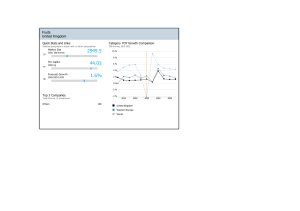

De-risking the company for strong returns by the end of 2022 Investor presentation November 2020 1 | November 27, 2020 Table of contents 2 1. Outokumpu in brief (slide 3) 2. New strategy (slide 15) 3. Business areas (slide 32) 4. Markets (slide 41) 5. Sustainability (slide 51) 6. R&D (slide 61) 7. Latest financials Q3 2020 (slide 66) 8. Appendix (slide 81) | November 27, 2020 Outokumpu in brief Outokumpu – global stainless steel producer Net sales €6.4bn Adjusted EBITDA €263m Sales by business area* Ferrochrome 2% Stainless steel deliveries Sustainability leader with Operations in 90% >30 recycled content countries 2.2mt Sales by destination* Other operations 6% Asia & Oceania 7% Other countries 5% Long Products 8% North America 22% 4 | November 27, 2020 United Kingdom 5% Consumer goods 10% Automotive 12% Distributors 46% Architecture, building & construction 3% End-customers 54% Germany 24% Italy 9% Europe 63% 10,390 Sales by customer segment* Other Europe 21% Americas 21% Personnel Sweden 3% Finland 4% *Outokumpu in 2019 Listed in Nasdaq OMX Helsinki Chemical, petrochemical and energy 1% Heavy industries 12% Other 5% Metal processing & tubes 11% We take care of our employees and our customer satisfaction is by far the highest in the industry Organizational health index1 Safety development2 Customer satisfaction3 1st quartile Outokumpu 8.7 Competitors 2nd 58% quartile 3rd 4.4 quartile 4.1 4th 3.2 quartile 2016 2017 2018 2019 2016 2017 2018 2019 1) 2) 3) 5 | November 27, 2020 McKinsey organizational health index Total recordable injury frequency Percentage, Outokumpu customer satisfaction survey 2019 72% Absolutely or very satisfied customers3 Financial development in 2016–2019 Net debt below Cumulative adjusted EBITDA Gearing improved by €1.1 €1.7 35% billion* billion * At the end of 2019, excluding IFRS16 adjustment; implementation impact on January 1, 2019 6 | November 27, 2020 Flat stainless and ferrochrome core businesses, Long Products in accelerated turnaround Turnaround Core business 7 BA Europe BA Americas BA Ferrochrome BA Long Products • #1 in Europe in terms of volume • #2 in the US in terms of volume • Unique integration to stainless steel • World-class mills in Finland, Sweden and Germany • Most modern stainless facility in the US, sole producer in Mexico • First quartile in terms of cost competitiveness • Broad range of bars, wire rod, wire, rebar and semi-finished products • Leading offering: unique & demanding specialties, best-in-class service capabilities • Ferritics investment, ramp-up starting in Q4 | November 5, 2020 • Significant progress in production, distribution and product range • Kemi mine: the only chrome mine in EU area • CO2 footprint 42% of the industry average • Deep Mine project to secure ore availability • Strategic review finalized, accelerated turnaround program launched by the new management • Headcount reduction of approximately 100 people Stainless steel is the future for sustainable modern society with its unbeatable features Corrosion resistant 8 | November 27, 2020 Corrosion resistant Sustainable Heat resistant Hygienic High strength Heat Aesthetic resistant Durable Cost efficient The world needs long lasting, hygienic and sustainable solutions 9 | November 27, 2020 Economic and population growth Healthcare, clean water, appliances.. Infrastructure, mobility and urbanization Buildings, elevators, trains, bridges,… Climate change and limited resources Energy investments, resource efficiency,… Sustainable stainless steel Long-lasting, recyclable solutions Expectations for real demand growth lowering Expected stainless steel real demand in 2025 Global stainless steel real demand in 2019 Heavy industries Architecture, Building & Construction Heavy industries Other +16% +21% 44.2 million tonnes Chemical, Petrochemical & Energy 10 | November 27, 2020 Consumer goods & Medical +36% 53.6 Automotive million tonnes Chemical, Petrochemical & Energy +12% Source: SMR, July 2020 +34% Architecture, Building & Construction +6% Automotive Other Consumer goods & Medical +23% We have a balanced customer portfolio* End-customers Consumer goods 10% Distributors 46% Automotive 12% End-customers 54% Architecture, building & construction 3% Chemical, petrochemical and energy 1% Heavy industries 12% Other 5% Metal processing & tubes 11% *Sales in 2019 11 | November 27, 2020 54% Distributors 46% • Long term contracts • Large quantities • Special grades • Ferritics and duplex • Technical advice • Develop relationships & receive volume discounts • Spot contracts • Standard products and grades • Austenitic cold rolled and tubular products • Speculative behaviour • Value added services Flat products Outokumpu has the broadest product portfolio globally. The use of our steel reduces the carbon footprint of our customers’ products. Slab Hot rolled black coil Hot rolled white coil Quarto plate Cold rolled white coil Precision strip Long products Cast semis Rolled and forged billet Wire rod Bar Rebar Wire Outokumpu stainless steel deliveries by product form* Cold rolled 69% Hot rolled white coil 17% Quarto plate 4% Long products 5% Semi finished stailess steel products 6% * Sales in 2019 12 | November 27, 2020 Ferrochrome Chrome is the most important raw material used in stainless steel production. Outokumpu has its own chrome mine and ferrochrome works and this makes us uniquely self-sufficient. Ferrochrome contains 50–54% of chrome. Most of our ferrochrome is used in our own melt shops and approximately 25% is sold to other producers. Outokumpu is the only producer of Ferrochrome in Europe. We have a solid presence in key regions Avesta* Fagersta Tornio* Degerfors Kemi Sheffield Nyby Krefeld* Helsinki Richburg Dillenburg Calvert Dahlerbrück Integrated melt shop, hot and cold rolling Other mills Mine Service centers Headquarters in Helsinki, Finland San Luis Potosí * 13 | November 27, 2020 R&D centers Fully integrated production asset base Europe Tornio 1,000 tonnes Finland Americas Avesta + Krefeld + Degerfors Nyby Dillenburg Sweden Germany Sweden Calvert Mexinox Sheffield USA Mexico UK Melting 1,450 450 900 Hot rolling 1,450 900 870 750 150 130 120 Finishing Cold rolling Hot white band Quarto plate Long products 14 | November 27, 2020 Long Products Total Richburg Degerfors Fagersta USA Sweden Sweden 450 3,250 3,220 2,720 500 350 150 250 150 25 40 40 65 New strategy Strong foundations support strategy execution Megatrends drive stainless steel demand growth Great people and strong safety performance 16 | November 27, 2020 Leader in sustainability High customer satisfaction 72% Turnaround in the Americas Stable operations and continuous improvement culture 17 Margin improvement, cash flow and de-leveraging as main sources of value creation Phase 3: 2026– Phase 2: 2023–2025 Phase 1: 2021–2022 Margin improvement and de-leveraging the balance sheet Investing in growth and sustainability Targeted productivity investments to improve margins Continue de-leveraging the balance sheet 17 | November 27, 2020 Customer’s first choice in sustainable stainless steel Our priority for 2021–2022: De-risking the company for strong returns Strengthen accountability for performance Lean & agile organization Active performance management Financial discipline Profitability improvement Europe Continue operations and commercial excellence Americas Commercial turnaround, incl. ferritics investment Ferrochrome Commercial optimization Long Products Holistic operations and commercial turnaround 18 | November 5, 2020 Strong returns; Reliable partner to stakeholders €200 million EBITDA improvement* *run-rate improvement from actions by year-end 2022. <3.0x Net debt / EBITDA Strengthened accountability for performance 19 Lean and agile organization Active performance management Financial discipline • Simplified structure • • • De-layered organization Business Area Boards to manage performance Priority to secure strong balance sheet • New management team • • • 1,000 planned reductions Executional certainty through three-phase program Highly selected investments to improve cost position • Stronger business orientation in decision making • Quarterly external reporting on progress with Q1 2021 • Improved asset management to reduce maintenance capital expenditure | November 27, 2020 20 Planned headcount reductions will improve cost competitiveness Legal headcount, average for the period excluding VDM, AST, OSTP transaction in 2013/14 10,977 10,485 10,468 10,645 10,118 * < 9,000 ** 2016 20 | November 27, 2020 2017 2018 2019 * At the end of the period ** Planned headcount 2020 Q3 2021 2022 €200 million EBITDA run-rate improvement delivered by end of 2022 21 Customer excellence • Enhanced product mix in all business areas • Growth in selected segments • Leverage specialty grades leadership Cost & capital discipline • • • • Lean & agile organization • Planned 10% reduction in Group headcount by end of 2021 • De-layered organization • Strong performance management | November 27, 2020 Increased raw material efficiency Maintenance optimization Strict asset management Annual CAPEX €180 million in 2021 and 2022 €200 million EBITDA improvement* *run-rate improvement from actions by year-end 2022. New steering model ensures diligent strategy execution 22 | November 27, 2020 • Concrete initiatives in each business area to deliver bottom-line impact • Disciplined weekly tracking of progress by Transformation Office led by CFO • Monthly CEO chaired Business Area Boards to address potential deviations • External commitment: quarterly reporting on progress, starting with Q1/21 Business area Europe: Customer engagement at the core of the new strategy Commercial excellence 23 Grow specialty grades sales Strengthen commodity grades sales supported by new products and high quality technical sales through improved cost competitiveness and stronger customer engagement | November 27, 2020 Cost & capital discipline Continue Accelerate raw material cost optimization manufacturing excellence program Reduce Optimize fixed costs maintenance spend & drive procurement savings Lean & agile organization Personnel measures De-layered structures Business area Americas: From turnaround to continuous improvement and growth Commercial excellence Strengthen Grow Continue Optimize commercial footprint in the US and Mexico in automotive, appliances, and pipe & tube segments slab cost optimization freight costs Ferritics investment Capture full benefits from the €30 million investment made in ferritics offering, ramp-up starting 24 Cost & capital discipline | November 27, 2020 Continue manufacturing excellence program Lean & agile organization Personnel measures in Mexico Business area Ferrochrome: Strong potential for future value creation Increase Reduce Improve sales through new product development reliance on spot market and logistics costs fine concentrating plant capabilities and mining efficiencies Deep Mine investment Finalize the €283 million mine expansion investment to secure our ore availability until the beginning of the 2040s with current ferrochrome production. • 25 €123 million cash out Capex in 2021-2022 | November 27, 2020 Business area Long Products: Turnaround driven by operational improvements & commercial excellence Accelerated turnaround program launched by the new management will deliver significant improvement in financial performance 26 | November 27, 2020 Reduce Roll-out Align headcount by approximately 100 people manufacturing excellence program fixed costs to current volumes Extract Commercialize Expand fair value from the unique offering, especially in semis investments made to Fagersta bar product range and distributor presence Indexed market demand (Index, 2018 = 100) 27 | November 27, 2020 1. Europe and NAFTA/USMCA, Source: CRU, SMR Outokumpu planning premise 2022 93 96 2021 78 2020 2019 100 97 2018 2022 2021 2020 2022 2021 2020 Market demand 2019 100 89 78 86 90 98 84 94 2018 100 97 2019 Flat products NAFTA/USMCA 2018 Improvement plans factor in potentially slow market recovery Long products1 Flat products Europe Significant progress to deleverage the company, but further improvement needed Return to shareholders €0.2 billion Cumulative operating cash flow €1.3 billion Net investments €0.2 billion €0.9 billion CAPEX, €0.7 billion divestitures €1.1 billion €0.8 billion net debt reduction Includes €0.1 billion non-cash increase in net debt 2015–2019 28 | November 27, 2020 Q3 2020 net debt Net debt / LTM EBITDA 4.5x Target 2022 <3.0x Net debt / EBITDA Priority to strengthen balance sheet to create shareholder value Operating cash flow Return to shareholders 29 Phase 1: 2021–2022 Phase 2: 2023–2025 Improved from low levels driven by €200 million EBITDA improvement Continued focus, supported by higher and improving margins Following a review of the January-September 2020 financial results, Outokumpu's Board of Directors has decided that owing to the importance of strengthening the Company's balance sheet no dividend will be paid for the financial year 2019. The Board confirms that in the challenging market environment improving the Company's financial position will continue to be of highest priority. CAPEX €360 million of which €122 million to DeepMine Continued capital discipline: High return investments to lower cost Net debt / EBITDA <3.0x by period end De-leveraging continues Focused capital allocation – annual CAPEX €180 million in 2021-2022 Annual capital expenditure In 2021-2022 CAPEX focused on ongoing strategic investments and retaining maintenance on a sustainable level 250 • Maintenance CAPEX optimized to support the current operational level 150 • Deep Mine investment to be finalized in 2022 100 • After 2022 potential to invest in productivity, sustainability and growth • 200 50 0 2018 2019 2020 Deep Mine investment Maintenance & efficiency 30 | November 27, 2020 2021 2022 Strategic Investments Actions to strengthen sustainability leadership Current sustainability performance 1. 2. 3. 4. 31 | November 27, 2020 Targets Safety and wellbeing • >50% reduction on incidents1 since 2015 • Organizational health index (OHI) in 2nd quartile • Ultimate goal zero accidents • Ensure industry leader position Circular economy • >85% recycled content, highest in the industry • Energy efficient processes and reuse of side streams • Increase the share of recycled content CO2 reduction • >75% lower carbon footprint than Asian producers2 • 8MT reduction on customers' CO2 footprint in 20193 • 20% lower carbon footprint by 2023 • Carbon neutral in 20504 Lost time injury frequency rate Outokumpu average carbon footprint: 1.6 t/ton of crude steel vs. China and Indonesia estimate at 7.6. Outokumpu average carbon footprint: 1.6 t/ton of crude steel vs vs global average of 5.4. Outokumpu stainless deliveries of 2.2m in 2019 Our carbon neutrality commitment relates to scope 1+2. Regarding scope 3, we’re working closely with our RM suppliers to ensure that they identify opportunities to reach carbon neutrality by 2050 Business areas Outokumpu’s assets work as one integrated system Sales by business area in 2019 € 6,403 million Avesta Fagersta Tornio Degerfors Kemi Sheffield Nyby Krefeld Richburg Dillenburg Calvert Dahlerbrück San Luis Potosí Europe Americas Long Products Ferrochrome 33 | November 27, 2020 #1 stainless steel producer in Europe, #2 in the US Business area EUROPE AMERICAS 28% Market share #1 Production facilities Finland, Sweden & Germany Largest customer segments Distributors Automotive Appliances Heavy industries Main competitors 34 | November 27, 2020 #2 21% US & Mexico Distributors Appliances Automotive Pipes & tubes LONG PRODUCTS US Europe 11% 10% UK, Sweden & US Distributors Metal processing Heavy industries Tubes FERROCHROME 4% #6 Finland Stainless steel producers State-of-the-art production facilities – Europe Outokumpu’s assets work as one integrated system with large integrated sites in Tornio, Finland and Avesta, Sweden feeding rest of the mills Europe. Outputs include a wide range of austenitic and ferritic standard stailess steel grades and tailored and high performance products. Tornio • Largest single site stainless steel production facility in Europe by cold rolling capacity • Only stainless steel facility in the world fully integrated with ferrochrome • Most sustainable stainless steel mill in the world and largest recycling center in Europe • Unique rolling, annealing and pickling (”RAP”) line producing minimum thickness tolerance, high surface quality and corrosion resistance Degerfors • Site producing quarto plate in high performance stainless steel • Plate service center for complex projects • Also part of BA Long Products • Fully integrated site with focus on high performance stainless grades • Inventor of duplex stainless steel grades • Prefab and press plate special manufacturing units • Delivers hot band to Nyby and sites in Germany for cold rolling and slabs to Degerfors for quarto plate production • Cold rolling mill focusing in duplex, high-alloyed austenitic and heat resistant special grades | November 27, 2020 Degerfors Nyby Krefeld Dillenburg • Cold rolling mill specialized in customized finishing processes for unique decorative surfaces Krefeld 1,000 tonnes • Cold rolling mill producing comprehensive range of grades, dimensions and surface finishes Melting Hot rolling Dahlerbruck Finishing • Cold rolling • Hot white band • Quarto plate • Cold rolling mill producing precision strip 35 Tornio Nyby Dillenburg Avesta Avesta Tornio Finland 1,450 1,450 750 150 Avesta + Krefeld + Degerfors Nyby Dillenburg Sweden Sweden Germany 450 900 130 120 500 150 State-of-the-art production facilities – Americas The Americas’ production units are located in Alabama, US and San Luis Potosí, Mexico. The production sites are supported by distribution centers in Illinois, Pennsylvania and California, US and a service center in Argentina. The business area produces standard autenistic and ferritic grades as well as tailored products. Calvert, US 1,000 tonnes • Fully integrated site with comprehensive product portfolio • Most technically advanced mill in the USA • Feeds hot rolled coils to Mexinox • Austenic and duplex grades, ferritics capabilities built by 2020 San Luis Potosí, Mexico Calvert • Cold rolling mill specialized in ferritic stainless steel grades • Only stainless steel mill in Mexico serving both domestic market and supplying ferritics back to the USA San Luis Potosí 36 | November 27, 2020 Calvert Melting 900 Hot rolling 870 Finishing • Cold rolling • Hot white band 350 150 San Luis Potosí 250 State-of-the-art production facilities – Long Products The integrated mill in Sheffield, UK feeds semi-finished products to finishing facilities in Sweden and US. Long Products’ product offering consists of a broad range of bars, wire-rod, wire, rebar and semi-finished products in standard and tailored grades. Sheffield Richburg • Melt shop & continuous casting, a bar finishing facility and wire rod mill • Cold finished long products manufacturing facility serving the American market • Inventor of martensitic stainless steel grades • Feeds Long Products’ other mills with blooms and billets and BA Europe with slabs Fagersta Degerfors • Global wire rod supplier in a broad range of stainless steel grades and sizes. • Hot rolling mill that is a global supplier of high quality bars as well as rolled and forged billets in a wide range of stainless steel grades • Belongs to the world´s leading producers of stainless wire rod with a flexible and high quality manufacturing program | November 27, 2020 Degerfors Richburg Sheffield • Flexible high quality production of comprehensive range of long products • Also houses a stocking, processing and distribution center 37 Fagersta 1,000 tonnes Sheffield UK Melting 450 Finishing • Long Products 45 Richburg US Degerfors Sweden Fagersta Sweden 40 40 65 State-of-the-art production facilities – Ferrochrome Ferrochrome is an integral part of Outokumpu’s operations, and supported by our Kemi mine. It is a clear competitive advantage to us. Majority of the produced ferrochrome is consumed internally by our own mills, and approximately 25% is sold to other producers outside the company. Tornio Tornio • Ferrochrome works with three smelting furnaces – at the same site as our integrated stainless steel mill • Integrated operations in Tornio allow ferrochrome to be transferred to stainless steel melt shop in liquid form enabling considerable cost and energy savings • Annual ferrochrome production capacity 530kt Kemi • The only chrome mine in the EU area • One of the most cost competitive ferrochrome producers globally • Low carbon footprint • Expansion extends the underground mining activities to 1,000 meters to secure continuous chrome supply for coming decades 38 | November 27, 2020 Kemi We secure future long-term ore supply by deepening of Kemi mine EUR 283 million investment in vertical mine expansion New main level at 1,000 meters depth: new ore handling and hoisting system 39 | November 27, 2020 CO2 footprint of our ferrochrome only 42% of the industry average We extract significant value through integrated ownership of mines and smelters Competitive cost base 40 | November 27, 2020 Predictable cost and quality Fast response to changes Efficient inventory management Markets Current market requires decisive actions COVID-19 impacting stainless demand Low priced imports take market share Stainless flat consumption, kt Market shares in Europe, % Outokumpu vs. imports Prices historically low EU base price development, €/t 1200 30 4000 800 28 3000 2000 2016 2017 2018 USMCA 2019 EU 2020 26 400 24 0 2016 2017 Outokumpu Source: SMR, McKinsey, Eurofer, CRU 42 | November 27, 2020 2018 2019 2020 Imports 2016 2017 2018 2019 2020 High import penetration, price pressure and low demand have changed the market dynamics • Unfair trade practices and growing competition from Asian producers • New pricing mechanisms: from alloy surcharge to transaction pricing 43 | November 27, 2020 • Trade wars have led to market disruption • Shift towards NPI leads to a change in scrap pricing Trade defense actions by EU insufficient – Urgent need to address unfair market practices and carbon leakage CO² footprint (per ton) Imports have significantly higher carbon footprint 7.6 European safeguards need to be renewed and improved 5.4 1.6 Outokumpu Global Asia Market shares in Europe Despite this, the share of imports has grown | November 27, 2020 WTO dispute against Indonesian export restriction on raw materials 30 28 26 24 2016 2017 2018 Outokumpu 44 Full potential of trade defense measures (anti-dumping & anti-subsidy) to be applied 2019 2020 Imports Effective measures needed to prevent carbon leakage Scrap is a competitive advantage and driver for sustainability 45 Global competitiveness vs. other forms of nickel Abundance of scrap Scrap and the importance for carbon neutrality Scrap and correlation to LME nickel Scrap is the most competitive traded nickel unit Both Europe and Americas are scrap long Realization of significant reduction of CO2 emissions Market moving towards decoupling of scrap from LME pricing | November 27, 2020 Nickel price climbed higher during Q3/20 Transaction prices 304 stainless, USD/tonne Average nickel price, USD/tonne 3,400 Ferrochrome benchmark price, USD/lb. 2,900 +0% 2,400 1,900 1,400 Q2/20 Europe USA China Source: CRU & Metal Bulletin 46 | November 27, 2020 Q3/20 Q2/20 Q3/20 Imports into Europe spiked in July as the new quarterly import quota period started Third-country cold rolled imports1 into Europe, 1,000 tonnes 100 Third-country cold rolled imports2 into the US, 1,000 tonnes 50 50 31% 80 30 40 40 60 30 40 20 20 14% 30 20 10 20 10 0 0 From rest of world From rest of Asia From Indonesia 47 | November 27, 2020 1. 2. From China Import penetration 10 0 0 From rest of world From rest of Asia From Indonesia From China Import penetration Cold rolled, monthly average. Source: Eurofer, October 2020 (Q3’20 based on Jul-Aug actuals and forecast for September) Cold rolled, monthly average. Source: Foreign Trade Statistics, American Iron & Steel Institute, Oct 2020 (Q3’20 based on Jul-Aug) New import quota period started in October, quota for other countries already fully utilized EU cold-rolled quota utilization* EU hot-rolled quota utilization* 100% kt 91 % 32 19 51 Days in Turkey Q4 48 44 2 United States 29 50 30 India 49 25 15 South Korea 15 16 11 79 33 100 80% 91 168 60% 40% 40% 20% 20% 32 4 0% Days in Q4 Other European safeguards Anti-dumping & anti-subsidy investigation • • • Current safeguards will expire in June 2021 Safeguards need to be renewed and improved Carbon Border Adjustment • • • Part of the European Green Deal | November 27, 2020 80% 60% 0% Taiwan Malaysia Vietnam Other 100% In August, expiry review of the current anti-dumping duties on cold-rolled stainless steel from China and Taiwan (imposed in 2015) was initiated In September, anti-dumping investigation on cold-rolled stainless steel from India and Indonesia started In October, definitive anti-dumping duties on hot-rolled stainless steel from Indonesia, China and Taiwan was imposed for five years *Source: European Commission’s website for tariff quota consultation, situation in October 30, 2020 Raw materials - price development Nickel1, USD / tonne 21,000 1.5 19,000 Q3/20 1.14 USD/lb. 1.3 17,000 15,000 1.1 13,000 0.9 11,000 Oct 19, 2020 15,653 USD/t 9,000 Oct 19, 2020 8.8 USD/lb 12 0.7 400 European spot price Carbon steel scrap4, USD / tonne Oct 19, 2020 261 USD/t 350 300 10 250 8 4 100 | November 27, 2020 Oct Sep Aug Jul Jun May Apr Mar Feb Jan'20 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'19 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'18 150 Oct Sep Aug Jul Jun May Apr Mar Feb Jan'20 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'19 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'18 49 200 6 Oct 19, 2020 0.75 USD/lb. Jul Jun May Apr Mar Feb Jan'20 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'19 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'18 Molybdenum3, USD / lb. 14 European contract price 0.5 Oct Sep Aug Jul Jun May Apr Mar Feb Jan'20 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'19 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan'18 7,000 Ferrochrome2, USD / lb. Data source: 1) Nickel Cash LME Daily Official 2) Contract - MetalBulletin - Ferro-chrome Lumpy CR charge basis 52% & Cr quarterly major European destinations Cr ; Spot: Platts Charge Chrome 52% DDP Europe 3) MetalBulletin - Molybdenum Drummed molybdic oxide Free market Mo in warehouse; 4 Ferrous Scrap Index HMS 1&2 (80:20 mix) $ per tonne fob Rotterdam Stainless steel market Major stainless steel producers 50 Outokumpu’s market share Million tonnes 2019 2018 Tsingshan 9.8 10.2 Europe 28% TISCO 4.5 5.5 NAFTA 21% POSCO (incl. ZPSS) 3.3 3.3 Globally ~6% Acerinox 3.3 3.2 Outokumpu 3.2 3.3 Aperam 3.0 2.1 | November 27, 2020 2019 Source: Global crude stainless steel capacity, SMR January 2020 Sustainability We are committed to reaching carbon neutrality by 2050 in-line with EU Green Deal targets 20% lower carbon footprint by 2023 Carbon neutral by 2050 1 1) Our carbon neutrality commitment relates to scope 1+2. Regarding scope 3, we’re working closely with our RM suppliers to ensure that they identify opportunities to reach carbon neutrality by 2050 52 | November 27, 2020 We are the leading producer of sustainable stainless steel globally and we have the lowest carbon footprint in the industry Carbon footprint less than 30% of the global industry average Industry leading recycled content globally 90% Low ferrochrome carbon footprint: High usage of carbon neutral electricity in Europe 42% +80% of industry average Energy and material efficiency 53 | November 27, 2020 Stainless steel from China and Indonesia has up-to five times higher carbon footprint CO2 emissions of stainless steel producers Drivers of high carbon footprint for Chinese and Indonesian stainless steel Tonne of CO2 per tonne crude steel 8 1. Low utilization of recycled material 6 2. Low nickel content ore and high emissions from blast furnaces 4 2 3. Use of coal as main electricity source 0 Outokumpu* Global average** China & Indonesia*** *) Source: Outokumpu January 2020 **) Average of ISSF study 2018 and China and Indonesia ***) Outokumpu estimates for China and Indonesia 54 | November 27, 2020 We are on track to reach our science based target 20% lower carbon footprint by 2023 Tonne of CO2 per tonne crude steel Outokumpu CO2 emissions intensity 1 Outokumpu CO2 footprint by category (2019) 2.0 1.5 28% 47% 1.0 0.5 18% 7% 0.0 20142016 2019 2023 target Direct 55 | November 27, 2020 1) CO2 emissions per ton of stainless steel Indirect Transport Raw materials Our sustainability work has been recognised… Gold rating – top 5% performer – from supplier sustainability platform EcoVadis 56 | November 27, 2020 Outokumpu is included in the Sustainability Yearbook 2020 indicating we are in the top 15% sustainability performers of steel industry Outokumpu is rated “Prime” by ISS ESG indicating that our sustainability performance is above the sector-specific threshold fulfilling ambitious performance requirements …and we have clear priorities to do more Carbon neutral roadmap • Energy efficiency improvements • Selected capex • Green electricity sourcing • Carbon Capture Utilization • EU Green deal funding 57 | November 27, 2020 Sustainability credentials • Customer engagement of industry average • Develop sustainability certificates • ResponsibleSteel™ membership Lobbying to achieve a level playing field • Secure legislation that supports our business • Trade defense • EU safe guards • Energy taxation • Carbon border adjustment We focus on 6 UN Sustainable Development Goals Outokumpu business is based on recycling and is a part of circular economy. Company focuses on resource efficiency as recycled content, the use of byproducts to replace natural resources, as well as increasing the energy efficiency in production process. This sustainable approach is supported by several key performance indicators which focus on efficiency. We are committed to the United Nation’s Sustainable Development Goals (SDGs) and our focus was realigned with the updated strategy during 2019. We have selected six SDGs that are the most relevant to us in terms of our contribution. 58 | November 27, 2020 Products: Stainless steel is long lasting, requires low maintenance and is 100% recyclable. The main raw material is recycled steel. This makes stainless steel products a solution for responsible consumption. Safety of our employees is our undisputed priority Total recordable injury frequency rate (TRIFR) 8.7 TRIFR target for 2020 <3.0 4.4 2016 59 | November 27, 2020 2017 4.1 2018 3.2 3.0 2019 2020 target We aim to be among the industry leaders in safety with the ultimate goal of zero accidents. R&D We are using R&D and technology to increase our customers’ competitiveness Our R&D vision 2023 Being the industry benchmark in profitable stainless steel solutions and becoming the development partner of choice for our customers. Our unmatched technical competence creates extraordinary value and attracts new talents Current and future product demands Product support and problem solving capabilities New process technologies Ensuring and improving process efficiency Digital tools and data science R&D expenses EUR 17 million in 2019 (0.3% of net sales) 62 | November 27, 2020 Automotive applications for major OEMs Enabler for battery packs • Qualified by major OEMs • H-Series stainless steel • Higher passenger protection Fuel cell technology • New design by Outokumpu • Close collaboration with a German OEM Weldable Sandwich • Sound dampening • High strength • Formable 63 | November 27, 2020 Marine applications for demanding environments Exhaust cleaning (Scrubbers) • Excellent corrosion performance • Long lifetime in harsh conditions • Close collaboration with market leaders Ocean thermal energy • Heat exchanger with superior corrosion resistance • Improved heat transfer Oil, Gas & Off-Shore • High corrosion resistance • Highly durable • Tests in > 2 km Atlantic depth 64 | November 27, 2020 Process development for higher efficiency 65 Inclusion Reduction Surface quality Digital Manufacturing • Smart melt shop treatment to reduce inclusions • Excellent results with up to 40% reduction • Substantial scratch defect reduction in German operations • Frequency reduced by 70% • | November 27, 2020 • • Connected quality inspection along process route Artificial Intelligence Digitally enabled process improvements Latest financials Q3 2020 Highlights during Q3 • Result negatively impacted by lower demand due to COVID-19 and typical seasonality in Europe • Safety performance remained strong • Strong performance in Americas • Import penetration spiked in Europe • Long Products’ strategic review concluded, accelerated turnaround program initiated by the new management team 67 | November 27, 2020 Strong cost mitigation actions in the third quarter Group adjusted EBITDA, EUR million Adjusted EBITDA quarter-on-quarter comparison1, EUR million Deliveries 7% lower Fixed cost compressions Prices declined in Europe Planned maintenance work 106 73 45 45 22 Q3 Q4 Q1/20 Q2 Q3 Net of Pricing timing and Costs Q2/20 Deliveries & mix hedging 1) Indicative columns based on management estimates 68 | November 27, 2020 Ferrochrome Others Q3/20 Key figures Q3/20 Q3/19 Q2/20 1,000 tonnes 488 533 523 Sales EUR million 1,254 1,590 1,420 Adjusted EBITDA EUR million 22 45 45 Net result EUR million -63 -27 -37 EUR -0.15 -0.06 -0.09 Operating cash flow EUR million 170 12 72 Net debt EUR million 1,105 1,336 1,243 Gearing % 45.1 51.4 49.2 EUR million 35 48 52 % 0.2 1.0 1.1 10,118 10,507 10,213 Stainless steel deliveries Earnings per share Capital expenditure* Return on capital employed, ROCE Personnel at the end of the period *Capex cash flow 69 | November 27, 2020 BA Europe – high import pressure, typical seasonality and lower prices resulted in a challenging quarter Europe adjusted EBITDA, EUR million Adjusted EBITDA quarter-on-quarter comparison1, EUR million Lower prices and weaker product mix 68 67 33 Various cost saving actions 30 9 Q3 Q4 Q1/20 Q2 Q3 Q2/20 Deliveries Pricing & mix 1) Indicative columns based on management estimates 70 | November 27, 2020 Net of timing and hedging Costs Others Q3/20 BA Americas – solid performance and cost compression actions improved the result Adjusted EBITDA quarter-on-quarter comparison1, EUR million Americas adjusted EBITDA, EUR million Lower fixed costs supported profitability 20 14 10 3 -11 Q3 Q4 Q1/20 Q2 Q3 Q2/20 Deliveries Pricing & mix 1) Indicative columns based on management estimates 71 | November 27, 2020 Net of timing and hedging Costs Others Q3/20 BA Long Products – weak performance continued, accelerated turnaround program starts Long Products adjusted EBITDA, EUR million Adjusted EBITDA quarter-on-quarter comparison1, EUR million Deliveries 22% lower -2 -1 -4 -3 -9 Q2/20 Q3 Q4 Q1/20 Q2 Q3 Deliveries Pricing & mix 1) Indicative columns based on management estimates 72 | November 27, 2020 Net of timing and hedging Costs Other Q3/20 BA Ferrochrome – planned maintenance work completed, start-up successful Ferrochrome adjusted EBITDA, EUR million Adjusted EBITDA quarter-on-quarter comparison1, EUR million Cost increase in line with guidance 25 19 24 16 9 Q3 Q4 Q1/20 Q2 Q3 Q2/20 Deliveries 1) Indicative columns based on management estimates 73 | November 27, 2020 FeCr price Costs Others Q3/20 Decisive working capital management and EUR 72 million VAT deferral boosted cash flow Q3/20 cash flow, EUR million Annual Capex, EUR million 240 2020 Capex EUR 180 million 200 160 EBITDA Working Provisions, capital pensions, financial charges and other Operating cash flow Net cash from investing activities Cash flow before financing activities 2020 cumulative cash flow, EUR million 120 80 40 0 2019 EBITDA 74 | November 27, 2020 Working capital Provisions, pensions, financial charges and other Operating cash flow Net cash from investing activities Cash flow before financing activities 2020 Expansion, digitalization & other Kemi mine Annual maintenance Net debt reduced to EUR 1.1 billion, gearing at 45% Net debt, EUR million 1,800 Net debt/LTM adjusted EBITDA 80% IFRS16 impact* EUR 131 million 69% 70% 1,600 51% 1,400 45% 40% 45% 48% 60% 49% 45% 1,200 50% 40% 30% 1,000 < 3.0 20% 800 600 10% 1,610 1,242 1,091 1,241 1,155 1,249 1,243 1,105 2015 2016 2017 2018 2019 Q1 2020 Q2 2020 Q3 2020 Net debt 75 | November 27, 2020 0% 9.8 4.0 1.7 2.6 4.4 2015 2016 2017 2018 2019 Gearing * Implementation impact on Jan 1, 2019 4.0 4.6 4.5 Q1 Q2 Q3 Target 2020 2020 2020 2022 Total liquidity reserves amounted to EUR 0.9 billion at the end of September Debt maturity profile*, EUR million Debt structure* 18% 800 16% 7% 13% 13% New EUR 125 million convertible issued in July 600 400 32% 200 0 Bonds Long-term loans from financial institutions Lease liabilities Other long-term loans 76 | November 27, 2020 Convertible bonds Pension loans Commercial papers Short-term loans Cash & cash equivalents * September 30, 2020 2020 2021 2022 Current debt Non-current debt Unutilized facilities 2023 2024 2025+ Outlook for Q4 2020 As communicated previously, the COVID-19 pandemic is expected to have a significant impact on the stainless steel industry throughout 2020, and increases uncertainty. Outokumpu expects its stainless steel deliveries for the whole Group to remain stable in the fourth quarter compared to the third quarter. The seasonal year-end maintenance work in Tornio, Finland is expected to have an approximately EUR 10 million negative impact on the fourth quarter result compared to the third quarter. Adjusted EBITDA is expected to remain at the same level during the fourth quarter compared to the third quarter. 77 | November 27, 2020 Outokumpu operative cost components* SG&A (excl. personnel D&A total and D&A) • Raw materials 60% • Energy and other consumables 10–15% Other cost of sales • Personnel expenses 10–15% Energy and consumables Personnel Raw materials *Cost components in 2019 78 | November 27, 2020 • Other cost of sales includes e.g. freight, maintenance and rents and leases Over 4% productivity improvement in 2019 – more to come in 2020 Raw material excellence Reduction of net working capital Productivity improvement is based on numerous local projects Procurement initiatives Continuous debottlenecking of key equipment Moving towards a single operating system Reliability 79 | November 27, 2020 For more information, call Outokumpu Investor Relations or visit www.outokumpu.com/investors Linda Häkkilä Investor Relations Manager Mobile: +358 40 071 9669 E-mail: linda.hakkila@outokumpu.com Päivi Laajaranta Executive Assistant Phone +358 9 421 4070 Mobile +358 400 607 424 E-mail: paivi.laajaranta@outokumpu.com 80 | November 27, 2020 Q4 result The date to be confirmed Appendix Production steps – cold rolled coil Kemi mine Ferrochrome works Sintering furnace Underground mine Steel melting shop Liquid ferrochrome Recycled steel Hot rolling mill Walking Beam Furnace Hot annealing and pickling line Hoisting Smelter Crushing Cold rolling plant Heavy medium separation Sendzimir Mill Ferrochrome Converter Electric Arc Furnace Roughing Mill Storage Cold annealing and pickling line Steckel Mill Grinding Spiral concentration AOD Converter Polishing line Continuous Casting Machine 82 | November 27, 2020 Tandem Mill Bell Furnace Slitting Line Cut-to-lenght Line Outokumpu is a global leader of advanced solutions and our stainless steels can be divided in four groups Deliveries by product group in 2019 Duplex 5% Ferritic 18% Other 8% Austenitic (CrNiMo) 16% Austenitic (CrNi) 53% Stainless steels are iron-chromium (Fe-Cr) alloys often with nickel (Ni) additions that ”do not rust in sea water”, ”are resistant to concentrated acids” and ”do not scale at temperatures up to 1100 °C”. Molybdenum (Mo) and other alloying elements are sometimes added to achieve specific properties. Over the years ever since the development of stainless steel, the number of grades have increased rapidly. 83 | November 27, 2020 Austenitics Ferritics Duplex Martensitic Nickel content Non-magnetic No nickel Magnetic Low nickel content Magnetic No nickel Magnetic Corrosion resistance Corrosion resistance Corrosion resistance Corrosion resistance Strength / Hardness Strength / Hardness Strength / Hardness Strength / Hardness Deformability Deformability Deformability Deformability Surface aesthetics Surface aesthetics Surface aesthetics Surface aesthetics Raw material costs Raw material costs Raw material costs Raw material costs Versatile stainless steels with good combination of properties for wide range of applications Applications which have lower requirements regarding corrosion and deformability Applications which require a high resistance to stress, corrosion, cracking and/or strength Applications which require high strength and hardness Stainless steel prices reflect various factors 84 Macro-economic trends Raw material prices and currency fluctuations Development in consumer industries Cost of capital | November 27, 2020 Short-term and long-term capacity utilization Transport costs Competition Import duties and other trade restrictions Traditional stainless steel base price model consists of three components Alloy surcharge Base price Extras Alloy surcharge Customer-specific, usually monthly base price Material-specific charges for nonstandardized products Product-specific instrument to pass alloy costs along the value chain Base price Extras 85 | November 27, 2020 The logics behind our net of timing and hedging Underlying position Exposure Hedging Committed* sales Short 100% Committed** purchases Long 100% Net realizable value Excess stock Long 100% NRV, accounting principle Base stock Long Balance between managing earnings & cash flow volatility Metal hedging Timing Pricing in, pricing out * priced-out or pricing out ** priced-in or pricing in 86 | November 27, 2020 Corporate Governance Outokumpu Oyj, the Group’s parent company, is a public limited liability company, listed on Nasdaq Helsinki and incorporated and domiciled in Finland. In its corporate governance and management, Outokumpu Oyj complies with the laws and regulations applicable to Finnish public companies, the company’s Articles of Association and the Corporate Governance Policy approved by the company’s Board of Directors. Outokumpu Oyj follows the Finnish Corporate Governance Code, effective as of January 1, 2016. The Finnish Corporate Governance Code is issued by the Finnish Securities Market Association and adopted by Nasdaq Helsinki. The governing bodies of the parent company Outokumpu Oyj, i.e. the General Meeting of Shareholders, the Board of Directors, and the President and Chief Executive Officer (CEO), have the ultimate responsibility for the management and operations of the Outokumpu Group (“the Group”). The Outokumpu Leadership Team supports and assists the CEO in the efficient management of the Group’s operations. The latest Corporate Governance Statement and other updated corporate governance information can be found on the Group’s Corporate Governance website. The General Meeting of Shareholders convenes at least once a year. Under the Finnish Companies Act, certain important decisions such as the approval of financial statements, decisions on dividends and increases or reductions in share capital, amendments to the Articles of Association, and election of the Board of Directors and auditors, fall within the exclusive domain of the General Meeting of Shareholders 87 | November 27, 2020 Outokumpu organization President & CEO Heikki Malinen Europe 88 | November 27, 2020 Finance Human resources Technology & Sustainability Strategy Americas Ferrochrome Long Products Dividend payments Net income, EUR million Dividend per share, EUR 392 86 144 130 -75 Following a review of the JanuarySeptember 2020 financial results, Outokumpu's Board of Directors has decided that owing to the importance of strengthening the Company's balance sheet no dividend will be paid for the financial year 2019. -439 2014 89 | November 27, 2020 2015 0.10 0.25 0.15 2016 2017 2018 2019 The Board confirms that in the challenging market environment improving the Company's financial position will continue to be of highest priority. Ownership structure & major shareholders Nominee registered and non-Finnish holders 17% Finnish institutions, companies and foundations 24% Solidium 22% Households 37% 1) 90 | November 27, 2020 Directly registered shareholders on September 30, 2020 Solidium and governance 91 • Holding company wholly owned by the State of Finland AA • Major shareholder in 12 listed companies including SSAB, Elisa, Sampo, Nokia, Tieto, Metso and Valmet • Mission is to strenghten and stabilize Finnish ownership in nationally important companies and to increase the value of their holdings in the long term • Shareholder of Outokumpu following its takeover of the 31.1% government stake in 2009 • Participated in the Outokumpu rights issues in 2012 and 2014 • Currently no seat in Outokumpu Board of Directors but they use power via Shareholder’s Nomination Board work. | November 27, 2020 Board of Directors Chairman of the Board of Directors Kari Jordan Chairman of the Remuneration Committee 92 | November 27, 2020 Members of the Board of Directors Kati ter Horst Member of the Audit Committee Eeva Sipilä Chairman of the Audit Committee Pierre Vareille Julia Woodhouse Member of the Remuneration Committee Member of the Audit Committee Vesa-Pekka Takala Member of the Audit Committee Outokumpu leadership team 93 Heikki Malinen Pia Aaltonen-Forsell Thomas Anstots Niklas Wass Tamara Weinert President & CEO CFO EVP, Commercial, Business Area Europe EVP, Operations, Business Area Europe Acting President, Business Area Americas Martti Sassi Johann Steiner Jan Hofmann Stefan Erdmann President, Business Area Ferrochrome Chief Human Resources Officer Chief Strategy Officer Chief Technology Officer | November 27, 2020 Group key financials 2019 2018 20173) 2016 2015 1,000 tonnes 2,196 2,428 2,448 2,444 2,381 Sales € million 6,403 6,872 6,356 5,690 6,384 Adjusted EBITDA € million 263 485 631 309 165 Net result € million -75 130 392 144 86 Return on equity 1) % -2.8 4.8 15.4 6.4 3.9 Return on capital employed 1) % 0.8 7.0 11.3 2.6 5.3 Operating cash flow 2) € million 371 214 328 389 -34 Net debt € million 1,155 1,241 1,091 1,242 1,610 Gearing % 45.1 45.1 40.1 51.4 69.1 € million 221 260 174 164 154 headcount 10,390 10,449 10,485 10,977 11,833 Key figures Stainless steel deliveries Capital expenditure 2) Personnel at the end of the period 94 | November 27, 2020 1) 2) 3) Key figure definition changed in 2016. Figures for 2015 have been restated. Figures for 2014 have not been restated 2014 presented for continuing operations. Figures for 2017 have been restated due to IFRS 15 adoption. Figures for 2014–2016 have not been restated. Balance sheet Assets (EUR million) 2019 2018 Non-current assets Intangible assets Equity and liabilities (EUR million) 2019 2018 Equity attributable to the equity holders of the Company 2,562 2,750 1,053 798 - 1 12 12 335 318 Provisions 85 65 29 35 1,514 1,229 427 511 Derivative financial instruments 17 20 607 585 2,767 2,659 Investments in associated companies and joint ventures 38 53 Derivative financial instruments Financial assets at fair value 31 86 Deferred tax liabilities 5 2 229 247 Defined benefit plan assets 68 72 Trade and other payables Trade and other receivables 2 2 Total non-current liabilities 3,747 3,706 Property, plant and equipment Derivative financial instruments Deferred tax assets Total non-current assets Non-current liabilities Non-current debt Defined benefit and other long-term employee benefit obligations Current liabilities Current assets Inventories 1,424 1,555 Investments at fair value 13 13 Provisions 25 5 Derivative financial instruments 15 15 Current tax liabilities 17 12 Trade and other receivables 514 640 1,475 1,471 Cash and cash equivalents 325 68 Total current liabilities 1,962 2,019 2,291 2,292 TOTAL EQUITY AND LIABILITIES 6,038 5,998 Total current assets TOTAL ASSETS 95 Current debt | November 27, 2020 6,038 5,998 Trade and other payables Share-related key figures Key figures 2018 2017 2016 2015 Earnings per share 1) 2) € -0.18 0.32 0.95 0.35 0.23 Cash flow per share € 0.90 0.52 0.79 0.94 -0.08 Equity per share 1) 2) € 6.22 6.70 6.59 5.84 5.60 Dividend per share € 0.10 3) 0.15 0.25 0.10 - % 3.6 4.7 3.2 1.2 - neg. 10.00 8.15 24.31 11.85 € 2.81 3.20 7.74 8.51 2.73 € million 1,155 1,312 3,223 3,541 1,138 411,774,715 410,563,719 412,671,549 413,860,600 415,489,308 884,254 826,636 1,021,607 955,682 1,345,515 Dividend yield Price/earnings ratio 1) 2) Trading price at the end of the period Market cap at the end of the period Number of shares at the end of the period 4) 1,000 shares Trading volume 5) 96 2019 | November 27, 2020 1) 2) 3) 4) 5) IFRS 16 – Leases has been adopted on January 1, 2019 using the modified retrospective approach. Comparative information has not been restated. Figures for 2017 have been restated due to IFRS 15 adoption in 2018. Figures for 2014–2016 have not been restated. The Board of Directors’ proposal to the Annual General Meeting Excluding treasury shares Includes only Nasdaq Helsinki trading Cash flow Key figures 97 2019 2018 2017 2016 Net result for the financial year € million -75 130 392 144 Total adjustments € million 330 313 259 134 Change in working capital € million 218 -112 -180 307 Provisions, pensions, financial charges and other € million -97 -112 -135 -187 Income taxes paid € million -5 -5 -8 -9 Operating cash flow € million 371 214 328 389 Net cash from investing activities € million -65 -229 -63 -81 Cash before financing activities € million 306 -14 264 308 | November 27, 2020 Business area Europe Key figures 2019 2018 2017 2016 2015 1,000 tonnes 1,459 1,547 1,592 1,625 1,578 € million 4,089 4,267 4,156 3,767 4,156 € million 66 97 81 93 120 Adjusted EBITDA € million 216 248 404 295 203 Adjustments to EBITDA € million 17 10 - -26 -25 EBITDA € million 233 259 404 270 177 Adjusted EBIT € million 82 134 281 143 38 Depreciation and amortization € million -134 -114 -123 -160 -165 Capital expenditure € million 44 76 70 81 85 Operating capital € million 1,901 1,934 1,848 1,808 2,061 headcount 6,753 6,806 6,748 7,038 7,394 Stainless steel deliveries Sales of which intra-group Personnel at the end of period 98 | November 27, 2020 Business area Americas Key figures 2019 2018 2017 2016 2015 1,000 tonnes 601 762 742 690 533 € million 1,346 1,715 1,546 1,325 1,214 € million 3 45 33 21 37 Adjusted EBITDA € million -27 -5 21 -27 -120 Adjustments to EBITDA € million - - - 21 -17 EBITDA € million -27 -5 21 -6 -136 Adjusted EBIT € million -84 -56 -31 -81 -200 Depreciation and amortization € million -56 -51 -52 -54 -80 Capital expenditure € million 20 18 18 17 19 Operating capital € million 914 1,084 1,072 1,127 1,279 headcount 1,934 1,991 2,094 2,219 2,265 Stainless steel deliveries Sales of which intra-group Personnel at the end of period 99 | November 27, 2020 Business area Long Products Key figures 2019 2018 2017 2016 2015 1,000 tonnes 226 285 264 245 213 € million 642 740 591 487 551 € million 137 220 186 153 162 Adjusted EBITDA € million -7 25 16 -1 10 Adjustments to EBITDA € million - - - 19 - EBITDA € million -7 25 16 18 10 Adjusted EBIT € million -16 18 10 -8 2 Depreciation and amortization € million -8 -6 -7 -7 -8 Capital expenditure € million 18 30 8 8 7 Operating capital € million 157 179 113 139 151 headcount 883 892 584 628 658 Stainless steel deliveries Sales of which intra-group Personnel at the end of period 100 | November 27, 2020 Business area Ferrochrome Key figures 2019 2018 2017 2016 2015 1,000 tonnes 505 497 415 469 457 € million 461 542 610 371 410 € million 293 345 483 269 295 Adjusted EBITDA € million 96 210 217 80 107 Adjustments to EBITDA € million - - - -0 - EBITDA € million 96 210 217 80 107 Adjusted EBIT € million 67 179 187 48 76 Depreciation and amortization € million -29 -30 -29 -29 -31 Capital expenditure € million 103 79 34 20 21 Operating capital € million 692 640 648 617 634 headcount 472 441 437 426 428 Ferrochrome production Sales of which intra-group Personnel at the end of period 101 | November 27, 2020 Disclaimer This presentation contains, or may be deemed to contain, statements that are not historical facts but forward-looking statements. Such forward-looking statements are based on the current plans, estimates and expectations of Outokumpu’s management based on information available to it on the date of this presentation. By their nature, forward-looking statements involve risks and uncertainties, because they relate to events and depend on circumstances that may or may not occur in the future. Future results of Outokumpu may vary from the results expressed in, or implied by, the forwardlooking statements, possibly to a material degree. Factors that could cause such differences include, but are not limited to, the risks described in the "Risk factors" section of Outokumpu’s latest Annual Report and the risks detailed in Outokumpu’s most recent financial results announcement. Outokumpu undertakes no obligation to update this presentation after the date hereof. 102 | November 27, 2020