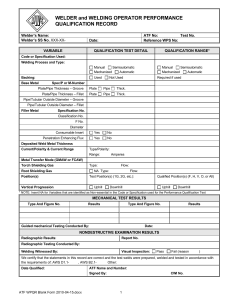

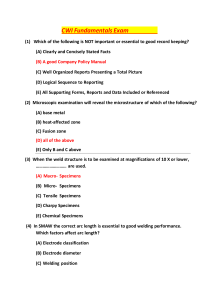

Generalized Guidelines for Structural Steel Welding Inspection As per AWS D1.1 Structural Welding Code: Steel Standard Terms CJP: Complete Joint Penetration PJP: Partial Joint Penetration CJP PJP Fillet Weld Scope General Requirements Design of Welded Connections Prequalification Qualification Fabrication Inspection Stud Welding Strengthening and Repair of Existing Structure Limitation of Code The code is not intended to be used for the following: (1) Steels with a minimum specified yield strength greater than 100 ksi (690 MPa) (2) Steels less than 1/8 in. (3 mm) thick. (3) Pressure vessels or pressure piping (4) Base metals other than carbon or low-alloy steels. AWS D1.6, Structural Welding Code — Stainless Steel, should be used for welding stainless steel structures. Whenever contract documents specify AWS Dl.l for welding stainless steel, the requirements of AWS D1.6 should apply. Design of Welded Connections Part A: Common Requirements for Design of Welded Connections (Nontubular and Tubular Members) Part B: Specific Requirements for Design of Nontubular Connections (Statically or Cyclically Loaded) Part C: Specific Requirements for Design of Nontubular Connections (Cyclically Loaded Part D: Specific Requirements for Desing of Tubular Connections (Statically or Cyclically Weld Joint Configuration Weld Joint Configuration: Fillet Weld Weld Joint Configuration: Fillet Weld Built Up Members 3.0 Prequalification of WPS As per article 3 prequalification of WPS is exempt from WPS qualification if following conditions are met 2. Welding Process: SMAW, SAW, GMAW (except GMAW-S) and FCAW which conform to all of the provisions of this section shall deemed as l prequalified. 3. Base Metal & Filler Meta Shall conform this table Prequalification of WPS 4. Procedure approved by Engineer 5. Minimum Preheat & Inter-pass Temperature RequirementShall be as per Table 3.2 of page 68 (AWS D1.1: 2008 Code) 6. Limitation of WPS variables “All prequalified WPSs to be used shall be prepared by the manufacturer, fabricator or contractor as written prequalified WPSs, and shall be available to those authorized to use or examine them. The welding parameter listed below shall be specified on the written WPSs . Change in these parameter , beyond those specified on the written WPS shall be considered essential changes and shall require a new or revised prequalified written WPS Amperage (Wire Feed Speed) i. ii. Voltage iii. Travel Speed iv. Shielding Gas Flow Rate Prequalification of WPS Common Requirements for Parallel Electrode and Multiple Electrode SAW 3.9 Minimum Fillet Weld Requirement- Shall Conform following table 4.0 Qualification: WPS Welding Qualification (WPS) is not necessary unless any of the requirement of prequalification (section 3) does not met. 5.0 Fabrication 6.0 Inspection 6.11: NDT GENERAL COMMENTS For CJP Groove weld and Non Tubular Statically loaded section, other than Visual Inspection no additional NDT is required form the code requirement unless additional NDT method like DPT/ MPI specified by the owner user. Contactor shall perform such test as 6.9 Inspection: Visual Inspection Table 6.1: Visual Inspection Acceptance Criteria 6.1 Inspection: Visual Inspection Acceptance Criteria NDT Requirements