7.FIMA Proveedor Residuos - EAWC-ENVA

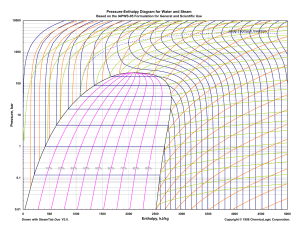

Anuncio

Ralph Hofmeier – CEO Irma Velazquez MSc COO velazquezi@eawctechnologies.com EAWCTECHNOLOGIES.COM SISTEMA ENVA 2 La conversión de vapor de baja presión (0.6-5-10) bar en energía electrica EAWCTECHNOLOGIES.COM FUNCIONAMIENTO DEL MÓDULO DE ENERGÍA 3 ESTRUCTURA 1. Interruptor 2. Salida de vapor 3. Entrada de vapor 3 1 EAWCTECHNOLOGIES.COM 2 4 RENDIMIENTO Pel kW 1,000 Input pressure in bar(Pa) 151.0 100 310.0 221.4 3 61.0 29.0 116.1 86.1 57.0 5 2 1,5 22.3 10 10.9 1 500 1,500 2,500 3,500 4,500 Note: Outlet pressure (p2) 1,2bar(Pa) 5,500 6,500 7,500 8,500 9,500 Steam kg/h EAWCTECHNOLOGIES.COM 5.2 5 EAWCTECHNOLOGIES.COM VENTAJAS 6 EL MÓDULO DE ENERGÍA ENVA § Garantiza bajos costos de producción de energía a lo largo de la vida de utilizacion. § Se enciende como un bypass y no causa ningún problema a los procesos de producción existentes. § Se puede integrar en los diseños de las plantas existentes. § Muestra un ROI atractivo que suele ser menor de 3 años. § No hay inversión de alto riesgo. EAWCTECHNOLOGIES.COM § Aumenta la eficiencia de los recursos y reduce la huella de CO2. 7 EAWCTECHNOLOGIES.COM APLICACIÓN 8 Se genera energía en lugar de desperdiciar el vapor Reducción del abastecimiento externo de electricidad La conservación de energía y reducción de costos de energía en beneficio del negocios y el beneficio al medio ambiente. Reducción de las emisiones de CO2 y ahorro de combustibles fósiles Ahorro de energía primaria EAWCTECHNOLOGIES.COM El Vapor no utilizado no se desperdicia y genera electricidad. La electricidad generada puede alimentar la red (Cogeneración de electricidad) VENTAJAS Después del uso de una cantidad específica de vapor el restante inutilizado es expulsado a la atmosfera por medio de chimeneas Otra alternativa, el vapor se condesa y se reutiliza en el proceso o es destruido por medio de un reductor de presión PROCESO ENVA PROCESO SIN MÓDULO POSIBILIDADES 9 EM AND CONDENSATION WITH ENERGY MODULE WITHOUT ENERGY MODULE Steam vent control Steam vent control HD Process Valves ND Steam User Three-way Valve Steam dryer Control Valve p bar Process Valves t °C Three-way Valve Condenser G Electricity EFFICIENCY IMPROVEMENT: ü ü ü ü Reduction of external energy procurement Generation of electric energy to feed into the grid Reduction of CO2 emission Pressure and temperature reduction Tank with Pump EAWCTECHNOLOGIES.COM Steam generator 10 EM AND LET OFF STEAM WITHOUT ENERGY MODULE WITH ENERGY MODULE Steam vent control HD Process Valves Steam user ND Three-way Valve Steam dryer Control Valve p bar Process Valves Three-way Valve t °C G Electricity EFFICIENCY IMPROVEMENT: ü Reduction of external energy procurement ü Generation of electric energy to feed into the grid ü Reduction of CO2 emission EAWCTECHNOLOGIES.COM Steam generator Steam vent control 11 EM AND PRESSURE REDUCTION WITHOUT ENERGY MODULE Steam vent control Reducing Valves Process Valves ND Process Valves Process Valves WITH ENERGY MODULE Steam . User Three-way Valve Check Valve Steam dryer Control Valve p bar t °C G Electricity EFFICIENCY IMPROVEMENT: ü ü ü ü Reduction of external energy procurement Generation of electric energy to feed into the grid Reduction of CO2 emission Pressure reduction EAWCTECHNOLOGIES.COM Steam generator HD 12 INDUSTRIAS APLICACIONES § § § § § La condensación del vapor § Plantas de Energía a partir de § § § § Química Alimentación y bebidas industria farmacéutica Industria / Las fábricas de papel para trabajar madera Fundiciones / Acero industria del aluminio Los productores de energía independientes Petroquimica / Refinerías § § § § Biomasa Cogeneración / CHP Plantas de incineración de residuos Presión-reducingstation Centrales térmicas solares EAWCTECHNOLOGIES.COM CAMPOS DE APLICACIÓN 13 EAWCTECHNOLOGIES.COM PROYECTOS 14 • En una instalación municipal • En una fábrica de ladrillos de arena de cal • En una fábrica de ladrillos • En una planta de energía de biomasa • Cocinas • La producción es de entre 63.000 y 637.000 kWh al año y en el ahorro de 40 a 407 toneladas de CO2 al mismo tiempo. • Sin consumir energía eléctrica adicional. EAWCTECHNOLOGIES.COM • El ENVA puede ser utilizado en: 15 MUNICIPAL UTILITY, LÜNEN In co-operation with the Ardagh glassworks, "Stadtwerke Lünen" (municipal utility) use waste gas heat from the glass production for several purposes. The initial gas temperature of 460 °C is cooled down to 230 °C in a waste heat recovery steam generator (WRSG). On a high-pressure pipe the steam from the WRSG is then used by a steam motor to produce electrical energy. From that highpressure pipe, a medium- and a low-pressure pipe supply the production plant with steam. The Energy Module is integrated in the medium-pressure system in parallel to other facilities relevant for the production cycle. Only steam which is not required for other purposes is fed into the Energy Module with a pressure of about 3 bar at 133 °C. Technical Data: Application: Back pressure system in series with condenser Outlet pressure: 1.3 bar (abs) at 107 °C Steam mass flow: ~500 kg/h saturated steam Electrical output: ~11 kW Electricity produced: ~88,000 kWh/a CO2 saving: ~ 60 t/a Set to work: December 2009 EAWCTECHNOLOGIES.COM Input pressure: ~3.0 bar (abs) at 133 °C 16 SAND-LIME BRICK FACTORY At the sand-lime brick factory in Höltinghausen, autoclaves are used for hydrothermal hardening of calcareous sandstone. The autoclaves are filled with steam and kept under a steam pressure of up to 16 bar for up to 8 hours, depending on the composition of the mixture. When the hardening process is completed the steam is supplied to other autoclaves. The remainder of the steam, which still has exergic energy, is reduced by means of the Energy Module from a pressure of 4 bar to a lower pressure; at the same time electrical energy is produced. The expanded steam is used in a preheater for production of processed condensate and fresh water. Technical Data: Application: Expansion of steam for preheater Input pressure: ~3.0 bar (abs) at 134 °C Electrical output: ~18 kW Electricity produced: ~63,000 kWh/a CO2 saving: ~ 40 t/a Set to work: April 2010 EAWCTECHNOLOGIES.COM Outlet pressure: 1.3 bar (abs) at 107 °C Steam mass flow: ~1,400 kg/h saturated steam 17 BRICKWORKS (SWITZERLAND) In a kiln the bricks are baked and hardened. Thermo-oil is used for heat recovery. It is heated with the hot gas from the kiln and is then transported through pipes to sites where heat is required for production purposes. Among others, waste heat is used for production of steam which is the fed into the Energy Module to produce electrical energy. The expanded steam with a temperature of approximately 105 °C is used in a heat condenser for heating purposes. Technical Data: Application: Heat recovery and steam production Input pressure: 4.0 bar (abs) at 144 °C Outlet pressure: 1.2 bar (abs) at 105 °C Electrical output: ~9 kW Electricity produced: ~72,000 kWh/a CO2 saving: ~46 t/a Set to work: June 2011 EAWCTECHNOLOGIES.COM Steam mass flow: ~600 kg/h saturated steam 18 BIOMASS POWER PLANT The biomass power plant is operated with biogenous solid fuels such as residuals from woodworking or forest wood unsuitable as timber or lumber. Steam overheated in the waste heat boiler is supplied to a condensing turbine for production of electricity. The Energy Module is assembled between turbine and vaccum condenser so that the increased pressure difference of the remaining steam can be used for production of additional electrical energy. The condensate is processed and pumped back into the boiler. Technical Data: Application: Back pressure plant in series with a condenser Steam mass flow: ~5,000 kg/h saturated steam Electrical output: ~75 kW Electricity produced: ~637,000 kWh/a CO2 saving: ~407 t/a Set to work: October 2011 EAWCTECHNOLOGIES.COM Input pressure: 1.5 bar (abs) at 111 °C Outlet pressure: 0.5 bar (abs) at 81 °C 19 COKERY At the cokery, process steam is filtered by means of steam washers. For protection of the washers the pressure of the process steam must be reduced from 3.3 bar to 1.3 bar. The Energy Module is switched in parallel to an existing pressure reducing station. It expands the steam, reduces the pressure and produces electrical energy. Technical Data: Application: Pressure reducing station Input pressure: 3.3 bar (abs) at 137 °C Electrical output: ~65 kW Electricity produced: ~382,000 kWh/a CO2 saving: ~244 t/a Set to work: Sept. 2012 EAWCTECHNOLOGIES.COM Outlet pressure: 1.3 bar (abs) bei 107 °C Steam mass flow: ~3,000 kg/h saturated steam 20