1 Default Value for Input (Factory Configuration) X2 X3 X4 X5 X6 X7 FasTrax/FR n/a 0 2 20 n/a n/a n/a n/a 2 2 n/a 3 2 2 FasTraxCL n/a 0 2 20 n/a n/a n/a 2 2 2 2 3 2 2 SplitSecond n/a 0 2 20 n/a 20 n/a n/a 2 2 n/a 3 2 2 Protecdor/CL n/a 0 2 20 20 20 n/a n/a 2 2 n/a 3 2 2 Protecdor/CL PRO n/a 0 2 20 20 n/a n/a n/a n/a 2 n/a 3 2 2 Protecdor XL n/a 0 2 20 20 20 n/a n/a 2 2 n/a 3 2 2 Protecdor XL PRO n/a 0 2 20 20 n/a n/a n/a n/a 2 n/a 3 2 2 Trakline 20 0 2 20 20 20 n/a n/a n/a 2 n/a 3 2 2 Iso-Tek n/a 0 2 20 20 20 n/a n/a n/a 2 n/a 3 2 2 Barrier Glider 20 0 2 20 20 n/a n/a n/a n/a 2 n/a 3 2 2 Barrier Fold n/a 0 2 20 20 20 n/a n/a n/a 2 n/a 3 2 2 n/a = Not available for change Valid Values for Output Settings Value 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Valid Values for Output Settings Function Value On when door closed (Interlock Out) On when door Not Closed On during preannounce to close On when door full open On when door not full open On when door faulted On when door not faulted On when activation command On during run Open On during run Close On during run (Open or Close) On when door on limit (open or close) On when I-Zone alarm On when door open for 30 seconds On when door open for 60 seconds On when door open for 120 seconds On during sequential activation On when not running open On when not running close On when not running (open or close) Output Disabled 21 22 23 24 25 26 27 28 29 Function Flash 3Hz (=/> Version 2.2.5) Flash 2Hz (=/> Version 2.2.5) Partial Timer Act rev I-Zone Pass Door Open Alarm Interlock Out N.O. Interlock Out N.C. Preannounce and Close Photoeye Test Valid Values for Input Settings: *Value 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Function Description Interlock In Allows door to open (Only Available for inputs X2, X3 & X5) (Note: Interlocking is disabled if no inputs are defined as interlock) Stop Stops door (Normally-Closed) Activation Opens Door Toggle Opens/Closes Door Close Closes door Sequential Act. Opens Door Reverse Reverses or Holds open door Stop Stops door (Normally-Open) Manual Open Opens door (used for open-close-stop, normal activation will not resume from stop) Auto/Man Places Door in Toggle Mode when input is on. Partial Open Activation (8000/CL/XL/8900) (=/> Version 2.2.5) Partial Open Toggle (8000/CL/XL/8900) (=/> Version 2.2.5) Toggle / Auto Toggle with Automatic close (=/> Version 2.2.5) Hand / Auto Consult Customer Service Disable Disables Input Reverse N.C. Reverses or Holds open door using normally close contacts Clean * Value number may or may not appear on display. Pub. No. i-COMM_A FEBRUARY 2016 33 i-COMM™ CONTROLLER FASTRAX/FR/CL LOGIC TABLE ® FasTrax Encoder i-COMM Quick Reference Input Table Input XO X1 X2 X3,X6,X7 X4 X5 X8,X9 Input Function Open PB Stop PB Torque Reverse Activation Command Close PB Toggle Command IZone Sensors (Right & Left) X10 18" Photoeye Input X11 54" Photoeye Input X12 X13 X14 Open/Reset Switch Induction Loop Activation Fault Input Comments On to open door On to stop door Off to reverse door On to open door On to close door On to toggle open or close Not Available on FasTraxCL Must be on for door to close. Off when blocked. Must be on for door to close. Off when blocked. On to reset from fault. On to open door Must be on for door to run. Note(s) 1 1 1 1 1 2 2 Encoder Adjustment Descriptions (Refer to i-COMM and Owners Manuals for additional detail) Open Distance Set Open Position Set Close Position Open Position Adjust Close Position Adjust Use this option to set the overall opening distance of the door (in feet). For example, for an 9 foot tall FasTrax, this option should be set to “8” (to allow room for fine adjustment). This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. For example if this option was set to 100” the door would open 100 inches from the closed position. It is recommended to adjust the closed position of the door first, before adjusting the open position. Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. For example, if this option was set to -1.0” the door would closed approximately 1.0 inch more. If this option was set to 2.0” the door would close 2.0 inches less. Timer Adjustment 1. PRESS [ENTER], Controller will stop and fault door. 2. Press [UP] until desired timer is displayed, display will read "Set Close Timer" or "Set Preannounce". 3. Press [ENTER], Display will show current timer value. 4. Using [UP] & [DOWN] keys select desired time. 5. Press [ENTER] to return to Main Menu. 6. Press [DOWN] until exit is displayed. 7. Press [ENTER] to save values. 8. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates NOTES: (1) Default setting shown in table & comments. Record any changes on space provided. Consult i-COMM manual for additional details. (2) Device operation can be changed through menu. Consult i-COMM manual for additional details. 53850564-1 34 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER RITE-HITE DOORS NOTES PAGE This page intentional left blank. Pub. No. i-COMM_A FEBRUARY 2016 35 i-COMM™ CONTROLLER SPLITSECOND REFERENCE CHART TM SplitSecond Series i-COMM Quick Reference Input Table Input XO X1 X2 X3,X6,X7 Input Function Manual Open Command Stop Command N/O Torque Reverse Activation Command X4 X5 Comments On to open door On to stop door Off to reverse door On to open door Close Command Toggle Command X8 Not Used X9,X10,X11 Photoeye Input X12 X13 X14 Open/Reset Switch Induction Loop Activation Fault Input Note(s) 1 On to close door On to toggle open or close 1 Not Used All must be on for door to close. Off when blocked. On to reset fromfault. On to open door Must be on for door to run. 2 2 Encoder Adjustment Descriptions (Refer to i-COMM and SplitSecond Manuals for additional detail) Open Distance Use this option to set the overall opening distance of the door (in feet). For example, for an 8ft wide SplitSecond. This option should be set to “8”. This measurement is used for initial position setup only. For small adjustments of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Set Open Pos. Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close Pos.” can be used if it is more convenient to place the door in the closed position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Set Close Pos. Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open Pos.” can be used if it is more convenient to place the door in the open position. NOTE: This option approximately sets the open and close positions. For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust” Open Pos. Adjust Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and closed position. For example if this option was set to 100” the door would open 100 inches from the closed position. It is recommended to adjust the closed position of the door first, before adjusting the open position. Close Pos. Adjust Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed position. For example, if this option was set to -1.0” the door would closed approximately 1.0 inch more. If this option was set to 2.0” the door would close 2.0 inches less. Timer Adjustment 1. PRESS [ENTER], Controller will stop and fault door. 2. Press [UP] until desired timer is displayed, display will read "Set Close Timer" or "Set Preannounce". 3. Press [ENTER], Display will show current timer value. 4. Using [UP] & [DOWN] keys select desired time. 5. Press [ENTER] to return to Main Menu. 6. Press [DOWN] until exit is displayed. 7. Press [ENTER] to save values. 8. Reset Door. Preannounce Timer is the amount of time the Preannounce to close output will be on before door closes. Close Timer is the amount of time the door will remain open before the preannounce to close timer activates NOTES: (1) Default setting shown in table & comments. Record any changes on space provided. Consult i-COMM manual for additional details. (2) Device operation can be changed through menu. Consult i-COMM manual for additional details. 53850563-1 36 Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER PROTECDOR/CL/XL LOGIC TABLE Pub. No. i-COMM_A FEBRUARY 2016 37 38 AAA AAA AAA AAA AAA 6KOGT#FLWUVOGPV AAA AAA AAA AAA AAA AAA 1RGP&QQT %NQUG&QQT 7UGT1WV 7UGT1WV +PVGTNQEM 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 7UGT1WV 2TGCPPQWPEG 7UGT1WV 7UGT1WV 7UGT1WV (CWNV (NCUJKPI2WUJÄDWVVQP 0QPÄ&GFKECVGF 176276(70%6+10 1RGP.KOKV5YKVEJ %NQUG.KOKV5YKVEJ 7UGT+PRWV #EVKXCVKQP 7UGT+PRWV #EVKXCVKQP 0QPÄ&GFKECVGF 6QIING%QOOCPF #EVKXCVKQP%QOOCPFÄ1RGP #EVKXCVKQP%QOOCPFÄ1RGP 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 4GXGTUG 0QPÄ&GFKECVGF 1RGP4GUGV5YKVEJ +PFWEVKQP.QQR#EVKXCVKQP 0QPÄ&GFKECVGF +0276(70%6+10 % : : : : : : : : : : : : 4Q : : : : : : : : : : : : 4E : : : : : : : : : : : : 1 : : : : : % : : : : 4E : : : : 1PYJGPFQQTKUQRGPKPI 1PYJGPFQQTKUENQUKPI 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 1PYJGPKPHCWNV 0QPÄ&GFKECVGF %1//'065 1HHYJGPFQQTQRGPGF 1HHYJGPFQQTENQUGF 1PVQQRGPFQQT 1PVQQRGPFQQT 0QPÄ&GFKECVGF 1PVQVQIINGQRGPQTENQUG 1PVQQRGPFQQT 1PVQQRGPFQQT 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 1HHVQTGXGTUGFQQT 0QPÄ&GFKECVGF 1PVQTGUGVHTQOHCWNV 1PVQQRGPFQQT 0QPÄ&GFKECVGF %1//'065 Ä 016'5 &GXKEGQRGTCVKQPECPDGEJCPIGFVJTQWIJOGPW %QPUWNVKÄ%1//OCPWCNHQTCFFKVKQPCNFGVCKNU &GHCWNVUGVVKPIUJQYPKPVCDNG EQOOGPVU4GEQTF CP[EJCPIGUQPURCEGRTQXKFGF%QPUWNVKÄ%1// OCPWCNHQTCFFKVKQPCNFGVCKNU -'; 11RGP5VCVG 1(( %%NQUGF5VCVG 10 4Q4WPPKPI1RGP :/C[DG10QT1(( 4E4WPPKPI%NQUG 4Q : : : : 56#6'6#$.' 1 : : : : : : : : : : : : 56#6'6#$.' 24'55='06'4?%QPVTQNNGTYKNNUVQRCPFHCWNVFQQT 2TGUU=72?WPVKNFGUKTGFVKOGTKUFKURNC[GFFKURNC[YKNN TGCF5GV%NQUG6KOGTQT5GV2TGCPPQWPEG 2TGUU='06'4?&KURNC[YKNNUJQYEWTTGPVVKOGTXCNWG 7UKPI=72? =&190?MG[UUGNGEVFGUKTGFVKOG 2TGUU='06'4?VQTGVWTPVQ/CKP/GPW 2TGUU=&190?WPVKNGZKVKUFKURNC[GF 2TGUU='06'4?VQUCXGXCNWGU 4GUGV&QQT 2TGCPPQWPEG6KOGTKUVJGCOQWPVQHVKOGVJG 2TGCPPQWPEGVQENQUGQWVRWVYKNNDGQPDGHQTGFQQT ENQUGU %NQUG6KOGTKUVJGCOQWPVQHVKOGVJGFQQTYKNNTGOCKP QRGPDGHQTGVJGRTGCPPQWPEGVQENQUGVKOGTCEVKXCVGU - - - - - - ;&% ;&% ;&% ;&% ,Ä ,Ä (WPE 0#/' : : : : : : : : : : : : : : : (WPE 0#/' 6/ KÄ%1//.1)+%6#$.' $#44+'4).+&'4 i-COMM™ CONTROLLER BARRIER GLIDER / FOLD LOGIC TABLE Pub. No. i-COMM_A FEBRUARY 2016 i-COMM™ CONTROLLER ISO-TEK LOGIC TABLE +51Ä6'- 6/ KÄ%1//.1)+%6#$.' 0#/' +0276(70%6+10 (WPE : : : : : : : : : : : : : : : 1RGP.KOKV5YKVEJ %NQUG.KOKV5YKVEJ AAA 7UGT+PRWV #EVKXCVKQP AAA 7UGT+PRWV #EVKXCVKQP #RRTQCEJ1RGP.KOKV5YKVEJ AAA 6QIING%QOOCPF AAA #EVKXCVKQP%QOOCPFÄ1RGP AAA #EVKXCVKQP%QOOCPFÄ1RGP 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 4GXGTUG 0QPÄ&GFKECVGF 1RGP4GUGV5YKVEJ +PFWEVKQP.QQR#EVKXCVKQP 0QPÄ&GFKECVGF 0#/' 176276(70%6+10 (WPE - - - - - - ;&% ;&% ;&% ;&% ,Ä ,Ä AAA AAA AAA AAA AAA 8(&N5RGGFDKV 8(&N5RGGFDKV $TCMG1WVRWV 7UGT1WV +PVGTNQEM (CWNV (CWNV 7UGT1WV 2TGCPPQWPEG 7UGT1WV 7UGT1WV 7UGT1WV (CWNV (NCUJKPI2WUJÄDWVVQP 0QPÄ&GFKECVGF 56#6'6#$.' 1 % : : : : : : : : : : : : : : : : : : : : : : : : 4E : : : : : : : : : : : : %1//'065 1PYJGPFQQTCEVKXCVGUUYKVEJ 1PYJGPFQQTCEVKXCVGUUYKVEJ 1PVQQRGPFQQT 1PVQQRGPFQQT 1PYJGPFQQTCEVKXCVGUUYKVEJ 1PVQVQIINGQRGPQTENQUG 1PVQQRGPFQQT 1PVQQRGPFQQT 0QPÄ&GFKECVGF 0QPÄ&GFKECVGF 1HHVQTGXGTUGFQQT 0QPÄ&GFKECVGF 1PVQTGUGVHTQOHCWNV 1PVQQRGPFQQT 0QPÄ&GFKECVGF %1//'065 56#6'6#$.' 1 : : : : 6KOGT#FLWUVOGPV 24'55='06'4?%QPVTQNNGTYKNNUVQRCPFHCWNVFQQT 2TGUU=72?WPVKNFGUKTGFVKOGTKUFKURNC[GFFKURNC[YKNN TGCF5GV%NQUG6KOGTQT5GV2TGCPPQWPEG 2TGUU='06'4?&KURNC[YKNNUJQYEWTTGPVVKOGTXCNWG 7UKPI=72? =&190?MG[UUGNGEVFGUKTGFVKOG 2TGUU='06'4?VQTGVWTPVQ/CKP/GPW 2TGUU=&190?WPVKNGZKVKUFKURNC[GF 2TGUU='06'4?VQUCXGXCNWGU 4GUGV&QQT 2TGCPPQWPEG6KOGTKUVJGCOQWPVQHVKOGVJG 2TGCPPQWPEGVQENQUGQWVRWVYKNNDGQPDGHQTGFQQT ENQUGU %NQUG6KOGTKUVJGCOQWPVQHVKOGVJGFQQTYKNNTGOCKP QRGPDGHQTGVJGRTGCPPQWPEGVQENQUGVKOGTCEVKXCVGU Pub. No. i-COMM_A FEBRUARY 2016 4Q : : : : : : : : : : : : % : : : 4Q : : : : 4E : : : 1PYJGPFQQTKUQRGPKPI 1PYJGPFQQTKUENQUKPICPFHCUVQRGP 1PVQGPICIGOQVQTDTCMG 7UGTUGNGEVCDNGQWVRWV 1PYJGPPQHCWNV 1PYJGPPQHCWNV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 1PYJGPKPHCWNV 0QPÄ&GFKECVGF -'; 11RGP5VCVG %%NQUGF5VCVG 4Q4WPPKPI1RGP 4E4WPPKPI%NQUG 1(( 10 :/C[DG10QT1(( 016'5 &GXKEGQRGTCVKQPECPDGEJCPIGFVJTQWIJOGPW %QPUWNVKÄ%1//OCPWCNHQTCFFKVKQPCNFGVCKNU &GHCWNVUGVVKPIUJQYPKPVCDNG EQOOGPVU4GEQTF CP[EJCPIGUQPURCEGRTQXKFGF%QPUWNVKÄ%1// OCPWCNHQTCFFKVKQPCNFGVCKNU Ä 39 i-COMM™ CONTROLLER TRAKLINE LOGIC TABLE 64#-.+0'5'4+'5 6/ 6/ KÄ%1//.1)+%6#$.' 0#/' +0276(70%6+10 (WPE : : : : : : : : : : : : : : : 1RGP.KOKV5YKVEJ %NQUG.KOKV5YKVEJ AAA 7UGT+PRWV #EVKXCVKQP AAA 7UGT+PRWV #EVKXCVKQP 0QPÄ&GFKECVGF AAA 6QIING%QOOCPF AAA #EVKXCVKQP%QOOCPFÄ1RGP AAA #EVKXCVKQP%QOOCPFÄ1RGP 6/ +Ä<QPG5GPUQT 6/ +Ä<QPG5GPUQT 2JQVQG[GÄ4GXGTUG&QQT 2JQVQG[GÄ4GXGTUG&QQT 1RGP4GUGV5YKVEJ +PFWEVKQP.QQR#EVKXCVKQP (CWNV+PRWV 0#/' 176276(70%6+10 (WPE - - - - - - ;&% ;&% ;&% ;&% ,Ä ,Ä AAA AAA AAA AAA AAA 4WP1RGP 4WP%NQUG 5GPUQT5YKVEJ&KUCDNG 7UGT1WV +PVGTNQEM (CWNV (CWNV 7UGT1WV 2TGCPPQWPEG 7UGT1WV 7UGT1WV 7UGT1WV 0QPÄ&GFKECVGF +Ä<QPG#NCTO 56#6'6#$.' 1 % : : : : : : : : : : : : : : : : : : : : : : : : 4E : : : : : : : : : %1//'065 1HHYJGPFQQTRCUUGUUYKVEJ 1HHYJGPFQQTRCUUGUUYKVEJ 1PVQQRGPFQQT 1PVQQRGPFQQT 0QPÄ&GFKECVGF 1PVQVQIINGQRGPQTENQUG 1PVQQRGPFQQT 1PVQQRGPFQQT 1HHVQTGXGTUG JQNFQRGP 1HHVQTGXGTUG JQNFQRGP 1HHYJGPRJQVQG[GUDNQEMGF 1HHYJGPRJQVQG[GUDNQEMGF 1PVQTGUGVHTQOHCWNV 1PVQQRGPFQQT /WUVDGQPVQTWPÄ+HQHH EJGEMGÄUVQRQTQXGTNQCF 56#6'6#$.' 1 : : : : : 6KOGT#FLWUVOGPV 24'55='06'4?%QPVTQNNGTYKNNUVQRCPFHCWNVFQQT 2TGUU=72?WPVKNFGUKTGFVKOGTKUFKURNC[GFFKURNC[YKNN TGCF5GV%NQUG6KOGTQT5GV2TGCPPQWPEG 2TGUU='06'4?&KURNC[YKNNUJQYEWTTGPVVKOGTXCNWG 7UKPI=72? =&190?MG[UUGNGEVFGUKTGFVKOG 2TGUU='06'4?VQTGVWTPVQ/CKP/GPW 2TGUU=&190?WPVKNGZKVKUFKURNC[GF 2TGUU='06'4?VQUCXGXCNWGU 4GUGV&QQT 2TGCPPQWPEG6KOGTKUVJGCOQWPVQHVKOGVJG 2TGCPPQWPEGVQENQUGQWVRWVYKNNDGQPDGHQTGFQQT ENQUGU %NQUG6KOGTKUVJGCOQWPVQHVKOGVJGFQQTYKNNTGOCKP QRGPDGHQTGVJGRTGCPPQWPEGVQENQUGVKOGTCEVKXCVGU 40 4Q : : : : : : : : : : : : : % : : : : 4Q : : : : 4E : : : : %1//'065 1PVQQRGPFQQT 1PVQENQUGFQQT 1PYJGPFQQTQRGPGFCPFFQQTENQUGF 7UGTUGNGEVCDNGQWVRWV 1PYJGPPQVKPHCWNV 1PYJGPPQVKPHCWNV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 7UGTUGNGEVCDNGQWVRWV 0QPÄ&GFKECVGF 1PFWTKPI+Ä<QPGCNCTO -'; 11RGP5VCVG %%NQUGF5VCVG 4Q4WPPKPI1RGP 4E4WPPKPI%NQUG 1(( 10 :/C[DG10QT1(( 016'5 &GXKEGQRGTCVKQPECPDGEJCPIGFVJTQWIJOGPW %QPUWNVKÄ%1//OCPWCNHQTCFFKVKQPCNFGVCKNU 1RVKQPCNWUGFQPN[HQT+Ä<QPGUGPUQTU[UVGO &GHCWNVUGVVKPIUJQYPKPVCDNG EQOOGPVU4GEQTF CP[EJCPIGUQPURCEGRTQXKFGF%QPUWNVKÄ%1// OCPWCNHQTCFFKVKQPCNFGVCKNU Ä Pub. No. i-COMM_A FEBRUARY 2016