Weld Seam Detection System SND8

Anuncio

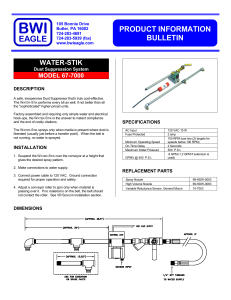

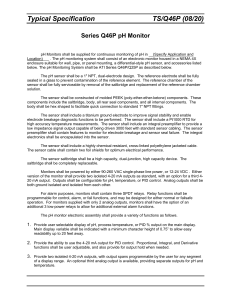

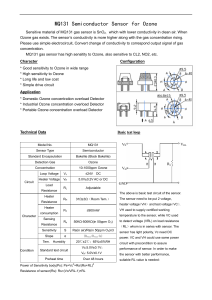

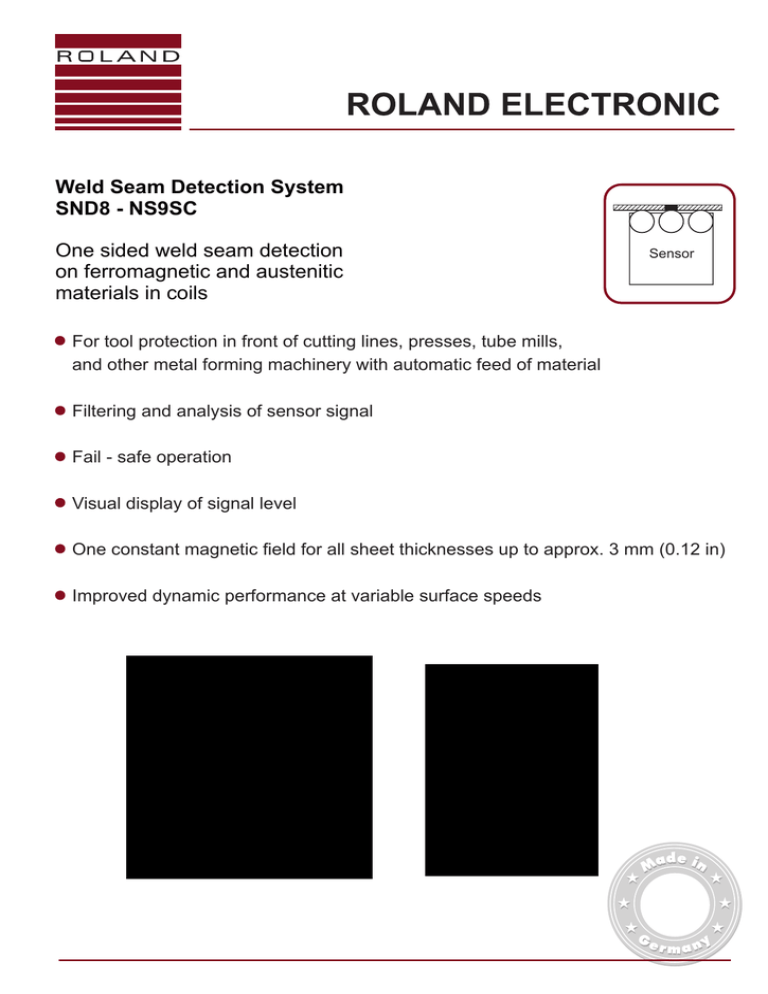

Weld Seam Detection System SND8 - NS9SC One sided weld seam detection on ferromagnetic and austenitic materials in coils Sensor For tool protection in front of cutting lines, presses, tube mills, and other metal forming machinery with automatic feed of material Filtering and analysis of sensor signal Fail - safe operation Visual display of signal level One constant magnetic field for all sheet thicknesses up to approx. 3 mm (0.12 in) Improved dynamic performance at variable surface speeds WELD SEAM DETECTION SYSTEM SND8 - NS9SC Application The automatic processing of coils and strips requires the dependable detection of weld seams. This applies to body shops in the automotive industry or the production of welded tubes and similar products. Weld seams that are not detected in the production process may lead to the destruction of dies and machine break down, faulty production and costly repairs. The Weld Seam Detector SND 8 has been specifically developed for such applications. The sensor NS9SC was specifically designed for butt welds in coils up to a sheet thickness of approx. 3 mm. Measuring Principle The sensor reacts to the magnetic properties of the materials. Weld seams lead to characteristic changes in the magnetic field. These changes are detected by the sensor and processed by the control unit resulting in a switch signal for the machine controls. Sophisticated methods of signal filtering and analysis are applied to discriminate between noise and the weld seam signal. 132.5 Sensor 92 30 x 30 Earth ground screw 55 6 24 M5 24 105 M8 26 6 M6 x 10 M8 17.5 17.5 180 64.5 M5 These two screws must not be used or removed ! 0.75 18 55 M5 57 20 57 165 43.5 101.5 Weight: 9200g 70 Space for movement of the plug 22 7 WELD SEAM DETECTION SYSTEM SND8 - NS9SC WELD SEAM DETECTOR SND 8 Fault Sensitivity 888 Signal Power ROLAND ELECTRONIC D - 75210 KELTERN Made in Germany Gerät Nr. Netz TELEFON FAX V 07236 - 9392-0 07236 - 939233 Technical data ± 10% 230 / 115 VAC, 50-60 Hz ( 5 X 20 ) 1.25 A mtr approx. 50 VA 1 LED 5 - 45° C dry two way contacts 250 V max. 8 AAC max. 400 W / 2 kVA 5 x 107 operations 110 ms, ± 20% The velocity can range between 0.1 to 1000 m/min. 5 - 30 V DC = Sensor ON 0 - 2 V DC = Sensor OFF maximum current < 10 mA 4.2 kg Operating voltage Fuse Power consumption Sensor control Ambient temperature Relay outputs for weld seam and fault Relay switching voltage Relay switching current Relay switching power Contact life (mechanical) Relay on delay Relative motion sensor/object Opto coupled inputs for sensor switch and reset Weight of control unit (without sensor) Cable SKNS8S Receptacle sensor connection 1 2 3 6 7 8 4 5 1 2 5 4 3 6 7 Plug control unit connection 1 2 3 4 5 6 7 8 7 6 2 1 5 3 1 2 3 Order data: 4 4 5 6 7 SND8S Weld Seam Detector NS9SC Sensor for coils SKNS8S-5 Cable between detector and sensor (standard length 5m) Terminals 13 14 15 12 11 9 10 Bus PCB SND 8 PgdS Plexiglass cover with lock PRODUCT PROGRAM DOUBLE SHEET CONTROL SYSTEM Simple and complex double sheet monitoring systems can be assembled from a broad product programs: System with two sensors e. g. for transfers Double Sheet Detection System UDK20 PRODUCT PROGRAM SHEET THICKNESS MEASUREMENT SYSTEM From a broad product program suitable sheet thickness measurement and sheet thickness control instruments can be selected. For ferrous and non ferrous materials Non contact or contact measurement Simple units for limit control Sophisticated systems with elaborate documentation satisfying SPC requirements GMBH Otto-Maurer-Strasse 17 Phone: +49(0)7236-9392-0 info@roland-electronic.com 75210 Keltern / Germany Fax: +49(0)7236-9392-33 www.roland-electronic.com May 2016 Rev. 1.1 - Subject to technical modification and error. System with one Sensor For ferrous and non - ferrous materials Touch and no - touch systems With or without force of attraction Adjustment via Teach-In or potentiometer Standalone systems or remote control via PLC One channel or up to 255 pre-programmable channels For original equipment or retrofitting

![SND8-NS11 Data sheet [1535.695] kB](http://s2.studylib.es/store/data/006339759_1-6f1403d5f6f4f98ee8e1232deb0e46b4-300x300.png)