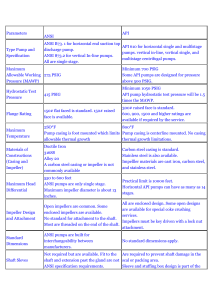

Sawcutting at joints. Inspection of slab settlement. Drilling holes (left) and pumping grout (right). By Susan C. McCraven C racked, bumpy, and uneven concrete surfaces can present both minor and major problems. Does the neighborhood rollerhockey gang complain that your jagged driveway prevents them from playing like Gretzky? Do the forklift operators ache like bronco riders after a long workday on your warehouse floor? Or are you worried about tripping hazards and liability issues because of uneven public sidewalks and entranceways? Slabjacking may be your answer. Concrete leveling contractors and pump equipment manufacturers point out that slabjacking has many advantages over slab removal and replacement, and many good applications. As early as the 1930s, pressure injection was used to raise deteriorated slabs and roadways. J.W. Poulter is believed to have developed the first machine for what was then called mudjacking for highway work. Early grouts ranged from soils such as clay, sand, and loam, to portland cement, fly ash, lime, and casting plaster. Though dangerous, even hot asphalt was pumped into voids under roadways to prevent water penetration. Selecting the proper pump and proportioning the grout are critical to success, a lesson learned in the 50-year history of slabjacking. Slabjacking process When approaching a new job, the slabjacking contractor first assesses the settlement of the concrete slab. Slabjacking: Inadequate subgrade compaction isn’t the only cause for settlement of concrete slabs on ground. “While improper subgrade compaction prior to the placement of a concrete slab can lead to subsidence and cracking problems, loss of soil support due to water seepage through joints is often the cause of sinking concrete. You can look for the telltale signs of water erosion after a rain at the bottom of a sloped, sunken concrete driveway. You’ll often see a sand washout,” according to Darrel Maute, sales manager with A-1 Concrete Leveling, Belleville, Mich. If the sunken slab has to be isolated from adjacent slabs or structures, the contractor may use sawcuts at joints (relief cutting) to relieve binding. Surveying equipment and grade and string lines are used to establish the correct p U t I p Pum Finish elevation. A-1 CONCRETE LEVELING Truck-mounted pump and slurry mixer. elevations. Based on experience, the contractor custom drills a specific pattern of holes in the existing concrete slab or floor using a diamond bit or a percussion drill with a carbide bit. Depending on the pumping system that will be used, these access holes range from 1 inch to 2 inches or more in diameter. The contractor then hydraulically pumps a grout mixture through the holes and into the voids beneath the concrete. If the subsided slab has adhered to the soil, the contractor may have to create a void using air pressure equipment. At pressures that vary from 10 to 150 psi, the pumped grout mixture fills the void, exerting pressure on the concrete and the subsurface material and lifting the slab. During the lifting operation, the pump operator monitors both volume and pressure. The amount of pressure used depends upon the grout slump (stiffness), the weight of the slab, and the area of void space. Contractors decide on the proper slump for a given application based on years of experience. Jim Sexton, manager at Airplaco Equipment Co., Cincinnati, cautions, “Trying to raise a slab too rapidly with too much volume often can create more problems than you are trying to correct.” Slabjacking must be performed with controlled and even pressure grouting, as portions of the slab may crack if subjected to significantly different subgrade pressures. Once the concrete is properly aligned and lev- eled, the drill holes are patched. Within about 24 hours, the grout mixture solidifies and forms a stable bearing surface for the slab. Special care is taken to ensure that the slab slopes properly to drain water away from foundations. Manufacturers of larger pumps have equipment that can be adapted for slabjacking. “While today’s jack pump designs can discharge material at volumes from 100 to 300 cubic feet per hour and with line pressures up to 600 psi, slabjacking operations typically use lower pressures and volumes,” according to Sexton. This article does not address pumping equipment used for similar pressure grouting applications such as void filling, undersealing, and tunnel injection repair. and new slab construction.” While driveways, sidewalks, pool decks, and other residential repairs remain the bread-and-butter work for slabjacking contractors, commercial, manufacturing, and roadwork are often well suited to the advantages of slabjacking. For example, Kent Concrete Lifting recently realigned a press foundation that had settled due to equipment vibration. “The plant managers could not afford to have the press offline for any longer than necessary. We were able to get in, level up Not just residential Most people think of slabjacking as a residential repair for driveways and sidewalks that have settled and tilted out of alignment. However, Dean Stacer, division manager of Kent Concrete Lifting, Redford, Mich., explains, “Slabjacking has many applications besides residential. Slabjacking can be used for road leveling at intersections, realignment of bridge approaches, warehouse floor repair, and equipment foundation stabilization in manufacturing plants. When you are looking for the shortest downtime, slabjacking can provide concrete leveling in much less time than demolition Slabjacking, often called mudjacking, is an economical alternative to costly replacement of sunken concrete slabs Before and after shots of slabjacking roadway repair. DWYER MAGNUM PUMPS the foundation, and patch the surface in 8 hours. The equipment was back online in 24 hours,” said Stacer. Depending upon the municipality or state, safety regulations defining a legal tripping hazard can vary. In nursing homes, flooring with a 1⁄ 2inch variation from level can constitute a tripping hazard. For public sidewalks, most municipalities consider 1 inch or more to be unacceptable. Maintaining proper elevation is particularly critical for concrete entrances to public buildings. “We can repair the concrete entrance ways to commercial and business establishments and not inconvenience the tenants with building closure and lost work time. There are many advantages and applications where slabjacking is the best alternative to the mess, noise, and downtime of demolition work,” advises Maute. Advantages The alternative to slabjacking for restoring the levelness and proper elevation of a slab is to demolish the existing concrete and construct a new slab. Slabjacking has many advantages over such drastic measures: Low cost: Slabjacking can result in significant cost savings. Prices in the Midwest typically range from $1 to $3 per square foot for slabjacking, compared with $5 to $8 per square foot to rip out and construct a new floor. Maneuverability/access: The size of pumping equipment makes the slabjacking pump plant highly maneuverable, enabling it to access fairly small or congested areas. Most equipment can pump up to 150 feet away. Little mess: Cleanup is fast and minimal compared For more information with the dust and debris of demoliThe following companies manufacture pumping tion. Drill hole equipment specific to slabjacking: patches are less Hydraulic Mudpumps, Ernest Cvetezar, noticeable than the President, PO Box 1054, 4903 Vista Road, color difference of Manitowoc, WI, 54221-1054, 800-626-2464, a newly placed slab Fax: 920.684.9008, www.mudpumps.com, or next to older concircle 1 on the reader service card. crete. Magnum Pumps, Dwyer Companies, Katie M i n i m a l Dwyer, Director of Advertising, 6083 Schumacher downtime: Besides Park Drive, West Chester, OH, 45069, 513-777the significant cost 1635, Fax: 513.777.5374, kdwyer@dwyercompa savings, an nies.com, or circle 2 on the reader service card. owner’s greatest Airplaco Equipment Co., James R. Sexton, advantage is the Manager, 4141 Airport Road, Cincinnati, OH, minimal down45226-1643, 513-321-2950, Fax: 513.321.8178, t i m e . info@airplaco.com, or circle 3 on the reader Manufacturing service card. facilities can mini- mize the time their equipment and operations are offline. Aesthetics: Instead of patched drilled holes, concrete cores can be cut out and grouted back into the holes after pumping. This repair method costs more but is a good alternative for owners who are concerned with a more uniform appearance in the repaired slab. Landscaping: Today’s landscaping costs (materials and labor) can be significant. Slabjacking operations do little to no damage to landscaping adjacent to the lifted slab, compared with slab replacement. Waste disposal: With slabjacking, there are no disposal costs for demolished concrete. Disadvantages Not every aspect of slabjacking is perfect. Here are some of the reasons to proceed with caution: Appearance/aesthetics: Some owners do not want a finish with noticeable patches. While some contractors try to match existing concrete color and aggregates, or use cores, the patches are still often noticeable. Over time, though, the patched areas tend to blend in with the surrounding concrete. Underground utility lines: There can be complications with existing utility conduits or heating ducts in the ground beneath the slab. Without proper care, pressurized grout can create enough force to move existing utilities out of alignment or push grout into pre-existing cracks in pipes or lines. Utility lines must be identified prior to slabjacking operations. Cracking: While existing cracking can be made less noticeable once the Grout mixes, applications, cost, and pumps Aggregate Fillers Natural Soil Lime Fly Ash (Mud) (Top soil/clay) (Crushed limestone / hydrated lime, lime kilndust, etc.) (Type F/C, C & F) Binder (if any) Properties Cement Cement Cement Cement Variable consistency due to raw materials such as chunks of stiff clay, rocks, plant roots, naturally occurring organic materials and other. These materials offer the greatest potential pumping, shrinkage, strength, etc. Variations. Easily displaced/eroded with water, vibration, freeze/thaw cycles. Must use adequate amount of binder. Crushed limestone dust/fines are typically found in limited areas. This material is dry, very absorbent, irregular/rough surface, yielding potential pumping problems, high shrinkage. Hydrated lime is likewise very absorbent, rough surface, varies in chemistry causing consistency control problems. Sand can be used as an effective filler. Must use adequate amount of binder to avoid displacement, as with the natural soil materials. Class F typically used, readily available with low absorbency. Class C is available and can be used as a binder, filler, etc. Depending on the chemistry Class F/C can be D.O.T. certified for state, city, municipal projects. Class C/F fly ash is very pumpable and can offer very stiff to flowable grouts. This material can yield low to medium compressive strengths depending on the needs. Available dry or wet depending on source and/or potential use. Binder may prove optional depending on the basic chemistry. Fillers may be used to take up space in a grout to minimize cost, minimize shrinkage, provide higher strengths, etc. Fillers generally consist of calcareous sands, powders, coarse aggregates, or special normal/lightweight materials. Aggregates are often used to improve mixing consistency from ready mixed plants (especially dry batched plants). Aggregates are always used in combination with a binder (i.e., portland cement) and/or fly ash or other fine filler materials. Availability of Materials Materials are readily available, but can be expensive due to screening and shredding. This material is not readily available in most areas and generally not economically viable due to transportation cost. This material is readily available (byproduct of the elec. utility industry) and extremely economical. Only use silo and/or pugmill (possible pond ash). Natural aggregates/materials are readily available and economical. Any materials manufactured and/or modified drive the cost up (i.e., lightweight agg.) Residential Can be used, has greatest failure rate/warranty-call backs. Can be used, but must use binder to avoid displacement (erosion, etc.) This material should be first choice for good predictable results/cost. Rarely used, most often used when large voids dictate. Light Commercial Can be used, has greatest failure and potential problems. Can be used, but must use binder to avoid displacement (erosion, etc.). This works very well with good predictable results. Sometimes used to offset large volume cost and/or speed up a project. Municipal Very rarely able to use, most often specifications prohibit use. Can be used and often acceptable under specifications, not best choice. Most often specified and works great. Used often to speed up a job with large volumes and/or for best consistency. Cost Availability of consistent, clean materials drives the raw material and trucking cost up as well as jobsite problems to the point material is not cost-effective. Availability of this material, as well as the potential longterm problems, makes this material not cost-effective in most areas of the country as compared with other readily available materials. This material is not only readily available, but in most cases is very costeffective. Using fly ash is a very good use of a recyclable material. Aggregates provide a costeffective filler and mixing stimulator if pump can handle the material. Rotor Stator Consistent jams and inconsistency can be expected if material is not screened (very clean). Works OK, but with high water demand can cause consistency problems. This material offers little if any concerns for jamming up pump with consistency in batching. This pump design when coordinated with maximum size coarse aggregate. Should pump well if grout/concrete is designed properly. Ball Valve Expect consistent problems in pumping and valve jam-ups. Works OK but with varying water demands can cause consistency problems and jam-ups. Must be batched and mixed consistently, and ,if so, can work OK with experience and quality materials (no bottom ash). These pumps are extremely sensitive to max. size coarse aggregate and cementitious combination in order to pump at all. Generally only good for rich grout. Swing Tube Expect very little if any difficulty pumping. Expect very little if any difficulty pumping. Consistency isn’t the concern here. Expect no problems in mixing, pumping, and placing this material. Maximum size coarse agg. is again important in matching pump and materials design, but the swing tube is least sensitive with any materials. 3 6 Concrete Construction July www.worldofconcrete.com Information provided by DWYER MAGNUM PUMPS Bulk/Filler Materials Before and after shots of slabjacking roadway repair. DWYER MAGNUM PUMPS slab is leveled, it is possible to cause new cracks if one section of the slab is raised too rapidly. Slab drift: Slabs can drift laterally during the slabjacking operation. If the grouting material is unstable, the material eventually can wash out, leaving the slab without proper subgrade support. Pumps and grout According to Brian Dwyer, president of Dwyer Magnum Pumps of Cincinnati, “Using the right concrete pumping equipment and the right grout mix can make the difference between success and failure on slabjacking projects.” (See description of Magnum’s newest pump in Product Update, p. 62.) Most slabjacking projects require grout mixtures with low slump because of shrinkage concerns. Low slump grout can be more difficult to pump, which means selecting the right pump for the project is necessary. The most common types of pumps used for slabjacking or pressure grouting are rotor stator pumps, ball valve pumps, and swing valve pumps. Understanding the characteristics of a pump and the material to be used is important because of variables like viscosity and curing time of the mix, lifting pressures, live loads on the slab, de-pressuring line requirements, and safety concerns. Like other technologies today, slabjacking equipment is benefiting from manufacturing innovations. With over 20 years of manufacturing experience in the slabjacking industry, Ernie Cvetezar, president of Hydrau- lic Mudpumps, Manitowoc, Wis., says, “I have seen more progress in functionality, convenience, and equipment capacity in the past 2 years than ever before.” Equipment costs vary. “A standard slabjack pump will range from $5000 to $16,000, and a mounted unit with pump and mixer can range from $18,000 to $26,000,” according to Sexton. Various types of pumps are used in the slabjacking industry: Rotor stator pumps: are capable of handling only very fluid (high slump) mixes containing little or no aggregate; deliver materials at low pressures. Typical mixes include very lean cement and water. Rotor stator pumps have no reverse pumping capability and are suitable for smaller, lightweight slabjacking jobs. Ball valve pumps: are capable of handling medium to very fluid (medium to high slump) mixes with some small aggregate; can handle a wider range of mixes than rotor stator pumps. Ball valve pumps have no reverse pumping. Swing valve pumps: are capable of pumping a wide spectrum of material from extremely thick to very fluid (very low to very high slump) mixes with aggregates; are capable of pumping at very high pressure; have reverse pumping capability, which allows for depressurizing the lines safely and cleanly; are well suited for a variety of slabjacking projects. (For a handy reference, see the table on page 36, for suitability of various pumps and grouts for different job requirements.) Training Most slabjacking contractors provide their own training for employees using manufacturers’ operation manuals and videos. Some equipment manufacturers also will provide training if requested. Cvetezar had this to say about training: “Slabjacking is often believed to be more of an art than a science. While HMI provides training manuals for our equipment, our customers still prefer the expense of sending their personnel to us for training. It is always best to learn from a master.” ■ Publication #C01G032 Copyright © 2001 Hanley-Wood, LLC All rights reserved