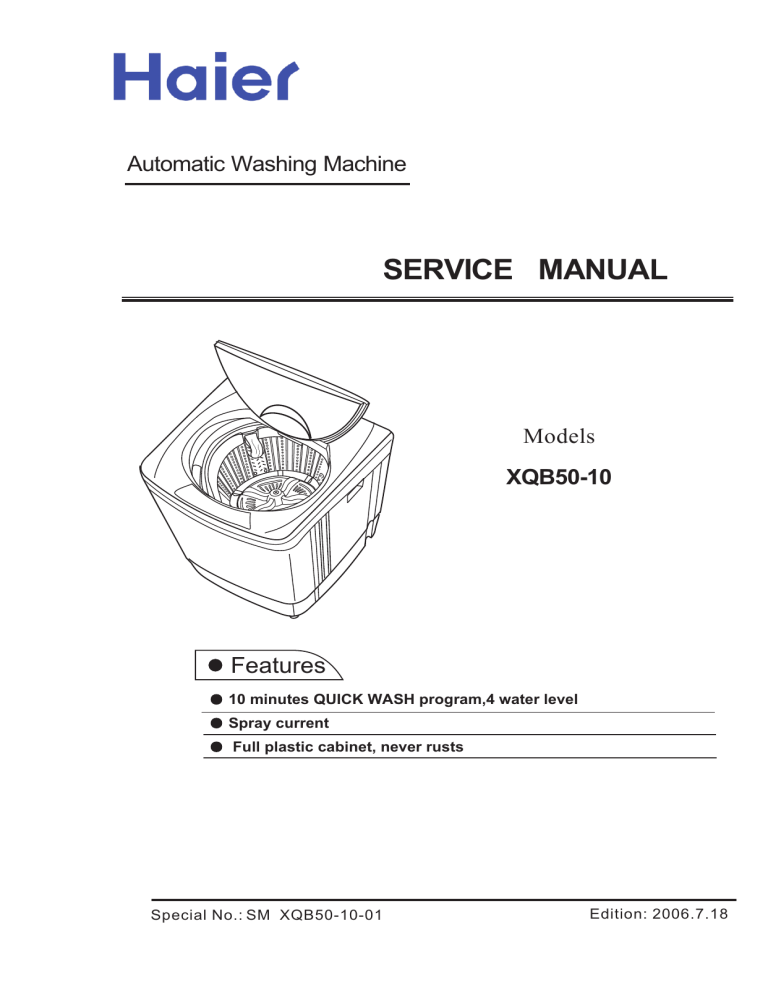

Automatic Washing Machine SERVICE MANUAL Models XQB50-10 Features 10 minutes QUICK WASH program,4 water level Spray current Full plastic cabinet, never rusts Special No.: SM XQB50-10-01 Edition: 2006.7.18 Automatic Washing Machine Model: XQB50-10 Contents 1.Contents 1 2.. Features 2 3. Specifications 3 4. Safety precautions 4 5. Warning and cautions 5 6. Net dimension 6 7. Installation and accessory parts 6 8. Parts and functions 10 9. Maintenance service and trouble shooting 11 10. Wiring diagram 17 11. Exploded view 18 12. List of parts 20 Automatic Washing Machine Model: XQB50-10 Features Brand new appearance: The model is novel and nice, with full streamline curving shape to make the whole unit compact in structure. Music prompting: It adopts the nationally originated music buzzer, which will prompt you the current mode during washing with sweet music. Low vibration and low noise: the low noise retarder clutch, motor and mute drain motor, and the advanced air damping system can guarantee the washing machine operating under low vibration and noise. Automatic power-off function: If the washing machine is not started after the power is switched on, or the washing is finished, the power will be switched off automatically after 5 minutes for the sake of safety. Alarm against breakdown: the washing machine will alarm with abnormal display and buzzer when the drain hose is not put down, or when top lid is open, or the laundries are slanting during automatic program or spinning, or when the imbalance can not be revised. Automatic imbalance-revising function: during spinning, if the laundries are slanting and bumping the tub, the washing machine will add one rinse automatically to revise the imbalance. 10-minute quick wash program (suitable for laundries less than 2.0kg): please select this program to wash laundries with light dirt. This program only costs 10 minutes for the whole washing procedure from water inlet, wash, rinse to spin. 4-water level selection: This machine offers 4 water level selection with lowest 20L level. It can offer water levels corresponding laundries from below 1.0kg to 5.0kg. It can save more water. 2 Automatic Washing Machine Model: XQB50-10 Specifications Model New Model Free standing Built under EAN code Energy eff iciency class Features for use Wash capac ity Spin capacity Preset Residual dampness Contral model contraller Normal computerized Fuzzy c omputerized Frequency c onvers ion Service features Programs Short cycle Inlet heating select Heating selection Spinning cycle (selector ) Spinning cycle (v ariable) Start/Pause Automatic balncing Aes thetics Drain type Door (glass=g / plast ic=p) Adjustable f eet Desiccatio n Air-dry Drying Te chnical d ata Voltage/f requency Water cons umtpion Wash pow er Spin pow er Special func tion Air- Bubble Feet w heel Water f all current Dimensions (measurements) Height / built under Width Depth / w ith open door Dimensions packed ( measurements packed) Height Width Depth Net weight Gross weight 20'Container load 40 Container load 40H Container load XQB50-10 × 6901570056449 — kg kg H % 5 5 <115% × × × 6 × × × F directly drain (drain down ) _ × × V/Hz L W W 110v 60Hz 117 380 250 × × × × mm mm mm 890 520 520 mm mm mm kg kg Set s Set s Set s 970 586 586 25 29 80 160 160 3 Automatic Washing Machine Model: XQB50-10 Safety precautions Please plug the plug on special 110V AC receptacle.Please guarantee that the earthing wire is ear-thed reliably. The power cord plug should be convenient to be pluged in or pluged out with hand while the washing machine runs normally. Be sure to pull the plug out and close the water tap when the machine is idle,when moving the machine,or when cleaning the machine.Do not use wet hand to insert or pull out the power plug. earth Do not bend ,extend,twist,bind by force.Do not press or nip it with weight. Keep the pin of the power plug clean,if the power plug is polluted with dust, please wipe with dry cloth carefully. Do not put the machine at damp place like the bathroom. Never wash it with water. Do Not put wet laundries on the control panel. Do not use water hotter above 50 C . In case the washing machine is installed on ground with carpet, do not block the ventilation hole with carpet. Do not wash water-proof laundries like the raincoat, bike covers etc. to avoid abnormal vibrations in spinning. The ventilation holes at the bottom soft items Do not let the machine share one receptacle with other electric appliances. If the power plug is damaged, or the plugging into the receptacle is loose, do not use the plug any more. 4 Automatic Washing Machine Model: XQB50-10 Warning and cautions Do not stretch hands into the working machine. It is dangerous even if the rotation is slow. Take special care of the children.Do not let the children climb the washing machine. Do not put any hot or heavy items (such as the kettle with hot water ) on the washing machine. Do not decompose, repair or alter the machine by yourself. Do not wash laundries with volatile materials (such as thinner, petrol etc.) l Petro The handicapped or children without care shall not use the machine. To . prevent your laundries and washing machine from damage,be sure to take out all of the foreign materials from your pocket,such as coins,buttons,sand or hairpins etc. Before washing,please check if the water tap is open ,and if the water inlet pipe is connected properly. It is suggested to use low-foaming washing powder Thinner Keep the machine away from direct sunlight and heat source like the heater. To prevent the lint in the tub from blocking the cascade outlet and influencing the cascade effect, please keep the lint filter in good condition, and install it to proper position during washing. Automatic Washing Machine Model: XQB50-10 Net dimension Unit mm Figure 1 INSTALLATION AND ACCESSORY PARTS Please install and adjust the washing machine according to the requirement of this manual. It is important for user's safe and proper using the machine. Adjust the installation position The distance of washing machine to wall should be longer than 20mm.The largest allowed slope of the base of the machine is 2 . The slanting or rough ground will result in unstable running or stoppage of the machine. Please adjust it with following methods: Confirm it's horizontal: Hang the lead line to confirm if it is horizontal. <2 Automatic Washing Machine Model: XQB50-10 INSTALLATION AND ACCESSORY PARTS Adjust the adjustable foot: 1.To twist the adjustable foot, please first lift up the side of the foot slightly, loosen the adjustable nut, and twist the foot. 2.Fasten the nut after adjustment. Adjustable nut Loosen High Fasten Adjustable foot Low How to change the direction of the drain hose 1.Lean the machine down gently with the front surface facing the ground. 3.Extend the drain hose from the left side. Push the drain hose into the groove with hands. Back Front Soft item 2.Pull out the drain hose from the right side groove. Use this groove after direction changing Push the drain hose into the groove with hands at this point Automatic Washing Machine Model: XQB50-10 INSTALLATION AND ACCESSORY PARTS Usage of the drain hose The drainage shall be smooth with the drain hose. 1.The height of the drain hose shall be less than 10cm , or the drainage will not be smooth enough and cause incomplete drainage. <10cm 2.Do not tramp or press the drain hose. 3.If the drain hose is too long, cut it at mid point. To make smooth drainage, cut the front end of the hose slantingly. 4.If extra drain hose is needed , please make separate purchase. The inner diameter of the extra hose shall not less than 40mm, and the length shall not exceed 1.5m. > 30mm <1.5m If the extra hose is too long, cut it either at point A or B. A B Automatic Washing Machine Model: XQB50-10 INSTALLATION AND ACCESSORY PARTS Install the water inlet hose 1. Insert a new flat washer into each end of the inlet hoses. Firmly put the washers in the coupling. Note: Use the new hose sets supplied with the washer. Any other old hose sets should not be used. You may have to use pliers to tighten the coupling. Do not over tighten because you may cause damage to the valve. 2. Connect the water inlet hoses to the water faucet. 3. Connect the other ends to their respective cold and hot water inlet valve located at the rear of the washer Nut of the water inlet hose Water absorption cushion Jointer of the water inlet valve 4.Fasten the nut. Swing it gently to confirm if it's suitable. Check the connection between the water inlet hose and the water tap 1.Swaying the hose gently to confirm if it is fastened stable. 2.After installation, open the tap to check if it leaks. 3.Do not bend the hose with overstrain. 4.Before each usage please check if the connection between the water inlet hose and the water tap, and the connection between the water inlet hose and washer are firm, so as to prevent dropping from improve Installation position. Take down the water inlet hose 1.Close the water tap. 2. Pull off the water inlet hose from the water tap and washer Automatic Washing Machine Model: XQB50-10 Parts and functions Top lid A Top lid B Detergent box Lint filter(Installed by user) Control panel Filter cover Inner tub Control panel film Pulsator Cabinet Figure 1 base frame Sop mat Adjustable foot water valve Cabinet handle Drain hose Power line back cover fixed foot (3) Figure 2 Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 1. Trouble alarm and solve method Phenomena The reason How to settle Buzzing upon reservation starts, Nixie tube indicates "E0" The top lid is not closed Close the top lid No or slow drain, nixie tube indicates "E1" , buzzing. Is the drain hose put down? Is the drain hose blocked by foreign material? Put down the drain hose. Open and close the top lid once. Clean the foreign material. Open and close the top lid once. Running pauses during spin, nixie tube indicates "E2”, buzzing The top cover leaves open Close the top lid Are the laundries put slantingly? Re-order the laundries. Close the top lid. Level the machine in right position. Open and close the top lid once. Safety switch actuates, not spin, (after self-correction twice), nixie tube displays "E3", buzzing Is the machine slanting? The water tap is not open No or slow water filling (not reaching the level in 15 min), nixie tube indicates "E4", buzzing The water inlet valve is blocked The water pressure is too low and the current is too small Not wash The machine does not act Not spin There's abnormal sound inside the machine The water faucet leaks Is there power failure? Is the power plug loose? Does the water level arrive at the set water level? Is the power plug loose? Is the top lid closed? Are the laundries put orderly? Is the machine slanting? Are the laundries slanting in spinning? Is the jointer screw of the water inlet hose is loose or twisted awry? Open the water tap. Push the START/PAUSE button. Clean the water inlet valve. Push the START/PAUSE button. Wait for the normal water pressure before use. Use it when the power is on. Insert the power plug tightly. Affusion to the set water level. Insert the power plug tightly. Close the top lid Put the laundries orderly. Level the machine properly. Re-order the laundries. Fasten the jointer screw properly. 2. Test program (test without water) Push and hold the PROGRAM SELECTION and PROCEDURE SELECTION buttons, then push down the power switch to enter buzzer Test program. Push the PROCEDURE SELECTION to select wash test program and spin test program. Spin test program Buzzer test program Wash test program Test name Test content Buzzer The buzzer rings once. All of the indicators flash. After 3 seconds, nixietube displays Test 88, all of the indicators flash and the buzzer rings intermittebtly 3 times (0.3s program connected, 0.3s shutoff). The power is switched off automatically after finishing. The WASH indicator flashes the STANDARD indicator is on. Run washing Wash with water for 5 minutes. During washing, you can change the current selection by Test program the PROGRAM SELECTION button The STANDARD indicator is on; WASH and RINSE indicators flash. Run spinning Spin Test without water for 5 minutes. The alarm during that procedure is the same as the program alarm in normal spinning program. 11 Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 3. Trouble-shooting charts If you replace the computer sequencer without checking the other components carefully, the computer sequencer may be damaged again. Therefore, please first check if the other components working normally before replacing the computer sequencer in maintenance. 1. No action(The indicator is off) Confirm that there's no power failure, and the power plug is inserted reliably. The power switch is at "On" mode. Measure the voltage of the two ends of the power input of the sequencer. Exist Replace the sequencer. Pull off the power Not exist plug Measure the resistance between the light blue wire terminal in the white plug on top of the wire unit and the N pin on the power receptacle. The resistance is 0. Infinite Measure the resistance between the light blue wire terminal in the red plug on top of the wire unit and the light blue wire of the lower part. Infinite Replace the wire unit. Measure the resistance between the brown wire terminal in the white plug on top of the wire unit and the brown wire of the lower part. The resistance is 0. The resistance is 0. Replace the power cord. Infinite Check if the fuse is burnt? No Yes Replace the fuse. Check if the connection between the fuse and the wires of the two ends are well? No Yes Replace the computer sequencer. Connect the fuse and the wires of the two ends. 12 At this time please check if the other electric components work normally. Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 2. No water filling Switch on the power. Push the "Start/Pause" button. Confirm the action sound of the water inlet valve? Remove the foreign materials of the water inlet valve filter screen or raise the water pressure to 0.03Mpa-0.78MPa before use. Exist Not exist Measure the voltage of the two ends of the water inlet valve? Exist Replace the water inlet valve. Not exist Measure the voltage of the two ends of the computer sequencer? Exist Replace the wire unit. Not exist Replace the computer sequencer. At this time please check if the water inlet valve works normally. 3. No rotation in washing (or rotate to one direction only) Start the test without water. Enter no-water washing. Check the action of the motor. It acts. Not exist Measure the voltage of the two ends of the motor. Not exist Exist Replace the wire unit. Measure the voltage of the two ends of the output of the computer sequencer. Not exist Replace the computer sequencer. At this time please check if the capacitor and motor works normally. Please check the transmission system carefully. If it is normal of the bearing part locking the clutch. Exist If the motor overheat protector acts? Yes Please check the reason. No If the capacitor has broken circuit or short circuit? No Yes Replace the motor. Replace the capacitor. Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 4. No draining Set rinse or spin. Start the machine. Check if the drain motor acts? Roll up normally Check the drain system like the drain valve etc. No Measure the voltage of the two ends of the drain motor. Exist Replace the drain motor No Exist Measure the voltage of the two ends of the output of the computer sequencer. Exist Replace the wire unit. No Exist Replace the computer sequencer. At this time check if the drain motor works normally. 5. Keep filling water Open the water faucet without switching on the power. If the water can fill into the water inlet valve Yes Replace the water inlet valve. No Switch on the power. Do not push the "Start/Pause" button. If the water can fill into the water inlet valve Yes At this time please check if the water inlet valve is well. No Check if the wire connecting the computer board to the water level sensor is bad? Replace the computer sequencer. Yes Replace the wire unit. No Select 1 or 2 water level and start the machine to check if the gas cell has water? Yes It leaks gas. Please check and repair the gas guide system. Please smear 801 glue in installation of the connecting pipe. Please smear 801 glue in installation of the gas cell cover. Yes Clear various factors like the foreign Materials. Blow from the connecting pipe to the water level sensor and gas cell to see if there's blocking. No Check if the gas guide system is blocked? No Replace the water level switch. Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 6. No spinning The washing and draining are normal. Check the On/Off point of the microswitch and stop switch. No On/Off point Replace the microswitch or stop switch. Normally Check if the clutch pawl is pulled enough. No Replace the drain motor. Yes Replace the retarder clutch. At this time please check if the drain motor is well. 7. Too much spinning noise If the washing machine is set horizontally? Yes Set the machine horizontally. No If the hanger is wrongly used? Yes Replace the hanger. No If the noise of the motor is too much? Yes Replace the motor. No If the motor is fastened tightly? Yes If the bearing of the retarder is well? No No Fasten the motor. Replace the retarder. Yes If the departing of the ratchet and pawl is well? Yes Adjust the angle or the distance of the ratchet and pawl. The distance between the ratchet and the pawl is above 2mm. Yes Adjust the cabinet to acquire balance. Yes Adjust the gap between the balance ring and the outer tub. No If the machine body vibrate resonantly with the cabinet? No If the balance ring is rubbing the outer tub cover? No If the connecting pipe or the wire unit bumps the outer tub? No The hanger seat is lack of oil. Inject oil at the hanger seat. Yes Fix the connecting pipe and the wire unit. Automatic Washing Machine Model: XQB50-10 Maintenance service and trouble shooting 8. Too much noise in washing If the noise of the motor is too much? No If the motor fastened tightly? Yes No Replace the motor. Fasten the motor. Yes The pulsator is rubbing the bottom of the inner tub. Add pulsator gasket. Automatic Washing Machine Model: XQB50-10 Wiring diagram The capacitor coil L is used to protect the circuit,please do not dismantle it Black White Blue Brown Coil Water inlet valve Yellow Yellow Cover switch White Blue White White Red/white Red/white Stop switch Brown Gray Brown Computer sequencer Orange Orange Control panel seat Water level sensor Figure 1 There is overload protector installed in the motor. In case that the motor is overload or meets breakdown in working, the protector will act and stop the motor. When the breakdown is removed, the motor will resume normal working. Actual Circuit Diagram Blue Yellow Retractor Cabinet White Motor Capacitor Red Yellow Red Red Blue White Brown Fuse Black 17 Figure 2