TERMODINMICA 1 (SEM0233)

Anuncio

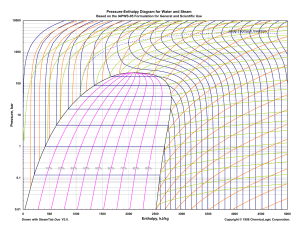

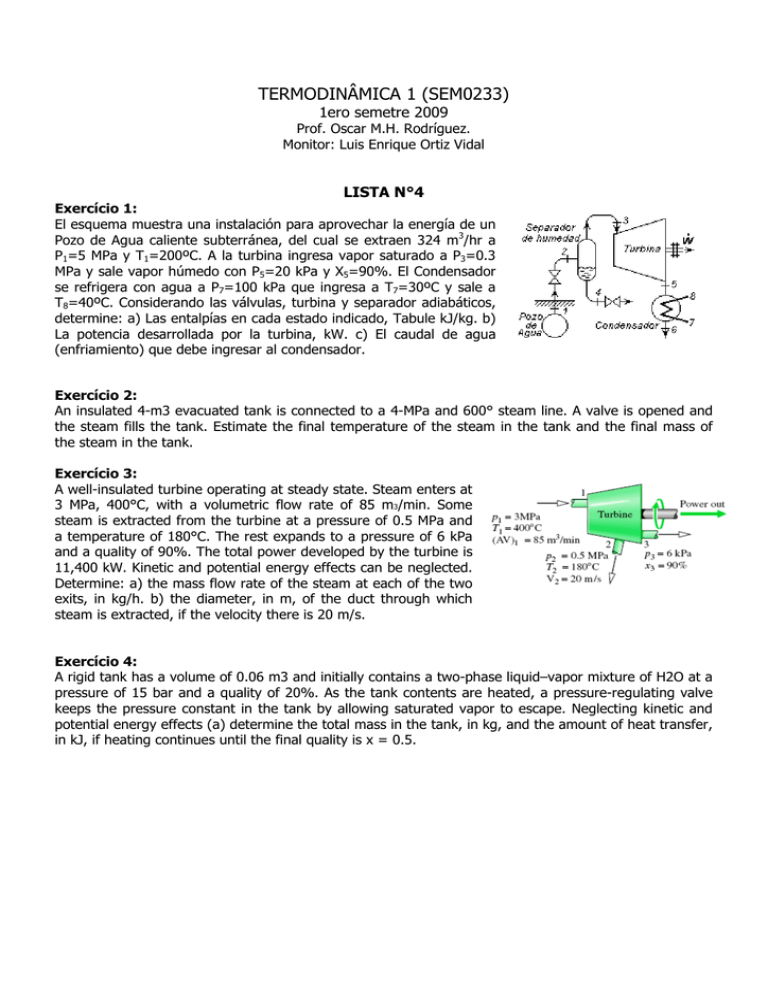

TERMODINÂMICA 1 (SEM0233) 1ero semetre 2009 Prof. Oscar M.H. Rodríguez. Monitor: Luis Enrique Ortiz Vidal LISTA N°4 Exercício 1: El esquema muestra una instalación para aprovechar la energía de un Pozo de Agua caliente subterránea, del cual se extraen 324 m3/hr a P1=5 MPa y T1=200ºC. A la turbina ingresa vapor saturado a P3=0.3 MPa y sale vapor húmedo con P5=20 kPa y X5=90%. El Condensador se refrigera con agua a P7=100 kPa que ingresa a T7=30ºC y sale a T8=40ºC. Considerando las válvulas, turbina y separador adiabáticos, determine: a) Las entalpías en cada estado indicado, Tabule kJ/kg. b) La potencia desarrollada por la turbina, kW. c) El caudal de agua (enfriamiento) que debe ingresar al condensador. Exercício 2: An insulated 4-m3 evacuated tank is connected to a 4-MPa and 600° steam line. A valve is opened and the steam fills the tank. Estimate the final temperature of the steam in the tank and the final mass of the steam in the tank. Exercício 3: A well-insulated turbine operating at steady state. Steam enters at 3 MPa, 400°C, with a volumetric flow rate of 85 m3/min. Some steam is extracted from the turbine at a pressure of 0.5 MPa and a temperature of 180°C. The rest expands to a pressure of 6 kPa and a quality of 90%. The total power developed by the turbine is 11,400 kW. Kinetic and potential energy effects can be neglected. Determine: a) the mass flow rate of the steam at each of the two exits, in kg/h. b) the diameter, in m, of the duct through which steam is extracted, if the velocity there is 20 m/s. Exercício 4: A rigid tank has a volume of 0.06 m3 and initially contains a two-phase liquid–vapor mixture of H2O at a pressure of 15 bar and a quality of 20%. As the tank contents are heated, a pressure-regulating valve keeps the pressure constant in the tank by allowing saturated vapor to escape. Neglecting kinetic and potential energy effects (a) determine the total mass in the tank, in kg, and the amount of heat transfer, in kJ, if heating continues until the final quality is x = 0.5.