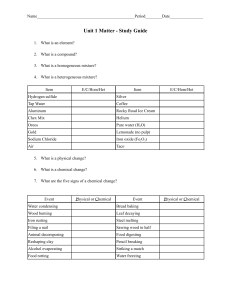

A Research Note Freezing Time Predictions for Different IFinal Product Temperatures A. C. CLELAND and R. L. EARLE ABSTRACT A modification to an empirical food freezing time prediction formula is proposed that allows the formula to be used for a range of final product temperatures. Over a large data set (275 runs) the percentage difference between experimentally measured times and predictions has a mean of 0.2% and a standard deviation of 6.8% for the improved formula compared to - 2.4% and 8.5%. respectively, prior to modification. Ninety percent of the predicted freezing times by the new method were within 2 11% of the experimentally measured times and +- 9% of predictions by an accurate finite difference scheme. This performance compares favorably with other published freezing time prediction methods. The same type of modification for varying final product temperature may be suitable for other empirical formulae. INTRODUCTION ONE OF THE DESIRED consequences arising from the use of a recently proposed systematic methodology for assessmentof freezing time prediction methods for foods (Cleland and Earle, 1984) was that areas in which improvements to prediction methods could be made would emerge. One area highlighted was that prediction formulae based on curve-fitting of experimental data collected in experiments terminated at one final product temperature performed poorly in comparison when applied to situations with different final product temperatures. This was because there is no term for varying Tn, in such prediction formulae. The formulae of Cleland and Earle (1982) and Hung and Thompson (1983) were found to be limited in this way, whereas those of Pham (1984a, b) and de Michelis and Calvelo (1983) were not. This note proposes a modification to the Cleland and Earle formula of the form: t, = (tf to T,,) . 1 - E 1.65 Ste k, In(E-1 (1) where T,r is - lO”C, and T, must be less than T,.. A further condition is that Tn, must be below the temperature range where the bulk of the latent heat release takes place. The modification may also be applicable to other empirical formulae such as that of Hung and Thompson. The form of Eq. (1) was derived by consideration of finite difference results in Cleland and Earle (1984). Plots of In [(T,, - T,)/(T,r - T,)] versus time were constructed using temperature data after the main phase change region. As would be expected from heat conduction theory for constant thermal properties these showed straight lines. The slopes of the straight lines were linearly related to the Stefan number, and were found to be inversely proportional to the frozen material thermal conductivity. The factor of 1.65 was the fitted constant required. This constant applies for all materials. The variation of it between materials, and between different Biot numbers was sufficiently small (less than 10%) for a single average value to be used. RESULTS THE SPECIFIC FORM of the new Cleland and Earle formula uses T,r = - 10°C (because - 10°C was the final product center temperature in the data set from the earlier work) and is: Authors Massey C/eland and Earle are affiliated with the Dept. of Biotechnology, Univ., Palmerston North, New Zealand. 1230-JOURNAL OF FOOD SCIENCE- Volume 49 (1984J where P = 0.5 [1.026 + 0.5808 Pk + Ste (0.2296 Pk + O.lOSO)] R = 0.125 [1.202 + Ste (3.41 Pk + 0.7336)] Pk = CL(Ti - Tr)/AH,o Ste = C,(Tf - T,)/AHlo (3) (4) (5) (6) and EHTD is defined in the manner of Cleland and Earle (1982). As a calculation example the problem in Heldman (1983) was chosen. A 2 cm diameter strawberry is frozen from 10°C initial temperature to a final temperature of - 25°C. The cooling medium is at - 35”C, and the surface heat transfer coefficient is 70 W/ m2”C. Thermal data were taken from Table 3 of Cleland and Earle (1984), using the procedures described in that paper to ‘evaluate frozen phase properties: CL = 4.09 X lo6 J/m3’C AHlo = 318 x lo6 J/m3 Tf = -O.S”C C, = 2.15 x lo6 J/m3”C k, = 2.08 W/m”C Application of Eq. (2) to (7) led to the following parameters: T, = -35°C T fin = - 25°C Ti = 10°C EHTD = 3 Pk = 0.135 Ste = 0.233 P = 0.568 R = 0.185 (Tfin - T,)/( - 10 - T,) = 0.400; tf = 10.13 X 1.169 min = 11.85 min. This freezing time to - 25°C of 11.85 min is close to the finite difference prediction by Scheme A in Cleland and Earle (1984) which was 11.55 min. The freezing time to - 10°C is 10.13 min by this procedure. These results appear plausible but testing is required over a range of conditions so new calculations were carried out for the composite data set in Cleland and Earle (1984). The consequential changes to Tables 6 and 8 of that paper are shown in Tables 1 and 2 respectively. It was also considered worthwhile to attempt to apply the analogous procedure to modify the method of Hung and Thompson (1983) using Tref = - 18°C. AH18 tf = U(T, - T,)(EHTD) (8) where P = 0.7306 - 1.083 Pk + Ste (15.4OU - 15.43 + 0.01329 Ste/Bi) R = 0.2079 - 0.2656 U Ste Pk = CL(Ti - Tr)lAHI, Ste = C&T, - T,)/AHI, , u = 1 + 0.5C~ (Ti - Tj2 - 0.5Cs (Tr + 18)2 AHIS 0, - T,) and Bi = hD/k, (8) (9) (10) (11) (12) (13) This procedure can only apply for values of T, below - 18°C. Table l-Summary of comparisons between experimental and predicted freezing times for five prediction method9 Methods Finite differences Cleland and Earle de Michelis and Calvelo Hung and Thompson Pham Data source Mean sd. Mean s.d. Mean sd. Mean s.d. Mean s.d. Hung and Thompson 23 Tylose slabs 9 potato slabs 9 carp slabs 9 ground beef slabs 9 lean beef slabs -1.3 -3.9 3.1 6.8 2.8 8.7 4.9 12.9 16.6 11.6 -3.3 -7.3 -1.6 2.6 -4.3 7.0 3.3 9.9 13.4 7.4 -3.8 -5.1 -2.4 -1.8 -8.0 7.7 3.5 11.1 13.9 8.9 1.1 2.9 2.8 2.5 0.8 2.9 4.0 4.1 4.8 4.0 -4.3 -4.2 6.1 10.1 7.9 14.1 8.4 18.9 18.9 14.7 C/e/and and Ear/e 43 Tylose slabs 6 potato slabs 6 lean beef slabs 30 Tylose cylinders 30 Tylose spheres 72 Tylose bricks 0.0 -0.5 4.8 -1.8 -0.3 -3.8 5.3 5.1 4.7 5.2 3.3 5.8 1.6 -0.5 2.1 -1.0 1.6 -0.9 2.8 4.0 3.6 5.2 5.7 3.9 3.7 4.1 0.8 2.3 -1.3 4.4 2.3 4.8 5.1 5.1 4.7 8.0 11.3 10.8 1.8 3.5 0.8 11.9 5.7 11.8 7.9 8.6 9.5 -4.1 -2.6 5.6 -6.5 -0.5 -26.1 6.2 3.5 4.4 8.2 10.3 9.6 -0.1 8.6 7.4 6.3 8.2 8.2 10.0 -0.9 4.1 4.9 6.6 1.8 3.8 9.2 11.5 -2.2 -11.3 10.5 10.8 were calculated by the modified de Michelis and Calvelo 5 lean beef slabs 24 lean beef bricks, rods, finite cylinders 1.8 2.6 a All data expressed as percentage differences from experimental data. Results for the Cleland and Earle. and Hung and Thompson * Ignores 4 experiments methods forms. in which T, Z T,Bt Table 2-Summary of percentage differences between (A) experimental under test and predicted freezing times from finite difference@ data and predicted freezing times, and (6) predicted freezing times from the methods Methods Data source A// 275 experiments; (A) comparison Mean Standard deviation Maximum Minimum Range enclosing 90% of data Correlation (r) with finite differences to experimental 207 experiments to - 10°C; (A) comparison Mean Standard deviation Maximum Minimum Range enclosing 90% Hung and Thompson de Michelis and Calvelo 0.2 6.8 23 -21 -10 to 11 0.746 0.3 6.7 18 -24 -10t09 0.762 3.2’ 9.3 33 -18 -11 to 20 0.480 -8.7 15.1 38 -48 -35to15 0.619 3.5* 10.1 33 0.865 1.3 5.4 15 -13 -9t08 0.738 - 11.8 13.9 16 -48 -38to8 0.501 data -1.1 9.4 22 -21 -13to15 0.838 -2.8 9.2 18 -24 -17to 13 0.929 “; -5t09 0.552 0.5 5.1 14 3.0 8.2 31 to experimental of data data 0.5 6.0 23 -21 -9 68 experiments to - 18°C; (A) comparison Mean Standard deviation Maximum Minimum Range enclosing 90% of data Correlation (r) with finite differences (B) comparison Pham data Correlation (r) with finite differences All 275 experiments; Mean Standard deviation Maximum Cleland and Earle to experimental to 10 12to21 0.522 2.3 6.2 0.8 14.9 38 -28 17to28 0.857 to finite differences -0.5 5.3 17 Minimum -18 -15 Range enclosing 90% of data -9t08 -9t08 207 experiments to - 10°C; (6) comparison Mean Standard deviation Maximum Minimum Range enclosing 90% of data to finite differences 68 experiments to - 18%; (B) comparison Mean Standard deviation to finite differences -2.7 6.1 13 Maximum Minimum -18 1.3 5.0 18 -21 -7t09 Range enclosing 90% of data a Results for the Cleland and Earle, and Hung and Thompson * Ignores 4 experiments in which T, > T,d 2.1 4.3 14 -14 -5t08 -4.4 4.3 4 -14 -15 -12to8 -1210 formulae were calculated by the modified For the strawberry example the following data were calculated using Eq. (8) to (13) and Table 3 of Cleland and Earle (1984): Bi = 0.673 AH,, = 378 X lo6 J/m3 Sii = 0.196 Pk = 0.114 U = 0.992 P = 0.578 R = 0.156 (T,, - T,)/( - 18 - T,) = 0.588 tr = 11.97 x 1.083 min = 12.96 min. The freezing time to - 18°C is 11.97 min and the time to - 25°C -19 -8t017 -8.4 12.0 15 -50 -3oto9 4.4' 8.7 31 -21 -9 to 19 -11.0 12.1 15 -49 -31 to 6 0.8 -0.8 7.8 13 -28 -11 to9 9.3 19 -24 -18to 1 14 forms. is 12.96 min. Results from application of Eq. (7) to (13) to the composite data set in Cleland and Earle (1984) are shown in Tables 1 and 2. DISCUSSION THE PREDICTION ACCURACY for the Cleland and Earle formula shown in Tables 1 and 2 is now as good as for any other method for a final center temperature of - 18°C and over the Volume 49 (19841-JOURNAL OF FOOD SCIENCE- 1231 FREEZING TIME PREDICTIONS ... whole data set, thus vindicating the use of Eq. (1). Correlation with finite difference predictions is also much improved. The improved formula thus meets the criteria’in Cleland and Earle (1984). The proposed modification improves the performance of the Hung and Thompson formula at - 10°C. Correlation with finite difference predictions is now virtually identical at both final center temperatures in the data set. However, because of variations in data from different sources (Cleland and Earle, 1984) agreement with experiments is not even across the whole data set. The similarity in the agreement with finite differences at the two Tfi, values suggests that the modification may suit the Hung and Thompson formula across a range of final center temperatures. CONCLUSIONS A MODIFICATION to the Cleland and Earle freezing time pre. diction formula is shown to make it as accurate as any other method over the data set studied for final product temperatures that differ from - 10°C. The prediction accuracy of the Hung and Thompson formula is also improved, by a corresponding modification, for final temperatures other than - 18°C. SYMBOLS Bi - CL - cs - D EHTD h H - Biot number hD/k, volumetric specific heat capacity of unfrozen material (J/m3”C) volumetric specific heat capacity of frozen material (J/m3”C) characteristic dimension (full thickness) (m) equivalent heat transfer dimensionality surface heat transfer coefficient (W/m2”C) enthalpy (J/m3) E. COLI IN SEAFOODS USING FLUOROGENIC ASSAYS 4). For the M-Endo-MUG assay, a total confirmatory rate of 90.0% was obtained for the fluorescent colonies (56 out of 62 fluorescent colonies). A false-positive rate of 10.0% was observed (Table 6). One of the problems commonly encountered during seafood analysis is the presence of stressed or injured microbial cells. Stressed cells have the ability to recuperate and grow on nonselective media, but not on selective media (Clark and Ordal, 1969; Ray and Speck, 1973). The ability of Lauryl Tryptose Broth-MUG (LTB-MUG) to detect heat-stressed cells was examined by Feng and Hartman (1981, 1982). The LTB-MUG system (fluorescence) was superior to the VRB-2 method in detecting heat-injured cells. This is expected, since LTB is a relatively nonselective medium. Perhaps, this is one of the reasons why the LBMUG assay in this study resulted in higher recoveries of E. cali from the seafood samples tested. The three assays described in this study are rapid (24 hr), sensitive, and save labor and material cost. Any of the three fluoragenic assays can be routinely used by the seafood industry to discriminate seafood samples with high total coliforms and/or E. coli (fecal contamination) present. REFERENCES BAM. 1976. L’Bacteriological Analytical Manual.” Food & Drug Administration, Washington, DC. Buehler, J.J.. Katzman, P.A.. and Daisy, E.A. 1951. Studies on Balucuronidase from Escherichia coli. Proc. Sot. Exe. Biol. Med. 76: 672. Clark, C.W. and Ordal, Z.J. 1969. Thermal injury and recovery of Salmonella typhhnurium and its effect on enumeration procecedures. Appl. Microbial. 18: 332. Chordash, R.A. and Insalata. N.F. 1978. Incidence and pathological significance of Escherichia coli and other sanitary indicator organisms in food and water. Food Technol. 31(10): 64. 1232~JOURNAL OF FOOD SCIENCE-Volume 49 (1984j AHlo - L ks - r t T, Tf Tfi, - Ti T ref - U - enthalpy change in product between Tf and - 10°C (J/m3) enthalpy change in product between Ti and - 18°C (J/m3) thermal conductivity of frozen material (W/m”C) latent heat of freezing (derived from AHI or AH,s by subtracting the sensible heat component) (J/m3) correlation coefficient freezing time (set, min or hr) cooling medium temperature (“C) temperature at which freezing commences (“C) final product center temperature at end of freezing process (“C) initial product temperature (“C) final product temperature used as a reference in empirical freezing formulae (“C) ratio of temperature driving forces defined in eq. (12) REFERENCES A.C. and Earle, R.L. 1982. Freezing time predictions for foods a simplified procedure. Int. J. Refrig. 5: 134. Cleland, A.C. and Earle, R.L. 1984. Assessment of freezing time prediction methods. J. Food Sci. 49: 1034. de Michelis, A. and Calvelo, A. 1983. Freezing time predictions for brick and cylindrical-sha ed foods. J. Food Sci. 48: 909. Heldman, D.R. 1983. P actors influencing food freezing rates. Food Technol. Cleland, 37(4): 103. Hung, Y.C. and Thompson, D.R. 1983. Freezing time prediction for slab shape foodstuffs by an improved analytical method. J. Food Sci 48: 555. Pham, Q.T. 1984a. An extension to Plank’s e uation for predicting freezing times of foodstuffs of sim le shape. Int. J. nefr3: (k press) Pham, Q.T. 1984b. An anaPytrcal method for pre ictmg freezing times of regtangular block of foodstuffs. Int. J. Refrig. MS received 3/19/84; accepted 4/10/84. (In press) . . . From page 1187 Dahlen. G. and Linde. A. 1973. Screening plate method for detection of bacterial B-glucuronidase. Appl. Microbial. 26: 863. Doyle, M.L., Katzman. P.A., and Daisy, E.A. 1955. Production and properties of bacterial B-glucuronidase. J. Biol. Chem. 217: 921. Duncan, D.B. 1955. Multiple range and multiple F-tests. Biometrics 11: 1. Feng. P.C.S. and Hartman. P.A. 1981. Fluorogenic assays for the immediate detection of Escherichia coli. Abs. Ann. Mtd. American Society for Microbiology 219, QllS. Feng, P.C.S. and Hartman, P.A. 1982. Fluorogenic assay for the immediate confirmation of Escherichia coli. Appl. Environ. Microbiol. 43: 1320. Firstenberg-Eden. R. and Klein, C.S. 1983. Evaluation of a rapid impedimetric procedure for the quantitative estimation of coliforms. J. Food Sci. 48: 1307. Jav. J.M. 1978. “Modern Food Microbioloav.”-_ 2nd ed. D. Van Nostrand Company. New York, NY Kilian, M. and Billow, P. 19’76. Rapid diagnosis of Enterobacteriaceae: I. Detection of bacterial glycosidases. Acta Pathol. Microbiol. Stand. Sect. B. 24: 245. Kilian. M. and B;\low. P. 1979. Raoid identification of Enterobacteriaceae. Acta Pathoi. Microbial. &and. Sect. B 87: 271. Kushinsky, S., Chen. V.L., and Otterness, I. 1967. Activity of Bglucuronidase. Nature 214: 142. LeMinor, L. 1979. Tetrathionate reductase, B-glucuronidase and ONPG-test in the genus Salmonella, Zentralbl. Bacterial. Hyg. I. Orig. A 243: 321. Mead, J.A.R., Smith, J.N.. and Williams, R.T. 1955. The biosynthesis of the glucuronides of umbelliferone and 4-methy umbelliferone and their use in fluorometric determination of fl-glucuronidase. Biochem. J. 61: 569. Ray. B. and Speck. M.L. 1973. Discrepancies in the enumeration of Escherichia coli. App. Microbial. 25:b94. of Methods for the MicroSpeck, M.L. (Ed.) 1976. “ Compendium biological Examination of Foods.” American Public Health Association. Washington, DC. Steele, R.G.D. and Torrie. J.H. 1960. “Principles and Procedures for Statisticians.” McGraw-Hill Co., Inc. New York, NY. Wehr, H.M. 1982. Attitudes and policies of governmental agencies on microbial criteria for foods - an update. Food Technol. 36(g): 45. MS received 12/19/83; revised 416184; accepted 4/11/84. Presented at the 42nd Annual Meeting of the Institute Technologists, New Orleans, LA, June 19 - 22. 1983. of Food .