DaimlerChrysler Corporation

Packaging and Shipping

Instructions

REDUCE

US

CL

E

RE

CY

E

RE

REVISED JULY 1, 2002

OUR PACKAGING AND

SHIPPING GOALS

ARE

To deliver defect-free parts without damage, on time, cost effectively,

directly and with as little handling as possible AND

To achieve 100% use of returnable containers, thus eliminating the waste and

expense of cardboard and packaging by-products in DaimlerChrysler Corporation.

Scope: These instructions are applicable to DaimlerChrysler Corporation, DaimlerChrysler

de Mexico S.A. de C.V., DaimlerChrysler Canada Inc. and their suppliers.

CONTENTS

Section ........................................................... Page

Section ........................................................... Page

1.0

Introduction .......................................................................... 1

1.1

Compliance ........................................................................... 1

2.0

Packaging & Shipping Data ................................................... 1

3.0

General Requirements ....................................................... 1, 2

5.6.6

5.6.7

5.7

5.8

5.9

5.10

5.10.1

5.10.2

Removal of Old Labels ........................................................ 14

References ........................................................................... 14

Cleaning, Damage & Repair of Containers ......................... 14

Implementation to Returnable/Expendable Programs .......... 15

Combination Returnable & Recyclable ......................... 15, 16

Types and Descriptions ........................................................ 16

Racks ................................................................................... 16

Standard Containers ....................................................... 16-20

4.0

4.0a

4.1

4.1a

4.2

4.2a

4.3

4.3a

4.3.1

4.3.1a

4.3.2

4.3.3

4.3.4

4.3.5

Recyclable Packaging ............................................................. 2

Payment for Expendable Packaging - 092 Process .................. 2

Wooden Pallets .................................................................. 3, 4

Wooden Pallets - Four Way Entry .......................................... 4

Corrugated Pallets ................................................................. 4

Corrugated Pallets (International Only) ................................. 4

Expendable Containers .......................................................... 5

Proper Palletization ................................................................ 6

Corrugated Pallet Boxes ......................................................... 6

Corrugated Pallet Boxes (International Only) ........................ 6

Corner Supports .................................................................... 6

Corrugated Cartons ........................................................... 6, 7

Interior Dunnage ................................................................ 6-8

Containment ......................................................................... 9

5.0

5.1

5.1a

5.2

5.3

5.4

5.5

5.6

5.6.1

5.6.1a

5.6.1b

5.6.1c

5.6.1d

5.6.1e

5.6.1f

5.6.1g

5.6.2

5.6.3

5.6.4

5.6.5

Returnable Containers ........................................................... 9

Recyclable Backup ................................................................. 9

Recyclable Backup (International Only) ........................ 10, 11

Ownership .......................................................................... 12

Identification ....................................................................... 12

A.S.N.s - Advance Shipping Notes ...................................... 12

Container Shortages and Overages ...................................... 12

Labels .................................................................................. 12

Destination Label and Shipping Instructions ....................... 13

Label ................................................................................... 13

Bar Code Labeling ............................................................... 13

Tags (Hang Tags) ................................................................. 13

Label Location ..................................................................... 13

Destination Label ................................................................ 13

Label Protection .................................................................. 13

Plant Shipping Address ........................................................ 13

Packaging and Shipping Label ............................................. 14

Multiple, Common Item Packs ............................................ 14

Mixed Item Loads ................................................................ 14

Cardholder Label Plate ........................................................ 14

6.0

6.1

6.1.1

6.2

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.3

6.4

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

Transportation ..................................................................... 21

Primary Modes .................................................................... 21

Railroad Boxcar ................................................................... 21

Truckload Direct Carrier ..................................................... 21

Intermodal .......................................................................... 21

Truckload Geographic Shipping/Receiving .......................... 22

Scheduled Delivery Program ............................................... 22

Dedicated Logistics Centers ................................................. 22

Common Carrier (LTL) ...................................................... 22

Supplier Delivery/Private Carrier ......................................... 22

Parcel Delivery .................................................................... 22

Emergency Methods ............................................................ 22

Packing Slips and Bills of Lading ......................................... 22

Direct Shipments ................................................................ 22

Consolidation ...................................................................... 22

Customs Papers ................................................................... 23

Third Party Consignment .................................................... 23

Packing Slips ....................................................................... 23

7.0

Forms and Exhibits ................................................... 23, 29-35

Label Locations on Various Shipping Packs .................... 24, 25

Master/Mixed Load Labels .................................................. 26

Destination Label ................................................................ 27

Packaging & Shipping Label Detailed Outline .................... 28

Unit Load Data Sheet (ULDS) ............................................ 29

U.S. Customs Invoice .......................................................... 31

Supplier Container Cost Analysis ........................................ 33

Test Package ........................................................................ 35

Package Data Sheet .............................................................. 37

Glossary ............................................................................................ 39

Sources to Obtain this Manual ......................................................... 40

of handling planned for the final destination and its

intended point of use. Recyclable dunnage,

containers and/or supplier owned returnables must

be approved by the receiving plant’s Material

Handling Engineer.

1.0 Introduction

The following are DaimlerChrysler’s packaging and

shipping requirements to which each supplier must

adhere. This revised version of the manual

becomes effective July 1, 2001 and supersedes the

prior July 1,1999 publication. The purpose of this

manual is to inform our supply base of our general

guidelines required to achieve optimum part quality

delivery to and zero solid waste discharge from our

facilities. With the cooperation of all parties, we can

continually make improvements, increase our

competitiveness, and minimize costs.

To ensure that all packages and shipments will reach

their intended point of use without damage to parts,

all packages must be tested under simulated real-life

conditions. Initial shipments of new packaging must

be accompanied by a completed version of the Test

Package label (See Page 33). Suppliers looking for

other testing guidelines may refer to ASTM standards

D-4169, D-1083, and D-999. DaimlerChrysler’s

Corporate Material Handling Engineering

Department will provide feedback to suppliers

regarding the results of the Test Package shipment

and the acceptability of the package design.

1.1 Compliance

Due to the significant importance to our

operations, the adherence to these packaging and

shipping requirements is mandatory and will be

continuously monitored. Non-compliance to the

instructions contained in this manual will be

brought to the attention of the supplier by means

of an RDR, “Receiving Discrepancy Report” issued

by our receiving plants. RDR’s may also be issued

by DCX (SUPPERS) approved Logistics providers

(consolidators/poolpoints).

Charges for repackaging and/or disposal of any

non-recyclable materials will be billed back to the

shipping location. Any persistent violation or

recurring problem will be referred to the

appropriate DaimlerChrysler buyer for corrective

action as necessary.

All features/surfaces considered critical to the quality

or operation of the part (e.g., machined surface, bore,

etc.) must be protected from damage and/or

moisture, road dust, wood chips, or other debris as

required by DaimlerChrysler Product Engineering.

Protective caps and plugs used to protect these

surfaces must be made of clear, low density

polyethylene, LDPE, SPI4, unless otherwise

specified.

Supplier initiated packaging or cost improvements

are encouraged, but must be initiated and approved

through the DaimlerChrysler Program to ensure that

our plants’ productivity is not adversely affected.

2.0 Packaging and Shipping Data

Upon quotation all suppliers must furnish the actual

cost for each item purchased to package the part to

the appropriate purchasing activity via the Package

Data Sheet, Clause Number 282, (See Page 35 for

form 84-183-8000). Costs for the pallet, box or

container, dunnage, and containment (e.g., strapping

or glues), must be submitted separately for inclusion

into the purchase order.

3.0 General Requirements

The determination of the type of recyclable dunnage,

containers and/or supplier-owned returnable (per

guidelines on Pages 2-9 of this manual) package

design is the supplier’s responsibility, and the supplier

must ensure that the parts and all packaged

shipments are received in acceptable (damage free)

condition and are efficiently and economically

packaged for the method of transportation and type

All packaging must conform to all government and

transportation rules and regulations.

The packaging of hazardous materials must follow

relevant regulations of the U.S. Dept. of

Transportation, which prescribes the proper method

of classification, packaging, marking, and labeling of

each shipment. Furthermore, where other federal,

state, or local standards and/or regulations are in

effect the packaging and labeling must comply.

1

For all manually handled conveyances, the container

and product gross weight combined must not exceed

local plant contractual limits or governmental

regulations. NOTE: DaimlerChrysler Ergonomic

Guidelines currently recommend for small lot

containers containing product, a maximum weight of

30 lbs (13.63 kg).

Except in emergency situations and with expedites,

suppliers must request deviations from these

guidelines in writing from the affected receiving

location. Deviations originating from

DaimlerChrysler Corporation will be provided to the

supplier in writing by the affected activity.

When recyclable packaging is used instead of the

returnable container, the associated container entry

for the part A.S.N. must be either “00000EXP” or

“0000EXPM,” as appropriate.

Mixing of part numbers on a pallet unit load is

discouraged. However, when unavoidable due to

handling/shipping expense, unit loads must have the

proper “Mixed Load” label as seen on page 26. Each

unit load must also be identified with a properly

addressed “Destination Label” (See Page 27). A

“Master Label” must be used when multiple packs

of the same part numbers are shipped, each shipment

must be properly labeled. For further clarification,

reference Trading Partner Labels Manual Level B10

(May 1995) and section 5.6 of this manual.

4.0a Payment for Expendable Packaging - 092

Process

The supplier is required to submit for 092 payment

on the ITA segment of the ASN. Starting January 2,

2001, 092 charges will not be accepted through an

810 transaction for all North American ERS plants.

If your PRIMARY packaging for a part is expendable

and NOT returnable, your expendable charges must

be in the 198 clause on your PO. The container

number assigned to these parts is EXPLLLWWHH,

showing the length width and height of the

cardboard box.

Suppliers must assure that packaging materials in

need of repair are not used for shipping purposes.

Suppliers must follow their “Routing Instructions”

and use the specified transportation designated by

DaimlerChrysler Logistics.

If you are assigned a container and are out, and need

to ship in cardboard, you are to put 00000EXP or

0000EXPM on the ASN in the associated container

line and in the RC line.

DaimlerChrysler Material Handling Engineering and

the receiving location have the option, if necessary, of

approving or rejecting a supplier’s selection of

packaging materials and sources.

Effective January 2, 2001 Prior to shipping

expendable packaging (cardboard), as a legitimate

alternative to the assigned returnable container, into

4.0 Recyclable Packaging

All packaging previously referred to as expendable, will

for the intent of this manual be referred to as recyclable.

For more information reference AIAG RC 7 & 8.

Width

Length

Overall

Height

Notched Stringer

(Runners)

Figure 1. Flush Notched Stringer

Type Pallet (4 way entry)

Opening 2-1/2” from top of notch to

bottom of bottom deckboard

Opening

Height 3-1/2”

2

ANY DaimlerChrysler facility, excluding Mopar,

Mexico, and International, a supplier must contact

LINC.

4.1 Wooden Pallets

Type

All wooden pallets shipped into DaimlerChrysler

facilities must be of double face non-reversible wood

construction and be of flush stringer design, (Figure 1).

Supplier must provide: a contact name, phone

number, supplier name, supplier code, part number

shipped in expendable, date of expendable shipment

and the plant to which the expendable was shipped.

The Ship ID number or SID number reported to

LINC must match exactly what is submitted to

DaimlerChrysler for payment of the 092. Invoices

for cardboard will be rejected if this communication

is not made prior to a shipment of parts in

expendable packaging. The LINC operator is

responsible to provide the supplier with an incident

number; provided either over the phone or as a reply

to the suppliers e-mail. The supplier should record

the incident number as a reference if questions arise

regarding 092 invoices. Invoices for cardboard will

be rejected if this process is not followed.

Single wing, double wing, or block pallets are not

allowed.

Pallets must not be smaller in length and width than

the load.

All pallets must be able to support a 2800# load

while triple stacked; wooden pallets must conform to

Spec M of the Uniform Voluntary Standards for

Wooden Pallets published by The National Wooden

Pallet and Container Manufacturers Association, and

be stencilled in letters no less than 1-1/2” high on a

stringer “SPEC M” for multiple use and the

dimensional length and width.

Please fill out the Supplier Container Cost Analysis

form in the back of the manual when submitting

for packaging costs.

Deck Boards

All deck boards must be either 32” (812mm) or 48”

(1219mm) in length, no less than 5/8” thick, and

attached by a minimum of two double screw nails on

each side to the stringers parallel to the 3.5” (88mm)

entry openings.

Figure 2. Typical Corrugated Pallets

3

dispensation, on International shipments. If you are

concerned that the weight of your load cannot be

supported by a corrugated pallet, contact your Corporate

or Plant Material Handling Engineer for approval prior

to shipping.

Cross Ties

All pallets and pallet bins must be constructed with

cross ties on the stringers (runners) identical to the

deckboards.

Footprints & Entry

Four footprints are allowable:

Entry

Width

Length

2

30” (762mm) X 32” (812mm)

4

40” (1016mm) X 48” (1219mm)

4

45” (1143mm) X 48” (1219mm)

4

48” (1219mm) X 54” (1372mm)

Use of larger sizes (i.e., sea-containers) requires plant

approval.

Reuse

Pallets meeting DaimlerChrysler’s specifications can

be, and are encouraged to be, reused provided they

are inspected for durability prior to shipment and

conform to the requirements of the Voluntary

Standards for Wooden Pallets published by the

NWPCMA.

Repurchase

Suppliers wishing to purchase quantities of the

specified pallets back from DaimlerChrysler may

contact our plant recycling teams.

4.1a Four Way Entry

All pallets are to be four way entry. Deviations must

be approved by the receiving plant.

4.2 Corrugated Pallets

Corrugated pallets are an allowable alternative to

wooden pallets in lightweight applications if they are

recyclable, (i.e., not impregnated with polymers or

wax). Use requires prior approval, in writing, from

the receiving location and/or Corporate Material

Handling Engineering. If used, they are to meet the

footprint specifications for wooden pallets and be

designed to withstand 90% humidity at 150 degrees

Fahrenheit (65.6 degrees Celsius) exposure during

handling, transit and storage.

Some examples of typical corrugated pallets are

shown in (Figure 2).

Figure 3. Certificate of Box Maker

4.2a Corrugated Pallets (International Only)

Corrugated Pallets are mandatory, unless given prior

4

a. Handling labor

b. Handling equipment

c. Transportation cost

(cube utilization)

d. Packaging

e. Floor space

f. Direct labor

g. Recyclability

4.3 Expendable Containers

Generally, selection of a corrugated container will

depend upon the specific part or material, the

method of transportation and the method of

handling required by the supplier and the receiver.

However, certain basic factors deserve consideration.

Packages which are to be manually handled are

subject to more rough handling than those handled

mechanically and consequently require more

protection. Package size, strength and type must be

selected to fit the method of transportation and the

applicable carrier regulations, extent of protection

from the elements, number of transfer points,

distance of travel, and the roughness of route.

The specific method used should be chosen to best

fulfill the prerequisites of good packaging practice for

any given commodity.

Other factors of equal importance that must receive

due consideration are the packaging costs. In

finalizing the design, the following factors must be

considered:

Figure 4. Breakaway pallet box

with perforations on bottom.

Paper Tube

Corrugated

Column

Pre-Formed

Paper Column

WOOD

PAPER

Figure 5. Corner support options.

5

All expendable containers must be loaded to cubic

capacity to maintain load density and package

integrity, and to obtain optimum freight rates.

However, containers should not be stacked, unless

they are the same type of container. (i.e.

EXP0583232 and EXP0483424 should not be

stacked on top of each other).

110” (2794mm) under full load. If attached to a

wooden pallet, they must also be of breakaway design

with minimal staple usage to allow easy disassembly

(Figure 4). The breakaway design features die cut

perforations on the top and bottom flanges. Staples

are placed inside the perforated area to secure the box

to the pallet or top supports. Boxes must contain

cutting guides to prevent part damage.

4.3a Proper Palletization

Each shipping unit must be properly palletized in

level layers to allow for stacking and proper

utilization of transportation. (Note: If your

“Standard Pack Quantity”(defined in glossary) does

not equate to a level layer contact the appropriate

Plant “Just in Time” JIT coordinator or Plant

Logistics Analyst for resolution.

Each pallet box must be properly labeled on two

adjacent sides per DaimlerChrysler Labeling

Instructions (see Section 5.6).

4.3.1a Corrugated Pallet Boxes (International

Only)

All corrugated pallet boxes must be of sufficient strength

to withstand triple stacking to a height of 110” under

full load. If however, you are using your corrugated

pallet box for International shipments, the stacking

height requirements is to 88”.

It is mandatory that when a supplier ships in

sufficient volume to warrant palletization that the

parts or materials be loaded on a pallet or packaged as

a unit load.

4.3.2 Corner Supports

When corner posts are required for stacking strength,

the preferred option is corrugated posts glued into

place. Wooden corner supports require plant

approval and must not be stapled to the boxes,

instead they are to be held in place by use of die cut

fold ins (Figure 5) with the flaps stapled over them.

All containers, trays, caps, and multi-wall tubes must

have a manufacturer’s certificate with bursting,

puncture, or ECT edge crush test visible on the

assembled container (Figure 3).

Rice paper, or yellow corrugated is not allowed.

Shipments to Europe and Mexico may require more

durable packaging than materials shipped to the US

and Canada. Shipments to our European operations

require the use of specially designed, stackable

containers used to fully cube out the ISO container.

4.3.3 Corrugated Cartons

Two basic types of corrugated cartons are allowable;

(Pages 7 & 8) however the only acceptable methods

of sealing manually handled cartons are strippable

reinforced tape or spot gluing. Asphaltic or plastic

tapes are not allowed. Staples are only acceptable

with prior approval from the receiving plant.

4.3.1 Corrugated Pallet Boxes

All corrugated pallet boxes must be of sufficient

strength to withstand triple stacking to a height of

Cartons must not overhang the pallet or weigh more

than maximum allowed by local plant contractual

limits or governmental regulations. (See NOTE on

page 2 for limits).

Carton sizes must be equivalent (dimensions/density) to

existing DaimlerChrysler standard returnable containers

used in assembly and manufacturing locations.

All cartons must be secured to a pallet per

DaimlerChrysler guideline 4.3.5.

Figure 6. Properly Palletized

6

All cartons shipped on a pallet must be properly

palletized (Figure 6).

standard J-1344 and/or meet any local governmental

regulations which may apply.

Mixed loads are to be properly labeled per

DaimlerChrysler Labeling Specifications (see Section

5.6) and the following criteria must be observed

when shipping to a manufacturing plant:

Dunnage should be designed to minimal levels, (e.g.,

as little as possible) and still protect the part.

The following are not allowed as packaging

materials for DaimlerChrysler:

a. Right and left hand parts are not to be mixed

on the same pallet.

b. Cartons must be uniform in size to maintain

load stability.

c. Only one plant per load.

d. Avoid shipping less than a full layer.

Starch

Co-polymers, SPI 7

Cross link polyethylene

PP-Polypropylene, SPI 5

ABS-Acrylonitributylstyrene

EPS (sheets also)

Rubber - rice paper

Co-mingled material

Foam sheeting - wooden crates

Cushion foam pkg

4.3.4 Interior Dunnage

No mixed material is acceptable.

All plastic materials must be recyclable and marked

with the standard symbol in accordance with SAE

Half Slotted

Box with

Cover (HSC)

Can be used as combination shipper and self

package and for various applications where cover

must be removed and replaced.

Single Face

Consists of one layer of corrugated medium

bonded to single layer of linerboard. Provides

cushioning for products wrapped in it.

7

Single Wall

Has a second facing glued to the other side of

the fluted medium. Results in a rigid structure.

Double Wall

Adds another fluted medium and another sheet

of linerboard for greater strength. It has three

facings with two fluted corrugated medium sheets

between them. Has a high stacking strength and

is a good application for heavy products.

Triple Wall

Consists of four facings with three fluted

corrugated medium sheets between them. Offers

exceptional strength for packaging very large or

heavy products.

8

4.3.5 Containment

The preferred method of containment is plastic, heat

sealed strapping of green polyester. The use of

unitizing adhesives for cartons is acceptable and

encouraged. It is the suppliers responsibility to secure

all material unit loads with adequate banding.

5.1 Recyclable Backup

Suppliers must maintain a sufficient supply of

suitable recyclable packaging to be used for

expedited shipments, production pilot programs,

alleviating container shortages, service orders,

and/or plants not participating in the returnable

container program, e.g., CKD. This backup

packaging must be dimensionally (interior) the

same as, be in the same footprint as and maintain

the identical density as the returnable container it

is replacing. Each backup recyclable container

must accommodate the identical interior dunnage

(where required) as the corresponding returnable

container. Identical footprints are required to

insure that line display and workstations do not

demand layout restructuring when wrong-sized

alternative packaging is used. Backups must also

meet all other applicable corporate material

handling specifications if used. (Also reference the

Process Sign-Off Procedure and the Production

Part Approval Process).

Metal banding and/or seals are allowed on an

exception basis only.

PVC stretch film is not allowed.

Shrink film is acceptable only if any labels used

and adhered to the film are of the same material.

5.0 Returnable Containers

Returnable containers are intended to be used

repeatedly and frequently and have proven to be the

packaging of choice for DaimlerChrysler. Their

success as cost effective packaging depends on how

well they are cared for, controlled, and returned to be

reused.

A variety of factors deserve consideration in the

decision to use returnables, factors such as:

a.

b.

c.

d.

e.

f.

g.

Initial cost

Facility/equipment constraints

Repair costs

Transportation costs

Standardization

Return ratio

Geographic relationships

(location of suppliers)

h. Volume

i. Handling costs

j. Cleaning

k. Environmental concerns

l. Product protection

m. Tracking costs

n. Administrative costs

o. Visual inventory management

p. Ergonomic issues

Due to these factors returnable containers are not

always the most cost effective choice for packaging.

(For more information reference AIAG-RC-5).

9

5.1a Recyclable Backup (International Only)

In most cases the Recyclable Backup container may be used as the International Shipping Carton (container). The

following dimensions were designed for sea container cube utilization. The small lot sizes are similar to

DaimlerChrysler’s returnable tote system. These sizes are required unless otherwise in agreement with the receiving

plant. The supplier is responsible for the packaging design, prototype, and purchase of all corrugated packaging.

Carton Inside

Dimensions

Corrugated

Carton Code

Carton Outside Dimensions

Length Width Height Length

Width

Height

Carton Specifications HSC

Compres(Lids = 200# B

sion

Single Wall)

Value

(pounds)

CM120705

9.9

5.5

4.3

11.8

6.1

4.6

611

CM121505

13.9

10.1

4.3

15.7

10.7

4.6

749

CM121507

13.9

10.1

6.9

15.7

10.7

7.3

749

CM121509

13.9

10.1

8.9

15.7

10.7

9.3

879

CM241505

21.8

13.6

4.3

23.6

14.3

4.6

928

CM241507

21.8

13.6

6.9

23.6

14.3

7.3

928

CM241509

21.8

13.6

8.9

23.6

14.3

9.3

928

CM241514

21.8

13.6

14.2

23.6

14.3

14.5

928

CM241109

21.8

10.1

8.9

23.6

10.7

9.3

877

CM242207

21.8

20.8

6.9

23.6

21.4

7.3

1024

CM242209

21.8

20.8

8.1

23.6

21.4

8.4

1024

CM242211

21.8

20.8

10.1

23.6

21.4

10.4

1024

CM321507

31.1

13.6

6.9

32.8

14.3

7.3

1031

CM481507

45.3

13.6

6.9

47.1

14.3

7.3

1205

CM481511

45.3

13.6

10.1

47.1

14.3

10.4

1205

CM482207

45.3

20.8

6.9

47.1

21.4

7.3

1278

pallet

48

44.5

tray/lid

48

44.5

5

liner

(I.D.) (2

req’d)

47.1

42.8

varies**

Use only 100% recyclable hotmelt or glue.

Pallet must be 100% corrugated and have 4 way entry.

Use Plastic or Nylon banding if required.

10

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# C SINGLE

WALL - 44ECT

275# CB DOUBLE

WALL - 48ECT

350# DOUBLE

WALL

350# DOUBLE

WALL

The following carton sizes are comparable to DaimlerChrysler’s large lot sizes and are designed for the best sea

container cube utilization. It is important if you are designing packaging for International Shipments that you stay

within the following footprints, unless your part dictates a new size. Please contact your Corporate or Plant Material

Handling Engineer for approval prior to shipments.

Carton Inside

Dimensions

Carton Outside Dimensions

Corrugated

Carton Code

Length

Width

Height

Length

Width

Height

Require

Carton

Individual Compression

Lids

Value

B-1

44.4

42.9

38.0

47.0

45.0

44.0

yes

6624#

B-2

44.4

42.9

16.0

47.0

45.0

22.0

yes

6624#

B-3

42.4

21.4

16.0

45.0

23.5

22.0

yes

5640#

B-4

67.3

27.8

16.0

70.0

30.0

22.0

yes

6400#

B-5

50.1

42.3

16.0

52.8

44.5

22.0

yes

6000#

B-6

57.3

33.6

16.0

59.5

36.5

22.0

yes

6756#

B-7

34.3

26.6

16.0

36.5

30.0

22.0

yes

5532#

B-8

42.3

33.3

16.0

44.5

36.0

22.0

yes

6156#

B-10

50.4

27.9

16.0

53.0

30.0

22.0

yes

5840#

B-11

41.4

26.7

16.0

44.0

28.9

22.0

yes

6516#

B-12

56.4

27.8

16.0

59.0

30.0

22.0

yes

5868#

Specifications

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

350#CB/CB

DOUBLE/DOUBLE WALL

- 110ECT

B2, B4, B7, and B10 are the preferred carton sizes.

Use only 100% recyclable hotmelt or glue.

Banding: Nylon if required.

Pallet must be 100% corrugated and have 4 way entry.

If your parts are outside the above dimensional specifications, work with your current corrugated supplier and obtain

approval prior to shipping. The above specifications are listed as 350# CB double/double wall (4 ply corrugated). In

most cases, a triple wall corrugated will meet the requirements of International shipments.

11

5.2 Ownership

Returnable containers can be either DaimlerChrysler

or supplier-owned and be made of either metal or

plastic. The use of wooden pallets as returnables is

discouraged due to their confusion with the

recyclable pallets. All DaimlerChrysler returnable

containers are not to be used for any WIP (work in

process) or storage of any raw materials.

DaimlerChrysler Corporation does not pay deposits

on returnables.

e) For racks, the associated “container” is the rack.

A separate returnable container line item must be

created for each unique associated rack/container

and for each associated removable dunnage, pallet,

lid, sleeve, etc. indicating the total number of each

piece included in the shipment.

Specific A.S.N. requirements for both parts and

packaging are located in the “DaimlerChrysler EDI

Conventions Manual – 856 Advance Ship Notice” This

manual is available by three methods: from the

DaimlerChrysler EDI group, via the SPIN home

page, or directly at URL http://supplier.chrysler.com/

general/edi/drg_trans_prod.shtml.

For all supplier-owned returnables, suppliers must

complete and submit a “Unit Load Data Sheet”

(See Page 24) for written approval to the

Corporate Material Handling Engineering or to

the appropriate receiving plant prior to use of these

returnables..

Many DaimlerChrysler systems and the third party

container management systems rely on the integrity

of part and container A.S.N.s. Failure to properly

submit packaging A.S.N.s will result in container/

dunnage shortage and excess costs to

DaimlerChrysler. These excess costs incurred by

DaimlerChrysler can, and will, be charged back to

the supplier via a Receiving Discrepancy Report

(RDR).

5.3 Identification

All returnable containers, racks, trays, totes, etc.

mu4st have clear identification of their container

number in 1-1/2” letters, either embossed into the

containers or painted in a contrasting color. In

addition, supplier-owned returnables must have the

supplier’s name and return point clearly stencilled in

1-1/2” letters on the container.

5.5 Container Shortages and Overages

Container, rack, and dunnage shortages must be

brought to the attention of the plant responsible for

the shortage and to the appropriate C.M.S. Analyst

in the Corporate Material Handling Engineering

Department.

5.4 A.S.N.s - Advance Shipping Notices

The Associated Container field must be entered for

each buyer part (BP) line item on the A.S.N. To

improve data integrity, enter data for this field at the

same time as each A.S.N. is created to ensure proper

identification of the unique packaging actually

shipped (see guidelines below for unit loads). The

container number must be entered as either eight (8)

or ten (10) characters in the ten character identifier

field and is comprised of letters and/or numbers (i.e.

0CC00091 or 0CTA241109).

Overstock conditions must be brought to the

attention of the plant responsible for the over

shipment.

If the above issues are not resolved to a supplier’s

satisfaction, or if it is unknown which plant is

responsible, please contact the C.M.S. Analyst as

directed on the Supplier Information Network

(SPIN) or to your third party container management

company’s representative.

General guidelines for identifying the associated

container in a unit load for input to the A.S.N. are:

a) For pallet and lid combinations, the associated

container is the pallet.

b) For tray, pallet and lid combinations, the

associated container is the tray.

c) For pallet and tote combinations, the associated

container is the tote.

d) For containers or containers with removable

dunnage, the associated container is the container.

5.6 Labels

Suppliers must insure that all materials shipped to

DaimlerChrysler Corporation Plants are correctly

labeled and that the labels are properly attached or

inserted into the holders on the racks or containers.

12

5.6.1 Destination Label and Shipping

Instructions

To minimize misdirection of packaged parts and

materials, it is essential that the exact shipping

address of the receiving plant be shown in a manner

that can be easily read and understood.

5.6.1c Tags (Hang Tags)

The tag size shall be the same as described

immediately above, plus the material necessary to add

a reinforced eyelet. (See Pages 24 and 25)

5.6.1d Label Location

The label or tag shall be attached to two adjacent sides

of each individual package/container (See Page 23

AIAG B-10) exceptions may apply where there is no area

on the sides of the containers to apply the label. For unit

load packaging that is shrink wrapped the master label

and mix load labels must be applied to the outside.

When individual containers are palletized and made

into a unit load for mechanical handling, the master

label shall be attached to two adjacent sides of the unit

load. (See Pages 24 and 25)

Consequently, the following shipping instructions

shall apply for proper addressing of parts and

material shipped or delivered to DaimlerChrysler

plants by outside suppliers or by other

DaimlerChrysler plants.

5.6.1a Label

The label paper shall be white in color with bold,

black printing. The required label size is 4 in. (102

mm) high by 6 in. (152 mm) wide or ISO size A6.

All labels must meet the AIAG specifications for

quality, reflectivity, and readability. Labels must be

scannable from the exterior of the shipping unit (not

covered by banding, cardboard, or shrink wrap.

5.6.1e Destination Label

A label that identifies the receiver of a shipping pack

when the package is routed through a consolidation

point, shall contain the plant and dock destination

code, ship date, plant address and bar code symbol of

the destination location. A “Dock Specific”

Destination label must be on every unitload or skid

routed through a consolidation center (poolpoint/

ILC). Refer to page 27 of this manual. No mixing of

plants or plant dock locations on a single skid or

pallet is allowed.

The character size of the “Plant Location Code” shall

be 1 in. (25.4 mm) high. The character size of the

“DaimlerChrysler Plant Name,” and “Street Address”

shall be 0.20 in. (5.1 mm) high. The character size of

the “Dock Location Code” shall be 1 in. (25.4 mm)

high.

5.6.1b Bar code Labeling

The bar height for the LOCATION (1L) bar code

symbol shall be a minimum of 1 in. (25.4 mm) high.

For all other specifications refer to the various

references for BAR CODE SYMBOLOGY listed in

Section 2 and specific bar code requirements in

Section 4 of AIAG B-10. DaimlerChrysler’s bar code

labeling requirements reside within the parameters

set forth by the current Automotive Industry Action

Groups (AIAG) B-10 Trading Partner Labels

Manuals issued on May 9, 1995. This guideline is the

standard for the automotive industry with which

DaimlerChrysler expects all suppliers to adhere.

Adhesive types can be pressure sensitive or dry

gummed as long as adherence to the package

substrate is assured and application is wrinklefree and

only for use on expendable packaging. For

returnable/durable packaging, use only as authorized

by DaimlerChrysler Corporate Material Handling

Engineering Department.

5.6.1f Label Protection

Label protection against moisture, weathering,

abrasion, etc., may be required in harsh

environments and is encouraged wherever practical.

Laminates, sprays, window envelopes, and clear

plastic pouches are examples of possible protection

method. Care must be taken to assure that labels

meet reflectivity and contrast requirements and can

be scanned with contact and non-contact devices.

5.6.1g Plant Shipping Address

The plant shipping address is mandatory in the

identification of packages or unit loads shipped by

highway carrier to DaimlerChrysler Corporation

plants by outside suppliers or by other

DaimlerChrysler plants. The plant shipping address

shall include the plant name, plant dock, plant

location code, plant street address, city, state and zip

code.

13

The supplier shall refer to their most recent material

release authorization for the correct shipping and dock

location address.

5.6.7 References

Examples of these guidelines/labels are on pages 26-28

of this manual. Any request for clarification to the

current stated format or guidelines can be addressed to:

5.6.2 Packaging and Shipping Label

The packaging and shipping label is used to identify

the contents in the container being shipped to the

plant. It shall include the part number, part

description, supplier name, supplier code, quantity,

engineering level change, safety item identification,

date manufactured, plant dock location, drop zone

location and serial number. All part numeric

identifications shall have the bar code identifier

directly below them. DaimlerChrysler request that

the character size for the part number on the

packaging label should be 0.5 inches (12.7mm).

Refer to page 28 of this manual.

CIMS 484-00-30

Material Handling Engineering Department

DaimlerChrysler Corporation

800 Chrysler Drive

Auburn Hills MI 48326-2757

Requests for the AIAG B-10 Trading Partner Labels

Manual can be directed to:

Automotive Industry Action Group (AIAG)

26200 Lahser Road Suite 200

Southfield MI 48034

(248) 358-3570

Fax (248) 358-3253

5.6.3 Multiple, Common Item Packs

A Master Label is required to be used to identify the

total contents of a multiple single pack load of the

same part number. The label shall be placed on the

unit load in such a manner that when the pack is

broken apart the label is discarded (e.g., attach to

outside of stretch wrap). For further information see

AIAG B-10 pages 18 and 23.

5.7 Cleaning, Damage & Repair of Containers

It is the suppliers responsibility to ensure that all

returnable containers are free of debris that would

impact the quality of the material being packaged

prior to loading with DaimlerChrysler parts.

It is the supplier’s responsibility to inspect all racks

and containers prior to loading to ensure that

damaged equipment which could cause damage to

parts or injury to handlers/operators is segregated

and removed from the system for subsequent repair

or scrap disposition by DaimlerChrysler Material

Handling Engineering personnel or their

representative(s). As damaged equipment is so

segregated, it should be collapsed, folded down

(where applicable) and clearly marked as “Damaged”.

At this point suppliers should call their C.M.S.

Analyst who will advise what procedure to follow at

that point and/or what transportation arrangements

to make if equipment is to be forwarded to a

DaimlerChrysler plant or directly to a repair source.

5.6.4 Mixed Item Loads

A Mixed Load Label shall be used to identify a load

of multiple single packs of different part numbers,

see page 26 of this manual. For further information

see AIAG B-10 pages 18 and 23. Note: Mix loads

are required to have a Master Label of each

individual part applied to the shipments. The label

shall be placed on the unit load in such a manor that

when the pack is broken apart the label is discarded

(e.g., attach to outside of stretch wrap or affix to the

banding).

5.6.5 Cardholder Label Plate

Containers equipped with cardholder label plate

require a minimum of an 8 pt. card stock label.

At DaimlerChrysler plants, Production Control

personnel should make arrangements with Corporate

Material Handling Engineering managers/analysts to

conduct or arrange for on-site inspection and

disposition (repair or scrap) of this damaged

equipment when sufficient quantities accumulate to

cost justify such arrangements.

5.6.6 Removal of Old Labels

Assuring that the removal of old labels prior to

shipping has been completed remains the

responsibility of the supplier, this includes standard

container returns that are managed by third party

container management facilities.

14

returnable dunnage, preconcepts, prototypes and

prototype reviews are not required.

5.8 Implementation to Returnable/Expendable

Programs

Several economic factors influence the selection of a

returnable container program: complexity, materials,

quality, labor, freight, cleaning, disposal, and tooling

costs. Once a part is selected for returnables, a

package must be designed and implemented.

Step 4. Testing/Test Packs

Once a prototype has been approved testing for all

returnable programs is required to be performed by

our design source or by test shipment to the receiving

location. Full package quantities must be released for

this purpose, once testing is completed parts

will be returned if requested. Test shipments to a

receiving location must be clearly identified with an

8-1/2” (216mm) X 11” (280mm) sign stating “Test

Pack”, “Hold in Receiving Area”, “Notify contact

name” and “Phone contact number” (See Page 33

for form), Note: Any changes to existing

returnables must also be tested.

There are six steps to the successful implementation

of a returnable program all of which require the

participation and cooperation of our suppliers.

Step 1. Pre-concept Meeting

The pre-concept meeting is a pre-design meeting to

discuss packaging alternatives, packaging materials,

particular part characteristics, load/unload scenarios,

and timing. Suppliers must send a sample part or

math data to the latest change level. A supplier

representative qualified to address their concerns,

must be available in person, or for a conference call.

Step 5. Allocations

Normally DaimlerChrysler Corporation provides an

agreed upon quantity of returnables to cover

published transit times, in-plant floats and

operational reserves. Variations to this allocation

must be approved by your appropriate Corporate

Material Handling Engineering Manager. CMHE

and Logistics will work with the suppliers to identify

ship bank requirements. Quantities will be sufficient

to cover needs.

Step 1a. Pre-concept Meeting (International Only)

If the vehicle line will be manufactured overseas,

International packaging requirements must be discussed.

The determination must be made first, is it a Free Flow

Country or CKD Country. If Free Flow, it is possible the

domestic back up (or expendable packaging) may be

adequate for International shipments. If a CKD

country, it is the suppliers responsibility to submit

samples and costs associated with packing parts in lots of

36 or box quantities of 2,3,4,6,9,12,18, or 36 pieces.

Step 6.

New part number unit load data information is

loaded directly on-line into the C.R.A.T.E.S.

database by the TIER 1 suppliers. Unit load

information for any currently released part that is

on the C.R.A.T.E.S. add list is updated by the

CMHE Engineers.

Step 2. Prototype

Suppliers must loan or release a minimum of three

sample parts to our design source for design of a

prototype package. If required, parts will be returned

upon the successful completion and approval of the

prototype package.

5.9 Combination Returnable and Recyclable

Complexity and economics have forced a new

program into use for DaimlerChrysler, returnable

containers with recyclable dunnage. Parts not

meeting the economic criteria for total returnable

systems can still be containerized with the supplier’s

cooperation. In this program, DaimlerChrysler

supplies the container, the supplier is responsible for

the design, testing, and replacement of the interior

dunnage. Cost attributable to the dunnage is

included in the purchase order for recovery by the

supplier on a piece price basis. All cardboard must be

non-coated for recyclability.

Step 3. Prototype Review

Once a prototype package is produced a review is

scheduled with all parties concerned to assess the

package’s conformance to requirements as set at the

preconcept meeting, establish ship bank quantities,

and sign off on the completed design. Suppliers must

send a qualified representative to this meeting. If a

supplier is unable to send a representative, prototype

reviews can be held at the suppliers location. Note: For

parts not requiring a special design or specialized

15

Once contacted by our design source for this program, the core team chooses a DaimlerChrysler Corporation

standard container from the description in this manual and designs and provides a prototype of the recyclable

interior dunnage. A prototype review is held and test shipments performed, and containers are allocated to the

supplier.

Repurchase

Suppliers wishing to purchase quantities of their recyclable dunnage back from DaimlerChrysler may contact

our plant recycling teams.

5.10 Types and Descriptions

DaimlerChrysler has a wide variety of returnable racks and containers in use, both metal and plastic.

5.10.1 Racks

All of our CL and Low Profile racks are of tubular steel construction and are specifically designed to hold a

particular part. All bear an identifying part number and description. Ergonomic devices are incorporated into

the rack, such as swing arm dunnage bars and hands clear locking mechanisms.

5.10.2 Standard Containers

A wide variety of standard containers are available: metal and plastic, collapsible, non-collapsible, and nestable.

Plastic containers larger than 4 cu. ft. (2500 cu. mm) have a maximum weight capacity of 2500 lbs. (1136 kg);

collapsible metal containers have a maximum weight capacity of 4000 lbs. (1800 kg); non-collapsibles cannot

exceed 6000 lbs. (2700 kg). Examples of the more common containers of each type available are shown on the

following pages with a listing of exterior sizes, in inches, L x W x H, and tare weights, in pounds.

Non-Collapsible Metal Bins

The figure to the right is an example of our non-collapsible metal bins…

four types are available:

Outside Dims. Weight (lbs.)

0000CC3A 53” X 42” X 38”

385#

00000CC3 53” X 42” X 38”

320#

00000CC8 53” X 42” X 28”

300#

Inside Dims.

51” X 40” X 28”

51” X 40” X 28”

51” X 40” X 24”

Collapsible Metal Bins

The figure to the right is an example of our collapsible metal bins. Three

sizes are available:

Outside Dims. Weight (lbs.)

0CC00070 48” X 45” X 33”

305#

0CC00071 48” X 45” X 33”

305#

0CS00120 63” X 47” X 33.75”

484#

Inside Dims.

43.25” X 40” X 23.75”

43.25” X 40” X 23.75”

61.75” X 45.75” X 21.5”

16

Non-Collapsible Metal Baskets

Outside Dims.

0CS00699 72” X 48” X 34”

0CS00700 72” X 54” X 34”

0CS00701 72” X 48” X 34”

Weight (lbs.)

589#

507#

589#

Inside Dims.

66” X 41.62” X 27.13”

68.62” X 50.5” X 25.12”

68.62” X 44.25” X 25.12”

In addition there are two non-collapsible metal baskets, pictures not shown:

Outside Dims. Weight (lbs.) Inside Dims.

00CE1CY5 106” X 48” X 34”

665#

100” X 45” X 24”

00CE2CY4 80” X 48” X 34”

540#

74” X 45” X 24”

Collapsible Metal Baskets

The figure to the right is an example of our collapsible metal baskets. Three

sizes are available:

Outside Dims.

Weight (lbs.)

0CS00125 96” X 48” X 32.75”

620#

0CS00858 120” X 48.4” X 32.75” 715#

0CS00126 144” X 48” X 33”

850#

Inside Dims.

92.25” X 44.75” X 23”

115.75” X 44.75” X 23”

140.25” X 44.75” X 23”

Non-Collapsible Plastic Bins

The picture to the right is an example of our non-collapsible plastic bins.

0000CC30

0CC00050

0CC00058

0CC00040

Outside Dims. Weight (lbs.)

32” X 30” X 21.5”

48#

48” X 32” X 21.5”

60#

45” X 32” X 27”

75#

53” X 43” X 35”

172#

Inside Dims.

27.75” X 25.75” X 12.75”

44.25” X 27.1” X 12.75”

40.1” X 27.1” X 18.25”

50” X 39.75” X 26.5”

17

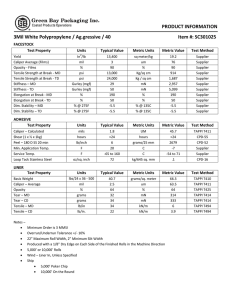

Collapsible Plastic Containers

The picture to the right is an example of our collapsible plastic containers.

Outside Dims.

0CC00031

0CC00032

0CC00034

0CC00035

0CC00039

0CC00041

0CC00042

0CC00043

0CC00044

0CC00045

0CC00046

0CC00048

0CC00049

0CC00051

0CC00052

0CC00069

0CC00073

0CC00074

0CC00075

0CC00076

0CC00077

0CC00078

0CC00091

0CC00092

0CC00093

0CC00094

0CC00095

0CC00096

0CC00097

0CC00098

0CC00099

0CC00152

30"

30"

30"

30"

40"

70"

70"

70"

48"

48"

70"

70"

40"

40"

48"

48"

48"

48"

48"

48"

48"

48"

48"

64"

64"

64"

64"

64"

64"

64"

64"

64"

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

32"

32"

32"

32"

48"

48"

48"

48"

45"

45"

48"

48"

48"

48"

45"

45"

45"

45"

45"

45"

45"

45"

45"

48"

48"

48"

48"

48"

48"

48"

48"

48"

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

34"

25"

25"

25"

39"

25"

34"

50"

50"

50"

50"

34"

25"

29"

48"

33"

34"

34"

42"

25"

25"

42"

33"

34"

34"

34"

41"

50"

34"

25"

41"

34"

Weight (lbs.) Inside Dims.

87#

68#

69#

68.5#

169#

173#

208#

303#

203#

183#

263#

228#

129#

142#

190#

136#

145.5#

147#

180#

121#

122#

180#

144.5#

204#

205.5#

207#

250#

265#

191#

174#

247#

196#

29.4" X 27.2" X 27.4"

29.4" X 27.2" X 19.6"

29.4" X 27.2" X 19.6"

29.4" X 27.2" X 19.6"

43.6" X 36" X 32.8"

66.4" X 44.5" X 17.9"

66.4" X 44.5" X 26.9"

66.4" X 44.5" X 43"

41.5" X 44" X 43.3"

41.5" X 44" X 43.3"

66.4" X 44.5" X 43"

66.4" X 44.5" X 26.9"

43.6" X 36" X 18.6"

43.6" X 36" X 23.1"

41.5" X 44" X 41.5"

41.5" X 44.3" X 26.6"

41.5" X 44" X 27.5"

41.5" X 44" X 27.5"

41.5" X 44" X 35.4"

41.5" X 44" X 18.6"

41.5" X 44" X 18.6"

41.5" X 44" X 35.4"

41.5" X 44.3" X 26.6"

61" X 44.5" X 26.9"

61" X 44.5" X 26.9"

61" X 44.5" X 26.9"

61" X 44.5" X 34"

61" X 44.5" X 43"

61" X 44.5" X 26.9"

61" X 44.5" X 17.9"

61" X 44.5" X 34"

61" X 44.5" X 26.9"

Nestable Plastic Totes & Pallets

The pictures to the right are examples of our nestable plastic totes and pallets.

STANDARD PARTS SYSTEM TOTE

0AIAG001

000BR104

000BR105

000BR106

Outside Dims. Weight (lbs.)

15” X 9” X 8”

3#

23” X 11” X 14”

7#

20.5” X 17” X 14”

9#

47” X 22” X 14”1

5#

Inside Dims.

12.8” X 6.8” X 6.1”

12.19” X 8.44” X 12.12”

20” X 16.19” X 12.12”

42.5” X 17.5” X 12.37”

PALLETS:

Outside Dims. Weight (lbs.)

0AIAG002 32” X 30” X 6.25”

30#

000BR108 47” X 44” X 7”

30#

0CP00002 47” X 44” X 10”

33#

Inside Dims.

not applicable

not applicable

not applicable

NOTE: THERE ARE TWO TYPES OF PALLETS IN CIRCULATION FOR

STANDARD PARTS, BOTH ARE CALLED 0AIAG002. SOME BLUE

MOLDED PALLETS HAVE BEEN MIS-IDENTIFIED AS 0CP00002.

18

Small Lot Returnable Containers

A wide variety of small lot containers are available. These sizes are standard throughout the corporation. All of

these containers fit on pallets and are supported by top caps. The chart below lists these returnable containers by

DaimlerChrysler part number, size and container weight.

CONTAINER

COLOR

# TOTES IN

33” UNIT LOAD

(APPROX.

HEIGHT)

CT120705

CT121505

CT121507

CT121509

CT241109

CT241505

CT241507

CT241509

CT241514

CT242207

CT242209

CT242211

CT242214

CT321507

CT481507

CT481511

CT482207***

CP4845VL

CP4845SP

BLACK

SUN BERRY

SUN MED. GREEN

SUN BEIGE

SUN BURNT ORANGE

SUN GREY

BLACK

SUN ROYAL BLUE

SUN GREY

SUN BERRY

SUN BEIGE

SUN MED. GREEN

BLACK

SUN TURQUOISE

SUN BURNT ORANGE

SUN BERRY

BLACK

BLACK

BLACK

48* 144**

24* 72**

12* 36**

12* 36**

24

36

18

18

12

16

12

8

8

6*

9

6

6

TOPCAP

PALLET

72* 216**

36* 108**

24* 72**

16* 48**

32

54

36

24

18

24

20

16

12

12* 24**

18

12

12

59-050-2005

59-050-2006

59-050-2007

59-050-2008

59-050-2020

59-050-2023

59-050-2022

59-050-2010

59-050-2014

59-050-2018

59-050-2004

59-050-2009

59-050-2025

59-050-2121

59-050-2011

59-050-2024

59-050-2021

59-050-6806

59-050-6805

8* 24**

12

12

12

8

6

6

6

6

4

4

4

4

2* 4**

3

3

2

9.4 x 5.5 x 4.3

9.4 x 13 x 4.3

9.4 x 13 x 6.8

9.4 x 13 x 8.8

21.4 x 9.3 x 8.9

21.4 x 13 x 4.3

21.4 x 13 x 6.8

21.4 x 13 x 8.8

21.4 x 13 x 13.8

21.4 x 20.5 x 6.7

21.4 x 21 x 8.1

21.4 x 21 x 10.2

21.4 x 21 x 13

29.4 x 13 x 6.9

45.4 x 13 x 6.6

45.4 x 13 x 9.9

45.4 x 20.5 x 6.4

ATTACHED

LID:

CTA121507

CTA121509

CTA241109

CTA241509

CTA241514

GREEN BASE, GREY LID

GREEN BASE, GREY LID

GREEN BASE, GREY LID

GREY BASE, GREEN LID

GREY BASE, GREEN LID

12* 36**

12* 36**

24

18

12

24* 72**

16* 48**

32

24

18

59-050-2029

59-050-2030

59-050-2015

59-050-2016

59-050-2017

12

12

8

6

6

9.4 x 13 x 6.8

9.4 x 13 x 8.8

21.4 x 9.3 x 8.9

21.4 x 13 x 8.8

21.4 x 13 x 13.8

# TOTES IN

50” UNIT LOAD

(APPROX.

HEIGHT)

CHRYSLER’S

NPM CODE

TOTES

PER LAYER

APPROX.

INTERNAL

BOTTOM DIM.

(LxWxD)

12 x 7 x 5

12 x 15 x 5

12 x 15 x 7

12 x 15 x 9

24 x 11 x 9

24 x 15 x 5

24 x 15 x 7

24. x 15 x 9

24 x 15 x 14

24 x 22 x 7

24 x 22 x 9

24 x 22 x 11

24 x 22 x 14

32 x 15 x 7

48 x 15 x 7

48 x 15 x 11

48 x 22 x 7

48 x 45 x 4

48 x 45 x 6

2.9

3.2

5.6

7.0

8.9

12 x 15 x 7

12 x 15 x 9

24 x 11 x 9

24 x 15 x 9

24 x 15 x 14

* BASED ON A 32 X 30 PALLET

** BASED ON A 48 X 45 PALLET

NOTE: The CT482207 container is not a standard DaimlerChrysler container, please use only with approval from CMHE.

Examples of small lot containers

CT121507

CT241509

19

APPROX.

OUTSIDE

DIM.

(LxWxH)

APPROX.

CONTAINER

WEIGHT

(lbs.)

1.3

1.9

2.9

3.3

3.9

3.9

4.5

5.2

7.3

5.9

6.5

7.5

7.1

5.5

7.7

9.9

10.3

16

46

Pallet, Lid, and Sleeve Combinations

A wide variety of pallet, lid, and sleeve combinations are available. All have an interlocking pallet, lid, and

sleeve to maintain stability while stacked full. Sleeves can be cut to any height and are made from welded

corrugated plastic or wire mesh. The chart below lists the identification of the pallet and its footprint,

length X width in inches, and tare weight in pounds.

Pallet/Lid

0CS0590A/B

0CS0855A/B

0CS0903A/B

0CS0904A/B

0CS00785

0CS00784

0CS00786

0CS00781A/B

0CS00199

0CP00010

0CS00592

0CS01978

0CP00004

0CS00790

0CS00598

0CS01079

Lid

Sleeve

Pallet

Dimensions

44” X 54”

74” X 47”

29” X 64.25”

44” X 58.5”

32” X 32”

32” X 56”

44” X 44”

45” X 48”

45” X 48”

45” X 48”

45” X 68”

48” X 52”

48” X 57”

48” X 65”

48” X 76”

48” X 87”

{

20

Weight (lbs.)

35#

45#

23#

34#

17#

19#

32#

35#

27#

32#

60#

50#

30#

71#

80#

30#

6.0 Transportation

Packaging design specifications such as size, weight,

and stackability drastically impact the cost of

transportation. When optimum packaging for a

product has been determined, facility constraints,

volume, density, and ship frequency are factored to

develop a shipping mode. Each supplier of

production parts and materials must have Supplier

Routing Instructions from DaimlerChrysler

Corporate Logistics listing your “Primary Carrier”.

engines, transmissions, and other dense commodities.

Eighty-six foot cars are used for stampings and

miscellaneous commodities.

“Primary Carrier (P1)” is the DaimlerChrysler

preferred carrier. Use of a carrier other than the

Primary carrier must be approved by

DaimlerChrysler Corporate Logistics. Routing

instructions will include information regarding

supplier routing for premium shipments, such as next

day air or ground expedite.

Consist Car a. Shipment authorized and developed in

conjunction with receiving activity

b. Boxcars are in assigned service at origin plant

c. Material is shipped in uniform quantities in a

repetitive manner throughout the model year

d. Loading patterns and/or dunnage arrangements

are pre-engineered

e. Special returnable dunnage or equipment may be

required to contain and/or protect material.

Rail shipments utilize either ‘consist’ or ‘common’

boxcars. Characteristics of each are as follows:

Note: On all cars void spaces must be minimized.

Spaces in cars greater than five inches must be braced

by wood or bulkheads to avoid damage in transit.

The “Expedite” mode of shipping is utilized when

unforeseen circumstances have necessitated deviation

from the Primary carrier and/or a different mode of

transportation and appropriate packaging will be

required. This deviation must be approved by and be

coordinated with Group Production Control; the

emergency method specified will govern the type of

packaging to be employed.

Common Car a. Material is not loaded in set quantities

b. Boxcars are not assigned to a specific activity.

6.2 Truckload Direct Carrier (M)

Truckload shipments are highly desirable because of

pick-up and delivery flexibility, and relatively short

travel time between shipping and destination points.

DaimlerChrysler’s standard truckload trailer is 53

foot long, 102 inches wide and 110 inches tall.

6.1 Primary Modes

DaimlerChrysler Corporation’s primary modes of

shipping are by Railroad Car, Truckload Direct

Carrier, Intermodal, Truckload “Geographic

Shipping/Receiving”, Scheduled Delivery Programs,

Dedicated Logistics Centers, Common Carrier Less

Than Truckload, Supplier Delivery/Private Carrier,

and Parcel Delivery.

Note: On all truckload shipments dead spaces must

be minimized. Spaces in truckloads greater than three

inches must be braced by wood or bulkheads to avoid

shifting and damage during transit.

6.1.1 Railroad Boxcar (R)

Railroad Boxcars are a carload shipment to a single

destination. Rail transportation tends to be more

economical when large volumes of material are

shipped, when racks sizes exceed standard over-theroad trailer dimensions, or long distances exist

between origin and destination.

6.2.1 Intermodal (X,RR)

Material is shipped between two points by a road and

rail combination. Intermodal routings can be a trailer

on flat car, a roadrailer, or a stack container.

Note: On all intermodal shipments dead spaces must

be minimized. Spaces greater than three inches must

be braced by wood or bulkheads to avoid shifting and

damage during transit.

Standard boxcar dimensions are 50’, 60’ and 86’ in

length. Fifty foot cars have been phased out of most

rail fleets. Sixty foot cars are used primarily for

21

The responsibility for correctly packaging, identifying

and addressing parts and materials remains with the

supplier.

6.2.2 Truckload Geographic Shipping/Receiving

(GS/GR)

Shipments containing two or more supplier on one

truck/shipment containing supplies for two or more

plants.

6.5 Packing Slips and Bills of Lading

Packing slips and bills of lading, whether direct

shipments or shipments moving through a

consolidation point, must be submitted with every

shipment.

6.2.3 Scheduled Delivery Program (GG)

Less than truckload shipments are picked up for a

specific DaimlerChrysler destination, with a

dedicated carrier, based on a Just In Time schedule.

A BOL represents an agreement between the supplier

and carrier that the freight pallet quantity is correct

and that the material is damaged free for pickup. A

signed BOL represents the carrier’s liability for pallet

quantity and that the material was in good shipping

condition when they picked it up. Where as the

supplier is liable that the individual part quantity is

correct and the material is in good shipping

condition. The supplier is responsible for the seals

and to note it on the BOL. If a seal is broke arrival at

the plant, the carrier is responsible for any missing

pallet material. If the seal is intact at the plant, the

supplier is responsible for content of the trailer. If the

carrier is not allowed on the suppliers dock, the

carrier is to mark on all of the BOLs Shipper Load &

Count (SL&C), therefore the supplier is responsible

for the entire load (shortage and damage due to

staging the material). The supplier is responsible to

properly secure all material on the trailer.

6.2.4 Dedicated Logistics Centers (GG)

Less than truckload shipments are picked up for

multiple DaimlerChrysler destinations, with a

dedicated carrier, into a cross-dock, based on a Just In

Time schedule.

6.2.5 Common Carrier LTL (LT)

LTL (less than truckload) direct with a common

carrier is utilized in certain circumstances when it has

been deemed the most efficient means of transport

due usually to geographic location of ship point.

6.2.6 Supplier Delivery/Private Carrier (PC)

In some instances suppliers provide regular parts

delivery service to DaimlerChrysler plants on their

own trucks, leased trucks or contract carriers. Return

loads of materials, containers, pallets, etc., can make

such moves even more beneficial to both parties.

6.5.1 Direct Shipments

Direct shipments move directly from a shipping

plant to a destination plant. Packing slips must be

prepared in duplicate. One copy of the packing slip is

to be firmly attached to the outside of one of the

containers in the shipment. The second copy of the

packing slip should be tendered to the carrier along

with two copies of the bill of lading.

6.3 Parcel Delivery (PD)

All shipments weighing 70 pounds or less should be

routed via United Parcel Service, unless otherwise

stated on routing instructions or by DaimlerChrysler

Production Control.

6.4 Emergency Methods (E, AE, AC)

DaimlerChrysler Corporations’ emergency methods

of shipping are via Expedited truck, “full” truckload,

air express, and air charter.

All emergency shipments must have prior approval of

the Production Control Releasing Activity. The

shipper must receive an AETC, (Authorization Excess

Transportation Charge) number which is to be

included on the bill of lading. The fact that

emergency routings are specified dictate that parts

must be received promptly and damage free.

22

6.5.2 Shipments Moving Through a

Consolidation Point Part or Material Information

Shipments moving through a consolidation point are

partial loads that are consigned through a

consolidation point for delivery to the destination

plant. Packing slips must be prepared in sets of four.

One copy of the packing slip should be firmly

attached to the outside of one of the containers in the

shipment. The other three copies of the packing slip

should be tendered to the carrier along with two

copies of the bill of lading. The bill of lading should

indicate that the packing slips are to be delivered to the

consolidator at the time of delivery of the material.

3. Unit of measure - if other than pieces per unit load.

4. Number of measure - Supplier Returnable

Containers - supplier owned returnable containers

such as wood or metal bins, boxes, racks, pallets,

trays, separators and or loose components on

which there are deposit charges must be identified

in compliance with Section 4.0.

5. Returnable Containers DaimlerChrysler owned

Identification number (example “0000CC30”).

6. Returnable Containers Supplier Owned

Identification number (example “00GM5131”).

7. DaimlerChrysler Purchase Order Number.

8. DaimlerChrysler Program or Release Number.

9. Engineering Change Letter.

10.Quantity Shipped.

11.DaimlerChrysler Part Number.

12.DaimlerChrysler Part Name.

13.Accumulative Shipped - Include this shipment

(schedule release items only).

14.Receiving Plant Register Number (not filled in by

supplier).

6.5.3 Customs Papers

All U.S. shipments destined outside of the U.S. must

have a customs invoice provided by the supplier and

included with other shipping documentation. See

page 29 for Sample of Customs invoice.

6.5.4 Third-Party Consignment

When making a third party consignment shipment,

the bill of lading must include: