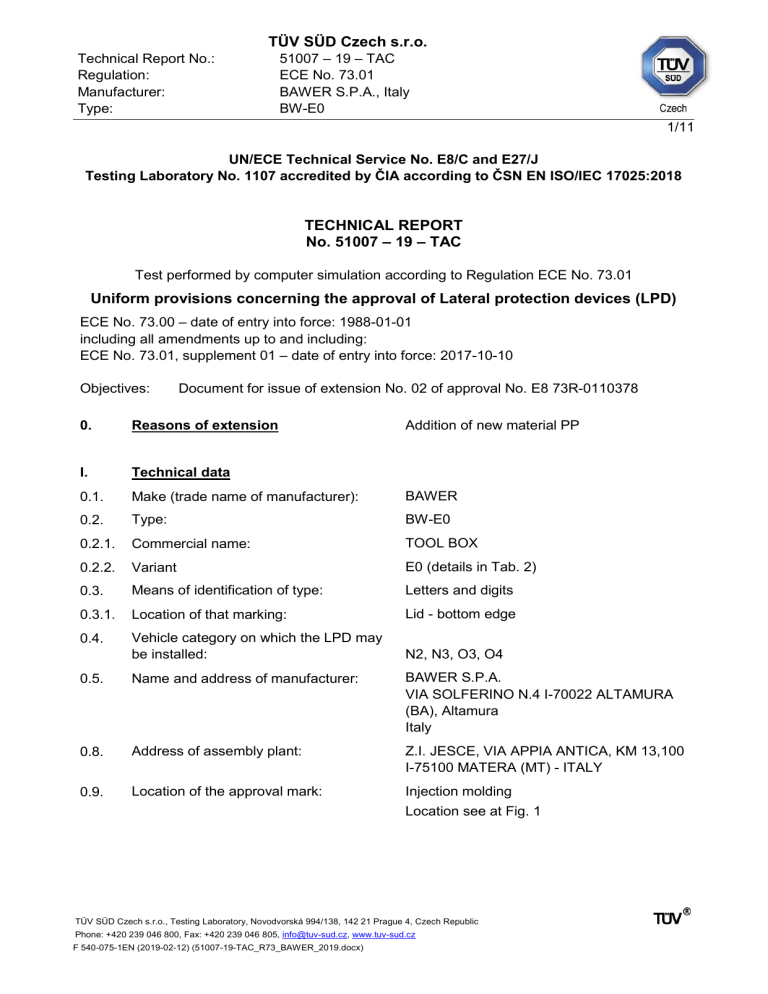

TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 1/11 UN/ECE Technical Service No. E8/C and E27/J Testing Laboratory No. 1107 accredited by ČIA according to ČSN EN ISO/IEC 17025:2018 TECHNICAL REPORT No. 51007 – 19 – TAC Test performed by computer simulation according to Regulation ECE No. 73.01 Uniform provisions concerning the approval of Lateral protection devices (LPD) ECE No. 73.00 – date of entry into force: 1988-01-01 including all amendments up to and including: ECE No. 73.01, supplement 01 – date of entry into force: 2017-10-10 Objectives: Document for issue of extension No. 02 of approval No. E8 73R-0110378 0. Reasons of extension Addition of new material PP I. Technical data 0.1. Make (trade name of manufacturer): BAWER 0.2. Type: BW-E0 0.2.1. Commercial name: TOOL BOX 0.2.2. Variant E0 (details in Tab. 2) 0.3. Means of identification of type: Letters and digits 0.3.1. Location of that marking: Lid - bottom edge 0.4. Vehicle category on which the LPD may be installed: N2, N3, O3, O4 0.5. Name and address of manufacturer: BAWER S.P.A. VIA SOLFERINO N.4 I-70022 ALTAMURA (BA), Altamura Italy 0.8. Address of assembly plant: Z.I. JESCE, VIA APPIA ANTICA, KM 13,100 I-75100 MATERA (MT) - ITALY 0.9. Location of the approval mark: Injection molding Location see at Fig. 1 TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 Technical Report No.: Regulation: Manufacturer: Type: 2/11 II. Test report 1. Test conditions 1.1. Test sample: The lateral protection device type BW-E0. Type, variant: BW-E0 Length 1000 mm Height 503 mm Depth 460 mm Materials PP, S235JR (details in Tab. 1) Material E modulus [GPa] 210 1.4 S235JR PP Yield strength [MPa] 235 24.5 Ultimate strength [MPa] 360 - Ductility [%] 26 50 Parts Support rods Box, lid, bushings Tab. 1 - Material properties 1.1.1. Technical data from the manufacturer: 1.1.1.1. Length of box: 300 – 1000 mm 1.1.1.2. Height of box: 300 – 503 mm 1.1.1.3. Depth of box: 300 – 460 mm L VARIANT DIMENSION [mm] H D MATERIALS THICKNESS MIN FINISHING 3,00mm - 0,10 BLACK PLASTIC Min Max Min Max Min Max E0 300 1000 300 503 300 460 PP E1 300 1000 300 503 300 460 PA6-30%GLASS FIBER 3,00mm - 0,10 BLACK PLASTIC Tab. 2 - LPD Variants - Technical data Testing laboratory does not bear any responsibility for possibly incorrect values of dimensions and materials including material data provided by the manufacturer and for test results found out based on these values. TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 3/11 1.2. Test procedures used: According to accredited procedure (1.14) of the non-linear calculation using FEM of lateral protection device according to ECE Regulation No. 73.01, par. 12, Annexes 3, 6. A horizontal static force of 1 kN is applied perpendicularly to any part of LPDs external surface by the center of a ram the face of which is circular and flat, with a diameter of 220 mm + 10 mm. The locking system is excluded from the simulation model. Its function is to keep the lid closed and locked to the body. No forces are transmitted via the locking system during the test. Load force acts in the direction of lid closing. The removable cassette was removed from the simulation model after consultation with customer. 1.3. Measuring and test equipment: Preprocessing: ANSA 19.1.1 Calculation: 1.4. Worst case evaluation: PamCrash 2016.05 The worst-case variant was chosen. The tested sample is the worst case with regard to the dimension of the device. Two worst loading cases were identified. LPDs support system is set to the most outward position. First worst case is the middle position on the lid. The load force bending arm on the lid is maximal in this position. Second worst case is the bottom edge corner of the lid. The force is concentrated more to one of the support assemblies and the bottom load position cause maximal bending moment in whole LPD structure. Both load positions can be seen on Fig. 2. 1.6. Test track or site: TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 4/11 1.7. Test criteria: The deflection of the device under load measured at the centre of the ram is not more than: (a) 30 mm over the rearmost 250 mm of the device; and (b) 150 mm over the remainder of the device. 2. The lateral protection device was loaded in accordance with Regulation No. 73.01. The load force is at Fig. 7. Maximal deflection of the LPD from both load cases is in Tab. 33. Overall deflection can be seen at Fig. 3 and Fig. 4 Test results Load case Load point Criterion [mm] Deflection under the load [mm] Residual deflection [mm] 1 2 Center 150 24.0 126.0 Bottom edge 30 6.1 23.9 Tab. 3 - Worst case deflections 3. Specimen submitted to test on: 2019-09-16 4. Date of test: 2019-11-25 III. Manufacturer’s information folder No. R073 – BW-E0 Revision 02 14 pages total of 2019-10-07 IV. Other documentation Figures: Drawings: Graphs: page 6-8 page 9-10 page 11 TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 Technical Report No.: Regulation: Manufacturer: Type: 5/11 V. Attachments No attachments The results presented above relate to the tested items only and to the sample as provided by the customer. Measuring and test equipment and test site meet the requirements of the applicable legislation. This report must never be reproduced incomplete and without a written permission of the testing laboratory. TÜV SÜD Czech confidentiality degree: confidential The final assessment and worst case evaluation exceed the accreditation scope. VI. Final assessment The described sample complies with the requirements of ECE Regulation No. 73.01 for issue of extension of approval This technical report consists of pages No. 1 to 11. Jakub Jelínek Vít Bursík Test executive Officially recognized expert Prague, 2019-11-26 TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 6/11 Figures: Fig. 1 – Marking location TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 7/11 Load 1 - center Load 2 – bottom edge Fig. 2 - Load positions TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 8/11 Fig. 3 - Load case 1 - Max. deflection (the criterion is 150 mm, fringe max is set to 28 mm for better visibility) Fig. 4 - Load case 2 - Max. deflection (the criterion is 30 mm, fringe max is set to 7 mm for better visibility) TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 9/11 Drawings: Fig. 5 - Tool box dimension TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 10/11 Fig. 6 - Tool box with support system TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx) TÜV SÜD Czech s.r.o. Technical Report No.: Regulation: Manufacturer: Type: 51007 – 19 – TAC ECE No. 73.01 BAWER S.P.A., Italy BW-E0 11/11 Graphs: Fig. 7 - Loading force End of the technical report TÜV SÜD Czech s.r.o., Testing Laboratory, Novodvorská 994/138, 142 21 Prague 4, Czech Republic Phone: +420 239 046 800, Fax: +420 239 046 805, info@tuv-sud.cz, www.tuv-sud.cz F 540-075-1EN (2019-02-12) (51007-19-TAC_R73_BAWER_2019.docx)