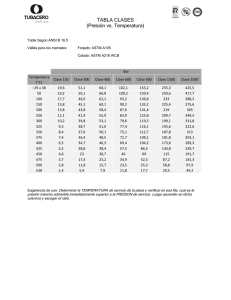

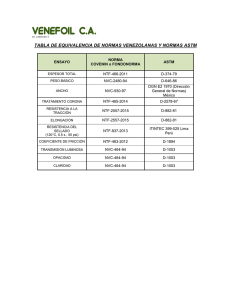

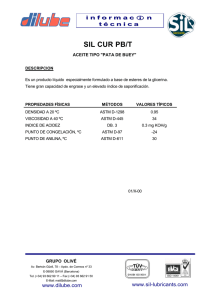

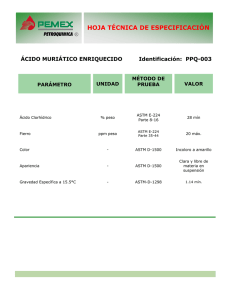

Aprobado para Construcción / Inclusión de Comentarios Approved For Construction / Comment Included Aprobado para Construcción / Inclusión de Comentarios Approved For Construction / Comment Included Aprobado para Construcción / Inclusión de Comentarios Approved For Construction / Comment Included 3 2 1 11/11/2020 A.P. F.G. M.R. 18/08/2020 A.P. F.G. M.R. 26/05/2020 A.P. F.G. M.R. 0 Aprobado Para Construcción / Approved For Construction 21/04/2020 A.P. F.G. M.R. B Para Comentarios de VOPAK / For Vopak Comments 24/03/2020 A.P. F.G. M.R. A Para Comentarios de AVANZIA / For AVANZIA Comments 10/03/2020 A.P. F.G. M.R. Fecha Realizó. Revisó. Aprobó. Rev. Objeto de la edición CLIENTE: CONTRATISTA: : PROYECTO Expansión de Almacenamiento de Químicos en la Terminal Altamira TITULO: ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Sheet Number nº pag. NA 1 Format 0 0 3 nº total pages Rev. 27 3 Scale Project No. ALT1725 Discipline Code L03 Activity Code BB0 Sequence Number 403 Carta CODIFICACIÓN DEL DOCUMENTO Libre ALT1725-L03-BB0-403-003 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 INDICE / INDEX 1 OBJETIVO / OBJECTIVE ................................................................................................................ 3 2 ALCANCE / SCOPE ......................................................................................................................... 3 3 3.1 3.2 3.3 3.4 3.5 3.6 ESPECIFICACIONES Y NORMAS / SPECIFICATIONS AND STANDARDS................................. 3 ASME (American Society of Mechanical Engineers) ....................................................................... 4 ASTM (American Society for Testing and Materials) ....................................................................... 4 API (American Petroleum Institute) .................................................................................................. 5 AWWA (AMERICAN WATER WORKS ASSOCIATION) ................................................................. 6 MSS (Manufacturers Standardization Society of the Valve and Fittings Industry) .......................... 6 NFPA (national Fire Protection Association) .................................................................................... 6 4 ABREVIATURAS / ABBREVATIONS .............................................................................................. 7 5 DESIGNACIÓN DE LA TUBERÍA / PIPE DESIGNATION ............................................................... 8 6 LIMITES DE DISEÑO DE SELECCIÓN DE MATERIALES / DESING LIMITS OF MATERIAL SELECTION ..................................................................................................................................... 9 7 SERVICIOS / SERVICES ................................................................................................................ 9 8 8.1 8.2 8.3 8.4 8.5 ESPECIFICACION / SPECIFICATION .......................................................................................... 12 CL150CSA ..................................................................................................................................... 12 CL150CGA ..................................................................................................................................... 17 CL150SSA...................................................................................................................................... 21 CL150PEAD ................................................................................................................................... 25 CL150PEAD BFW .......................................................................................................................... 26 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 2 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 1 OBJETIVO / OBJECTIVE El presente documento tiene como objetivo establecer las distintas clases de tuberías y los materiales que las componen según el servicio y las condiciones de proceso bajo las cuales operaran las tuberías del Proyecto Expansión de Almacenamiento de Químicos en la Terminal Altamira, ubicado en Altamira, Tamaulipas, México. 2 The purpose of this document is to establish the different classes of pipes and the materials that compose them according to the service and process conditions under which the pipes operate in the Project Expansión de Almacenamiento de Químicos en la Terminal Altamira, Located in Altamira Tamaulipas México. ALCANCE / SCOPE Establecer los requisitos para el suministro, pruebas de aceptación en fábrica, pruebas de aceptación en sitio, arranque, embalaje, garantías, transporte al sitio y manuales de instalación, operación, mantenimiento, para la fabricación de las válvulas manuales a utilizar en los las de compuerta, globo y retención a ser instaladas en los distintos sistemas de tuberías. Establish supply requirements, factory acceptance tests, on-site acceptance tests, commissioning, packaging, warranties, transportation to site and installation, operation, maintenance manuals for the manufacture of manual valves to be used in gates, globe and retention in the different piping systems facilities. El alcance especificación técnica comprende describir los requerimientos específicos para la selección de los materiales que serán usados en la fabricación de todas las tuberías de proceso y servicios a emplear en la construcción del Proyecto Expansión de Almacenamiento de Químicos en la Terminal Altamira. The scope of the technical specification includes the description of the specific requirements for the selection of materials to be used in the manufacture of all pipes and process services for the construction of the Project Expansión de Almacenamiento de Químicos en la Terminal Altamira. 3 ESPECIFICACIONES Y NORMAS / SPECIFICATIONS AND STANDARDS La jerarquía de aplicación debe ser conforme el orden de precedencia indicados a continuación: Códigos o Estándar Internacionales Aplicables y Guías de Diseño (ISO, ASME, API, ASTM, NACE, MSS, PFI, AWWA, NFPA), Estándar VOPAK. Cuando una fecha de edición no este indicada para un Código o Estándar Internacional, se deben aplicar la edición vigente en el momento de la firma de contrato. Se utilizarán como referencias, los códigos que se nombran a continuación: The application hierarchy must be in the order of precedence detailed below: Applicable international codes or standards and design guides (ISO, ASME, API, ASTM, NACE, MSS, PFI, AWWA, NFPA), VOPAK standards. When no edition date is indicated for an International Code or Standard, the current edition at the time of signing the contract. The following codes will be used as references: Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 3 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 3.1 ASME (American Society of Mechanical Engineers) ASME B16.9 Factory-Made Wrought Buttwelding Fittings. ASME B16.20 Metallic Gaskets for Pipe Flanges RingJoint, Spiral-Wound, and Jacketed. ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges. ASME B16.10 Face-to-Face and End-to-End Dimensions of Valves. ASME B16.11 Forged Fittings, Socket-Welding and Threaded. ASME B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings Classes 150, 300, 600, 900, 1500, and 2500 ASME B16.25 Butt Welding Ends ASME B16.34 Valves-Flanged Threaded and Welding End. ASME B16.5 Pipe Flanges and Flanged Fittings. ASME B31.3 Process Piping. ASME B36.10M ASME B36.19M Welded and Seamless Wrought Steel Pipe. Stainless Steel Pipe. ASME B18.2.1 Square and Hex Bolts and Screws (inch series). ASME B18.2.2 Square and Hex Nuts (inch series). 3.2 ASME B16.9 Factory-Made Wrought Buttwelding Fittings. ASME B16.20 Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound, and Jacketed. ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges. ASME B16.10 Face-to-Face and End-to-End Dimensions of Valves. ASME B16.11 Forged Fittings, Socket-Welding and Threaded. ASME B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings Classes 150, 300, 600, 900, 1500, and 2500 ASME B16.25 Butt Welding Ends ASME B16.34 Valves-Flanged Threaded and Welding End. ASME B16.5 Pipe Flanges and Flanged Fittings. ASME B31.3 Process Piping. ASME B36.10M ASME B36.19M Welded and Seamless Wrought Steel Pipe. Stainless Steel Pipe. ASME B18.2.1 Square and Hex Bolts and Screws (inch series). ASME B18.2.2 Square and Hex Nuts (inch series). ASTM (American Society for Testing and Materials) ASTM A105 Standard Specification for Carbon Steel Forgings for Piping Applications. ASTM A182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. ASTM A216 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service. ASTM A217 Standard Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for HighTemperature Service. ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. ASTM A351 Standard Specification for Castings, Austenitic, for Pressure-Containing Parts. ASTM A182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe ASTM A105 Standard Specification for Carbon Steel Forgings for Piping Applications. ASTM A182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. ASTM A216 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service. ASTM A217 Standard Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for HighTemperature Service. ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. ASTM A351 Standard Specification for Castings, Austenitic, for Pressure-Containing Parts. ASTM A182 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 4 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. ASTM A193 Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High Temperature or High Pressure Service and Other Special Purpose Applications. ASTM A234 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service. ASTM A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes. ASTM A335 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for HighTemperature Service. ASTM A403 Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. ASTM A672 Standard Specification for ElectricFusion-Welded Steel Pipe for HighPressure Service at Moderate Temperatures. 3.3 Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. ASTM A193 Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High Temperature or High Pressure Service and Other Special Purpose Applications. ASTM A234 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service. ASTM A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes. ASTM A335 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for HighTemperature Service. ASTM A403 Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. ASTM A672 Standard Specification for ElectricFusion-Welded Steel Pipe for HighPressure Service at Moderate Temperatures. API (American Petroleum Institute) API 594 Check Valves: Flanged, Lug, Wafer and Buttwelding. API 598 Valve Inspection and Testing API 599 Metal Plug Valves-Flanged and Welding Ends. API 600 Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted Bonnets. API 602 Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries. API 608 Metal Ball Valves – Flanged, Threaded and Welding Ends. API 609 Butterfly Valves: Double – Flanged, Lug – and Wafer-Type. API 594 Check Valves: Flanged, Lug, Wafer and Buttwelding. API 598 Valve Inspection and Testing API 599 Metal Plug Valves-Flanged and Welding Ends. API 600 Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted Bonnets. API 602 Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries. API 608 Metal Ball Valves – Flanged, Threaded and Welding Ends. API 609 Butterfly Valves: Double – Flanged, Lug – and Wafer-Type. Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 5 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 3.4 AWWA (AMERICAN WATER WORKS ASSOCIATION) AWWA C901 Polyethylene (PE) Pressure Pipe and Tubing, 3/4 in. (19 mm) through 3 in. (76 mm), for Water Service. AWWA C906 Polyethylene (PE) Pressure Pipe and fitting, 4 in (100 mm) through 63 in. (1600 mm) for Water Distribution and Transmission. AWWA C907 Injection-Molded Polyvinyl Chloride (PVC) Pressure Fitting, 4 in. through 12 in. (100 mm) through 300 mm) for Water, Wastewater, and Reclaimed Water Service. AWWA C901 Polyethylene (PE) Pressure Pipe and Tubing, 3/4 in. (19 mm) through 3 in. (76 mm), for Water Service. AWWA C906 Polyethylene (PE) Pressure Pipe and fitting, 4 in (100 mm) through 63 in. (1600 mm) for Water Distribution and Transmission. AWWA C907 Injection-Molded Polyvinyl Chloride (PVC) Pressure Fitting, 4 in. through 12 in. (100 mm) through 300 mm) for Water, Wastewater, and Reclaimed Water Service. 3.43.5 MSS (MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTINGS INDUSTRY) MSS-SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions. MSS-SP-67 Butterfly Valves. MSS-SP-72 Ball Valves with Flanged or Butt-Welding Ends for General Service MSS-SP-44 Steel Pipeline Flanges. MSS-SP-97 Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends. MSS-SP-75 High-Strength, Wrought, Butt-Welding Fittings MSS-SP-80 Bronze Gate, Globe, Angle and Check Valves. MSS-SP-85 Gray Iron Globe and Angle Valves, Flanged and Threaded Ends MSS-SP-110 Ball Valves Threaded, Socket – Welding, Solder Joint, Grooved and Flared Ends. MSS-SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions. MSS-SP-67 Butterfly Valves. MSS-SP-72 Ball Valves with Flanged or Butt-Welding Ends for General Service MSS-SP-44 Steel Pipeline Flanges. MSS-SP-97 Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends. MSS-SP-75 High-Strength, Wrought, Butt-Welding Fittings MSS-SP-80 Bronze Gate, Globe, Angle and Check Valves. MSS-SP-85 Gray Iron Globe and Angle Valves, Flanged and Threaded Ends MSS-SP-110 Ball Valves Threaded, Socket – Welding, Solder Joint, Grooved and Flared Ends. 3.53.6 NFPA (National Fire Protection Association) NFPA 13 Standard for the Installation of Sprinkler Systems. NFPA 14 Installation of Standpipe and Hose systems. NFPA 15 Water Spray Fixed Systems for Fire Protection. NFPA 20 Installation of Stationary pumps for fire protection. NFPA 22 Water tanks for private fire protection NFPA 24 Installation of private fire service Mains and their appurtenances. NFPA 291 Recommended practice for Fire Flow testing and Marking of Hydrants. NFPA 13 Standard for the Installation of Sprinkler Systems. NFPA 14 Installation of Standpipe and Hose systems. NFPA 15 Water Spray Fixed Systems for Fire Protection. NFPA 20 Installation of Stationary pumps for fire protection. NFPA 22 Water tanks for private fire protection NFPA 24 Installation of private fire service Mains and their appurtenances. NFPA 291 Recommended practice for Fire Flow testing and Marking of Hydrants. Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 6 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 4 ABREVIATURAS / ABBREVATIONS API ASME ASTM AWWA AWWA BO SM CONC ECC ERW FF HFW ISO ICN LP MSS NPS OD PND psia psig RT RF SMLS SO SW WN XS XXS GO SP FP SAW SCH GALV WT Instituto Americano del Petróleo Sociedad Americana de Ingenieros Mecánicos Sociedad Americana para pruebas y Materiales Asociación Americana para Trabajos Acuíferos Asociación Americana para Trabajos Acuíferos Espesor, Calibre Costura Concéntrico Excéntrico Soldadura por Resistencia Eléctrica Cara Plana Soldadura de Alta Frecuencia Organización Internacional para la Estandarización Numero de código del producto Líquidos PenetrantesPatron Largo Manufacturers Standardization Society Diámetro Nominal de Tubería Diámetro Externo Pruebas no Destructivas Libra por pulgada cuadrada absoluta Libra por pulgada Cuadrada Gauge Porcentaje de Radiografía Cara Realzada Sin Costura Deslizable Inserto Soldable Cuello Soldable Extra Fuerte Extra Extra Fuerte Operador de engranes Patrón Corto Puerto Completo Soldadura Cedula Galvanizado Espesor de Pared API ASME ASTM AWWA AWWA BO SM CONC ECC ERW FF HFW ISO ICN LP MSS NPS OD PND psia psig RT RF SMLS SO SW WN XS XXS GO SP FP SAW SCH GALV WT American Petroleum Institute American Society of Mechanical Engineers American Society for Testing and Materials American Water Works Association American Water Works Association Bore Seam Concentric Eccentric Electric Resistance Welding Flat Face High Frequency Welding International Organization for Standardization Item Code Number Penetrating LiquidsLong Pattern Manufacturers Standardization Society Piping Nominal Diameter Outsider Diameter Non Destructive Tests Pound per Square Inch Absolute Pound per Square Inch Gauge Radiography Percentage Raise Face Seamless SLIP-ON Socket Weld Welding neck Extra Strong Extra Extra Strong Gear Operator Short Pattern Full Port Welded Schedule Galvanized Wall Thickness Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 7 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 5 DESIGNACIÓN DE LA TUBERÍA / PIPE DESIGNATION Las líneas incluidas en los DTI’s y en los dibujos isométricos de tuberías, se identifican de acuerdo a la clase de tuberías. La designación de cada clase de tuberías en los datos se establece de acuerdo al siguiente código. The lines included in the DTIs and in the isometric drawings of pipes identify the agreement of the pipe class. The designation of each class of pipes in the data is established according to the following code. 1 XXX CLASE # / CLASS # 2 XXX MATERIAL / MATERIAL Primer Código / First code Clase de Presión / Pressure Class CL300 300 CL150 150 Tabla 1 Clase por presión / Table 1 Pressure Class Segundo Código/ Second code Tipo de Material /Type of Material CSA Acero al Carbono / Carbon Steel SSA Acero Inoxidable / Stainless Steel CGA Acero Galvanizado / Galvanized Steel PEAD Polietileno de Alta Densidad / High Density Polyethylene Tabla 2 Tipo de Material / Table 2 Type of Material La corrosión a utilizar en los sistemas se muestra a continuación en la tabla 3. The corrosion to be used in the systems is shown below in table 3. Material / Material Corrosión Permitida / Corrosion Allowed (in/mm) Acero Inoxidable / Stainless steel 0.00 / 0.00 Acero al Carbono, Acero Galvanizado / Carbon Steel, Galvanized Steel 0.0625 / 1.59 Polietileno de Alta Densidad / High Density Polyethylene 0.00 / 0.00 Tabla 3 Corrosión Permisible / Table 3 Corrosion Allowed Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 8 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 6 LIMITES DE DISEÑO DE SELECCIÓN DE MATERIALES / DESING LIMITS OF MATERIAL SELECTION Los espesores de pared de tubería indicados en la Especificación de Materiales son los adecuados para soportar las combinaciones de presión/temperatura mostrados. Los mismos se encuentran en el documento ALT1725L03-BB0-402-001 Cálculo de Espesores de Tuberías. Los valores de espesor de pared de tubería han sido calculados por el código de diseño, ASME B31.3, agregando el espesor de corrosión permitida y tomando en cuenta la tolerancia de fabricación aplicable. 7 The pipe wall thicknesses indicated in the Material Specification are adequate to withstand the pressure / temperature combinations shown. They are found in document ALT1725-L03-BB0-402001 Calculation of pipe thicknesses. The pipe wall thickness values were calculated according to the design code, ASME B31.3, adding the allowable corrosion thickness and taking into account the applicable manufacturing tolerance. SERVICIOS / SERVICES • • • • • • • • • • • • • • • • • • Acetona 2 Etil Aire Sosa Cáustica (Grado Diafragma) Sosa Cáustica (Grado Membrana) Ciclohexano Xileno Dietilen Glicol (DEG) Solución de espuma de fuego Agua Contra incendio Isopropanol (IPA) Metanol Spot (Metanol, Xileno, Tolueno) Nitrógeno Agua Monoetilenglicol (MEG) Drenaje Pluvial Drenajes Residuales • • • • • • • • • • • • • • • • • • Acetone 2 Ethyl Air Caustic Soda (Diaphragm Grade) Caustic Soda (Membrane Grade) Cyclohexane Xylene Diethylene glycol (DEG) Fire Foam System Fire Water Isopropanol (IPA) Methanol Spot (Methanol, Xylene, Toluene) Nitrogen Water Monoethylene glycol (MEG) Pluvial Drainage Residual Drains Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 9 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 INDICE DE SERVICIOS Circ. X-Ray Butt Joints Liq. Penetrant / Magnetic Particles. On Fillet weld (Liq. Penet. /Partic. Mag. en Soldadura Filete) Note 3/Nota 3 Visual Inspection (Inspección Visual) Class, Face Type, Material (Clase, Tipo Cara, Material) Thermal Treatment and Stress Relief (Trata. Térmico y Relevado de Esfuerzos) Trim (Inter.) Corro. tolerance (Toler. por corr.) Press. Ratings (Escala de Presión) Temp. Rating (Esc. de Temp.) Piping Spec. (Espec.de Tuberia) Service (Servicio) CL150CSA Acetone, 2 Ethyl, Cyclohexane, Xylene, Isopropanol (IPA), Methanol, Spot , Diethylene glycol (DEG), (Acetona, 2 Etilo, Cyclohexano, Xileno, Isopropanol (IPA), Metanol, Spot , Dietilenglicol (DEG) Acetone, 2 Ethyl, Cyclohexane, Xylene, Isopropanol (IPA), Methanol, Spot , Diethylene glycol (DEG), (Acetona, 2 Etilo, Cyclohexano, Xileno, Isopropanol (IPA), Metanol, Spot , Dietilenglicol (DEG) ) 5% 5% 100% Class 150 (Clase 150) RF CS (Note 1) (Nota 1) 8 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150CSA Caustic Sosa (Diaphragm Grade), Caustic Sosa (Membrane Grade) , (Sosa Caustica (Grado Diafragma), Sosa Caustica (Grado Membrana)) Caustic Sosa (Sosa Caustica) 100% 100% 100% Class 150 (Clase 150) RF CS (Note 1) (Nota 1) 10 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150CSA Fire Water (Agua Contra Incendio) Fire Water (Agua Contra Incendio) 0% 0% 100% Class 150 (Clase 150) RF CS (Note 1) (Nota 1) 8 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150CSA Water , Air (Agua, Aire) Instrument Air, Shower Water and Eyewash (Aire de Instrumentos, agua para ducha y lavado de ojos) 100% Class 150 (Clase 150) RF CS (Note 1) (Nota 1) 8 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150CSA Nitrógen (Nitrogeno) Nitrógen (Nitrogeno) 100% Class 150 (Clase 150) RF CS (Note 1) (Nota 1) 8 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150CGA Fire Foam (Espuma Contra Incendio) Fire Foam (Espuma Contra Incendio) 100% Class 150 (Clase 150) RF CS GALV (Note 1) (Nota 1) 8 0,062 5 in / 1,59 mm Atm psig to 149 psig, Ptest @ 20°C = 29.4 barg max -20 °F to 167 °F / -29 °C to 75 °C CL150SSA Monoethylene glycol (MEG), (Monoetilengli col (MEG)) Monoethylene glycol (MEG), (Monoetilengli col (MEG)) 100% Class 150 (Clase 150) RF SS (Note 1) (Nota 1) 15 0,0 in / 0,0 mm 180 psig to 266 psig , Ptest @ 20°C = 29.4 barg max -50 °F to 464 °F / -46 °C to 240 °C Description (Descripción) (Radiografia Juntas Tope circunferencial.) Note 2/Nota 2 0% 0% 0% 5% 0% 0% 0% 5% Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 10 de 27 Expansión de Almacenamiento de Químicos en la Terminal Altamira Codificación documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍA / PIPING MATERIALS SPECIFICATION Rev.: 3 Circ. X-Ray Butt Joints Liq. Penetrant / Magnetic Particles. On Fillet weld (Liq. Penet. /Partic. Mag. en Soldadura Filete) Note 3/Nota 3 Visual Inspection (Inspección Visual) Piping Spec. (Espec.de Tuberia) Service (Servicio) CL150PEAD Pluvial Drainage, Residual Drains (Drenaje Pluvial, Drenajes Residuales) Agua de Drenaje 0% 0% 100% CL150PEAD BFW Buried Fire Water (Agua Contra Incendio Enterrada) Fire Water (Agua Contra Incendio) 0% 0% 100% Description (Descripción) (Radiografia Juntas Tope circunferencial.) Note 2/Nota 2 Class, Face Type, Material (Clase, Tipo Cara, Material) Thermal Treatment and Stress Relief (Trata. Térmico y Relevado de Esfuerzos) Trim (Inter.) Corro. tolerance (Toler. por corr.) Press. Ratings (Escala de Presión) Temp. Rating (Esc. de Temp.) Class 150 (Clase 150) FF HDPE 10 0,0 in / 0,0 mm Design Pressure: 1,76 kg/cm² Design Temperat ure: 65 °C Class 125 (Clase 125) FF HDPE - 0,0 in / 0,0 mm Design Pressure: 12.34 kg/cm² Design Temperat ure: 70 °C Notes (Notas) : 1. ASME B31.3 indicates that Carbon Steel and Simplex Stainless Steel pipes with thicknesses less than or equal to 19 mm do not require heat treatment (ASME B31.3 indica que las tuberias de Acero al Carbono y Acero Inoxidable con espesores menores o iguales a 19 mm no requieren tratamiento termico). 2. Circumferential X-ray Butt Joint Test for NPS 2 ”and Greater (Prueba de juntas a tope de rayos X circunferenciales para NPS de 2” y mayores). 3. Liquid Penetrant/ Magnetic Particles on Fillet weld Joints test for NPS 1 1/2” and Smaller (Prueba de partículas magnéticas / líquidos penetrantes en juntas de soldadura de filete para NPS de 1 1/2” y menores. Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Página 11 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8, ESPECIFICACION / SPECIFICATION 8.1 CL150CSA Carbon Steel ASTM A106Gr B Main pipe material: Material certificates: 3.1 according to EN 10204:2004 Rating: CLASS 150 Corrossion allowance: 0,0625 in / 1,59 mm Service limits: TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Services Acetone, 2 Ethyl, Air, Caustic Soda (Diaphragm Grade), Caustic Soda (Membrane Grade), Cyclohexane, Xylene Fire Water, Isopropanol (IPA), Methanol, Spot (Methanol, Xylene, Toluene), Nitrogen, Water. NPS (inch) OD (mm) WT (mm) Schedule ITEM PIPE 1/2 21.3 3.73 1 33.4 4.55 3/4 26.7 3.91 1 1/2 48,3 5.08 2 60.3 3.91 2 1/2 73 5.16 3 88.9 5.49 4 114.3 6.02 80 6 168.3 7.11 40 8 219.1 8.18 COMMODITY From NPS To NPS ENDS TPIC1DAB0SC4000 2 12 BE Pipe ASTM A106 Gr. B ASME B36.10M BE SMLS Sch. 40 TPIC1DAP0SC8000 1/2 1 1/2 PE TPIC1DAP0SC8000 1/2 1 1/2 A4ECFADB0SC4000 2 10 273.1 9.27 Design code: ASME B31.3 CL150CSA 12 323.9 10.31 DESCRIPTION MATERIAL DESING ASTM A106 ASME B36.10M Pipe ASTM A106 Gr. B ASME B36.10M , Plain End SMLS Sch. 80 ASTM A106 ASME B36.10M TH Pipe ASTM A106 Gr. B ASME B36.10M , Threaded End SMLS Sch. 80 ASTM A106 ASME B36.10M 12 BW 45 deg Elbow (L.R) ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 ASTM A234 WPB ASME B16.9 A4ECAAESI000000 1/2 1 1/2 SW 45 deg. ASTM A105 ASME B16.11 Socket Weld. Class 3000 ASTM A105 ASME B16.11 A4ECAAETI000000 1/2 1 1/2 TH 45 deg. Elbow ASTM A105 ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 REMARKS 5 ELBOW CAP A9ECFADB0SC4000 2 12 BW 90 deg. Elbow (L.R) ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 A9ECAAESI000000 1/2 1 1/2 SW 90 deg. ASTM A105 ASME B16.11 Socket Weld. Class 3000 A9ECAAETI00000 1/2 1 1/2 TH 90 deg. Elbow ASTM A105 ASME B16.11 NPTF Class 3000 ACPCFADB0SC4000 2 12 BW Cap ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 ACPCAAESI000000 1/2 1 1/2 SW Cap ASTM A105 ASME B16.11 SW Class 3000 ACPCAAETI000000 1/2 1 1/2 TH Cap ASTM A105 ASME B16.11 NPTF Class 3000 ACRCFADB0SC4C40 2 12 BW Concentric Reducer ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 ASCCFAQ20SC8C40 1/2 2 BWxTH 1/2 2 BWxPE ASCCFAQP0SC8C80 1/2 1 1/2 PE ASCCFAQT0SC8000 1/2 1 1/2 TH AERCFADB0SC4C40 2 12 BW ASECFAQ20SC8C40 1/2 2 BWxTH ASCCFAQ100C8C40 Concentric Swage ASTM A234 WPB ASME B16.9, Seamless , Sch 40 X Sch 80 , MSS SP 95, BW x Threaded End Concentric Swage ASTM A234 WPB ASME B16.9, Seamless , Sch 40 X Sch 80 , MSS SP 95, BW x Plain End Concentric Swage ASTM A234 WPB ASME B16.9, Seamless ,Sch 80 , MSS SP 95, Plain Both Ends Concentric Swage ASTM A234 WPB ASME B16.9, Seamless ,Sch 80 , MSS SP 95, Threaded Both Ends ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ASTM A105 ASME B16.11 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ASTM A105 ASME B16.11 ASTM A234 WPB ASME B16.9 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB ASME B16.9 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 REDUCER ASECFAQ20SC8C40 ASECFAQP0SC8C80 ASECFAQT0SC8C80 TEE REDUCER TEE OLET 1/2 1/2 1/2 2 1 1/2 BWxPE PE 1 1/2 TH Eccentric Reducer ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 Eccentric Swage ASTM A234 WPB ASME B16.9, Seamless , Sch 40 X Sch 80 , MSS SP 95, BW x Threaded End Eccentric Swage ASTM A234 WPB ASME B16.9, Seamless , Sch 40 X Sch 80 , MSS SP 95, BW x Plain End Eccentric Swage ASTM A234 WPB ASME B16.9, Seamless ,Sch 80, , MSS SP 95, Plain Both Ends Eccentric Swage ASTM A234 WPB ASME B16.9, Seamless ,Sch 80, MSS SP 95, Threaded Both Ends ATECFADB0SC4000 2 12 BW Tee ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 ATECAAESI000000 1/2 1 1/2 SW Tee ASTM A105 ASME B16.11 Socket Weld. Class 3000 ATECAAETI000000 1/2 1 1/2 TH Tee ASTM A105 ASME B16.11, NFPT, Class 3000 ATRCAADB0SC4000 2 12 BW Reducer Tee ASTM A234 WPB ASME B16.9 BW Seamless Sch. 40 ARTCAAESI000000 1/2 1 1/2 SW Reducer Tee End ASTM A105 ASME B16.11 Socket Weld ,Class 3000 ASTM A105 ASME B16.11 ARTCAAETI000000 1/2 1 1/2 TH Reducer Tee ASTM A105 ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 AWLCAARD00C4C40 2 12 BW Weldolet, ASTM A105, ASME B16.9 BW Seamless Sch. 40 ASTM A105 MSS SP-97 ASLCAARAI000000 1/2 12 SW Sockolet, ASTM A105, CLASS 3000, MSS SP-97 ASTM A105 MSS SP-97 ATLCAARCI000000 1/2 12 TH Threadolet, ASTM A105, CLASS 3000, MSS SP-97 ASTM A105 MSS SP-97 ANLCAARAI600000 1/2 12 PL Nipolet, ASTM A105, CLASS 3000, MSS SP-97 ASTM A105 MSS SP-97 ANLCAARCI600000 1/2 12 TH Nipolet, ASTM A105, CLASS 3000, MSS SP-97 ASTM A105 MSS SP-97 BBFCAAER100000 1/2 12 RF Blind Flange ASTM A105 ASME B16.5 Raised Face (RF) Class 150, (125 - 250 AARH) ASTM A105 ASME B16.5 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ASTM A105 ASME B16.11 ASTM A234 WPB ASME B16.9 BWFCAAER10C400 2 12 RF Flange WN, ASTM A105, CLASS 150, RF, Sch 40, ASME B16.5, (125 - 250 AARH) ASTM A105 ASME B16.5 BCFCAAER10C800 1/2 1 1/2 SW Socket Weld ,Flange ASTM A105 ASME B16.5 RF CL150 Sch 80, (125 - 250 AARH) ASTM A105 ASME B16.11 BTFCAAER100000 1/2 1 1/2 TH Threaded Flange ,ASTM A105 ,Class 150, RF, ASME B16.5, (125 - 250 AARH) ASTM A105 ASME B16.5 FLANGE 5 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 12 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.1 CL150CSA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule Carbon Steel ASTM A106Gr B 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Acetone, 2 Ethyl, Air, Caustic Soda (Diaphragm Grade), Caustic Soda (Membrane Grade), Cyclohexane, Xylene Fire Water, Isopropanol (IPA), Methanol, Spot (Methanol, Xylene, Toluene), Nitrogen, Water. 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 48,3 5.08 2 60.3 3.91 2 1/2 73 5.16 80 3 88.9 5.49 4 114.3 6.02 6 168.3 7.11 40 8 219.1 8.18 10 273.1 9.27 Design code: ASME B31.3 CL150CSA 12 323.9 10.31 AHCCAAESI000000 1/2 1 1/2 SW Half Coupling ASTM A105 ASME B16.11 SW Class 3000 ASTM A105 ASME B16.11 ACLCAAESI000000 1/2 1 1/2 SW Full Coupling ASTM A105 ASME B16.11 SW Class 3000 ASTM A105 ASME B16.11 AHCCAAETI000000 1/2 1 1/2 TH Half Coupling ASTM A105 ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 5 5 COUPLING ACLCAAETI000000 1/2 1 1/2 TH Full Coupling ASTM A105 ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 SPECTACLE BLIND SPADE / SPACER ZF8CMCAR100000 1/2 12 RF Figure 8 , ASTM A 516 Gr. 70 ASME B16.48 / ASME B16.5 Raise Face (RF) (125 - 250 AARH), Thru bolt end Class 150 N/A Standard by ASME 16.48 ASTM A516 Grade 70 ASME B16.48 GASKET IGWBBIAR10G5000 1/2 12 RF Spiral Wound Gasket, 304 SS, CGI type , PTFE Filler (Joint thickness 4,5-4,8 mm) ASME B16.20/ASME B16.5 Flat Ring (RF) Class 150 N/A , Ring thickness 1/8" 304 SS ASME B16.20 BOLTS & NUTS YSTRQAA00000002 1/2 12 TH Stud Bolt with 2 heavy Hex Nuts Bolts: A193 Gr B7, Nuts: A194 Gr 2H ASME B18.2.1, Heavy Hex Nuts, Full Length Threaded, Class 2A for Bolts & Class 2B for Nuts. Cadmium-based corrosion resistant coating (25 microns thick ASTM B766 or equivalent). ASTM A193 B7/A194 2H ASME B16.5 VGIISGAHC8A1G 2 12 RF Gate Valve,150#,(125 - 250 AARH) RF,A216-WCB (Body),Trim 10, FP,OS&Y, BB, HO, API 600, B16.5. For caustic soda ASTM A216WCB API 600 / ASME B16.5 Exclusively for caustic soda VBALCAAAR1B01F 2 12 RF Gate Valve,150#,(125 - 250 AARH) RF ,A216-WCB (Body),Trim 10, FP,OS&Y, BB,HO, Extended Stem (1200 mm, grease fittings, drain and vent extension, as well as any additional required), Gear Operator, API 600, B16.5. For caustic soda ASTM A216WCB API 600 / ASME B16.5 Exclusively for caustic soda. Extended Stem Gear Operator VGFLCBAHS8A1G 1/2 1 1/2 SW Gate Valve , A105 , CL800, SW, Trim 10, HO,BB, OS&Y, FP, B16.11 ,API 602. For caustic soda ASTM A105 API 602/ ASME B16.11 Exclusively for caustic soda VGFLCBAHS8A1G 1/2 1 1/2 SWxNPT Gate Valve , A105 , CL800, SW x NPT, Trim 10, HO, BB, OS&Y, FP, B16.11 , API 602. For caustic soda ASTM A105 API 602/ ASME B16.11 Exclusively for caustic soda VCTLCABER11MI18 2 12 RF Swing Check Valve, 150#, (125 - 250 AARH) RF, W/Disc Stop, A216-WCB (Body), Trim 10, H or V,API594,CAT B, BS 1868,B16.5. For caustic soda. ASTM A216WCB API 600 / ASME B16.5 Exclusively for caustic soda VCTLCBATS81MI11 1/2 1 1/2 SW Lift Check Valve, CL 800, SW, A105 (Body), Trim 10, H or V,API 602,B16.11. For caustic soda. ASTM A105 API 602 / ASME B16.11 Exclusively for caustic soda VALVES FOR CAUSTIC SODA Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 13 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.1 CL150CSA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule ITEM VALVES Carbon Steel ASTM A106Gr B 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Acetone, 2 Ethyl, Air, Caustic Soda (Diaphragm Grade), Caustic Soda (Membrane Grade), Cyclohexane, Xylene Fire Water, Isopropanol (IPA), Methanol, Spot (Methanol, Xylene, Toluene), Nitrogen, Water. 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 48,3 5.08 2 60.3 3.91 2 1/2 73 5.16 80 COMMODITY From NPS To NPS ENDS 3 88.9 5.49 4 114.3 6.02 6 168.3 7.11 40 8 219.1 8.18 10 273.1 9.27 Design code: ASME B31.3 CL150CSA 12 323.9 10.31 DESCRIPTION MATERIAL DESING ASTM A216WCB API 600 / ASME B16.5 REMARKS VGAICABER1A1GD1 2 12 RF Gate Valve,150#,(125 - 250 AARH) RF,A216-WCB (Body),Trim 8, FP,OS&Y, BB,HO,API 600,B16.5 VGAICBAHS8A1GD1 1/2 1 1/2 SW Gate Valve , A105 , CL800, SW, Trim 8, HO, BB, OS&Y, FP, B16.11 , API 602 ASTM A105 API 602/ ASME B16.11 VGIICBAHC8A1GD0 1/2 1 1/2 SWxNPT Gate Valve , A105 , CL800, SW x NPT, Trim 8, HO,BB, OS&Y, FP, B16.11 ,API 602 ASTM A105 API 602/ ASME B16.11 VBALCAAAR1C01F0 6 8 RF Ball Valve, 150#,RF,Floating Ball, A216-WCB (Body),SS316 (Ball),Teflon Seat, Gear operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A216WCB API 608 / ASME B16.5 VBALCAAAR1C01FF 6 8 RF Ball Valve, 150#,RF,Trunnion Mounted, A216-WCB (Body),SS316 (Ball),Teflon Seat, Extended Stem (1200 mm, grease fittings, drain and vent extension, as well as any additional required), Gear Operator, Full Port ,ASME B16.34,B16.5. API 608 ASTM A216WCB API 608 / ASME B16.5 VBALCAAAR1C0YF0 2 4 RF Ball Valve, 150#,RF,Floating Ball, A216-WCB (Body),SS316 (Ball),Teflon Seat, Lever operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A216WCB API 608 / ASME B16.5 VBABCAABR1O0YF0 3 3 RF Ball Valve, 150#,RF,Floating Ball, A216-WCB (Body),SS316 (Ball),Teflon Seat, Spring Return (Deadman) Handle , Full Port , ASME B16.34,B16.5. API 608 ASTM A216WCB API 608 / ASME B16.5 VBALCBAPS8C0YF0 1/2 1 1/2 SW Ball Valve A105 Socket Weld , CL800 , Floating Ball, Trim 10 , Lever operator, Full Port , B16.11, API 608 ASTM A105 API 608 / ASME B16,11 VCTICABER11MI18 2 12 RF Swing Check Valve, 150#, RF, W/Disc Stop, A216-WCB (Body), Trim 8, H or V,API594,CAT B, BS 1868,B16.5 ASTM A216WCB API 600 / ASME B16.5 VCJICBATS81MI10 1/2 1 1/2 SW LIft Check Valve, CL 800, SW, A105 (Body), Trim 8, H or V,API 602,B16.11 ASTM A105 API 602 / ASME B16.11 VGARICAJR7L1YD7 2 12 RF Gate Valve,Class 150#,RF,A395, CI (Iron Body), Bronze Trim , FP,OS&Y, BB,HO,Solid Wedge, MSS SP70, B16.42, 285 psi WWP, UL LISTED /FM Approved According to NFPA24 for Firewater System ASTM A395 MSS SP70 / ASME B16.1 Fire Water VGARBBBBT7L1YD7 1/2 1 1/2 TH Gate Valve Body ASTM B62 , NPT, Bronze Trim, HO, Screw-over bonnet, OS&Y, Solid Wedge, FP, B16.11 ,MSS SP80, 175 psi WWP, UL LISTED /FM Approved According to NFPA24 for Firewater System ASTM B62 MSS SP80/ ASME B16.11 Fire Water VCTRICATR71FI17 2 12 RF Swing Check Valve, Class 150#, RF, W/Disc Stop, Iron Body ASTM A395, bronze Trim , Bolted Bonnet, Horizontal Swing, Drilled and Tapped for Ball Drip Outlet ,MSS SP71, ASME B16.42, 285 psi WWP, UL LISTED /FM Approved, according to NFPA24 for Firewater System ASTM A395 MSS SP71 / ASME B16.1 Fire Water VCTRIAATT71FI17 1/2 1 1/2 TH Swing Check Valve, ASTM B62, NPT, Bronze Trim, Horizontal Swing, Bronce Disc with Rubber, B16.11, 200 psi WWP, UL LISTED /FM Approved According to NFPA 11 for Fire Foam System ASTM B62 MSS SP80/ ASME B16.11 Fire Water ASTM A216WCB ASME B16.5 ASTM A126 CL B ASME B16.5 ASTM A105 ASME B16.11 WYSCA10R1210D00 2 12 RF Strainer Type “Y” with a straight pitch.Filter Body: ASTM A 216 WCB Ends: flanged WNRF class 150 # ASME B16.5. Packaging: Asbestos free Basket: 316 Stainless Steel. Mesh Perforation: 0.045" for filters from 2" to 3"; 0.125" for filters from 4" to 12". Extended Stem Gear Operator 7 "Y" type filters must have a drain fitted with a screw cap. For filters up to 2" in diameter, ½" drain; For Diameter from 2 ½" to 3", purge of 1". For 4” filters, purge 1 ½”. For filters from 6" to 12" it is considered a 2" drain. WYSBB10RC210D00 2 12 RF Strainer Y Class 150#, RF, Iron Body ASTM A126 CL B , Screen AISI 316SS from 20-100 mesh AHPCAAETI000000 1/2 1 1/2 TH Hex Head Plug ASTM A105 ASME B16.11 NPTM Class 3000 MISCELLANEUS ANIC1BAP0SC8003 1/2 1 1/2 PE Nipple ASTM A53 Gr. B ASME B36.10M Plain Both End Seamless Sch 80. Length: 100 o 150 mm ASTM A53 Gr. B ASME B16.10M ANIC1BAT0SC8003 1/2 1 1/2 TH Nipple ASTM A53 Gr. B ASME B36.10M Threaded Both End Seamless Sch 80. Length: 100 o ASTM A53 Gr. B 150 mm ASME B16.10M AHCCAAE2I00000 3/4 2 THxPE Quick Conection ASTM A105 B16.11 Threaded End x Plain End Seamless Class 3000 ANIG1BAO0SC8003 1/2 1 1/2 THxPE Nipple ASTM A53 Gr. B ASME B36.10M Threaded End x Plain End Seamless Sch 80. Length: ASTM A53 Gr. B 100 o 150 mm ASTM A105 Fire Water MSS SP80/ ASME B16.11 ASME B16.10M Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 14 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Carbon Steel ASTM A106Gr B Design code: ASME 3.1 according to EN 10204:2004 CLASS 150 CL150CSA 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Acetone, 2 Ethyl, Air, Caustic Soda (Diaphragm Grade), Caustic Soda (Membrane Grade), Cyclohexane, Xylene Fire Water, Isopropanol (IPA), Methanol, Spot (Methanol, Xylene, Toluene), Nitrogen, Water. Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 48,3 5.08 2 2 1/2 60.3 73 3.91 5,16 3 88.9 5.49 4 114.3 6.02 6 168.3 7.11 40 8 219.1 8,18 10 273.1 9,27 12 323.9 10,31 4 6 8 10 12 R R R 10 R R 80 Reducer table Small End 1/2 3/4 1 1 1/2 2 2 1/2 3 8 R Large End 6 R 4 (R) R (R) 3 R R (R) (R) (R) (R) (R) R R R 2 1/2 2 1 1/2 R R 1 R R 3/4 R 1/2 B31.3 12 R R R R = Reducer used (R) = reducer which is normally not used NPS 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 12 BOLT DIMENSIONS Number of Diameter bolts (inch) 4 4 4 4 4 4 4 8 8 8 12 12 Length (inch) SPADE / SPACER thickness (mm) 3 3 3 3 3.5 3.5 4 4 4.5 4.5 5 5 5 6 6 7 8 8 9 11 13 16 18 21 1/2" 1/2" 1/2" 1/2" 5/8" 5/8" 5/8" 5/8" 3/4" 3/4" 7/8" 1/2" PIPE BENDS Minimum required wall thickness after forming (mm) NPS Nom. wall thickn. (mm) at intrados at extrados 1/2 3/4 1 1 1/4 1 1/2 8 10 3.73 3.91 4.55 4.85 5.08 6.35 6.35 1.7 1.8 1.8 1.9 2.0 3.8 4.4 1.7 1.8 1.8 1.9 1.9 3.5 4.0 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 15 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Carbon Steel ASTM A106Gr B Design code: ASME 3.1 according to EN 10204:2004 CL150CSA CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Acetone, 2 Ethyl, Air, Caustic Soda (Diaphragm Grade), Caustic Soda (Membrane Grade), Cyclohexane, Xylene Fire Water, Isopropanol (IPA), Methanol, Spot (Methanol, Xylene, Toluene), Nitrogen, Water. Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule 1/2 21.3 3.73 1 33.4 4.55 1 1/2 48,3 5.08 2 60.3 3.91 2 1/2 73 5,16 3 88.9 5.49 4 114.3 6.02 6 168.3 7.11 40 80 10 273.1 9,27 8 219.1 8,18 12 323.9 10,31 BRANCH SIZE 90° BRANCH TABLE HEADER SIZE 3/4 26.7 3.91 B31.3 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 12 12 SL SL SL SL P/WL P/WL P/WL TL TR TR TR T 10 SL SL SL SL P/WL P/WL P/WL TL TR TR T 8 SL SL SL SL P/WL P/WL P/WL TR TR T 6 SL SL SL SL P/WL P/WL TR TR T 4 SL SL SL TL TR TR TR T 3 SL SL SL SL TR TR T 2 1/2 SL SL TL TL TR T 2 SL TL TL TL T 1 1/2 TR TR TR T 1 TR TR T 3/4 TR T 1/2 T REINFORCED SET-IN DETAIL Outside diameter reinforcing pad: see table above (note 1) 1/4" threaded (note 2) t P PR T TL SL WL = Set-in (Set-on for pigging lines) = Reinforced Set-in (Set-on for pigging lines), see value between brackets for outside diameter of reinforcing pads = Equal tee = Reducing tee + reducer = Sockolet = Weldolet Note: 1. Plate reinforcement material and thickness: same as header pipe 2. Tell-tale holes shall not be plugged, but shall be filled with a non-corrosive compound or grease to prevent the ingress of water after the test for tightness of the welds 3 Only to be used on hydrostatic testing 4 Only to be used on Pressure Instruments 5 Threaded joints must be NPT (ASME B1.20.1) and sealed with welding, except where cap plugs are installed. 6 Eliminated 7 Spring-closed valve: used to vent air from tankline to ensure tankline product is full. 8 Pipes that are received with flat ends should be chamfered on site according to the needs of the project. Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 16 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.2 CL150CGA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule ITEM Design code: Carbon Steel ASTM A53 Gr B Galv 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Fire Foam System Fire Water (Note 7) 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 2 1 1/2 2 1/2 48,3 60.3 73 5.08 3.91 5,16 80 COMMODITY From NPS To NPS ENDS TPIG1AAB0SC4000 2 12 BE TPIG1AAT0SC8000 1/2 1 1/2 A4EGFADB0SC4000 2 12 A4EGAAETI000000 3 88.9 5.49 4 114.3 6.02 ASME B31.3 CL150CGA 6 168.3 7.11 40 8 219.1 8,18 10 273.1 9,27 12 323.9 10,31 DESCRIPTION MATERIAL DESING Pipe ASTM A53 Gr. B (Galv as per A153) ASME B36.10M BE SMLS Sch. 40 ASTM A53-B ASME B36.10M TH Pipe ASTM A53-B (Galv as per A153) ASME B36.10M TH , SMLS Sch. 80 ASTM A53-B ASME B36.10M BW 45 deg Elbow (L.R) ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ASTM A234 WPB ASME B16.9 REMARKS PIPE 1/2 1 1/2 TH 45 deg. Elbow ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 A9EGFADB0SC4000 2 12 BW 90 deg. Elbow (L.R) ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 A9EGAAETI000000 1/2 1 1/2 TH 90 deg. Elbow ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 ACPGFADB0SC4000 2 12 BW Cap ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ACPGAAETI000000 1/2 1 1/2 TH Cap ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 ACRGFADB0SC4000 2 12 BW Concentric Reducer ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ASTM A105 ASME B16.11 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB MSS SP-95 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 ELBOW CAP ASCGFAD200C8C40 1/2 2 BWxTH ASCGFADT00C8C80 1/2 1 1/2 TH AERGFADB0SC4000 2 12 BW REDUCER ASEGFAD200C8C40 1/2 2 BWxTH Concentric Swage ASTM A234 WPB (Galv as per A153) ASME B16.9, Seamless ,Sch 40XSch 80, MSS SP 95, BW x Threaded End Concentric Swage ASTM A234 WPB (Galv as per A153) ASME B16.9, Seamless , Sch 80, MSS SP 95 Threaded Both Ends Eccentric Reducer ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 Eccentric Swage ASTM A234 WPB (Galv as per A153) ASME B16.9, Seamless , Sch 40XSch 80, MSS SP 95, BW x Threaded End Eccentric Swage ASTM A234 WPB (Galv as per A153) ASME B16.9, Seamless , ASEGFADT00C8C80 1/2 1 1/2 TH ATEGFADB0SC4000 2 12 BW Tee ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ATEGAAETI000000 1/2 1 1/2 TH Tee ASTM A105 (Galv as per A153) ASME B16.11, NFPT, Class 3000 Sch 80, MSS SP 95, Threaded Both Ends TEE ATRGFADB0SC4000 2 12 BW Reducer Tee ASTM A234 WPB (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ATRGAAETI000000 1/2 1 1/2 TH Reducer Tee ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 ASTM A234 WPB ASME B16.9 ASTM A105 ASME B16.11 MSS SP-97 REDUCER TEE OLET FLANGE AWLGAARD00C4C40 2 12 BW Weldolet ASTM A105 (Galv as per A153) ASME B16.9 BW Seamless Sch. 40 ASTM A105 ATLGAARCI000000 1/2 12 TH Threadolet, ASTM A105, CLASS 3000, MSS SP-97 (Galv as per A153) ASTM A105 MSS SP-97 ANLGAARCI600000 1/2 12 TH Nipolet, ASTM A105, CLASS 3000, MSS SP-97 (Galv as per A153) ASTM A105 MSS SP-97 BBFGAAER1S0000C 1/2 12 RF Blind Flange ASTM A105 (Galv as per A153) ASME B16.5 Raised Face (RF) Class 150 , (125 - 250 AARH) ASTM A105 ASME B16.5 12 RF Flange WN, ASTM A105 (Galv as per A153), CLASS 150, RF, Sch 40, ASME B16.5, (125 - 250 AARH) ASTM A105 ASME B16.5 BWFGAAER10C400C 2 BTFGAAER1SC800C 1/2 1 1/2 TH Threaded Flange ,ASTM A105 (Galv as per A153), Class 150, RF, ASME B16.5 (125 - 200 AARH) ASTM A105 ASME B16.5 5 AHCGAAETI000000 1/2 1 1/2 TH Half Coupling ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 5 ACLGAAETI000000 1/2 1 1/2 TH Full Coupling ASTM A105 (Galv as per A153) ASME B16.11 NPTF Class 3000 ASTM A105 ASME B16.11 5 SPECTACLE BLIND SPADE / SPACER ZF8CMCAR1000000 1/2 12 RF Figure 8 , ASTM A 516 Gr. 70 ASME B16.48 / ASME B16.5 Raise Face (RF) Thru bolt end Class 150 N/A Standard by ASME 16.48 ASTM A516 Grade 70 ASME B16.48 GASKET IGWBBIAR10G5000 1/2 12 RF Spiral Wound Gasket, 304 SS, CGI type , PTFE Filler (Joint thickness 4,5-4,8 mm) ASME B16.20/ASME B16.5 Flat Ring (RF) Class 150 N/A , Ring thickness 1/8" 304 SS ASME B16.20 BOLTS & NUTS YSTRQAA00000002 1/2 12 TH Stud Bolt with 2 heavy Hex Nuts Bolts: A193 Gr B7, Nuts: A194 Gr 2H ASME B18.2.1, Heavy Hex Nuts, Full Length Threaded, Class 2A for Bolts & Class 2B for Nuts. Cadmium-based corrosion resistant coating (25 microns thick ASTM B766 or equivalent). ASTM A193 B7/A194 2H ASME B16.5 COUPLING Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 17 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.2 CL150CGA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule Design code: Carbon Steel ASTM A53 Gr B Galv 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Fire Foam System Fire Water (Note 7) 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 2 2 1/2 48,3 60.3 73 5.08 3.91 5,16 80 3 88.9 5.49 4 114.3 6.02 ASME B31.3 CL150CGA 6 168.3 7.11 40 8 219.1 8,18 10 273.1 9,27 12 323.9 10,31 2 12 RF Gate Valve,150#, (125 - 200 AARH) RF, A216-WCB (Body),Trim 8, FP,OS&Y, BB,HO,API 600,B16.5 ASTM A216-WCB API 600 / ASME B16.5 1/2 1 1/2 TH Gate Valve , A105 , CL800, Threaded Ends , Trim 8, HO,BB, OS&Y, FP, B16.11 ,API 602 ASTM A105 API 602/ ASME B16.11 VBALCAAAR1C01F0 6 8 RF Ball Valve, 150#,RF,Floating Ball, A216-WCB (Body),SS316 (Ball),Teflon Seat, Gear operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A216-WCB API 608 / ASME B16.5 VBALCAAAR1C0YF0 2 4 RF Ball Valve, 150#,RF,Floating Ball, A216-WCB (Body),SS316 (Ball), Teflon Seat, Lever operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A216-WCB API 608 / ASME B16.5 VBALCBAPS8C0YF0 1/2 1 1/2 SW Ball Valve A105 Socket Weld , CL800 , Floating Ball, Trim 10 , Lever operator, Full Port , B16.11, API 608 ASTM A105 API 608 / ASME B16,11 VCTICABER11FI18 2 12 RF Swing Check Valve, 150#, (125 - 200 AARH) RF, W/Disc Stop, A216-WCB (Body), Trim 8, H or V,API594,B16.5 ASTM A216-WCB API 600 / ASME B16.5 VCTICABCT11FI10 1/2 1 1/2 SW ASTM A105 API 602 / ASME B16.11 ASTM A395 MSS SP70 / ASME B16.1 Fire Water ASTM B62 MSS SP80/ ASME B16.11 Fire Water VGAICABER1A1GD1 VBCSCBAAT1C1GD0 VALVES Lift Check Valve, Rating 800#, Socket Weld , A105 (Body), Trim 8, H or V,API 602,B16.11 Gate Valve,Class 150#,RF,A395, CI (Iron Body), Bronze Trim , FP,OS&Y, BB,HO,Solid Wedge, MSS SP70, B16.42, 285 psi WWP, UL LISTED /FM Approved According to NFPA24 for Firewater System Gate Valve Body ASTM B62 , NPT, Bronze Trim, HO, Screw-over bonnet, OS&Y, Solid Wedge, FP, B16.11 ,MSS SP80, 175 psi WWP, UL LISTED /FM Approved According to NFPA24 for Firewater System VGARICAJR7L1YD7 2 12 RF VGARBBBBT7L1YD7 1/2 1 1/2 TH VCTRICATR71FI17 2 12 RF Swing Check Valve, Class 150#, RF, W/Disc Stop, Iron Body ASTM A395, bronze Trim , Bolted Bonnet, Horizontal Swing, Drilled and Tapped for Ball Drip Outlet ,MSS SP71, ASME B16.42, 285 psi WWP, UL LISTED /FM Approved, according to NFPA24 for Firewater System ASTM A395 MSS SP71 / ASME B16.1 Fire Water VCTRIAATT71FI17 1/2 1 1/2 TH Swing Check Valve, ASTM B62, NPT, Bronze Trim, Horizontal Swing, Bronce Disc with Rubber, B16.11, 200 psi WWP, UL LISTED /FM Approved According to NFPA 11 for Fire Foam System ASTM B62 MSS SP80/ ASME B16.11 Fire Water ASTM A216-WCB ASME B16.5 Strainer Type “Y” with a straight pitch.Filter Body: ASTM A 216 WCB Ends: flanged WNRF class 150 # ASME B16.5. Packaging: Asbestos free WYSCA10R1210D00 2 12 RF MISCELLANEUS Basket: 304/316 Stainless Steel. Mesh Perforation: 0.045" for filters from 2" to 3"; 0.125" for filters from 4" to 12". "Y" type filters must have a drain fitted with a screw cap. For filters up to 2" in diameter, ½" drain; For Diameter from 2 ½" to 3", purge of 1". For 4” filters, purge 1 ½”. For filters from 6" to 12" it is considered a 2" drain. Strainer Y Class 150#, RF, Iron Body ASTM A126 CL B , Screen AISI 304SS from 20-100 mesh WYSBB10RC210D00 2 12 RF AHPGAAETI000000 1/2 2 TH Hex Head Plug ASTM A105 (Galv as per A153) ASME B16.11 NPTM Class 3000 ANIGAAAT0SC8003 1/2 1 1/2 TH Nipple ASTM A53 Gr. B galv. (Galv as per A153) ASME B36.10M Threaded End Seamless Sch 80. Length: 100 o 150 mm ASTM A126 CL B ASME B16.5 ASTM A105 ASME B16.11 ASTM A53 Gr. B ASME B16.10M Fire Water Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 18 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Design code: Carbon Steel ASTM A53 Gr B Galv 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Fire Foam System Fire Water (Note 7) Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 48,3 5.08 2 2 1/2 60.3 73 3.91 5,16 3 88.9 5.49 4 114.3 6.02 6 168.3 7.11 40 8 219.1 8,18 10 273.1 9,27 12 323.9 10,31 Small End 1/2 3/4 1 1 1/2 2 2 1/2 3 6 8 10 12 R R R 10 R R 8 R 4 (R) R (R) 3 R R (R) (R) (R) (R) (R) R R R 2 1/2 2 1 1/2 R R 1 R R 3/4 R 1/2 4 R 6 Large End CL150CGA 80 Reducer table ASME B31.3 12 R R R R = Reducer used, see detailed specification on sheet 1 (R) = reducer which is normally not used NPS 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 BOLT DIMENSIONS Number of Diameter bolts (inch) 4 4 4 4 4 4 4 8 8 8 12 1/2" 1/2" 1/2" 1/2" 5/8" 5/8" 5/8" 5/8" 3/4" 3/4" 7/8" Length (inch) SPADE / SPACER thickness (mm) 3 3 3 3 3.5 3.5 4 4 4.5 4.5 5 5 6 6 7 8 8 9 11 13 16 18 PIPE BENDS Minimum required wall thickness after forming (mm) Nom. wall thickn. at NPS at intrados (mm) extrados 1/2 3/4 1 1 1/4 1 1/2 8 10 3.73 3.91 4.55 4.85 5.08 6.35 6.35 1.7 1.8 1.8 1.9 2.0 3.8 4.4 1.7 1.8 1.8 1.9 1.9 3.5 4.0 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 19 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Design code: Carbon Steel ASTM A53 Gr B Galv 3.1 according to EN 10204:2004 CLASS 150 0,0625 in / 1,59 mm TEMPERATURE RATINGS: -20 °F to 167 °F / -29 °C to 75 °C PRESSURE RATINGS: Atm psig to 149 psig Ptest @ 20°C = 29.4 barg max Fire Foam System Fire Water (Note 7) Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule 1/2 21.3 3.73 3/4 26.7 3.91 1 33.4 4.55 1 1/2 48,3 5.08 2 2 1/2 60.3 73 3.91 5,16 3 88.9 5.49 4 114.3 6.02 HEADER SIZE 90° BRANCH TABLE CL150CGA 6 168.3 7.11 40 80 ASME B31.3 8 219.1 8,18 10 273.1 9,27 12 323.9 10,31 BRANCH SIZE 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 12 12 TL TL TL TL P P P P P TR TR T 10 TL TL TL TL P P P P TR TR T 8 TL TL TL TL P P P TR TR T 6 TL TL TL TL P P TR TR T 4 TL TL TL TL TR TR TR T 3 TL TL TL TL TR TR T 2 1/2 TL TL TL TL TR T 2 TL TL TL TL T 1 1/2 TR TR TR T 1 TR TR T 3/4 TR T 1/2 T REINFORCED SET-IN DETAIL Outside diameter reinforcing pad: see table above 1/4" threaded (note 2) (note 1) t P PR T TR TR+R TL Note: = Set-in (Set-on for pigging lines) = Reinforced Set-in (Set-on for pigging lines), see value between brackets for outside diameter of reinforcing pads = Equal tee = Reducing tee = Reducing tee + reducer = Threadolet 1. Plate reinforcement material and thickness: same as header pipe 2. Tell-tale holes shall not be plugged, but shall be filled with a non-corrosive compound or grease to prevent the ingress of water after the test for tightness of the welds 3. Only to be used on hydrostatic testing 4. Only to be used on Pressure Instruments 5. Threaded joints must be NPT (ASME B1.20.1) and sealed with welding, except where cap plugs are installed. 6. Eliminated 7. Galvanized steel only applies to the pipe after the deluge valve 8. All pipes and weldable connections from 2" to 12" must be designed based on flanged assemblies (spools) to be hot-dip galvanized will be Hot Dip Galvanized as per ASTM A153 after their manufacture 9. Pipes that are received with flat ends should be chamfered on site according to the needs of the project. Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 20 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.3 CL150SSA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule ITEM PIPE Design code: Stainless Steel ASTM A312 GR TP304L 3.1 according to EN 10204:2004 CLASS 150 0 mm TEMPERATURE RATINGS: -50 °F to 464 °F / -46 °C to 240 °C PRESSURE RATINGS: 180 psig to 266 psig Ptest @ 20°C = 29.4 barg max Monoethylene glycol (MEG) 1/2 21.3 2.77 3/4 1 26.7 33.4 2.87 3.38 40S 1 1/2 48,3 3.68 2 60.3 2.77 2 1/2 73 3.05 CL150SSA 3 88.9 3.05 4 114.3 3.05 10S 6 168.3 3.40 COMMODITY From NPS To NPS ENDS TPIS43BB0WS1000 4 12 BE Pipe ASTM A312 TP-304L ASME B36.19M BE Welded Sch 10S TPIS43BB0SS1000 2 3 BE TPISAIBP0SS4000 A4ESFCDB0WS1000 1/2 4 1 1/2 12 PE BW A95C1DAPOSS1000 2 3 BW A4ESAIESI000000 1/2 1 1/2 SW A9ESFCDB0WS1000 4 12 BW ELBOW A9ECFADB0SS1000 2 3 BW 8 219.1 3.76 10 273.1 4.19 DESCRIPTION TEE REDUCE TEE 12 323.9 4.57 MATERIAL DESING REMARKS ASTM A312 TP304L ASME B36.19M NOTE 7 Pipe ASTM A312 TP 304L ASME B36.19M BE Seamless Sch. 10S ASTM A312 TP304L ASME B36.19M NOTE 7 Pipe ASTM A312 TP-304L ASME B36.19M , Plain End SMLS Sch. 40S ASTM A312 TP304L ASME B36.19M 45 deg Elbow (L.R) ASTM A403 WP304L ASME B16.9 BW Welded Sch. 10S ASTM A403 WP304L ASME B16.9 45 deg Elbow (L.R) ASTM A403 WP304L ASME B16.9 BW Seamless Sch. 10S ASTM A403 WP304L ASME B16.9 ASTM A182 F304L ASME B16.11 90 deg Elbow (L.R) ASTM A403 WP304L ASME B16.9 BW Welded Sch. 10S ASTM A403 WP304L ASME B16.9 90 deg Elbow (L.R) ASTM A403 WP304L ASME B16.9 BW Seamless Sch. 10S ASTM A403 WP304L ASME B16.9 ASME B16.11 45 deg. Elbow ASTM A182 F304L ASME B16.11 Socket Weld Class 3000 A9ESAIESI000000 1/2 1 1/2 SW 90 deg. Elbow ASTM A182 F304L ASME B16.11 Socket Weld Class 3000 ASTM A182 F304L ACPCFADB0SS1000 2 12 BW Cap, ASTM A403 WP304L ASME B16.9, BW Seamless, Sch 10S ASTM A403 WP304L ASME B16.9 ASME B16.11 CAP REDUCER ASME B31.3 ACPSAIESI000000 1/2 1 1/2 SW Cap, ASTM A182 F304L ASME B16.11 Socket Weld ,Class 3000 ASTM A182 F304L ACRSFCDB0WS1S10 4 12 BW Concentric Reducer, ASTM A403 WP304L ASME B16.9, BW Welded, Sch. 10S ASTM A403 WP304L ASME B16.9 ACRSFCDB0SS1S10 2 3 BW Concentric Reducer, ASTM A403 WP304L ASME B16.9, BW Seamless, Sch. 10S ASTM A403 WP304L ASME B16.9 ASCSFCD100S4S10 1/2 2 BWxPE Concentric Swage ASTM A403 WP304L ASME B16.9 BW X Plain End SMLS Sch 10S X Sch 40S ASTM A403 WP304L ASME B16.9 ASCSFCDP00S4S40 1/2 1 1/2 PE Concentric Swage ASTM A403 WP304L ASME B16.9 Plain Ends SMLS Sch 40S ASTM A403 WP304L ASME B16.9 AERSFCDB0WS4S10 4 12 BW Eccentric Reducer, ASTM A403 WP304L ASME B16.9, BW Welded, Sch. 10S ASTM A403 WP304L ASME B16.9 Eccentric Reducer, ASTM A403 WP304L ASME B16.9, BW Seamless, Sch. 10S ASTM A403 WP304L ASME B16.9 Eccentric Swage ASTM A403 WP304L ASME B16.9 BW X Plain End SMLS Sch 10S X Sch 40S ASTM A403 WP304L ASME B16.9 AERSFCDB0SS1S10 2 3 BW ASESFCD100S4S10 1/2 2 BWxPE ASESFCDP00S4S40 1/2 1 1/2 PE Eccentric Swage ASTM A403 WP304L ASME B16.9 BW X Plain Ends SMLS Sch 40S ASTM A403 WP304L ASME B16.9 ACRSAIESI000000 1/2 1 1/2 SW Reducer Coupling , ASTM A182 F304L ASME B16.11 Socket Weld ,Class 3000 ASTM A182 F304L ASME B16.11 ATESFCEB0WS1000 4 12 BW Tee ASTM A403 WP304L ASME B16.9, BW Welded Sch 10S ASTM A403 WP304L ASME B16.9 Tee, ASTM A403 WP304L ASME B16.9 BW , SMLS, Sch. 10S ASTM A403 WP304L ASME B16.9 ASME B16.11 ATESFCEB0SS1000 2 3 BW ATESAIESI000000 1/2 1 1/2 SW Tee ASTM A182 F304L ASME B16.11 Socket Weld Class 3000 ASTM A182 F304L ARTSFCDB0WS1S10 4 12 BW Reducer Tee, ASTM A403 WP304L ASME B16.9, BW , Welded, Sch. 10S ASTM A403 WP304L ASME B16.9 ARTSFCDB0SS1S10 2 3 BW Reducer Tee, ASTM A403 WP304L ASME B16.9, BW , SMLS, Sch. 10S ASTM A403 WP304L ASME B16.9 Reducer Tee ASTM A182 F304L ASME B16.11 Socket Weld Class 3000 ASTM A182 F304L ASME B16.11 Weldolet ASTM A182 F304L , MSS-SP-97, ASME B16.9 BW Seamless Sch. 10S ASTM A182 F304L MSS SP-97 Sockolet, Class 3000, ASTM A182 F304L MSS SP-97 ASTM A182 F304L MSS SP-97 Threadolet, ASTM A182 F304L , CLASS 3000, MSS SP-97 ASTM A182 F304L MSS SP-97 Nipolet, Class 3000, ASTM A182 F304L MSS SP-97 ASTM A182 F304L ASME B16.5 Blind Flange ASTM A182 F304L ASME B16.5 Raise Face (RF) Class 150 (125 - 250 AARH) ASTM A182 F304L ASME B16.5 ASME B16.5 ARTSAIESI000000 AWLSFCRD00S1000 ASLSAIRAI000000 1/2 2 1/2 1 1/2 12 12 SW BW SW OLET ATLSAIRCI000000 ANLSAIRAI600000 BBFSAIER100000E 1/2 1/2 1/2 12 12 12 TH PL RF BWFSAIER10S100F 2 12 BW Flange WN, ASTM A182 F304L , CLASS 150, RF, Sch 10S, ASME B16.5, (125 - 250 AARH) ASTM A182 F304L BCFSAAER10C800C 1/2 1 1/2 SW Socket Weld Flange ASTM A182 F304L, CLASS 150, RF, Sch 40S, ASME B16.5 (125 - 250 AARH) ASTM A182 F304L ASME B16.5 COUPLING ACLSAIESIS00000 1/2 1 1/2 SW Full Coupling ASTM A182 F304L ASME B16.11 Socket Weld ,Class 3000 ASTM A182 F304L ASME B16.11 SPECTACLE BLIND SPADE / SPACER ZF8SMGAR1000000 1/2 12 RF Figure 8 , ASTM A240 TP 304L, ASME B16.48 / ASME B16.5, (125 - 250 AARH) Raised Face (RF) Thru bolt end Class 150 N/A Standard by ASME 16.48 ASTM A240 TP 304L ASME B16.48 GASKET IGWBBIAR0G50000 1/2 12 RF Spiral Wound Gasket, 304 SS, CGI type , PTFE Filler (Joint thickness 4,5-4,8 mm) ASME B16.20/ASME B16.5 Flat Ring (RF) Class 150 N/A , Ring thickness 1/8" 304 SS ASME B16.20 YSTSQCB00000002 1/2 12 TH Stud Bolt with 2 heavy Hex Nuts Bolts: A320 Gr. B8, Nuts: A194 Gr. 8 ASME B18.2.1/18.2.2 ASTM A320 B8/A194 Gr. 8 ASME B18.2.1/18.2.2 FLANGE BOLTS & NUTS 4 4 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 21 de 27 Cód. de Documento: EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 8.3 CL150SSA Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services NPS (inch) OD (mm) WT (mm) Schedule VALVES Design code: Stainless Steel ASTM A312 GR TP304L 3.1 according to EN 10204:2004 CLASS 150 0 mm TEMPERATURE RATINGS: -50 °F to 464 °F / -46 °C to 240 °C PRESSURE RATINGS: 180 psig to 266 psig Ptest @ 20°C = 29.4 barg max Monoethylene glycol (MEG) 1/2 21.3 2.77 3/4 1 26.7 33.4 2.87 3.38 40S 1 1/2 48,3 3.68 2 60.3 2.77 2 1/2 73 3.05 ASME B31.3 CL150SSA 3 88.9 3.05 4 114.3 3.05 10S 6 168.3 3.40 8 219.1 3.76 10 273.1 4.19 12 323.9 4.57 VGASSAAAR1A1GD1 2 12 RF Gate Valve,150#, (125 - 250 AARH) RF,A351-CF3 (Body),Trim 304L, FP,OS&Y, BB,HO,ASME ASME 16.34 / ASME ASTM A351 CF3 B16.5 B16.34,B16.5 VGBBSGAAS8A1GD0 1/2 1 1/2 SW Gate Valve , A182-F304L (Body) , CL800, SW, Trim 304L, HO, BB, OS&Y, FP, B16.11 , API 602 ASTM A182 F304L API 602 / ASME B16.11 VGIISGAHC8A1GD0 1/2 1 1/2 SWxNPT Gate Valve , A182-F304L (Body) , CL800, SW x NPT, Trim 304L, HO, BB, OS&Y, FP, B16.11 , API 602 ASTM A182 F304L API 602 / ASME B16.11 VBASSAAPR1B01F0 6 12 RF Ball Valve, 150#,RF,Floating Ball, ASTM A351 CF3 (Body),SS316 (Ball),Teflon Seat, Gear operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A351 CF3 API 608 /B16.5 VBALSAAAR1B01FF 6 12 RF Ball Valve, 150#,RF,Trunnion Mounted, ASTM A351 CF3(Body),SS316 (Ball),Teflon Seat, Extended Stem (1200 mm, grease fittings, drain and vent extension, as well as any additional required), Gear Operated, Full Port, ASME B16.34,B16.5. API 608 ASTM A351 CF3 API 608 /B16.5 Extended Stem Gear Operator VBASSAAPR1O0YF0 3 3 RF Ball Valve, 150#,RF,Floating Ball, ASTM A351 CF3 (Body),SS316 (Ball),Teflon Seat, Spring Return (Deadman) Handle, Full Port, ASME B16.34, B16.5. API 608 ASTM A351 CF3 API 608 /B16.5 6 VBASSAAPR1C0YF0 2 6 RF Ball Valve, 150#,RF,Floating Ball, ASTM A351 CF3 (Body),SS316 (Ball),Teflon Seat, Lever operator, Full Port , ASME B16.34,B16.5. API 608 ASTM A351 CF3 API 608 /B16.5 VCTBSAAHR11FI10 2 12 RF Swing Check Valve, 150#, (125 - 250 AARH) RF, W/Disc Stop, ASTM A351 CF3(Body), Trim 304L, H or V,API594,B16.5 ASTM A351 CF3 API 594 / ASME B16.5 VCTBSGATS81FI10 1/2 1 1/2 SW Lift Check Valve, Rating 800#, Socket Weld , A182-F304L (Body), Trim 304L, H or V, ASME B16.11 ASTM A182 F304L ASME 16.34 / ASME B16.11 ASTM A351 CF8M ASME B16.5 Strainer Type “Y” with a straight pitch.Filter Body: ASTM A 351 CF8M Ends: flanged WNRF (125-250 AARH), 150 # ASME B16.5. Packaging: Asbestos free WYSSH10R1210D00 2 12 RF Basket: 304/316 Stainless Steel. Mesh Perforation: 0.045" for filters from 2" to 3"; 0.125" for filters from 4" to 12". "Y" type filters must have a drain fitted with a screw cap. For filters up to 2" in diameter, ½" drain; For Diameter from 2 ½" to 3", purge of 1". For 4” filters, purge 1 ½”. For filters from 6" to 12" it is considered a 2" drain. AHPSAIETI000000 1/2 1 1/2 TH Hex Head Plug ASTM A182 F304L ASME B16.11 NPTM Class 3000 ASTM A182 F304L ASME B16.11 PE Nipple ASTM A182 F304L ASME B36.10M Plain Both End Seamless Sch 80S. Length: 100 o 150 mm ASTM A312 TP304L ASME B16.10M TH Nipple ASTM A182 F304L ASME B36.10M Threaded Both End Seamless Sch 80S. Length: 100 o 150 mm ASTM A312 TP304L ASME B16.10M Nipple ASTM A182 F304L ASME B36.10M Threaded End x Plain End Seamless Sch 80S. Length: 100 o 150 mm ASTM A312 TP304L ASME B16.10M PTFE ASME B16.20 MISCELLANEUS ANISAIAT0SC8003 ANISAIAP0SC8003 ANISAIAO0SC8003 IIK0A0AF12G2000 1/2 1/2 1/2 1/2 1 1/2 1 1/2 1 1/2 12 THxPE Insulation Gasket Kit, Compressed Fiber, For RF Flanges Class 150 , F type , PTFE Sealing Element , ASME B16.20/ASME B16.5 with Double Insulation Sleeve and Washer (thickness 1/8") . NOTE 8 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 22 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Design code: Stainless Steel ASTM A312 GR TP304L 3.1 according to EN 10204:2004 CLASS 150 0 mm TEMPERATURE RATINGS: -50 °F to 464 °F / -46 °C to 240 °C PRESSURE RATINGS: 180 psig to 266 psig Ptest @ 20°C = 29.4 barg max Monoethylene glycol (MEG) Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services 1/2 21.3 2.77 NPS (inch) OD (mm) WT (mm) Schedule 1 1/2 2 48,3 60.3 3.68 2.77 2 1/2 73 3.05 3 88.9 3.05 4 114.3 3.05 8 219.1 3.76 10 273.1 4.19 12 323.9 4.57 6 8 10 12 12 R R R 10 R R 10S Small End 1/2 3/4 1 1 1/2 2 2 1/2 3 8 R 4 (R) R (R) 3 R R (R) (R) (R) (R) (R) R R R 2 1/2 2 1 1/2 R R 1 R R 3/4 R 1/2 4 R 6 Large End CL150SSA 6 168.3 3.40 Reducer table 3/4 1 26.7 33.4 2.87 3.38 40S ASME B31.3 R R R R = Reducer used (R) = reducer which is normally not used BOLT DIMENSIONS NPS Number of bolts Diameter (inch) Length (inch) SPADE / SPACER thickness (mm) 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 4 4 4 4 4 4 4 8 8 8 12 1/2" 1/2" 1/2" 1/2" 5/8" 5/8" 5/8" 5/8" 3/4" 3/4" 7/8" 3 3 3 3 3.5 3.5 4 4 4.5 4.5 5 5 6 6 7 8 8 9 11 13 16 18 PIPE BENDS Minimum required wall thickness after forming (mm) NPS Nom. wall thickn. (mm) at intrados at extrados 1/2 3/4 1 1 1/2 8 10 3.73 3.91 4.55 5.08 6.35 6.35 1.7 1.8 1.8 2.0 3.8 4.4 1.7 1.8 1.8 1.9 3.5 4.0 Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 23 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Rev.:3 Design code: Stainless Steel ASTM A312 GR TP304L 3.1 according to EN 10204:2004 CLASS 150 Rating: Corrossion allowance: 0 mm Service limits: TEMPERATURE RATINGS: -50 °F to 464 °F / -46 °C to 240 °C PRESSURE RATINGS: 180 psig to 266 psig Ptest @ 20°C = 29.4 barg max Services Monoethylene glycol (MEG) Main pipe material: Material certificates: NPS (inch) OD (mm) WT (mm) Schedule 1/2 21.3 2.77 HEADER SIZE 90° BRANCH TABLE 3/4 1 26.7 33.4 2.87 3.38 40S 1 1/2 48,3 3.68 2 60.3 2.77 2 1/2 73 3.05 3 88.9 3.05 ASME B31.3 CL150SSA 4 114.3 3.05 6 168.3 3.40 8 219.1 3.76 10 273.1 4.19 12 323.9 4.57 10S BRANCH SIZE 1/2 3/4 1 1 1/2 2 2 1/2 3 4 6 8 10 12 12 SL SL SL SL P/WL P/WL P/WL TL TR TR TR T 10 SL SL SL SL P/WL P/WL P/WL TL TR TR T 8 SL SL SL SL P/WL P/WL P/WL TR TR T 6 SL SL SL SL P/WL P/WL TR TR T 4 SL SL SL TL TR TR TR T 3 SL SL SL SL TR TR T 2 1/2 SL SL TL TL TR T 2 SL TL TL TL T 1 1/2 TR TR TR T 1 TR TR T 3/4 TR T 1/2 T REINFORCED SET-IN DETAIL Outside diameter reinforcing pad: see table above (note 1) 1/4" threaded (note t P PR T TR TR+R TL SL WL = Set-in (Set-on for pigging lines) = Reinforced Set-in (Set-on for pigging lines), see value between brackets for outside diameter of reinforcing pads = Equal tee = Reducing tee = Reducing tee + reducer = Threadolet = Sockolet = Weldolet Note: 1. Plate reinforcement material and thickness: same as header pipe 2. Tell-tale holes shall not be plugged, but shall be filled with a non-corrosive compound or grease to prevent the ingress of water after the test for tightness of the welds 3. All valve hardware must be of the proper specification and compatible with the valve body material. 4. Weld neck flanges must have the same size and thickness pipeline to which they will be attached. 5. The box flanges for welding must correspond to the schedule of the pipe. 6, Spring-closed valve: used to vent air from tankline to ensure tankline product is full. 7. Pipes that are received with flat ends should be chamfered on site according to the needs of the project. 8. Insulation gasket kit to install between carbon steel and stainless steel flanges Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 24 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION 8.4 CL150PEAD Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services Rev.:3 Design code: Corrugated High Density Polyethylene Pipe ASME B31.3 CL150PEAD CLASS 150 0,00 in / 0,00 mm DESIGN TEMPERATURE: 65 °C DESIGN PRESSURE: 1,76 kg/cm² Pluvial Drainage , Residual Drains NPS (inch) OD (mm) WT (mm) ITEM 4 100 0.6 COMMODITY 6 150 1 8 200 1.1 From NPS 10 250 1.5 To NPS 12 300 1.7 15 375 2 ENDS 18 450 2.2 24 600 2.5 DESCRIPTION High-density polyethylene (HDPE) pipe with a hermetic seal made of elastomeric material, corrugated on the outside and smooth on the inside, bell SPIGOT & and spigot joint . White interior. Manufactured according to the specifications BELL of the NMX-T-021-SCFI-2014 standard. For pluvial and sanitary drainage (sections of 6.10m). Manufactured according to the specifications of the NMXE-241-CNPC-2013 standard. Thickness according to table. FM Approved MATERIAL DESING HDPE AWWA C906 TPPPACHP01CXXXP 4 24 A4EPACAS02CXXXE 4 24 TYPE INSERT High density polyethylene 45 degree insertion elbows with a hermetic seal made of elastomeric material for joining corrugated HDPE pipe manufactured according to the specifications of the NMX-E-215/2-CNCP-2012 standard. For pluvial and sanitary drainage. Thickness according to table. FM Approved HDPE AWWA C906 A9EPACAS02CXXXE 4 24 TYPE INSERT High density polyethylene 90 degree insertion elbows with a hermetic seal made of elastomeric material for joining corrugated HDPE pipe manufactured according to the specifications of the NMX-E-215/2-CNCP-2012 standard. For pluvial and sanitary drainage. Thickness according to table. FM Approved HDPE AWWA C906 TEE ATEPACAS02CXXXT 4 24 TYPE INSERT High density polyethylene Tee service union with a hermetic seal made of elastomeric material for corrugated HDPE pipe manufactured according to the specifications of the NMX-E-215/2-CNCP-2012 standard. For pluvial and sanitary drainage. Thickness according to table. FM Approved HDPE AWWA C906 YEE AYEPACAS02CXXXT 4 24 TYPE INSERT High density polyethylene Yee service union with a hermetic seal made of elastomeric material for corrugated HDPE pipe manufactured according to the specifications of the NMX-E-215/2-CNCP-2012 standard. For pluvial and sanitary drainage. Thickness according to table. FM Approved HDPE AWWA C906 COUPLING AHCCAAESI00XXXC 4 24 PIPE TO PIPE High-density polyethylene coupling with a hermetic seal made of elastomeric material for joining corrugated HDPE pipe manufactured according to the specifications of the NMX-T-021-SCFI-2014 standard. For pluvial and sanitary drainage. Thickness according to table. FM Approved HDPE AWWA C906 STUB END ASEPACAS02CXXSE 4 24 FF Stub End FF, High-density polyethylene for corrugated HDPE pipe . The steel backing ring must be adjusted to the outside diameter of the Stub End. Manufactured from forged steel ASTM A105 Class 150 # FF with dimensions ASME B16.5. Thickness according to table. FM Approved HDPE AWWA C906 GASKET IGNBABCF10G2000 4 24 FF Butyl Rubber Gaskets, Flat Face, 1/8 "Gasket Thickness, Class 150 # BUTYL ASME B16.5 BOLTS & NUTS YSTRQAA00000002 4 24 TH Stud Bolt with 2 heavy Hex Nuts Bolts: A193 Gr B7, Nuts: A194 Gr 2H ASME B18.2.1, Heavy Hex Nuts, Full Length Threaded, Class 2A for Bolts & Class 2B for Nuts. Cadmium-based corrosion resistant coating (25 microns thick ASTM B766 or equivalent). ASTM A193 B7/A194 2H ASME B16.5 VALVES VBASCAAAR1B01FF 4 24 RF Gate Valve,Rating 150#,RF,A216-WCB (Body),Trim 10, FP,OS&Y, BB,HO, Extended Stem (1200 mm, grease fittings, drain and vent extension, as well as ASTM A216-WCB any additional required), Gear Operator, API 600, B16.5. PIPE REMARKS ELBOW ASME B16.5 Extended Stem Gear Operator Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 25 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION 8.5 CL150PEAD BFW Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services Rev.:3 Design code: High Density Polytelene FM NFPA 24 CL150PEAD BFW CLASS 200 0,00 in / 0,00 mm DESIGN TEMPERATURE: 70 °C DESIGN PRESSURE: 12.34 kg/cm² Buried Fire Water NPS (inch) OD (mm) WT (mm) Schedule 2 63 3.8 3 80 5.4 4 6 100 150 6.6 10.7 RD9 8 200 13.4 10 250 16.6 ITEM COMMODITY From NPS To NPS ENDS DESCRIPTION MATERIAL DESING REMARKS PIPE TPPPACHP01C 2 10 PLAIN High Density Polyethylene (PE 4710) Tubing ASTM D3350-445574C, IPPS RD9 (200 PSIG), PPI TR-4, Flat Ends, Black with Red Stripes. FM Approved HDPE AWWA C901/C906 1 A4EPACAS02C 2 10 PLAIN 45 ° Elbow, High Density Polyethylene (PE 4710) ASTM D3350-445574C, IPS RD9 (200 PSIG), PPI TR-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 A9EPACAS02C 2 10 PLAIN 90 ° Elbow, High Density Polyethylene (PE 4710) ASTM D3350-445574C, IPS RD9 (200 PSIG), PPI TR-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 ACPPACAS02C 2 10 INSTER TYPE Plug, High Density Polyethylene (PE 4710) ASTM D3350-445574C, IPS RD9 (200 PSIG), PPI TR-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 ACRPACAS02C 4-10 3-8 PLAIN Concentric Reducer, High Density Polyethylene (PE 4710) ASTM D3350445574C, IPS RD9 (200 PSGI), PPI TR-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 AERPACAS02C 4-10 3-8 PLAIN Excentric Reducer, High Density Polyethylene (PE 4710) ASTM D3350445574C, IPS RD9 (200 PSGI), PPI TR-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 TEE ATEPACAS02C 2-10 3-8 PLAIN Tee, High Density Polyethylene (PE 4710) ASTM D3350-445574C, Ips RD9 (200 Psig), Ppi Tr-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 REDUCER TEE ARTPACAS02C 3-10 2 1/2-8 PLAIN Reducer Tee, High Density Polyethylene (PE 4710) ASTM D3350-445574C, Ips RD9 (200 Psig), Ppi Tr-4, Union By Butt Thermofusion System,. FM Approved HDPE AWWA C901/C906 2 SADDLE ASAPACAS02C 2-4 2-3 PLAIN Saddle, High Density Polyethylene (PE 4710) ASTM D3350-445574C, Ips RD9 (200 Psig), Ppi Tr-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C906 2 ADAPTER AFAPACAS02C 2 10 INSTER TYPE Flange Adapter, High Density Polyethylene (PE 4710) ASTM D3350-445574C, LPS RD9 (200 PSGI), PPI Tr-4, Union By Butt Thermofusion System. FM Approved HDPE AWWA C901/C907 2 BAFPAC1F12C 2 10 FF Slip Collar Type Flange for use with Flange adapter, DI ASTM A536 Gr 65/45/12, Class 125 ASME B16.1. FM Approved ASTM A395 MSS SP70 / ASME B16.1 Fire Water BWFGAAER10C 2 10 FF Flange WN, ASTM A105 ASME B16.5, FF, CL150 SCH 40 Spud Serrated or Standard (125 - 250 AARH Finish) ASTM A105 ASME B16.5 Fire Water GASKET IGNAA4CF10G 2 10 FF Ethylene Propylene Diene Rubber Gaskets (EPDN), 3mm thick, Shore hardness 60 to 70D, for class 150 # F.F RUBBER ASME B16.20 Fire Water BOLTS & NUTS YSTRQAA0000 1/2 12 TH Stud Bolt with 2 heavy Hex Nuts Bolts: A193 Gr B7, Nuts: A194 Gr 2H ASME B18.2.1, Heavy Hex Nuts, Full Length Threaded, Class 2A for Bolts & Class 2B for Nuts. Cadmium-based corrosion resistant coating (25 microns thick ASTM B766 or equivalent). ASTM A193 B7/A194 2H ASME B16.5 Fire Water VALVE VGARICAJR7L 2 12 FF Gate Valve, 125#, Flat Face, Iron Body ASTM A126-B, Iron/Copper Trim, OS&Y, Bolted Bonnet, Solid Wedge, HO, MSS SP-70, ASME B16.1, 175 psi WWP, UL LISTED / FM Approved for Firewater System ASTM A216-WCB ASME B16.1 Fire Water ELBOW CAP REDUCER FLANGE Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 26 de 27 EXPANSIÓN DEL ALMACENAMIENTO QUÍMICO EN LA TERMINAL ALTAMIRA Cód. de Documento: ALT1725-L03-BB0-403-003 ESPECIFICACIÓN DE MATERIALES DE TUBERÍAS PIPING MATERIALS SPECIFICATION Main pipe material: Material certificates: Rating: Corrossion allowance: Service limits: Services Design code: High Density Polytelene FM NFPA 24 CL150PEAD BFW CLASS 200 0,00 in / 0,00 mm DESIGN TEMPERATURE: 70 °C DESIGN PRESSURE: 12.34 kg/cm² Buried Fire Water NPS (inch) OD (mm) WT (mm) Schedule 2 63 3.8 90° BRANCH TABLE HEADER SIZE Rev.:3 3 80 5.4 4 6 100 150 6.6 10.7 RD9 8 200 13.4 10 250 16.6 BRANCH SIZE 2 3 4 6 8 10 10 TS TSR TSR TSR TSR TS 8 TRS TRS TRS TRS TS 6 TRS TRS TRS TS 4 TRS TRS TS 3 TRS TS 2 TS Este documento es propiedad de AVANZIA. No puede ser duplicado o distribuido para otro uso distinto al Proyecto al que se destina y al propósito por el cual se emite sin el consentimiento expreso de AVANZIA Pagina 27 de 27