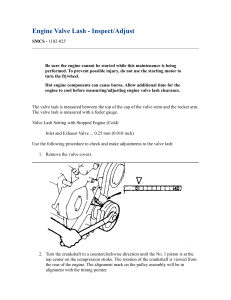

TOPIC: IDENT NO: DATE: SUPERSEDES: VGF* Cylinder Heads 7-4156 September 2021 New SUBJECT: Valve Adjustment MODELS AFFECTED: VGF Engines The purpose of this bulletin is to inform the field of the proper method to position the crankshaft for valve adjustment on VGF engines. NOTICE PREPARING ENGINE FOR VALVE ADJUSTMENT Shut the engine down and allow it to cool to room temperature before adjusting the valves. In any procedure where the rocker arms may have been removed or disturbed, the cylinder head replaced, or if it is suspected that the valves may have been adjusted incorrectly, do not rotate the crankshaft until all rocker arm adjusting screws and valve bridge adjusting screws have been backed off. Failure to back off the adjusting screws in these situations may cause contact between valves and pistons. ! WARNING Allow the engine to cool to room temperature before servicing the engine. Some engine components and fluids are extremely hot even after the engine has been shut down. Allow sufficient time for all engine components and fluids to cool to room temperature before attempting any service procedure. 1. Position cylinder No. 1 on the F18 and H24, or 1R on the L36 and P48 at TDC of the compression stroke. Rotate the crankshaft by barring the engine over in a counterclockwise direction (when facing the flywheel) until the piston of cylinder No. 1 is at TDC (compression stroke). 2. To determine when this piston is at top dead center (compression stroke), watch the rocker arms and valves on its mating cylinder (see Figure 1). As the exhaust valves on the mating cylinder are closing, the intake valves begin to open. At this point, the mating cylinder is in valve overlap (all four valves partially open). This means that all four valves on the cylinder to be adjusted are fully closed. * Trademark of INNIO Waukesha Gas Engines, Inc. All other trademarks are the property of their respective owners. 09/02/2021 Copyright © 2021, INNIO Waukesha Gas Engines, Inc. Page 1 of 3 Service Bulletin No. 7-4156 Table 1: H24SE, VGF H24 Crankshaft Positioning 1 2 7 3 3 2 4 7 5 6 Figure 1: Rocker Arm Adjustment 1 - Crossbar Adjustment 5 - Rocker Arm 2 - Exhaust Valve 6 - Valve Clearance Adjustment 3 - Measure Gap With Feeler Gauge 7 - Intake Valve 4 - Crossbar Both intake and exhaust valves are adjusted on each cylinder when it is at TDC. Begin with cylinder No. 1 or 1R and adjust valves on subsequent cylinders in the firing order, watching the mating cylinder go into valve overlap to determine TDC on each cylinder to be adjusted. Do this until all the cylinders have been adjusted. After all valves are adjusted and before starting the engine, use the engine barring device to manually rotate the engine in a counterclockwise direction, to be certain that no oversights have occurred that might cause valve and piston interference. SET VALVES ON CYLINDER WHEN VALVES OVERLAP ON MATING CYLINDER 1 4 2 6 8 5 7 3 8 5 7 3 1 4 2 6 Table 2: F18SE, VGF F18 Crankshaft Positioning SET VALVES ON CYLINDER WHEN VALVES OVERLAP ON MATING CYLINDER 1 5 3 6 2 4 6 2 4 1 5 3 Table 3: L36 Crankshaft Positioning SET VALVES ON CYLINDER WHEN VALVES OVERLAP ON MATING CYLINDER 1R 6L 5R 2L 3R 4L 6R 1L 2R 5L 4R 3L 6R 1L 2R 5L 4R 3L 1R 6L 5R 2L 3R 4L 09/02/2021 Copyright © 2021, INNIO Waukesha Gas Engines, Inc. Page 2 of 3 Service Bulletin No. 7-4156 Table 4: P48 Crankshaft Positioning SET VALVES ON CYLINDER WHEN VALVES OVERLAP ON MATING CYLINDER 1R 1L 4R 4L 2R 2L 6R 6L 8R 8L 5R 5L 7R 7L 3R 3L 8R 8L 5R 5L 7R 7L 3R 3L 1R 1L 4R 4L 2R 2L 6R 6L 09/02/2021 Copyright © 2021, INNIO Waukesha Gas Engines, Inc. Page 3 of 3