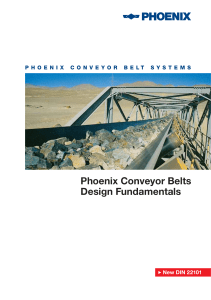

28/6/22, 11:45 Rubber Conveyor Belt Grades Explained - Blog - DYNA Engineering DYNA Engineering Rubber Conveyor Belt Grades & What They're Used For When looking at rubber conveyor belts, on the surface they all appear very similar. However, when designed and manufactured correctly, each different specification of rubber conveyor belting can have special properties to suit particular applications. The following different rubber grades follow the ISO 433 standard. Want to start off with the basics? Learn all about rubber/textile conveyor belts on our blog post ‘Understanding Textile Belts’. https://www.dynaeng.com.au/dyna/blog/rubber-conveyor-belt-grades-what-used-for/#:~:text=General-purpose rubber is the,when compared to Grade N. 1/5 28/6/22, 11:45 Rubber Conveyor Belt Grades Explained - Blog - DYNA Engineering Grade A - Abrasion Resistant Abrasion-resistant rubber, also known as Grade A, is used when the conveyed material is very rough and abrasive, and causes the rubber to wear from the belt too quickly. The conveyor’s specific cleaning system, such as brushes, scrapers and/or conveyor skirting, can also contribute to conveyor belt wear. Grade A rubber is used when the wear of the conveyor belt would occur too quickly when using general purpose grades. Even though Grade A rubber is more costly than general purpose grades, the cost of removing and installing replacement belts frequently can be excessive. Therefore, it may be more cost effective to go with a higher-wear rubber. An example of when you would use Grade A rubber belt would be on an iron ore conveyor. Iron ore is a very abrasive material and would wear away standard rubber quickly. Grade A rubber would give the conveyor belt a greater life and more up time on the conveyor. Grade E – Static Electricity Conducting As the name suggests, static electricity conducting rubber conveyor belting conducts static electricity produced during the transport and conveying process, and discharges the electric charge – usually into a grounding path. Minimising sparks from static electricity is a necessity when in the presence of potentially explosive materials such gases, liquids, powder and dust because the risk of explosion can be deadly. A common use of Grade E rubber belting is at a aluminium refinery. Aluminium can commonly discharge excess electrons which can cause a static electricity build up. Static electricity conducting belts are used to absorb the excess electrons and discharge them safely. Grade F – Fire Resistant Fire-resistant belting is usually used when transporting heated materials. Rubber has natural properties which can be ignited and burn. Grade F rubber belting has added properties which increase the ignition temperature and increases resistance to fire. An example of the use of Grade F rubber belts are at underground mines, coal mines and power stations. If a rubber conveyor belt were to catch underground, the smoke and air hazards could be potentially fatal, therefore fire-resistant belts are usually used to mitigate the risk. Work at coal mines and power stations involve heat processes. Fire-resistant belts help to reduce the risk of the heated process causing the conveyor belt to ignite. Grade M & N – General Purpose General-purpose rubber is the most common type of rubber conveyor belt and is used when special properties are not needed to suit an application. https://www.dynaeng.com.au/dyna/blog/rubber-conveyor-belt-grades-what-used-for/#:~:text=General-purpose rubber is the,when compared to Grade N. 2/5 28/6/22, 11:45 used Rubber Conveyor Belt Grades Explained - Blog - DYNA Engineering e spec al p ope t es a e ot eeded to su t a appl cat o . Grade N rubber is lower quality compared to Grade M. Grade M rubber has greater hardness, is more abrasion-resistant and is superior in strength when compared to Grade N. Therefore the only difference between Grade M and Grade N rubber is the quality of the rubber. Grade S – Static Electricity Conducting and Fire Resistant This is a combination of both Grade E and Grade F rubber. Grade S rubber conveyor belts are both static electricity conducting and fire-resistant. The reason this combination exists is because combination is the commonly used. Grade Z – Special Properties Grade Z rubber belting is a specially designed conveyor belt to suit a particular purpose. This grade is used when the rubber properties do not fit in any of the other categories. Combined Grades More than one grade can be used on a single rubber conveyor belt. For example, Grade MA rubber is both general purpose and abrasion resistant. DYNA Engineering Conveyor Belt Range DYNA Engineering conveyor belts are available in a complete range of fabric and steel cord construction. Our range includes rubber/textile belts, steel cord belts, and Chevron rubber belts. Our belts are all made to Australian Standard and can incorporate all the grades and special properties mentioned above. To find out what grades and special properties are best suited to your application, contact a DYNA Engineering representative today at dyna@dynaeng.com.au Related Blog Posts https://www.dynaeng.com.au/dyna/blog/rubber-conveyor-belt-grades-what-used-for/#:~:text=General-purpose rubber is the,when compared to Grade N. 3/5 28/6/22, 11:45 Rubber Conveyor Belt Grades Explained - Blog - DYNA Engineering Common Causes of Belt Damage Understanding Textile Belts Common Causes of Belt Mistracking Conveyor belts are a viable component in a When it comes to textile rubber conveyor maintain them correctly and minimise any different types and specifications can be some attention. The photo above shows a types, thicknesses… held in place by a rope. It’s common to see conveyor system. It is important to potential stoppages or damage to maintain the maximum up time and service life… Read More belts, also known as fabric belts, the Sometimes conveyor training rollers need overwhelming. There are so many different traditional training roller and frame being trainers tied with rope… Read More Read More Newsletter Stay up-to-date with our newsletter subscription! Subscribe Now PREVIOUS NEXT 5 Benefits of Conveyor Skirting Polyurethane vs Carbide Belt Scraper Blades Links Home Products Brochures Blog Services About Us Contact Us About DYNA Engineering is proudly Australian owned and operated in Bayswater, Western Australia. We have been specialising in the design, manufacture and supply of quality conveyor components for over 30 years. We also offer conveyor related services. Contact dyna@dynaeng.com.au 08 9473 4300 or 1800 801 558 https://www.dynaeng.com.au/dyna/blog/rubber-conveyor-belt-grades-what-used-for/#:~:text=General-purpose rubber is the,when compared to Grade N. 4/5