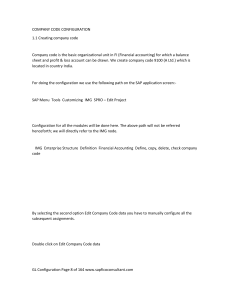

2021 IEEE 8th International Conference on Industrial Engineering and Applications Equipment Reliability Optimization Using Predictive Reliability Centered Maintenance 2021 IEEE 8th International Conference on Industrial Engineering and Applications (ICIEA) | 978-1-6654-2895-8/21/$31.00 ©2021 IEEE | DOI: 10.1109/ICIEA52957.2021.9436745 Kimuel Kier Mercado Rosita; Maria Victorina Rada School of Industrial Engineering and Engineering Management Mapúa University 658 Muralla St., Intramuros, Manila 1002, Philippines email: kkmrosita@mymail.mapua.edu.ph; mvdrada@mapua.edu.ph falls under continuous operations with reliability being indicative of the regular maintenance required to ensure smooth operation. Consistent maintenance ensures that machines operate optimally thereby introducing the concept of maintainability [2]. Maintainability in this case is defined as the potential to keep equipment in a specified desired state within strict tolerances using predetermined methods [3]. Maintenance is an important consideration in the enhancement of equipment reliability. Measures such as mean time to repair (MTTR) help define the reliability of a given component [4]. MTTR is easily determined using the number of repair hours and the total number of repairs within a specified period, means the higher the MTTR the greater it affects the production. Another measure mean time between failure (MTBF) is determined by dividing the total number of operation hours within a predetermined period by the number of failures [5]. Values such as the MTBF reciprocal are important in the determination of a machine’s reliability by isolating the episodes of failure in comparison to the sum of the time where operations are optimized. Information technology comes in handy in developing maintenance schedules. Diverse information technology tools are used to determine reliability. SAP is one such tool that can be customized for the collection of reliability data by analyzing maintenance reports as well as the general output of machines. Applying reliability-centered maintenance (RCM) demonstrated that the MTBF for the plant equipment can be improved, and the probabilities work will be developed by applying RCM in ABC manufacturing companies. Currently, breakdown maintenance, preventive maintenance, and corrective maintenance are generally practiced in these companies. Existing machine equipment is frequently challenged by sudden failures, manpower crisis, and unusual spares consumption, which directly affect production capacity and operational expenditure. RCM can be the gateway to overcome this situation. This study provides guidance for adopting RCM principles and implementing RCM in other industries. Reliability-centered-maintenance programs feature three stages: decision, analysis, and action. Customized RCM methodology has seven steps, and within these stages, it can assure that RCM programs are successfully implemented. Equipment reliability depends on several factors that need to be optimized, which translates into achieving the maximum or minimum value of their operation parameters. Abstract—Extending the work of (Prasetyo &Rosita, 2020) in this study, the application of Reliability Centered Maintenance (RCM) to optimize equipment reliability is presented through a framework developed for ABC manufacturing company. ABC company is a well-established manufacturing company in the middle east that already has their current maintenance strategy to maximize their equipment reliability but based on the data collected from SAP on where they stored their historical data from maintenance and operation, their MTBF is low and their MTTR is quite high. This is because of their high machine downtime hours and repeated failures. Reliability Centered Maintenance (RCM) integrates Preventive Maintenance (Interval-based), Reactive Maintenance, Proactive Maintenance and Condition Based Maintenance to increase the machines performance and the component will function in the required manner over its design life-cycle with a very less amount of machine downtime and parts failure. To implement RCM in ABC manufacturing company and apply the developed framework, the failure modes collected from SAP was analyzed using Failure Mode and Effect Analysis (FMEA) with the help of RCM Logic tree analysis for decision making and establishing maintenance criticality criteria. The last part of this paper shows the possible maintenance selection task for each failure modes that the company can consider, challenges in implementing RCM are also explained which might influence the plan of adopting the RCM process in an already established organization. It is also worth mentioning that the developed framework can be apply also in different manufacturing industries that want to implement Reliability Centered Maintenance (RCM). Keywords-component; reliability centered maintenance; maintainability; MTTR;MTBF; failure; reliability; machine; equipment I. INTRODUCTION Reliability is an indispensable attribute that plays a critical role in the life cycle, inherent properties, and the ability of equipment in engineering. Reliability is a measure of an equipment’s ability to operate efficiently within set limits and confines of time [1]. Optimizing reliability is paramount for the successful operation of equipment and the minimization of costs associated with downtime and unexpected breakdowns. Equipment is grouped based on the duration of time spent during operations with items falling under either intermittent or continuous work schedules. Equipment that spends most of its time running effectively 978-1-6654-2895-8/21/$31.00 ©2021 IEEE 348 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. To get decent profitability, a company needs high production machinery’s reliability and availability levels. Optimal benefits are realized when reliability is designed into a piece of equipment. However, it is important to improve equipment reliability throughout an equipment’s life to meet a company’s goals and objectives. Reliability-centered maintenance can be better understood as preventive maintenance where a systematic approach is developed to ensure equipment is maintained in a cost-effective manner effectively avoiding total disruption of operations [6]. There are many that can affect equipment reliability to achieve high equipment reliability. Engineering design, Materials used, manufacturing process, equipment operation and maintenance tasks are some of the issue that needs to be addressed to achieve such very high equipment optimization [7]. But, taking consideration of those issues is not as easy as we think it will require many information, modelling, analyzing samples, testing data more research analysis and possible reengineering. Maintenance and maintainability are two other issues which are also important in the context of to meet product reliability [7]. A piece of equipment’s complexity continues to increase as its age increases, and machine failure’s implications become ever more critical [7], mentioned that consequences of failure will vary depending on the involvement of the stakeholders. Every failure has an economic impact not only in the loss of production but also with the service level agreement to customers and may also possibly lead to safety and environment issues. These issues contribute highly to destroy company’s image and KPI’s if not properly managed by the key players of the organization. Failures cannot be entirely prevented but it is possible to reduce it damaged when they occur which is one of the purposes of maintenance and reliability analysis. The main problem addressed in this study can be defined as follows: • How can equipment reliability be optimized by using predictive reliability-centered maintenance? This study’s objectives are to develop a framework of RCM that can be used in ABC manufacturing company which will also be applicable in other similar industry to optimize their equipment reliability, apply, and evaluate the development framework based on company’s current strategy, and find out the challenges present for successful implementation of RCM in the existing system to optimize the equipment reliability. While it is not a new concept, many companies are not able to integrate reliability-centered maintenance in their daily operations. The impact that it has on equipment reliability is therefore overlooked with consequences that include higher operation and maintenance costs as well as downtime. Extending our previous work [8], this study carried out the comprehensive literature review of works related to RCM; then reliability analysis has been implemented using RCM framework steps specifically developed for the current plant strategy. The proposed work aims to provide guidelines and suggestions for implementing predictive RCM in ABC manufacturing companies’ maintenance department, thus optimizing equipment reliability. II. METHODOLOGY RCM seeks to prevent failure. RCM considers every aspect of failure despite their impact. Critical and non-critical reliability issues as well as the life of machines are some of the considerations of RCM [9]. RCM is designed to avoid equipment failure by working to predict and therefore avoid issues that can lead to breakdowns. The outcome is an ability to extend the machine’s operational life cycle while avoiding the complete disruption of production lines owing to failures that can be easily rectified. The proactive nature of RCM ensures that maintenance schedules are created and timeframes for inspections and repairs slotted during periods of low productivity to minimize chances of halting production. By determining the likelihood of failure, corrective action in the form of maintenance can be introduced thereby enhancing reliability even for old equipment [9]. Failure either in quality of the production process due to breakdowns, slow production, or even the complete stalling of operations are all justifications underpinning the importance of RCM in relation to reliability. Reliability-centered maintenance identifies all the reasons and can help to understand the reason of system function failure and what is the best approach to be used to address the failure. Its concept is quite simple, and its working method is defined by the following four features [10]: • Preserving functions. • Identifying failure modes that can make the system nonfunctional. • Failure consequences identification and prioritizing based on function criticality. • Selecting applicable and effective preventive maintenance action to prevent that prioritize functional failure. These demonstrate RCM as to prioritize functional importance need to be maintained and focus resources on those maintenance works that promote system reliability. There are seven questions that can support RCM process which will directly involve its function, assets, and the under-review system/ equipment, which listed as follows [11]: • Based on the asset current operating context, what are the functions and standard operating performance (functions)? • The possible ways that the system/ equipment will fail during normal operation (function failure)? • Contributing factors that results to failure (failure modes)? • Effects of each failure (failure effects)? • What impact that each failure gives (failure consequences)? • What are the predictive actions that can be done to prevent the failure (tasks/intervals)? • What are the alternatives in case the proactive did not work or can be seen (default actions)? 349 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. A. Reliability Centered Maintenance Framework The optimum goal of Reliability – centered maintenance is to improve productivity, minimize maintenance cost while maximizing equipment reliability. It can be done by doing predictive, time- based, condition based, proactive and reactive maintenance tasks [12]. By using the systematic approach organization can preserve the whole system function and it can also help in looking for the correct failure modes. An RCM’s program unfolds three stages: decision, analysis, and action. These stages have corresponding steps that need to be followed to ensure a successful RCM program. The proposed methodology was designed after a qualitative and quantitative observation in ABC manufacturing company relative to its profile and maintenance strategy. To optimize equipment reliability a detailed RCM framework steps to be carried out are listed below and the framework shown in Fig. 1. • Equipment Selection • Defining system boundaries • Identify important functionalities. • Functional failure identification • Identifying and evaluating the effects of failure mode • Identifying failure modes • Task Selection Figure 2. SAP netweaver dashboard In maintenance field the machine performance can be calculated through Meantime between failure and Meantime to repair, this is the basic key performance indicator to assess equipment reliability. Many maintenance organizations use SAP as their CMMS to calculate MTBF and MTTR. Computerized Maintenance Management System (CMMS) is a tool that support maintenance and for this study alone SAP is the one that serves as CMMS in ABC manufacturing company which helps activities of the maintenance [13], Figure 2 shows the SAP Dashboard in most maintenance organization. After a successful gathering of data using SAP and following of detailed RCM framework, we will be having a list of maintenance tasks which will be allocated in an applicable and cost-effective way. Here, applicable means that the tasks should be able to prevent failures or pull-out hidden failures while effective is related to the cost effectiveness of the alternative Preventive Maintenance strategies or will serve as a new Predictive Maintenance Model. It is important and necessary to assign maintenance activity to every failure mode because that activity should prevent the occurrence of the failure mode in the most structured way. III. RELIABILITY CENTERED MAINTENANCE This part of the paper presented all the RCM steps that needs to follow for the entire analysis. Figure 1. Reliability centered maintenance framework A. Equipment Selection Equipment selection and gathering data from maintenance and operation is considered the most important step in an RCM analysis [13]. A piece of equipment can be chosen through the following criteria: • Repeated failure happened recently. • More corrective maintenance was performed. • Total maintenance cost is high (spare parts usage is high). • Mean time between failures is low. • Mean time to repair is high. • High safety concerns. • High environmental effects. B. Data iof Reliability as per SAP SAP NetWeaver is the utilized software to collect information’s from ABC manufacturing company. It is a company that depends on their production into their automated machinery. ABC manufacturing company are bonded by SAP to integrate their historical data performed by the maintenance and operations team, that includes important details like actual work out in the machine which is vital in computing Meantime between failure and Meantime to repair. 350 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. B. Defining Sytem Boundaries This step identifies what of the equipment needs to be included in the RCM analysis and what does not. Boundary definition also consists of both input and output interfaces and the established system interactions, which is especially important if two adjacent pieces of equipment or systems are selected. To define system boundaries this study uses an IPO model. Fig. 3, shows the system boundaries of the study through Input, Process and Output (IPO) of ABC Manufacturing Company. E. Identifying and Evaluating the Effects of Failure Mode This step clarifies what the consequences are when failure occur including observation of the incident and the possible impact can occur in the production line. Safety impact assessment of the incident are also needed to take consideration. The step unfolds as follows: • Recording the information regarding the failure. • Consequence of each failure. • Assessing the failure. Figure 4. Failure mode and equipment analysis form Figure 4 shows the template for creating the failure effects in every functional location of tricot feed machine. F. Identifying/Analyzing Failure Modes through (FMECA) After knowing the system function and the functional failures that might happen in the equipment, the next step in the RCM analysis is to go more specific. The systematic approach of FMEA analysis is presented in. Here, all the equipment items are selected one by one for in depth analysis. Collected failure modes in each functional location are detected through SAP where the historical failures of the company are recorded. Then, every failure mode is evaluated by detecting their causes of failure and failure effects at the local and system level or end effects. The whole process is repeated as necessary until all equipment items and associated failure modes have been evaluated. Figure 3. System boundaries C. Identifying Important Functionalities This step is about the information regarding the system understudy main functionality, information as follows: • Function description. • Function representation. • Function interface. • Function equipment. • Function history. D. Functional Failure Identification Functional failure is an asset's inability to meet the expected structured performance. In this step, the overall goal is to identify the functional failure. Generally, functional failures in each discussed function there is a possibility of at least two functional failure this might cause a partial or complete loss. There are guides that can be used to identify the functional failure from the function, listed below. • Nothing from the function. • Less than the standard parameter of system performance • More than the standard parameter of system performance • Functional operation done prematurely. • Function’s fail due to over usage (e.g., too long operation) • Operational irregularity of the function. • Other functional failure that happened which is still appropriate within its functional group. There is a need to document all functional failure in a complete functional failure statement including its functional deviation to have a realistic analysis. Figure 5. Failure mode and equipment analysis form Figure 5 shows the FMEA form that will be filled up to input all failure modes of the machine as the proponent of the research study. After collecting and filling up all FMEA analysis every failure mode will be numbered sequentially using their failure ID. In getting the criticality analysis of the equipment to satisfy the Failure Modes and Criticality Analysis (FMECA). Each failure mode was listed based on their functional location. The numbering will be used as a pointer of every failure mode for evaluation of the criticality or risk priority of the failure- influenced by severity of the failure, occurrence of the failure and detection of the failure. On which, ranking of failure consequences is categorized by the severity index, while the occurrence on the other hand serves as an index which defined the number of failure occurrences happened, and the probability that a failure can be detected is dictates by the detection index assuming that it has occurred. The good practice is that annually occurrence index should be re-evaluated, SAP plays an important role to evaluate it. It 351 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. means that FMEA analysis is dynamic and should be monitored regularly. These parameters are measured in a scale of 1 to 10 where 1 indicates the lowest importance and 10 indicates the highest importance as per failure characteristics, [14]. Using the criteria for ranking failure mode assessment tailored from Machinery FMEA (MFMEA) the risk priority number is being calculated. (MFMEA) is a type of FMEA that focuses on design that improves the reliability and maintainability of the machinery for long term plant usage, [15]. Table I (a, b, c) shows the classification criteria for each of these parameters. Risk Priority Number (RPN) can be computed by multiplying the three mentioned indices, these are Severity (S), Occurrence (O) and Detection (D) and group the indices values by four. The purpose of getting risk priority number is to be categorized and prioritized each failure accordingly in the maintenance task allocation. It is computed as: function/ R(t) = 78%) 6 7 8 9 10 Rank 1 3 5 TABLE I A. CRITERIA FOR FAILURE MODE ASSESSMENT (SEVERITY) 7 Rank 1 10 Severity System Parameter is within specified limits; during normal maintenance adjustment can be done System Parameter is not within specified limits, but it is possible to adjust during normal production and there will be no impact or downtime. 3 4 Downtime up to 15 min with no production of defective parts 5 Downtime of 30 - 60 min with no production of defective parts or the production of defective parts for up to 30 min Downtime of 60 - 120 min or the production of defective parts for up to 60 min Downtime of 2 - 4 hours or the production of defective parts for up to 2 hours 6 7 8 9 10 Downtime of 15 - 30 min with no production of defective parts Downtime of 8+ hours or the production of defective parts for over 2 hours High severity: affects operator, plant, or maintenance personnel safety and/or effects noncompliance with government regulations with warning Very high severity affects operator, plant, or maintenance personnel safety and/or effects noncompliance with government regulations without warning TABLE I B. CRITERIA FOR FAILURE MODE ASSESSMENT (OCCURRENCE) Rank 1 2 3 4 5 (Reliability (Reliability (Reliability (Reliability (Reliability TABLE I C. CRITERIA FOR FAILURE MODE ASSESSMENT (DETECTION) RPN = S x O x D 2 Occurrence of the failure is every month function/ R(t) = 60%) Occurrence of the failure is every week function/ R(t) 37%) Occurrence of the failure is every day function/ R(t) = 20%) Occurrence of the failure is every shift function/ R(t) = 5%) Occurrence of the failure is every hour function/ R(t) < 1 or some MTBF) Occurrence Occurrence of the failure is every 5 years (Reliability function/ R(t) = 98%) Occurrence of the failure is every 2 years (Reliability function/ R(t) = 95%) Occurrence of the failure is every year (Reliability function/ R(t) = 90%) Occurrence of the failure is every 6 months (Reliability function/ R(t) = 85%) Detection The machine design will detect the possible causes and other failure almost every time thus machinery controls is not necessary. Machinery controls will prevent an imminent failure and isolate the cause Machinery controls will provide an indicator of imminent failure Machinery control will isolate the cause and failure mode after the failure has occurred, but will not prevent the failure from occurring Nothing in the current design can detect the failure After identifying the criticality of each failure mode, data will be used in the maintenance selection task selection step process where all failure modes are relisted. Since criticality of each failure modes are grouped it will be useful to identify the new frequency of the task. G. Maintenance Task Selection The last step of the RCM framework is the Maintenance tasks selection. This selection identifies which is the most suitable maintenance program for the company to be able to preserve the system function of the failure modes based on the FMEA. Afefy, 2010, explains an RCM logic tree analysis as shown in Figure 6, it is used for finding the best strategy of failure management. Each of the failure mode is placed into the top box of the decision tree, where the first thing to know is if the failure is hidden from normal operation perspective, those that can be seen by the operators during their normal duties. Also, from the figure, decision bins: 1.) Safety, 2.) outage-related, or economic-related were noticed and carried out sequentially. Each question is answerable with yes or no. From the RCM logic tree analysis, proper failure management strategy will be derived whether it is a Condition-based, Interval based, run to fail, failure finding or to Redesign the system. After selection of failure management strategy maintenance tasks are allocated with them to preserve the function. Maintenance tasks are selected by considering the technical and economic feasibility of the system. In Figure 7, maintenance selection task form is illustrated. Occurrence of the failure is every 3 months (Reliability 352 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. governed by the technical characteristic of the task in which the main purpose is to prevent the failure, [16]. If a proactive maintenance task cannot be found which is both technically feasible and worth implementing, then relevant default action must be taken. IV. CHALLENGES IN IMPLEMENTING RCM Like any other strategy, when implementing something there are challenges that we need to understand before we can implement RCM in one organization, listed below are the challenges in implementing RCM in ABC manufacturing company. 1) Benefits to the company: The fruit of using RCM cannot be seen in a short period of time it is derived over a medium to long term period which means gains of applying RCM could not be experienced by the company immediately which other company will not take a risk. 2) Already established PM Program: Significant changes need to do in the whole plant including work practices, the inter relationships between maintenance and operation and other branch that maintenance department are involved, they all need to adopt and adjust. 3) Operation discipline: Significant changes Data collection for the ABC manufacturing company is vital part for this analysis. Some equipment failure data cannot be analyzed correctly due to poor practice of the operation whenever they raise a Work Notification for the job. Work Notification will serve as the failure modes that will be use in the analysis. Machine wise failure data history is highly important for this study and insufficient or incorrect data is a big challenge of implementing RCM. 4) Organizational factor: Organizational factor factors play an important role as they are the who define the responsibilities, authorities build communication path which are essential for successful implementation of RCM. Any misunderstanding might result to internal resistance and lack of commitment. 5) Financial commitment: Lastly, financial commitment is also involved while on process specially the trainings and other project costs. Figure 6. RCM Logic Tree Analysis [16] Figure 7. Maintenance Task Selection Form Here, each strategy is written in abbreviated form where maintenance tasks are consists of Interval-based (IB), Run to failure (RTF), Condition-based (CB), Redesign (RD) and failure finding (FF). For Interval-based task; age of deterioration is identified, and the task takes place before that period or simply replaced when necessary. Condition based task; a reasonable time left after the detection method until the failure happens so that the task can be carried out. Failure finding type of maintenance task considers troubleshooting and functional testing of the equipment including the protective features and interlocks. Then, for non- critical item or machine parts if there is no suitable task found then run to fail is the suggested task given that it is easily can be seen by the operator during their normal duties. Redesigning the system is the least thing to consider because of high cost, this task is most suitable if the failure is repeated and all of the preventive tasks are already considered and monitored. Task frequency is also identified based on the extracted generic failure data, Original equipment manufacturers recommendation, current task intervals and invaluable team experience. The outcome of the maintenance selection task can be considered by the company specially the task and its schedule so they can update their current Preventive Maintenance strategy. One of the main purposes of RCM is to provide simple, precise and understandable criteria for deciding which (if there’s any) of the proactive task is technically beneficial in any given situation and if so, how often they should be done by the maintenance organization. The technical feasibility of proactive maintenance task is V. CONCLUSION AND RECOMMENDATION According to Prasetyo and Rosita, 2020, the opportunity of optimizing equipment reliability with the help of RCM is very huge. It also not only for automated machine but even for other type of industry (Prasetyo & Rosita, 2020). This paper shows how one manufacturing company with existing preventive maintenance strategy can utilize their data from SAP to optimize their equipment reliability through RCM. The ultimate goals of RCM analysis discussed in this paper are how the company can identify the failure modes in their equipment, their consequences and to create the most effective and applicable maintenance task to minimize the equipment failure risk and downtime using the tailored RCM framework. This will allow machine to perform in the most reliable way for plant long term usage which can help to increase the maintenance Meantime Between failure (MTBF) and decrease the Meantime to Repair (MTTR). For the company to successfully implement the RCM, correct 353 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply. implementation and understanding is vital from managerial level up to the operator. The managerial level should understand that there will be huge changes in the work practice, inter relationships between maintenance and other processes and departments involved. The managerial level should understand that proper staff training is required whenever one company wish to implement RCM and the benefit cannot be seen in a short-term implementation. The operators should be disciplined in doing their work orders raising because it will serve as a failure mode that will be used for RCM analysis. Lastly, financial commitment is also involved while process is ongoing. It is recommended to continuously monitor the derived maintenance selection task; it is necessary for continuous improvement of this study. Extended supporting efforts should be arranged to collect the results for necessary updates of the task selection. By following correct RCM path this program can help to improve machine reliability and can make business more competitive in the global market. Future researcher can consider exploring other reliability optimization technique/tools and utilize SAP to do their analysis. The filled-up copy of the forms discussed in this paper will be done by one of the authors of this paper in his thesis paper. [5] [6] [7] [8] [9] [10] [11] [12] REFERENCE [1] [2] [3] [4] [13] Thoma, K., Scharte, B., Hiller, D., & Leismann, T. (2016). Resilience engineering as part of security research: definitions, concepts and science approaches. European Journal for Security Research, 1(1), 319. doi:10.1007/s41125-016-0002-4 Roy, R., Stark, R., Tracht, K., Takata, S., & Mori, M. (2016). Continuous maintenance and the future – Foundations and technological challenges. CIRP Annals, 65(2), 667-688. doi: 10.1016/j.cirp.2016.06.006. Wang, S., Tomovic, M., & Liu, H. (2016). Comprehensive reliability design of aircraft hydraulic system. Commercial Aircraft Hydraulic Systems, 115-169. doi:10.1016/b978-0-12-419972-9.00003-6 Forsthoffer, M. S. (2017). Reliability optimization. Forsthoffer's more best practices for rotating equipment. 547-596. doi:10.1016/b978-012-809277-4.00012-7 [14] [15] [16] Pancholi, N., & Bhatt, D. (2016). Performance reliability improvement by optimizing maintenance practices through failure analysis in process industry – a comprehensive literature review. IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) 13(6), 66-73. doi:10.9790/1684-1306016673 Barabady, J., & Kumar, U. (2008). Reliability analysis of mining equipment: A case study of a crushing plant at Jajarm Bauxite Mine in Iran. Reliability Engineering & System Safety, 93(4), 647-653. doi: 10.1016/j.ress.2007.10.006. Blischke, W.R., Murthy, D.N.P. (2003). Case studies in reliability and maintenance. USA: John Wiley & Sons. Prasetyo, Y. T., & Rosita, K. K. (2020). Equipment reliability optimization using predictive reliability centered maintenance: a casestudy illustration and comprehensive literature review. 2020 7th International Conference on Frontiers of Industrial Engineering (ICFIE). doi:10.1109/icfie50845.2020.9266728 Naik, B., & Soni, P. (2016). Research review on reliability centered maintenance. International Journal of Innovative Research in Science, Engineering and Technology, 5-6. doi:10.15680/IJIRSET.2015.0506014 Anthony, M.S., & Glenn, R.H. (2003). RCM-a proven approach, RCM-gateway to world class maintenance (1st Ed.). 66-67. Moubray, J. (1997). Introduction to Reliability-centered maintenance, Reliability-centered maintenance (2nd Ed.). 6-21. Fuentes-Huerta, M. A., González-González, D. S., Cantú-Sifuentes, M., & Praga-Alejo, R. J. (2017). RCM implementation on plastic injection molding machine considering correlated failure modes and small size sample. The International Journal of Advanced Manufacturing Technology, 95(9-12), 3465-3473. doi:10.1007/s00170-017-1402-y Lopes, I., Senra, P., Vilarinho, S., Sá, V., Teixeira, C., Lopes, J., . . . Figueiredo, M. (2016). Requirements specification of a computerized maintenance management system – a case study. Procedia CIRP, 52, 268-273. doi: 10.1016/j.procir.2016.07.047 Ahmad, N., & Karim, M. A. (2016). A framework for application of reliability centered maintenance in the lead oxide production system. Applied Mechanics and Materials, 860, 123-128. doi: 10.4028/www.scientific.net/amm.860.123 Degu, Y., & Moorthy, R. (2014). Implementation of machinery failure mode and effect analysis in Amhara pipe factory. American Journal of Engineering Research (AJER), 3(01), 57-63. Afefy, I. H. (2010). Reliability-centered maintenance methodology and application: A case study. Engineering, 02(11), 863-873. doi:10.4236/eng.2010.211109 354 Authorized licensed use limited to: University of Prince Edward Island. Downloaded on July 05,2021 at 10:28:37 UTC from IEEE Xplore. Restrictions apply.